Apostolos

Members-

Posts

19 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Blogs

Gallery

Store

Everything posted by Apostolos

-

Well if anyone needs a scanned copy, or the actual books, they can message me details.

-

@AlZilla Thanks Al, that's exactly what I wanted to know, that someone has used the same or similar machine and can say, with some certainty, that it will most likely do the job I want to use it for(obviously I'm not holding you to account, machines, maintenance and operators are all variables). I don't think it's too high a price, I'm happy to pay a bit more for a properly serviced machine that will do the job. Hopefully I'll have some results I can share sometime soon.

-

@Wizcrafts Thanks for the tips on the machines Wiz, my issue is one of space however, as I mentioned at the start of this thread, I don't have the space for another machine with it's own table, which is the reason I'm hoping a domestic will serve the purpose.

-

Yeah, I tend to be a bit of a hoarder, but these struck me as relics deserving to be kept.

-

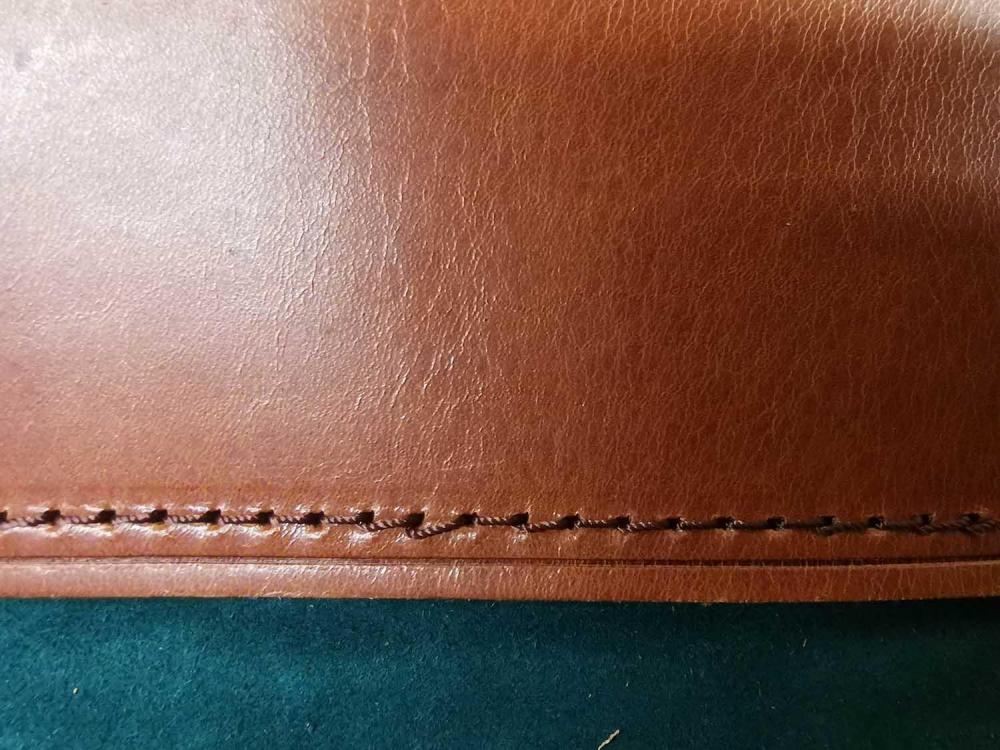

@kgg I hear you on the needles, I also have #140 needles but it seems to produce a good tight stitch on most things I sew with the 130 so I stick with those unless I move onto firmer leather. I have a table attachment for switching to a more flatbed orientation. The main reason I wanted a lighter machine is for sewing light stuff, it tends to bunch up with the heavy threads. Obviously on a site called leatherworker asking about sewing fabrics is maybe barking up the wrong tree, but I know the expertise of the people who hang out here is respectable, I have often dug through the archives to answer any questions, regarding not just machines. Thanks to everyone for taking the time to reply.

-

@AlZillaCorrect, not inexpensive at 120€, but if I try it out and it runs fine, I think I'll just go for it as I have neither the time nor the inclination to find a used machine from a private owner and try to get it back in shape.

