johnnydb

-

Content Count

136 -

Joined

-

Last visited

Posts posted by johnnydb

-

-

30 minutes ago, Spyros said:Question: if you use denim or any fabric lining, what do you do with the edges? You'd have to turn them right? Otherwise the fabric will fray.

I've never tried fabric lining but I was always curious.

Yes...you turn them under and first iron it so it creases at the edge before you glue it in and I usually put a line of stitches along that edge as well.

But you can also skive and turn the leather over the edge of the fabric as well....of course sewing the edge in place.

-

5 minutes ago, Meandmy1963 said:I wasn't looking for a specific answer I guess. More of a general opinion. I think one of you hit it on the head when you had a customer look inside and say "oh you haven't finished it then?". That's pretty much what I wanted to know. Seems like the general public would look at it as "unfinished" without some sort of lining. Not that it matters as it's my first bag and it's for myself. But if I'm going to be lining bags in the future I might as well give it a go. Thanks for the help everyone

I was actually thinking flannel if I were to do a lining

I like the look of oil tanned leather for messenger bags myself...kind of a messy worn look but totally reliable at the same time.

YMMV

(Your mileage may vary)

-

Personally I like to have anything but raw leather...so finishing it with some sort of lining is always good.

If you are going for a rugged look use some denim. Possibly some flannel but it would really depend on the colors.

And besides...if you are wanting an electronics pocket a lining will keep some of the leather "dust" from the raw side getting into your electronics.

-

8 hours ago, Northmount said:You are confusing things by introducing 3 phase motors in a subject that is single phase servo motors. You see to be confusing starting/run windings with 3 phase as well. So throw all that stuff out of this discussion.

These servos being discussed here are not being rewired to different voltage supplies at the motor. Hence those comments in your assertions are not valid. The difference is in the circuitry of the PC control boards, which have different part numbers for the different voltage supplies. These are not simple induction motors.

You also appear to be assuming the motor has the same HP output at the lower voltage. I agree to some extent that the current drawn by the motor when attached to 110 versus 220 VAC (with no other wiring changes) may tend to be greater during the starting cycle, but not at the instant the switch is thrown. Also depends on the attached load. If I put 2 pole induction motor on a variable auto transformer with no attached load, it will run at rated speed around 40-50 VAC. And the current draw is low. (Doesn't start as fast either.) You can see the current demand decrease due to the back emf as the motor speed increases. As you apply load, the current draw increases to match the load. All standard stuff and logic.

Further more, these digital sewing machine servo motors do not operate the same as simple induction motors. Simply stated, the electronics pulses the field (stator) windings as needed to run the motor at the speed demanded by the operator. (There is more to it than that, but let's keep it simple.) If there is a low load demand (HP), the pulse is of shorter duration. So a 220 VAC setup, may run adequately (depending on the electronics design) on 110 VAC. But you are not going to get the same performance, nor top end speed and power.

From what I was reading up on...these actually go by another name when I was learning this stuff....and probably because I am a primadonna at work everyone went along with the monkey who knew what to do.

So these servo motors are just lower voltage three phase motors controlled by a PBM which has something akin to a "magic ballast" that can utilize a variety of voltages up to a point because the SCRs (type of transistor) are going to only pulse out so much juice after the power is first being turned into DC then turned into the three phase AC by the pulsing SCRs needed to drive the motor in a precise proscribed manner.

Usually we use a VFD to do such things for the squirrel cage three phase rated for such...but these are a bit different as they are more for precise positioning of the armature... like I said....these I know by a different name...stepper motor is what I Know these by.

Now what I do know is that these motors will not have the same torque if they don't have enough voltage to create the DC voltage high enough with enough amps. Most of the voltage is erased by the rectifier anyway.

Meaning yes they will turn not under load but they will bog down quickly on the thicker leathers. They simply won't have the watts to power it all.

Personally I would stick to the rated voltage.

-

10 hours ago, evilblackdog said:According to this post and the s/n on my motor I should be able to convert it to 220 single phase. Do you have any thoughts on that?

To be honest though, if I can figure out how to remove all the Efka controls/automation stuff I'd just convert it to a manual servo driven machine.

