JClif88

-

Posts

15 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Blogs

Gallery

Posts posted by JClif88

-

-

10 hours ago, dikman said:

Full marks for your perseverance!

Thanks!, so far, if you don't need the super low speed control (less than 200rpm)I would highly recommend these motors, much cleaner setup, much more simple, the positioning options are brilliant, the power is significant and the single stitch function is great. I also managed to get it for £70 posted from Alibaba (although normal prices are more around £105)

-

@alex11 did you ever decipher your settings? I now have the same motor with the settings you described but I've not worked out what they do.

I've also accessed another menu by pressing the Set and + buttons which gives more options but I've still not worked these out either.

FWIW, I think the PF setting you describe resets the motor settings. Also on the needle position setting, 3 and 4 make the motor rotate a half turn upon pressing back on the pedal. Thus you get a needle up or down control.

-

After further messing about I've managed to set it up to lift the needle when pressing back on the pedal. The only thing I'm now working on is deciphering the menus.

-

@CowboyBobI've found that 200rpm so far is plenty slow for my purposes tbh, and the single stitch button and needle positioning features have been more than useful.

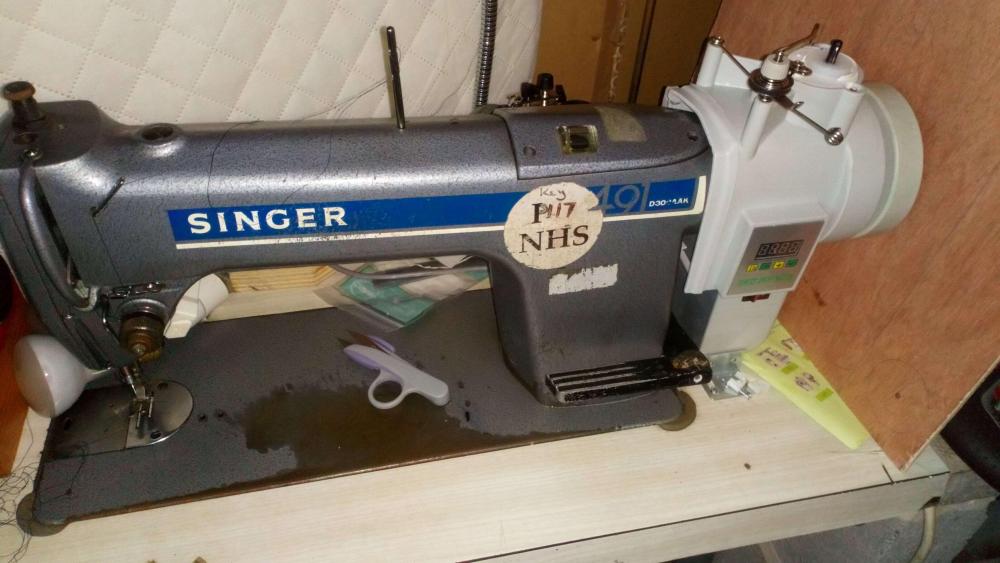

@JJN Pictures below. I can't upload more for some reason (keeps telling me I'm limited to 1.46mb). Basically the motor is just hung on the shank in place of the original handwheel/pulley. The angle steel at the front stops the motor spinning. On the back there is a long metal strip that sits into the original belt cutout that stops rotation in the other way (due to kickback when the motor stops)

-

So I finally got this and fitted it, I'm pretty pleased with it tbh, very easy to install, just needed some bracing fixing to the table to stop the motor spinning. Great control options, much neater than a belted setup and the lowest setting (200 rpm) is fine. Hopefully the quality is up to scratch.

It's a 750W motor and seems strong (I can't stop it with my hand). It also behaves like a stepper motor as it doesn't run smoothly, rather runs in stages. Also it has a nice Led light and single stitch button and also passes power through to an external lamp.

-

On 11/22/2020 at 4:52 PM, DonInReno said:

With the direct connect servo being fairly wide, adding another 7”-8” for an in-line reducer puts the handwheel waaaay over there. I can’t imagine it would be very enjoyable to sew with.

true,

Anyway, I have a DD motor coming, got it for about £70, will be interesting to see how well it works, I'm quietly confident that it will mount ok as I've heard they have mounted to Singer 591D's in the past. So just a case of trying to work out how to stabilise it which should be possible which a bit of angle steel.

-

pardon my ignorance....

don't these gearboxes have a driver input and the output shaft?

I'd imagined you could just have a motor->gearbox->sewing machine?

