Mrstsb

-

Content Count

27 -

Joined

-

Last visited

Posts posted by Mrstsb

-

-

Great, Thanks for all the information

-

Thank you Bob for this table. Would it not be suitable for sewing leather then?

-

Would anyone be able to tell me what these letters mean on a Pfaff 145 sewing machine-- 145-40B H3 SN

-

1 hour ago, kgg said:With info being hard to come by I would probably go with the 550 watt on the Singer and the 750 watt on the carpet edger. You are probably going to need more punching power doing jute/hard back carpets.

kgg

Great, I think that's the conclusion I've come to as well.

-

19 minutes ago, kgg said:If both are brushless servo motors there will be less torque, punching power, available on the 550 watt and spread over 5000 rpm while the 750 watt will have more available torque spread over less rpm's, 3500 rpm. However that can be like comparing apples to oranges if they weren't constructed with the same number of coils. More coils basically equals more torque and are more expense. A expensive 550 watt with 12 coils could be better then a cheap 6 coil 750 watt. You really have to look at the spec of the servo motor for things like brush vs brushless, number of coils, speed range, torque rating, etc.

The cheap servo motors generally have 6 coils while the better high torque ones like the Reliable SewQuiet 6000SM have 12 coils.

What machine are you planning on installing a servo motor on? I personally have 550 watt brushed servo motors on my machines which may not be available or common in your country.

kgg

Thanks for the detailed information regarding the motors. In the UK they are probably all imported from China and rebadged so I don't think I'll get the answers about coils etc. The machines I'm wanting to use them on are an old singer walking foot and a Karpet King carpet over edger

-

3 hours ago, Northmount said:Obviously the answer depends on what you are sewing including the thickness and temper of the leather, and how slow you want to go. Without those facts, there is no real answer.

No idea what I will be sewing at my stage of learning, just having a play with different materials at the moment. As to the speed, they are both quoting 200spm to 5000spm for the 550w and 3500spm for the 750w which doesn't make sense to me

-

In the UK there seems to be a choice of 2 sizes/power of servo motors. One is a 550w and the other is a 750w. Obviously there is a slight difference in price between the two but would there be any reason to have one over the other? Would the 550w one be more than adequate for sewing leather or for the sake of £30 would you go for the more powerful one?

-

I'd like to keep things simply as I'm really just learning how to sew. Have seen one for a good price but just want to put a servo motor on it as I don't know if all the fancy bits work

-

This might be a strange question but could the JUKI LU-1510-7 be "de-modenised i.e. could all the pneumatic stuff, automatic thread trimming stuff, automatic foot lifter stuff be removed and just make it into good solid old fashioned sewing machine you could plug in at home without the need for a compressor to make it work.

-

34 minutes ago, Constabulary said:Well, the Singer Manufacturing Co. we know for industrial sewing machines is no longer producing industrial sewing machines and no longer exists. They stopped loooooong time ago, several decades ago I´d say. Basically someone has bought the brand name Singer and they are now marketing sewing machines but they no longer manufacture industrial sewing machines in their own plants and The domestics machines are for sure made somewhere in Asia.

Singer nowadays is just a brand name among others. The head company is SVP they own the name Singer, Husqvarna / Viking and Pfaff.

When it comes to industrial sewing machines don´t expect anything from them, they are just marketing "domestic or consumer" sewing machines but no serious industrial sewing machines (or do they?).

All to my best knowledge.

Ah that makes sense now. So if you were to buy a new machine, who are the main players now in the industrial walking foot sewing machine market. I'd guess it would be durkopp adler. I'd bet they wouldn't last 40 years, especially if they are full of electronics

-

After picking up a Singer 211g256, I thought I'd get in touch with Singer and ask if they had any information or service manuals available to download regarding the said machine, seeing that it's over 40years old. Well I've just received a reply, saying, basically manuals aren't for end users and are strictly for Singer service technicians and dealers only and suggested finding a local one to take my machine to. Thank goodness for forums like this

-

1 hour ago, Wizcrafts said:That felt is to hold liquid silicon thread lube or sewing machine oil to lubricate the thread when it gets overheated while sewing at 2200 stitches per minute. Upholsterers usually run these machines flat out at their top speed. Smoke will come off the hot needle and melt nylon thread unless it is lubricated or oiled.