Yes...change out the drive motor to a single phase servo motor that is sized to produce the same sustainable torque as the current three phase motor. The HP equivalent won't be the same but it isn't that relevant as the torque.

-

19 minutes ago, Northmount said:That is incorrect. The previous discussion neglected back emf that limits running current, usually approximately 1/7 of the starting current which is mostly limited only by the resistance (copper losses) of the windings. A simple resistor circuit will not agree with your statement that it would draw more current at a lower voltage.

Woah...

Inductive resistance is offset by the run capacitor...but a 3hp motor will not use less watts because of a lower voltage. It must use the same. A Delta wired motor is a Delta wired motor...the only thing that changes is the taps for the coils. And if there isn't enough voltage to push through the coils (because the taps didn't change) it will sit there and Humm and get hot. And if for some reason half of the coils don't get used...then it might run but it will be "single phased" and burn up quickly.

And even though only one phase drops out on a three phase motor it's still termed single phasing by those of us coming in to replace the motor.

And there are a bunch of motors running around that can take either voltage...just a different set of contacts in the pecker head that you wire into. Most commonly seen in the pump motors for residential pools.

-

1 minute ago, Northmount said:Many motors have been damaged due to under voltage. They run hot, have low power output, run slow, cooling fans not as effective due to running slow, etc. Depends on your definition of "fry". As motor winding insulation breaks down due to running hotter than design, internal shorts may occur, and your motor could "fry".

If you only use the motor on lower than design voltage for a few minutes now and then, like many hobbyists, you may get away with few problems, just slow and weak output.

And what you are saying is also possible...I'd like to see the faceplate on the motor itself state that it can handle the different voltages. It's probably written in electrical speak...but it will state it.

And what you are talking about is called "single phasing" and definitely burns up three phase motors. If there isn't enough voltage to push the current through a coil it definitely will run hot and do as you say by burning up the insulation on the motor windings.

-

It will likely run on the 120v in most household current. (110 is industrial voltage). However the amps will be higher because a motor will draw the watts it needs to run.

So if a motor will use 5amps at 240V it will draw 10 amps at 120V (as stated previously)

It's possible to have a Gizmo inside the motor that can differentiate between the two voltages and automatically change the coil connections to accommodate the change.

And because I'm an electrician and kinda a stickler for accuracy.

Residential household power is a single phase of a Delta wired transformer that has been center tapped. Most phased current is 60 degrees apart but residential is 180 degrees apart.

In commercial/industrial power you have 110/208 volts or 277/480... because the phases are 60 degrees apart. Residential voltages add normally. In residential they are on the exact same plane...it's that old polar addition you did in high school math class that you have forgotten all about because you figured you would never need this in "real life".

-

I'm green with envy!

-

As I am a Commercial/industrial electrician professionally I can tell you explicitly that you are going to probably wish you hadn't purchased this machine.

Because there is a Gizmo that can transform the power you need from single phase 240V (if you have normal residential power available) and convert it to 208v 3 phase power, 5amps @ 60 hz....but you are definitely not going to like the cost of the gizmo. The transistors and controls of that Gizmo are ridiculously expensive...at least as much as this machine you just purchased and use a LOT of power at the same time.

https://www.northamericaphaseconverters.com/product/pro-line-rotary-phase-converter-pl-5/.

The gizmo is listed at $509 and is likely the one that you will need. And they are noisy little gizmos too. They need a professional electrician to install them too. (Good luck with that) most of us are rather comfortable with our couch time...so beyond the bill you need an incentive for him (of course you will pay a minimum of $250 just for him to show up and say "yes, you are right, you do need an electrician" and then whatever is required beyond that is more $$$....) maybe a nice new leather tool pouch or something will get him to actually show up to do the work.