-

@friquantIdeally I should test it, but I found this shop whilst at a nearby town, so I may just have to pay them another visit. @toxoThanks for your reply, I should have made it clear that the lining is only attached at the top, stitched into the construction, essentially a bag within a bag. @AlZillaThanks@AlZillaThanks for the info Al, I did mean tex 45, the one I found has the drop down feed dogs, I think. I will probably just make another trip there to give it a go and will most likely end up getting it if it seems solid. Thanks for all your replies!

-

Hi everyone, I own an adler 269 and make the odd handbag, tote, etc. The thing is, I have been lining them, mostly with light to medium fabric which is a bit of a pain to stitch on the adler. I mostly stitch with 135 top and bottom and a 130 needle, so need to change everything out, plus loosen the tensioners to get it to do a half decent job with #45 thread. I was considering a home sewing machine - I lack the space for another unit with its own table. There's a singer 237 (70s model with straight stitch and zig zag-full metal gearing) available from a used sewing machine dealer, who assures me it will suit my purposes. It may very well be enough, does anyone in here have any experience with something similar? At most I will be sewing light canvas, around 8 or 9 oz, but mostly lighter, stretchier fabrics. Thanks for any info!

-

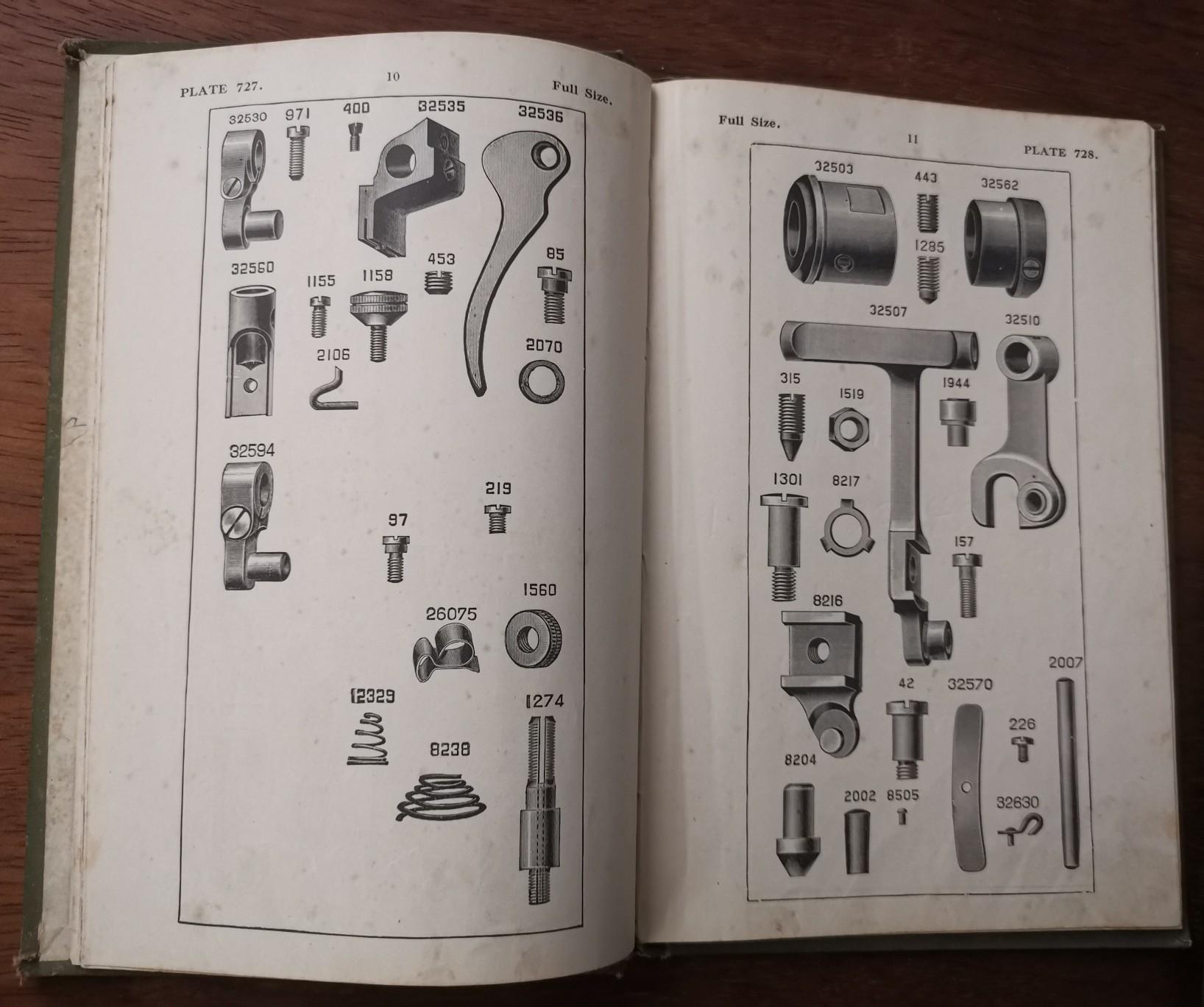

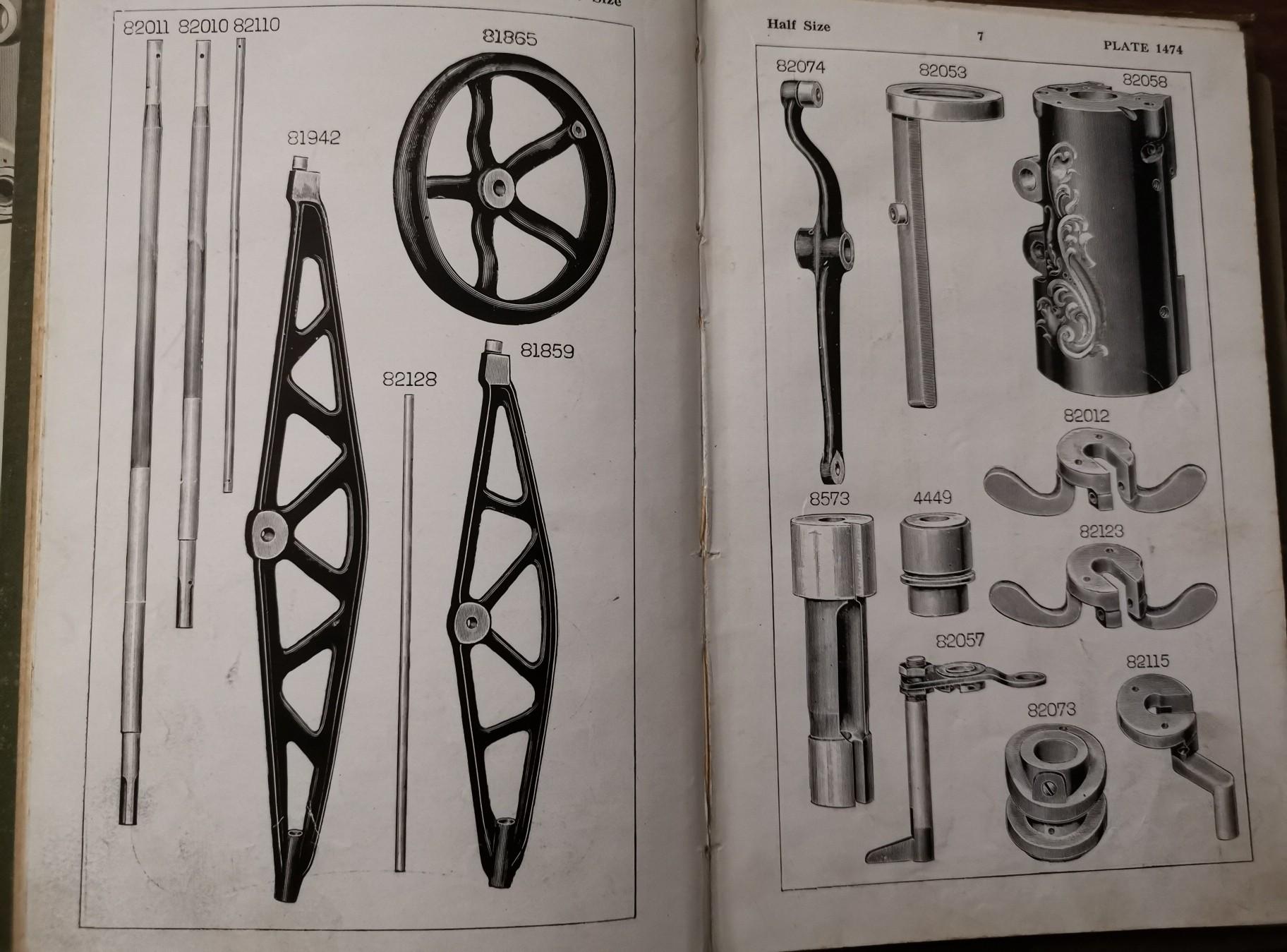

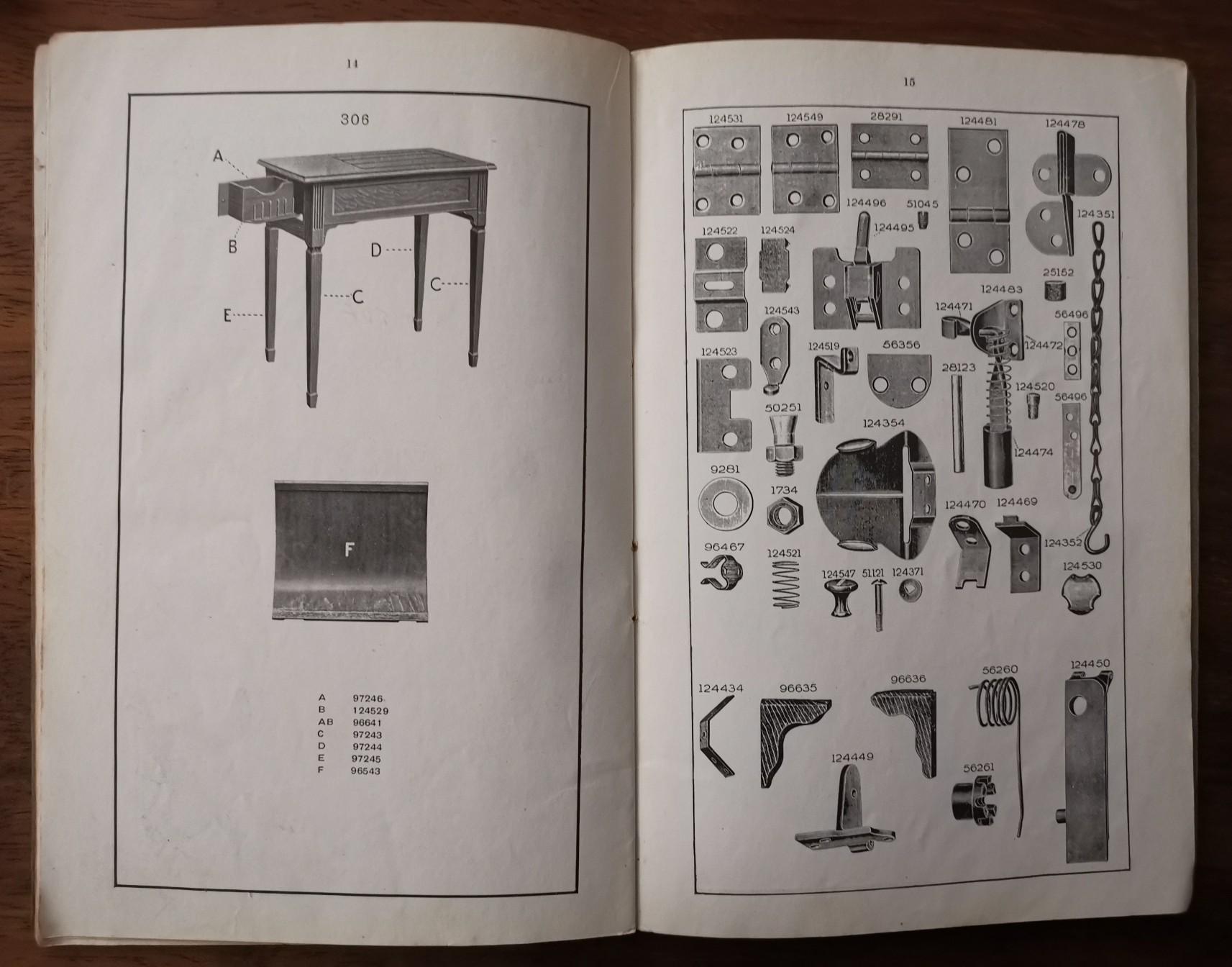

I spotted these whilst searching through an antique book store, I was so excited with the find the owner almost gave them to me for free. He said chances were pretty slim anyone else who might recognise their significance would find them there. Thought I'd share just for the historical significance. If anyone is interested I may be able to photo and email better quality files., just let me know.

