zzrguy

Members-

Posts

36 -

Joined

-

Last visited

Profile Information

-

Location

Long Island NY

-

Interests

Woodworking

Leather working

LW Info

-

Leatherwork Specialty

Just a hobbyists

-

Interested in learning about

Carving

-

How did you find leatherworker.net?

Google

Recent Profile Visitors

The recent visitors block is disabled and is not being shown to other users.

zzrguy's Achievements

Member (2/4)

-

That make a little more sense. I didn't think singer had a factory in Iran. But the guy I got it from was from there and said he brought it with him when he moved here

-

It is a 29-D-58 i'll post pictures of the tags when i get home. Thank you for the info on the thread and needles. I have to check the serial number but the girl at singerparts.com said it was made in Persia. I do want to get more info in the machine I always love a good backstory.

-

-

Ok I'm totally clueless with this needle and thread Speak for sewing. machine. I picked up a Singer Model 29-D-58 from a shoe store going out of business sad cause he was a small shop in Astoria Queen and been there over 40yrs. He just needed it gone. It in good shape for a machine that was made in Persia and traveled to the US over 40 yrs ago with its trendle. So I have no clue what needles I need for this machine or what is the max and min size thread this machine can use. I read the needle and thread Thread and now I'm even more confused. I'm not afraid to spend move on something that works but might not be the best for my use so I have a reference point and can try going up or down in size of thread and needle. I just need a starting point. Thank you all for any advise you can give me.

-

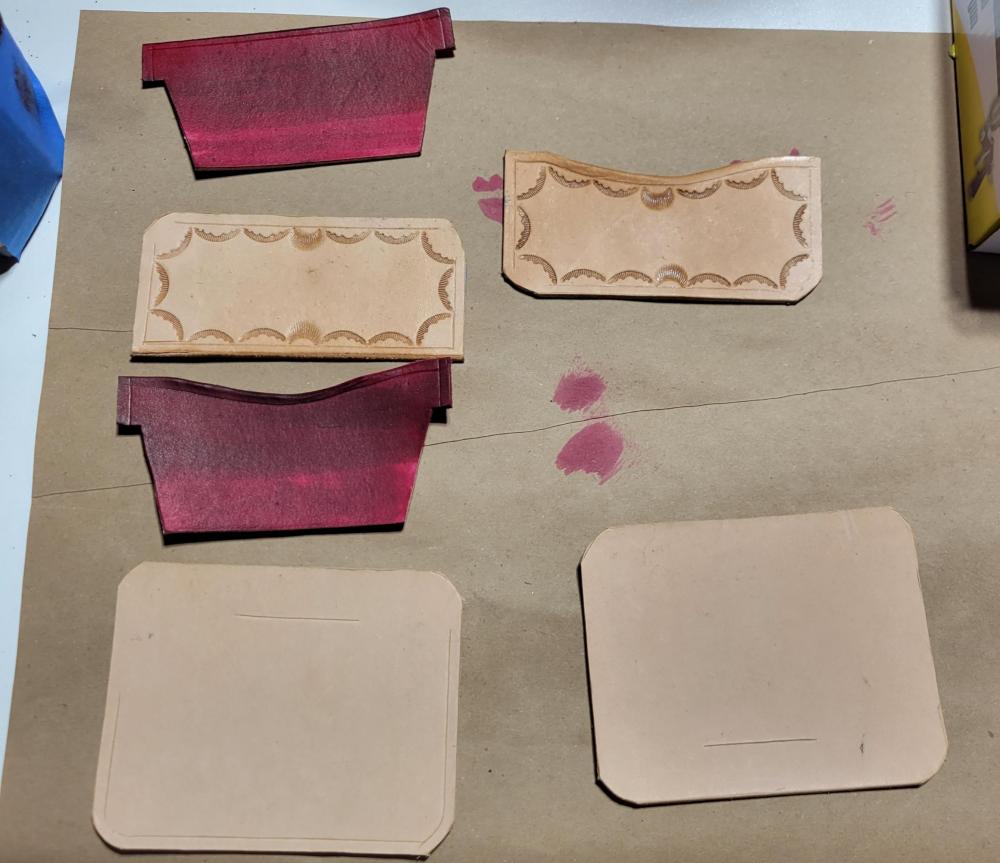

Down And dirty 3 hr wallet

zzrguy replied to zzrguy's topic in Purses, Wallets, Belts and Miscellaneous Pocket Items

I meant not covering fully. I buffed it up and there were areas that you could see the leather as if no dye soaked in. I didn't see that till I sealed it. -

My first Buscadero

zzrguy replied to PAMuzzle's topic in Gun Holsters, Rifle Slings and Knife Sheathes

Nice looking rig -

Down And dirty 3 hr wallet

zzrguy replied to zzrguy's topic in Purses, Wallets, Belts and Miscellaneous Pocket Items

Yeah it was a down and dirty job. Stamping did add alot to it. -

Down And dirty 3 hr wallet

zzrguy replied to zzrguy's topic in Purses, Wallets, Belts and Miscellaneous Pocket Items

-

So like it says this wallet was made in 3hr. Cut Stamped Dyed top coated and assembled. a close friend of our had a wallet failure and was leaving for vaction that day so i told her i could wipe up a wallet for her quick so she didnt have to deal with it allong with getting her family ready for a flite to Florida. Stamping came out nice as a little accent and her Dad was a NYC firefighter so the red accent was for Red lives matter for him. I need to learn the skive not shiving made it a little chunky and messed up my stitch line.Ill remake it when I got time and take time to skive and fit it better..

-

Huckleberry Holster my first patern ever

zzrguy replied to zzrguy's topic in Gun Holsters, Rifle Slings and Knife Sheathes

I'm Probably going to go with a loop around the hammer.The antiqueing didnt come out as dark as i wanted so the basketweave looks flaten out but its did flatten much. I like it in the Copper. Now to sand it to 3000 or 6000 grit and buff till shinny then replate the Nickel then buff to a shine then Chrome plating goes on with 3 or 4 coats -

Huckleberry Holster my first patern ever

zzrguy replied to zzrguy's topic in Gun Holsters, Rifle Slings and Knife Sheathes

Well heres a little more work to on the Huckleberry Rig I spen about 5hr Electro Stripping the Chrome off the gun here some picture for your enjoyment/ -

Huckleberry Holster my first patern ever

zzrguy replied to zzrguy's topic in Gun Holsters, Rifle Slings and Knife Sheathes

Actually pretty well it's a light gun and I want it to look real clean and classy so i went with the thinner straps. -

Huckleberry Holster my first patern ever

zzrguy replied to zzrguy's topic in Gun Holsters, Rifle Slings and Knife Sheathes

All done with one issue . The shoulder strap took the oil in way faster then the rest of the rig. And is noticeddarker. Now to refinish the gun. Anyone like puzzles -

Huckleberry Holster my first patern ever

zzrguy replied to zzrguy's topic in Gun Holsters, Rifle Slings and Knife Sheathes

-

Huckleberry Holster my first patern ever

zzrguy replied to zzrguy's topic in Gun Holsters, Rifle Slings and Knife Sheathes

.thumb.jpg.08e28690bfb331eb7b13235e02261ba0.jpg)