-

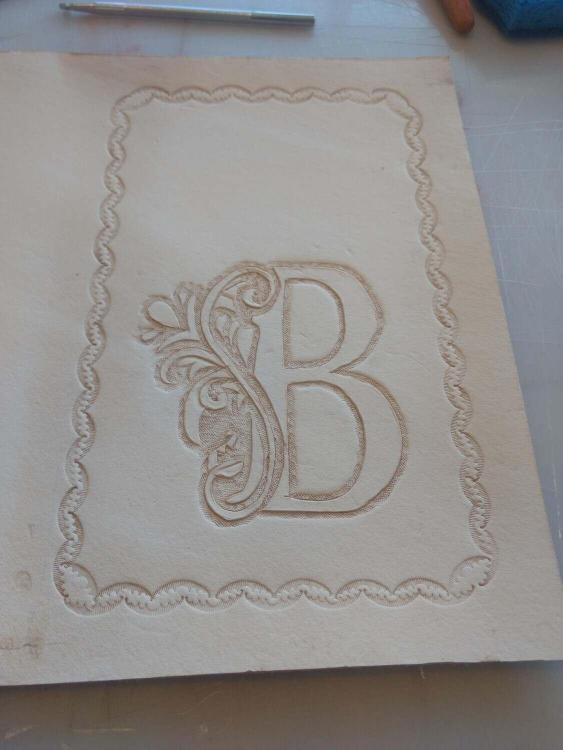

18 minutes ago, YinTx said:That is a really good look. Antiquing isn't always necessary and will sometimes bring out the flaws in the leather and tooling, or come out blotchy or streaky and just make you unhappy with the results. No antique may have been the right choice on this project! The finger carvings I did above have no antique also. No beveling either.

