-

Posts

64 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Blogs

Gallery

Store

Everything posted by palvim

-

I had one question about the machine set up that I have now. The guys I purchased the machine from say that the machine can definitely sew 135 thread. So I read through the manual again and I noticed something strange. The bobbin case latch on both the ls-1340 as well as ls-1341 are pointing down. On my machine it's pointing up. Is that strange?

-

Hi Uwe, I will not do an upgrade of the hook system. I guess in that case I'll have to sell the machine. However, I have advanced the hook timing and it definitely is stitching better. When I stitch straight I'm getting a very consistent stitch. On curves where I turn the flywheel by hand, the stitch gets all wonky. I am guessing this time it's the man behind the machine that is the problem. Is there a specific technique to do turns and sharp corners without missing the tensions?

-

I guess that's the right thing to do now. It seems we've tried enough. Now let the repair shop try. I'll be going the week after next. I'll update here. But I really hope this machine can handle 135 thread easily otherwise, I'll ask them to order the parts for the 1341 machine and install that. I counted from the parts manual and it's about 13 parts. I can say enough how grateful I am for all the help I've received so far. Thank you.

-

I've more or less got the machine to be where it was before. Hook timing seems to be ok Bobbin case opener a little better. But the same problem persists. I'm really curious if all parts that are listed in the parts manual need to be for 1341 to use the 1341 hook? Could it be that the machine actually is a 1341 but just has the wrong hook? The company specifications says the following. Cylindrical lockstitch machine with compound transport and high walking foot. The model is destined for medium and heavy sewing. Compound transport, large stroke of needle bar and foot lifting to 16 mm facilitate technical sewing. The hook is larger about 30% and it is especially useful in case of technical sewing with thick threads. The diameter of cylinder is 72 mm. There is energy-saving motor which saves even 70% of energy. For this model of machine JUKI parts are suitable. We offer assembled, ready to work set including: head, motor, top table and stand, a drawer, additional accessories, operating manual Technical parameters Type of stitch Flat lockstitch Type of transport compound Direct drive no Maximum length of stitch 9 mm Maximum speed 2000 spm Maximum foot lifting 16 mm Stroke of needle 36 mm Size of hook enlarged Lubrication open System of lubrication manual Automatic needle positioning no Automatic thread cutting no Automatic foot lifting no Automatic bartacking no Automatic walking foot no Automatic wiper no Automatic nipper no Control panel no System of needle DPx17 Thickness of thread #10 Clearance under arm 260 mm Built-in LED lamp no Controlled by smartphone no

-

I also notice that when the bobbin case opener is put in the right place more or less the machine jams somewhere and I can't rotate the flywheel further. Is the bobbin case installed wrongly?

-

Thanks @Uwe I just opened the throat plate and bottom plate to check my timing and to me it looks just right without doing anything to it. The feed lever is at 0. The hook also seems to meet the 1.7mm line from top of the needle hole just while it is coming up. Did I miss something? Could you check the video?

-

Hi @Uwe I understand. Pity that they sent me a machine that is not suitable for 135 thread. I guess I'll have to try and give it a shot to advance the hook timing and the bobbin case opener. I'm quite clear about the bobbin case opener setting. However is the hook timing for this machine seems a little complex. Is it the same video you shared Uwe in the Kobe 1341 thread?

-

I just noticed that the existing bobbins don't fit into the new hook. Is there a need to change the pickup lever if hook was to be changed to the new one? Or is it a one to one replacement and no other parts need to be changed?

-

Hi Uwe, Luckily, I might have the other hook assembly. I had asked for a table with wheels but they didn't send me that table. In exchange I asked for this hook to make my machine similar to Techsew's machine. You mean this hook in the picture is for size 138 thread? I didn't see in the manual about the hook sizes for thicker and thinner thread. Could this bigger size hook manage thread size 207 ? That would really be super!! I will never need to go above that. But I guess I'll have to take it to a service guy here in Sweden. Changing the entire hook assembly is a little out of my area of competence. I might screw it up even more and then I'm really stuck. But ok, at least it seems like we have found the main reasons why it doesn't work as it should. That's excellent. I can't thank you Uwe, Wizcrafts and DonInReno for your time to help me out. I'll take it to the service guys here and then update if this was the thing that fixed the issue.