-

13 hours ago, DonInReno said:

If a sewing servo had a NEMA nose so it would simply bolt up to a NEMA reducer it would be much easier! Lol

My current project is a Wittgenstein Alpha 3:1 reducer off eBay and SP-1100 servo from Keystone Sewing. It seems these reducers are available in a huge range of input and output sizes, as well as base adaptor measurements, both metric and inch. This one is 5/8” input, 7/8” output, with 70mm x 70mm holes in the base. The servo hasn’t made it here yet, but an adapter plate between the two will need to be made, or at least new holes drilled in the reducer base.

Other than the compact size there is no noticeable benefit over using a 3:1 pulley reducer.

This is really interesting, so in theory, could a planetary gearbox reducer be found to link a servo motor directly to the shaft?

It's good to know if I find the direct drive motor too fast, I might be able to use a planetary gearbox reducer to slow it down.....

-

On 11/18/2020 at 2:22 PM, DonInReno said:

I do like how compact they are - as long as you aren’t expecting it to sew slower than other generic servo motors it seems interesting.

I was curious how these super compact servos attach and found a photo from a different servo that seems to show one as it comes out of the box. On one end of the stator (spinny thing) there’s a bearing in the servo’s housing, but there isn’t a bearing on the other end - so I’m assuming the bearing supporting the machine handwheel serves as the output bearing of the motor. The adaptor plate and shaft connector you will need to make up will probably have to be quite exact.

The pictured unit looks like the ones they sell for Overlockers, but I suspect they are the same internally.

I've not actually used a servo motor yet but I'm hoping, bringing the speed down as far as possible on the control unit (around 400-500 RPM) should give me a usable range.

I contacted a US supplier about the Yuma motors and they've stated they have fitted them on to a Singer 591 so the shank on my 491 should be suitable, I just need a way of stabilising the motor which will require drilling and tapping my machine or fabricating some other mounting system.

It also seems that they supply converters with the units to adapt the servo to many common shank sizes (I think mine is 14.7mm)

I'm also interested in whether I can modify the controller to have better speed control via the optical sensor as shown on this forum which would be great.

-

Yes, this is a concern, I don't actually do lots of leather work so probably don't need a super slow speed but do want to work at a slower speed, I'm not sure how slow these motors can be tweaked to go and I'm hoping a bit of practice should be all that's required when it's tweaked right down.

On 11/15/2020 at 10:49 PM, DonInReno said:This type of motor motor set up is relatively new as a retrofit, not to mention there is no track record to go off of with that specific motor, so you are sailing in uncharted waters. Do you feel lucky?

In these cases I’m a fan of letting someone else take the risk - so I hope you get it, use the heck out of it and let us know how it goes!

Edit: After thinking about it a bit more the main thing I couldn’t live with is a lack of speed reducer.

-

Hi, I've been thinking about adding a direct drive Kotor to my singer 491D but I really cannot find a great deal of information on these. My main reasons are better torque and reduced gubbins around the table. Would you be able to offer any advice/feedback on your installation?

Would you recommend the direct drive option over a belted motor or not?

The issue for me is likely that it will be difficult to mount and will requite some fabrication and I've heard they are noisy and have quality control issues.

-

Reduced Gubbins about, no need for a synchronizer, no belt losses, no belt wear and a lighter table overall.

-

Does anyone have experience with adding a direct drive servo motor to a vintage industrial lockstitch machine?

It seems as though the direct drive motors seen here...

Should work but I want confirmation first, it doesn't seem like there is any local sellers (UK) and the only ones I can find would come from China, so I just want to make sure.

If anyone has any experience with them, I'd love to know what the speed control is like on them?

4-button servo controller instructions

in Leather Sewing Machines

Posted

Incase it's of use to anyone else, I contacted Yuma, and after much pestering managed to get some information regarding the settings on the Direct Drive Servo motors....

As described above there are two menus accessible. The settings that can be tweaked are listed below, from the manufacturer.

P5.1: there is no special meaning here

P5.2: P represents forward rotation of motor, e represents reverse rotation of motor

P5.5: here represents the braking force, and the numbers 1-5 represent the braking force from small to large

P5.8: there is no special meaning here

P5. A: it means to restore the factory settings

C. 1: Here you can set the maximum speed of the motor, every five plus minus, for example, the number 25 represents 2500rpm. When your operator tries to increase the speed, the speed here will not exceed the 2500rpm you set. When you set the speed, you also need to refer to the actual maximum speed of the motor

C. 2: it means to lock the speed of the motor before you run. R.0 means to unlock and r.10 means to lock the speed. When the speed is locked, the operator can't adjust the speed. The motor will run according to the speed you set before

C. 4: it's related to the current. It can adjust the force of the machine. The letters from left to right represent the current from small to large, and the force is also from small to large