YinTx

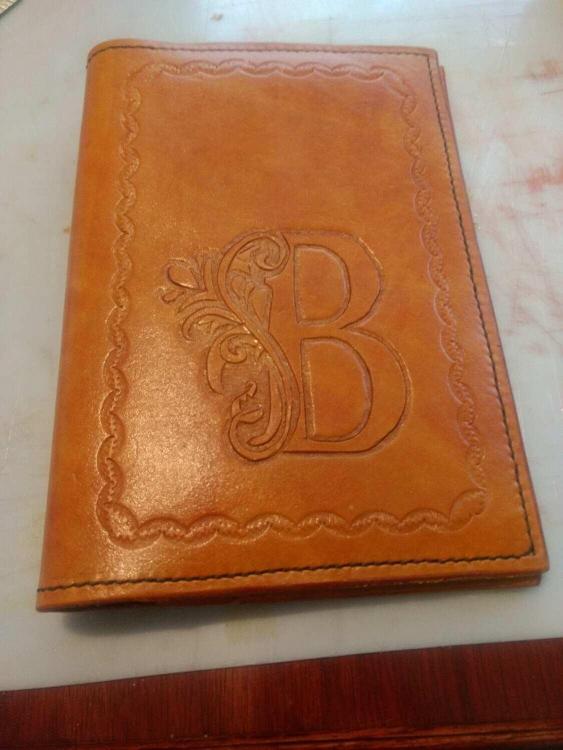

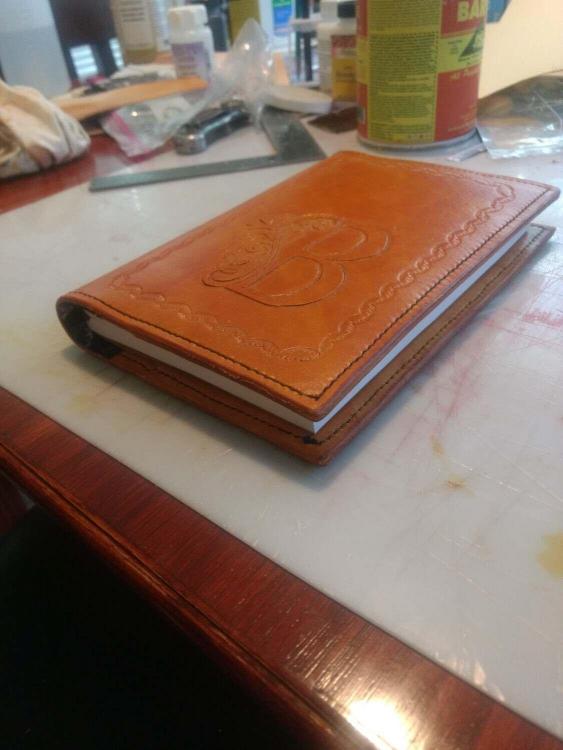

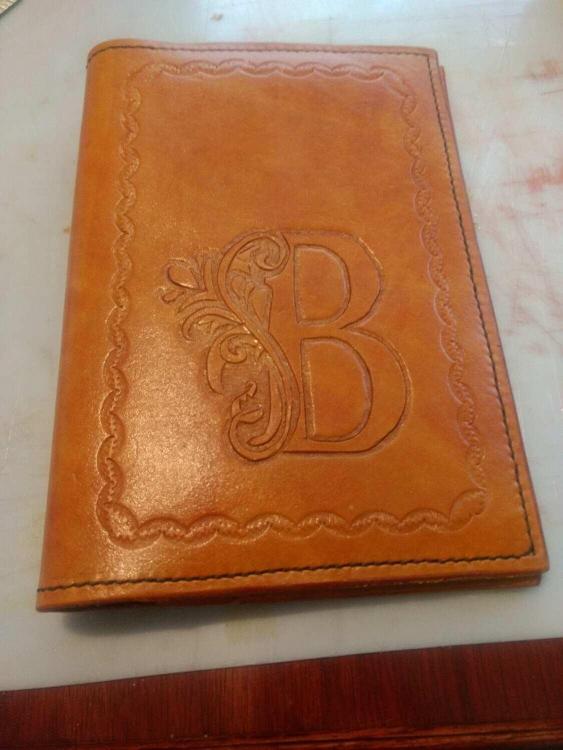

Yours above look great...I did this highlighted "B" 3 times to get it to look like it does. Just a Cussing and a fussing the whole time...(I'm having fun when I do that)

9 minutes ago, tsunkasapa said:Very nice! Your carving has improved greatly.

Thank you kindly...

I know that it's a matter of practice, practice, and more practice.

Currently my wife is jealous of her sister...she wants one but Red...and with an initial for her.

-

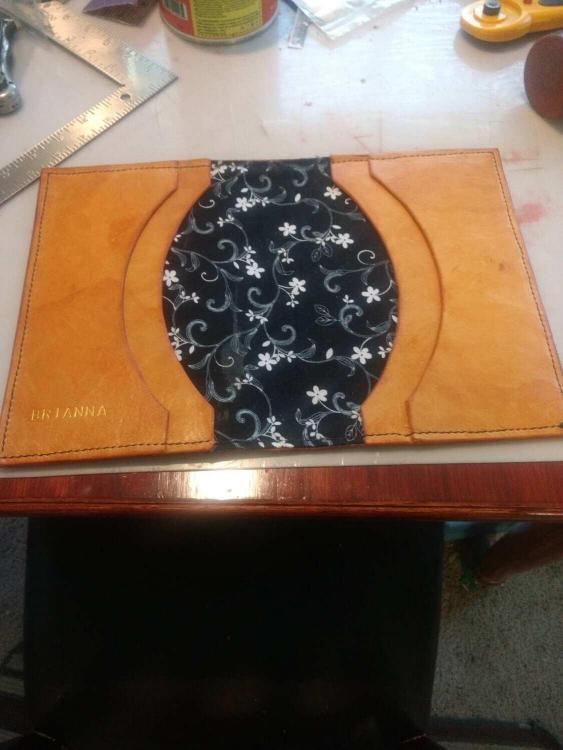

So it's a done deal. Used neatsfoot oil colored with feibings dye (not pro dye) to dye the project with.

Probably could have tried to antique it more with a resist and etc...just chose to try that another day...besides the oil/dye gave it a great unique aged character look and the feel is so soft for veg tan leather. Not stiff and inflexible. I showed it to another leathercrafter and he thought that I'd used chrome tanned leather to make it.

-

6 hours ago, Klara said:Compared to most forms of horseback riding leatherwork is ridiculously cheap. And I have feeling that you can spend a fortune on model airplanes - without having anything to show for it (except to other enthousiasts). Whereas with leather we make things we can actually use in daily life.

As someone who did spend a lot of money on RC Airplanes...

Radios start at $300 and the engines start at $150 then there's the plane itself made by hand....it gets expensive quickly.

And then you crash your plane...the parts can be salvaged usually...but often it's a do it all over again.

-

5 hours ago, Spyros said:For stamps and stuff I just bought the cheapest heat gun from the hardware store, $20 or so

Just easy and fast... useful for activating glue as well.

Yeah but it won't iron my shirt or the cloth I line a project with...just saying.