-

I'm so sorry for confusing you and wasting your time by using both layers looking the same. So sorry for that. Next time I'll definitely used two different looking leathers. I checked the bobbin case opening cycle and I think it is definitely wrong. I can distinctly see and hear two clicks. I guess I need to pull the bobbin case opening lever back so when the thread is just about to come out of the throat plate, the lever is already touching and pulling the bobbin case protruding thing to the middle of the throat plate notch. Am I correct?

-

I'm just wondering if the thread knot always shows up in the bottom, could it be that the bottom thread is getting stitch somewhere in its path as @Wizcraftswas suggesting? I know I had to force the machine to open the thread jams. Could it be that bar that pulls the bobbin case back to let the thread from the throat plate notch? I guess that's called bobbin case opening lever. I had to force the case through this lever by force. May it moved just a tiny bit. But in that case shouldn't the top thread be stuck meaning the knot should appear on the top instead of the bottom? May be a stupid question. How to check for burrs on the hook or elsewhere?

-

@Uwe Here is the video from the side. Unfortunately I don't have a speed reducer and this is the slowest it'll go. The leather is almost 7mm of veg tanned leather. Anyways, in the first video the stitching came perfect on both sides. But see the second video shot immediately after the first one. And there the bottom stitch turned out horrible. It's very hard to trust the machine.

-

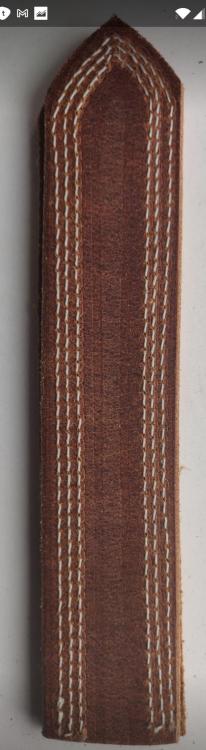

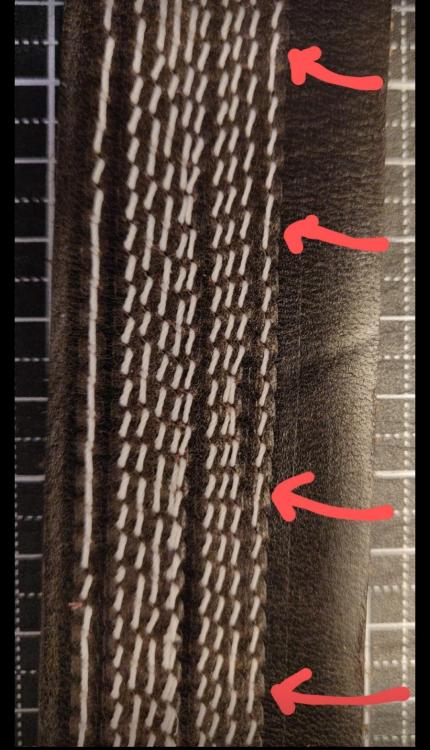

Thanks Uwe! I managed to steal one of my wife's pantyhoses. It now seems that after playing a bit with the tension, I can get the top tension quite right. Bottom is right too for the most part however, you can see sometimes the knot shows up in the bottom. Not sure why that happens. Pic 1: Good stitch - see the stitch on the rightmost. Pic 2: Bad stitch - see the stitch rightmost pointed with red arrows. And I might add that this is with thread size 92 and needle 140. If I use thread 135 with needle 140 (which I believe should still be ok) the problem worsens. You can see that in 2nd pic on the 6th stitch from the right. That's on thread 135 with 140 needle. And the bad one.