-

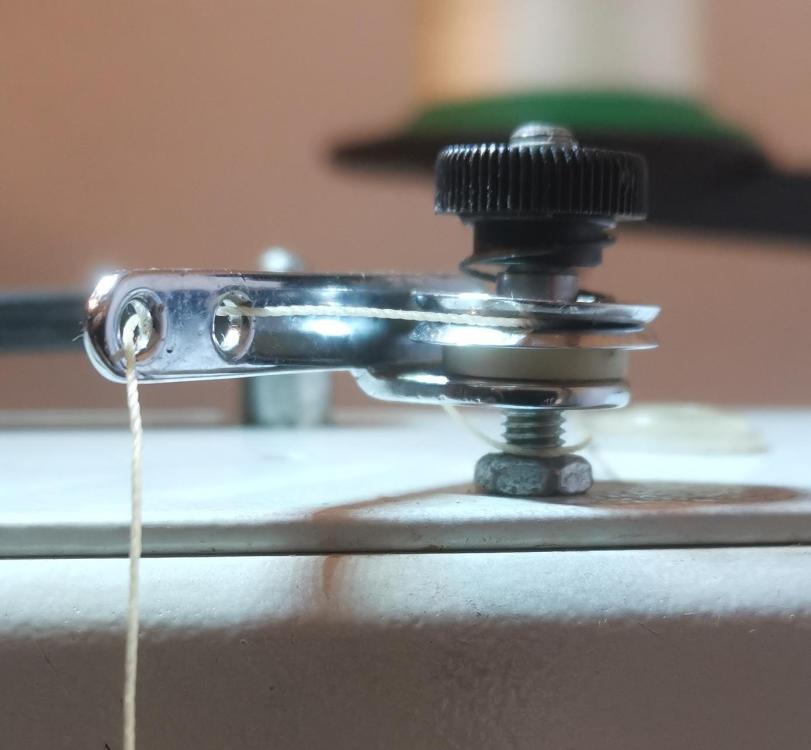

Hi, I own a 269-373 and was experiencing the same issue, so I'm going to assume they have the same bobbin winder assembly. The solution I came up with is to wind the thread around the threaded base of the tension assembly, then pass it through the first hole that leads it between the tensioning plates. This is probably an unorthodox way of going about the issue, so someone may chime in with a proper solution, but it's worked for me so far, give it a go. Regards, Apostolos

-

Adult area on Leatherworker.net

Apostolos replied to Johanna's topic in Announcements and Administrivia

Could I please be added as well? Thanks -

Forward and reverse stitching length adjustment

Apostolos replied to Moti's topic in Leather Sewing Machines

Hi, did you get the issue solved? I've got the same machine and am also having the problem. Thanks! -

Head/quartermoon knife restoration

Apostolos replied to BerkanaLeatherGoods's topic in Leather Tools

Hi, I'm pretty sure the knife in the top picture is a plough gauge blade. The notch under the handle is there to slot into the guide. Is there no makers mark on it at all? Someone with more expertise on old tools may chime in to correct me. -