If you aren't going to operate your machine at top speed, you don't need to concern yourself with the felt insert. But, if your needle starts getting squeaky in tough leather, add some liquid silicon lube to the felt with an eyedropper. Thread lube is sold by our advertising dealers, like @CowboyBob

Well there is no chance of me ever sewing at that speed so I can safely get rid of the felt, but thanks for the information. I'd be worried that the oil would stain the material you are sewing

-

4 hours ago, DonInReno said:The 211w156 is the walking foot with reverse. I’d guess the 256 has the oiling felt thread guide and the take up lever with the strange hood - we can’t see it, but I’m guessing you have the big bobbin. The “G” is made in Germany while the “W” machines are made in the US.

Here’s a manual that should work.

https://www.supsew.com/download/Singer/Singer 211G155, 211G156 Service Manual.pdf

Thank you for the link.

Could I ask- what is the point of the "oiling felt thread guide"

-

Thank you for that. I've watched some of Uwe's videos before and have found them very helpful and informative

-

I've just been very lucky and picked this machine up. I've posted some photos and have a couple of questions at the moment ( I'm sure there will be more as I don't know anything about these)

1- What does the 256 number mean on the model number, Can't seem to find any info on this model or manuals. Can find 211g146, 211g151 etc, there are lots of different models but all are 211's?

2- What is the felt oil pad for ( I've drawn a red ring round it)? Can I remove it and put a different guide there? I don't want oil marks on the material.

I must point out that I've taken the hook, feet, feed dogs off for cleaning. I've just got to work out how to re time it.

-

4 hours ago, Samalan said:I'm making one right now for my woodworking chisels with 4oz oil tan it's my intention to have the leather go over each handle rather than just stitching it flat like a cloth roll this makes the problem of closing the bottom of each chisel space so at the bottom of each space i will leave a small tab of leather in the center kind of like a jock strap sorry but this explains it best that small tab is part of the face it will go back and be stitched down it's a bit more work but i think it will work best the reason for doing this leather is not like cloth I think things will just fit better this way.

Would love to see a picture of this when you have finished

-

Thanks for your reply. I'm looking at using a machine

-

Thank you for your reply Wiz. It looks like parts are easily found as well

-

Is the seiko LSW-8BL a decent machine for leather? If I were looking at one secondhand is there any known problems with this model?

-

I'm new to sewing leather and would like to make a chisel roll for my woodworking chisels. What leather or suede is best for this sort of item?

-

If anyone has a consew 226r could you please have a look and tell me where the eye of the needle is, approximately, when the dog feed is just starting to move backwards.

I've seen a great film of someone setting up a consew 206 on this site and when he's timing the downward needle with dog movement, the needle is in a higher position to mine.

Even through mine is sewing, I'd love to know if I could make it sew better, if this timing is out

-

First of all a big thank you to Matt S, Uwe and Trox for their help with sourcing and setting up the replacement Bobbin Case Opener recently. I don't think I could have got my Adler 67 up and running properly without all your help. Also I can highly recommend Daniel at Hartley Sewing Machines in the West Midlands for any parts.