-

10 hours ago, Squid61 said:There are a lot of very good leathers that don't cost what Herman Oak costs. To read this thread one would think anything less the the best is crap leather, nonsense. I buy what I can afford and make it look like it should cost more, it's what craftsmanship is about. I also don't sell; I do occasionally make to order with the "customer" selecting and paying for the leather, labor is free, it's my hobby not a business.

Cheap leather is just fine...

There is a lot that can be done with oak tanned leather or chrome tanned or oil tanned. Each one has a purpose and use...it's not "all about the Craftsman" making the items....it's about what the end user will use effectively and like.

Sure I like the look and feel of certain leathers when working with them and some work better than others...but ultimately it isn't exactly about what I want...I'm just the guy putting it together. It's the people who use this stuff and like it that matters most.

I have no need for a phone case to hang off my belt other than to show off my work...if I was inclined. But I'm not inclined...

These people we make stuff for...they are the ones that count. If I can make it happen...great. if it requires something special they are going to have to cough up either for the leather or tools or both. Maybe I can find a workaround... maybe not. I can always try. My latest workaround was using a clothes iron, cheap iron letters and embossing tape. Worked like a charm.

-

16 hours ago, Tugadude said:I doubt there is any method guaranteed to work. Just way too many variables. If this is a persistent problem for you I would cut the pieces large and then after tooling cut to size. That's the only way to guarantee success every time, it seems to me.

Yeah...now I remember that leather shrinks after I screwed up...lol

9 inches went to 8½ in a heartbeat...

I just wet the leather the next time and cut it large...only shrunk an ⅛ inch this time.

-

Ok...

Leather shrinks and stretches... normal part of working with this stuff.

I've heard of pre-stretching leather. (Wetting it and then hanging weights on it)

But....

I cased a piece of leather that I had carefully cut to size and cut and tooled it and it shrunk so much that it was unusable.

Is there any way of predicting or rule of thumb of how much a piece of leather is going to shrink from oiling and dying or casing?

I know that we have to keep the heat away from it...but I'm just curious about what (if any) rule of thumb can be used to help predict this stuff.

-

-

On 10/15/2021 at 6:41 AM, PastorBob said:It could be imperfections in the tanning process where some of the chemicals they used remained on the leather. I have never tried it, but have heard use of deglazer can help remove the surface impurities. Another thought is to wet all the leather pieces and allow them to dry. I recently made a pocket humidor and its been drying for 3 days in front of a fan and is still not completely dry.

I discovered the reason why....it wasn't exactly a good reason either.

I had cased the leather and that indeed was the reason...but not the only reason. The leather had shrunk so much that it concentrated the dye. And also because it shrunk so much it is now unusable for the intended purpose.

So I've done another.... and it looks better than before...

So I'd post a picture up of the better version but the photo resizer isn't working anymore....I hit the button and it does nothing.

-

57 minutes ago, PastorBob said:I have a hard plastic tube made for storing cigars I use to form the shape when the leather is wet. As soon as the shape is formed, i remove the tube and set the wet leather pieces in front of the fan. This piece really needs to dry. It is dyed, then laser engraved. If not completely dry, it is too dark to really see the engraving on it.

One last question...how are you removing the leather smell from the leather? Usually cigars stored in a leather pocket sized holder retain the leather smell (because of the chemicals used in tanning the leather)

I've seen a bunch lined with wood or something else to reduce the scent of the leather....

And the retail for leather cigar cases is sweet too. (I am not interested in selling my crafts...just curious)

-

10 minutes ago, PastorBob said:It could be imperfections in the tanning process where some of the chemicals they used remained on the leather. I have never tried it, but have heard use of deglazer can help remove the surface impurities. Another thought is to wet all the leather pieces and allow them to dry. I recently made a pocket humidor and its been drying for 3 days in front of a fan and is still not completely dry.

Wet forming leather...I'm always impatient when waiting for it to dry and checking in on it to see if it has. What kind of jig/mold are you using?

-

5 hours ago, Klara said:Probably there's some mysterious chemical reason. I would wet the other pieces as well (I'm assuming you haven't) and let them dry under the same conditions as the first piece. On the photo it looks as if one of the "other" pieces were the same colour as the tooled piece - is that a trick of the light?