-

Hello All, I didn't want to hijack the Kobe 1341 thread hence writing here. I have a similar machine Juki LS-1341 copy. And I've had quite a bit of issues with thread jams and bobbin case being stuck etc. Sometimes to remove it, I've had to use some force. Problem is that I get very uneven stitch with 138 thread which this machine should easily handle. https://youtube.com/shorts/jjLYTC-UdCk?feature=share I'm wondering if someone could look through the timing and needle and hook position to tell if it is correct. Below are the three videos. 1. Timing of the hook in relation to the needle 2. Position of hook when pickup lever is at 12 noon. 3. The presser foot doesn't seem to move. Is that correct? https://youtube.com/shorts/VuLEKlz3f2k?feature=share

-

I have managed to get decent results with loosening the center foot and presser foot tension. Now I have virtually no marks on the top and very light marks on the bottom which is totally passable. Also the results with LR needle were much better compared to the diamond point needle which is really meant for textile as I understand. LR needle point is like a chisel. Hope this helps anyone else having issues with leather marks on their machine.

-

I am having similar issues and I have the same machine just a different brand. I had got the thread jams and all kinds of issues with the bobbin case being stuck etc. Somehow I managed to unjam and get the machine sewing again. This video is so helpful. I see that my hook point is more at 11 O' clock rather than 12 O' clock at the lever being in its highest position. I am wondering how to fix the hook point to be at noon. Could you point me to some instructions Uwe? Thanks.

-

Yes. It seems there is another spring that is adjustable for the center foot (see image. The screw is pointed with red arrow). I'll make that as loose as possible too. I have also been using the D point needle which probably makes bigger marks. I'll use the LR needles which should cut more smoothly. I'll try these two things and let you all know how it goes. Thanks for the help so far.

-

Hi Wizcraft, Correct me if I'm wrong. The top part looks ok. That's where I've made the springs loose for the presser feet as well as the center foot. The bad part is happening I guess due to the feed dog (under the leather being stitched). Did you mean there is some spring also for the feed dog or some way I can make it loose?

-

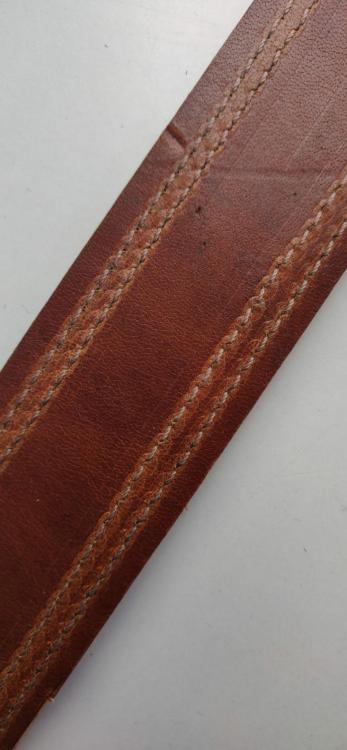

Hello All, I've purchased a LS-1341 type machine and trying to get it dialed in perfectly. I am not sure however why this happens on the underside. Please see the images attached. I've loosened the presser foot tension to its highest position. Any more turns and it'll pop out entirely. Any help is greatly appreciated. Thanks Vimal. And here is the problematic underside.

-

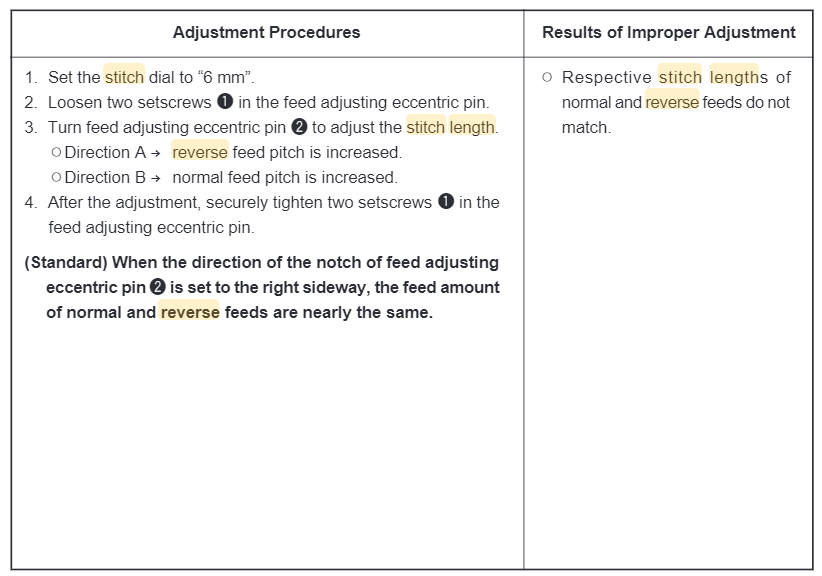

LS-1341 forward and reverse stitch misaligned

palvim replied to palvim's topic in Leather Sewing Machines

Thanks Uwe! Is the red arrow on your diagram pointing to the exact place in my diagram? -