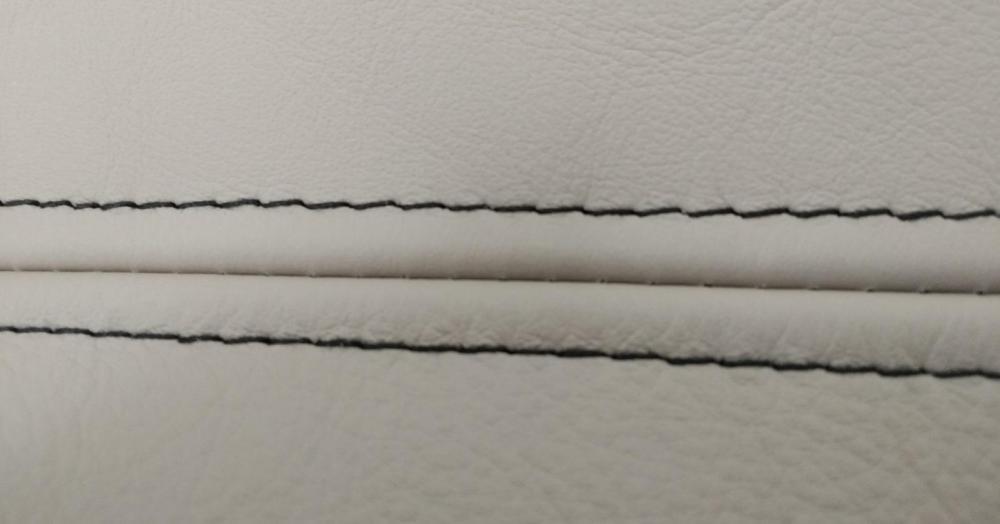

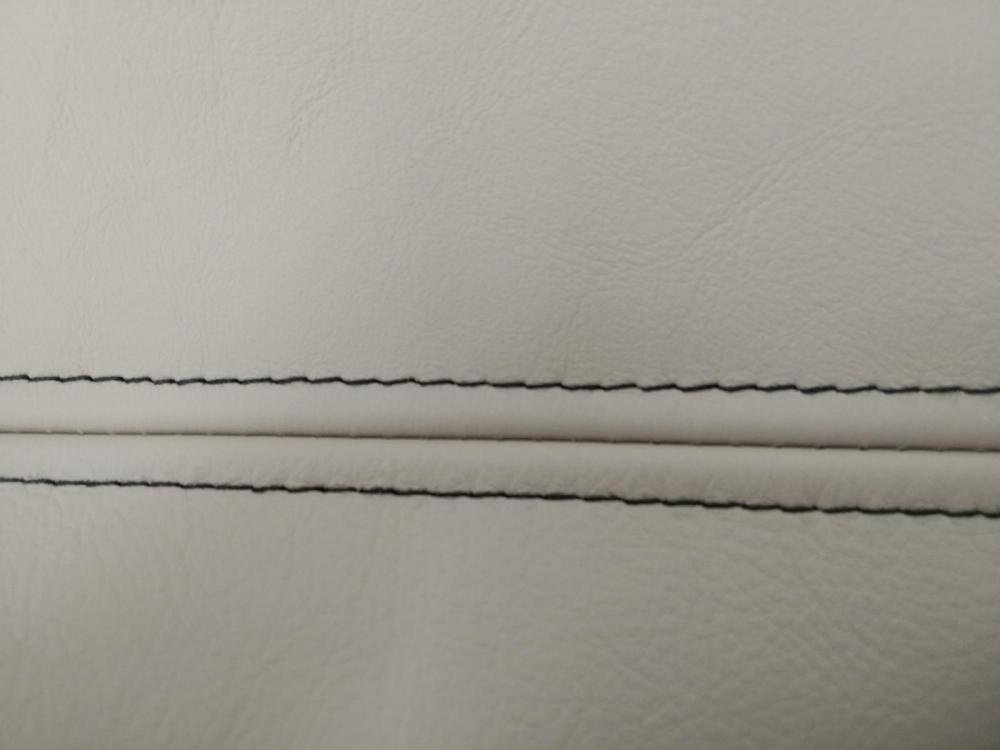

I wanted to show the pictures of how the machine is now sewing. To my very untrained eye the stitches look fine and the machine is not jamming up and seems happy with whatever is asked of it. I've looked at loads of pictures on the net of stitches and sewing on leather and I do like the way some seem to have a stitch that is more defined. I mean each stitch is visible, with almost a gap in between and not stitches that run into each other. I hope I'm explaining it right! It could be down to the needle type and/or thread. I've just been practicing with the needles and thread that came with the machine up to now. The needles are Nm 140/22 and 100/16 both are Type R, DP x 5 and No. 40 Thread. Anyway please have a look and I'd love to hear your thoughts for 'improvements' or observations. I'm happy to learn.

-

Thank you Uwe,

Sometimes it seems a very small world. I had found and watched the 3rd video a few times before I joined this forum so a big thumbs up for that. I'll watch the 1st one today and try and learn some more.

I'm looking forward to having a play on the machine once and if I can find the broken part.

-

Thank you Matt. I'll will get him to have a look at the gears and grease etc. i don't know where the timing belt is but we will have a look together under the machine. I can't look myself as it's too heavy to lift for me.

Where do you get parts for your machine. I've been Googling all day and can't find the part I'm looking for. I daren't use it at the moment( even through I was only practicing)

because of the broken part but it was sewing okay the majority of the time

Pfaff 145 model information

in Leather Sewing Machines

Posted · Report reply

So is there a way of making a H3 into a H4 machine?