Btw, are you 100% sure that the tooled piece is perfectly dry yet?

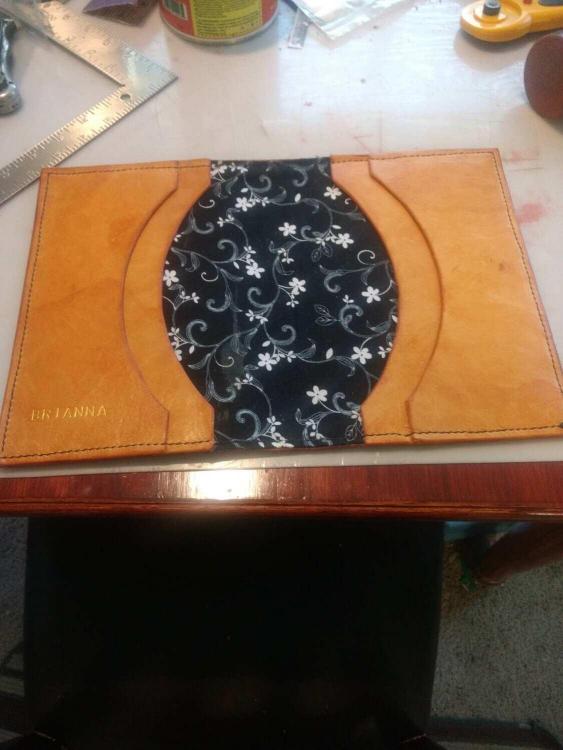

They're all the same...they are close in color...not really enough to make much of a difference...but it's enough that it made me pause for a second. The tooled piece dried on a wire rack for two days after tooling day and I skived it before I dyed it. It was most definitely dry. This morning after the dyeing last night they look closer...but the tooled piece still looks a half to a quarter shade darker. If the neatsfoot oil finishes drying today at some point I can begin to put the Trac gum on the inside pockets backside and pocket edges. The cover will get lined with cloth and stitched in with the pockets. (I hate that raw unfinished side in finished goods)

The next one I make is for my wife (I think she is a tad jealous of her sister's journal) ...since I'll see it on a much more regular basis I need to be even more careful and practiced. I hate seeing my flaws.

-

-

Don't sweat showing or explaining the errors...my feelings won't be hurt. The feelings I once had died decades ago...I keep them in a feelings coffin on the mantle over the fireplace.

But truthfully I have had four distinctly different careers that had no relationship to each other...learning new stuff and getting it done takes time and practice to be anywhere near competent...and someone else is always going to be better at it than me...just a fact of life. I don't get my feelings hurt whatsoever when it's constructive criticism.

And I noticed that if I was actually artistic instead of just following a stenciled pattern I made...it might be really addictive to do.

That being said...my wife thinks it's awesome...and hopefully her sister will think the same. (It's her college graduation/Christmas present)

I just got finished skiving the pockets and if all is dry tomorrow I will give all the pieces a dip in a oil/dye blend. (After I run the vacuum to get all the leather fluff from skiving....ugghhhh....I hate skiving)

Oh yeah.... gotta give the edge corners a serious trim too.

Then comes the lining of all the parts...

Converting the operating voltage of an Enduro servo motor

in Leather Sewing Machines

Posted · Report reply

A DC servo motor are usually those on RC cars and airplanes... sometimes toy robots too. They have permanent magnets. Not a lot of power or torque to them. And usually DC servo motors don't actually turn a full 360⁰. They turn 180⁰ at most.

AC servo motors are actually what we call Stepper Motors. They are usually three phase motors (internally but can be more phases depending on size...I've seen 12 phases but didn't have to do anything with it)

All the electricity fed into them is first turned into DC current by electronics and then transformed again into AC by electronics to carefully and precisely control the position of the armature. (As determined by a sensor) They are the only ones that will have the torque necessary to sew leather. So... you most likely have a stepper motor.

The input voltage needed is determined by the specs...it can be a wide range. So long as you don't fry the diodes for the rectifier you are gold.

Now the electronics controlling everything are usually powered by the initial power coming into the device. Tapped right off the cord almost. Look for a different colored terminal or markings to determine which is the hot, neutral, ground, and/or other hot.