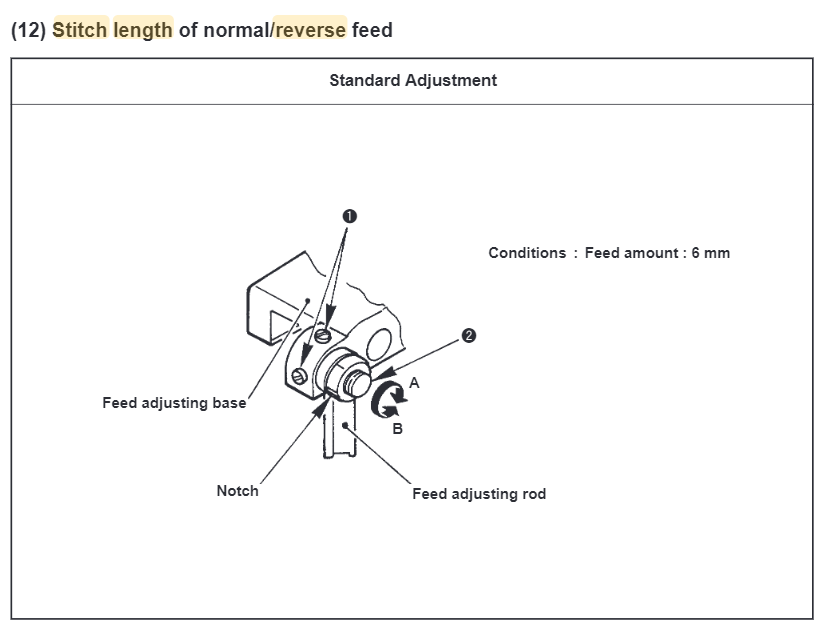

Hi All, I have purchased a LS-1341 type sewing machine. Everything works really well. The only thing that is annoying me is that the forward and reverse stitch lengths are not the same. I looked in the engineering manual and they have a picture and steps but I don't really understand where this part is on the machine. Could you please take a look at the pics from the engineering manual and steps i have attached here and guide me where this is to be found? Would be even better if someone could take a picture on their actual machine to show which part. Thanks a lot, Vimal.

-

With my very little knowledge of sewing machines, is it correct to assume that Juki LS-1341 a cylinder arm version of Juki DNU-1541S ? Reason I ask is that I wish to do lighter weight projects like wallets and bags. And wonder is these machines are essentially the same in terms of capabilities, I could go with 1341 and build a good flat bed attachment to essentially have only one machine. Please advise. Thank you.

-

Just wondering if there is any video or resource to do a complete overhaul of such type of machines. Would help a lot.

-

I don't think the motor is working. I tested it. I've purchased a small 90w replacement motor for one of them. It's the one which comes in a box without the table. If it works fine for sewing small thin leather items like wallets with 3-4oz X 2 then I'll probably get a bigger motor for the table version machine to sew canvas bags. In the manual it says it can take needle size 140. That means thread size 92 could be just fine.

-

Pondering over machine size CB3200 or CB4500

palvim replied to TJStrand's topic in Leather Sewing Machines

I totally agree with RockyAussie. I have a CB3200 and I would like to do the same and do bags. If you use 6oz leather and skive them, with the smallest thread (138) possible you really need to get the tension right otherwise it's easy to get the loop showing on front or back. I would much prefer to work with thread 92 or even 69 for bags and purses. Thread 92 is a good size for bags. Unfortunately, neither the cb3200 or cb4500 will take it unless you "dumb" it down. Don't know about you but I don't dare to make any changes to the machine. Especially since I run a company and would hate down time.