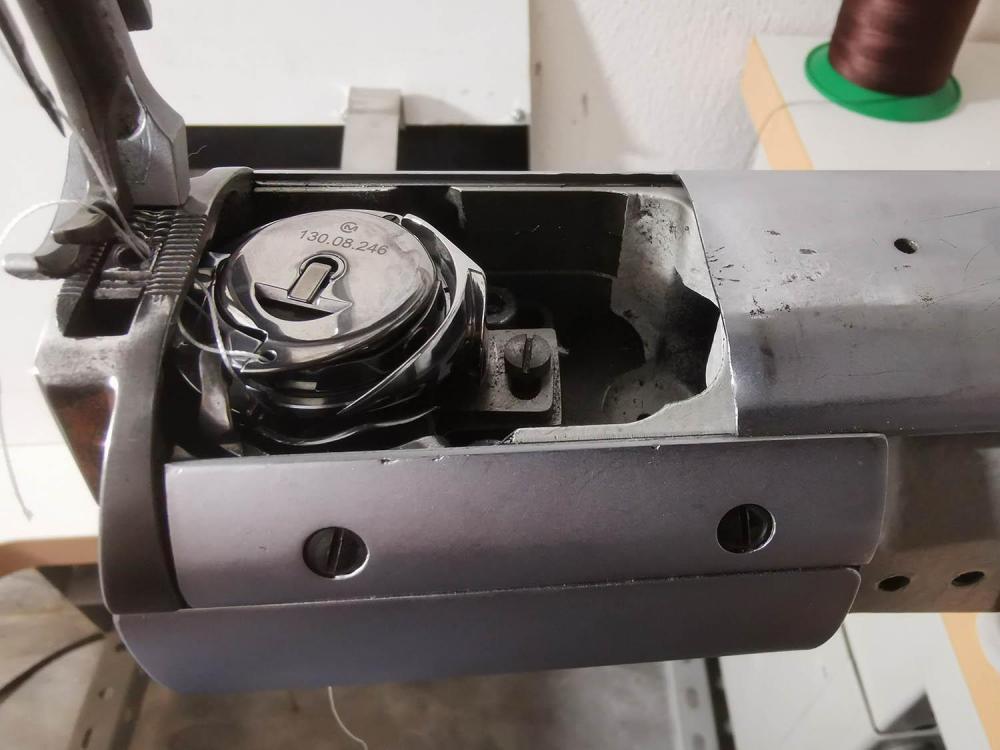

Thanks Glenn, I searched bobbin case opener and came up with an older thread about the part on an Adler 67. Uwe links a video there where he explains its function and how to adjust it. It seems mine was a little off, so there was no gap for the thread to pass freely through where the tab met the throat plate. I'll see how much of a difference this will make with the stitching. I couldn't manage to get it to sew the thicker pieces for the bag handle , but I suspect it is also an issue of the leather being stiffer, as it sewed the same thickness (6mm)of soft chrome tan with no problem. I've got some #160 needles on the way, so hopefully they might be the way to go when sewing thicker projects. Apostolos

-

Thanks Glenn, I'll try and get some #23 needles to give them a go. If you mean the sliding plate that hides the hook assembly, it's not catching there.

-

Thanks Wizcrafts, it seems like that's going to be the job for this evening. Regarding top tension, is there any difference between the three tensioning dials or do they simply add up tension on the thread? Thanks for all the suggestions, this place is gold.

-

You're right, I should play around with settings some more to see how it behaves. I was hoping someone might have some experience with this model and could confirm whether or not the thread and leather thickness are within its capabilities. On the site linked it does list main applications for the thread, which include belts and small leather goods. The dealer asked me what I would be sewing with the machine and suggested the particular thread, he doesn't supply it himself, so I doubt he benefits from getting me to use it.

-

Maybe you're right jimi, I might give it a try with #30 top and bottom. I'll have a search for the thread you're referring to DrmCa The thread I'm using is Onyx by Amann group (also sell serabond/serafil), it was suggested to me by the dealer who sold me the machine. https://www.amann.com/products/product/onyx/

-

Hi all, Longtime lurker, I have benefited a lot from the knowledge on here, it is time to ask for help on a specific matter. I recently got a Durkopp Adler 269-373 from, after many years of hand sewing. It is set up with 140/22 needles and I'm using #135 thread(EU 20). The dealer advised me to use 105(30) for the bottom thread, which I did for a bit but switched to same as top as it was problematic when sewing was visible both sides. That took a little bit of tinkering with tension to get right. I am working on a tote bag design and managed to sew the side panels to the base with few issues, just a couple of stitches in the run are a little more diagonal and loose (see pic). That was on roughly 4mm total thickness, 2mm suede and 2mm (probably)combination tan , medium temper. I want to sew a part of the handle that is going to be about 6mm thick, 2 pieces of 3mm of the combination tan leather, so I did some test run on scrap pieces. It's all over the place, bottom thread is pulling the top thread though and tinkering with the tension dial hasn't made any difference, even tried loosening the spring on the bobbin case, to no avail. From what I understand this machine shouldn't have any issues sewing with this weight of thread, or these thicknesses of leather, I'm pretty sure the needles are right for the thread size, not sure what's going wrong.. Also, when backstitching I often get a big mess of thread at the bottom (see pics) and occasionally when I start a stitch run it messes up on the first two stitches and if I continue it knocks the timing out so I need to block the hook assembly and operate the handwheel in reverse until it clicks into place. Thanks in advance for any advice, Apostolos