MariaMS

Members-

Posts

51 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Blogs

Gallery

Store

Everything posted by MariaMS

-

@dikman thanks. The collection and stories have grown over the years..... I have learnt such a lot restoring them and had a huge amount of entertainment. A couple more shots of the display. I do still get frustrated when I don't know the answer to something..... currently battling with setting the timing on a stop motion assembly on the Singer 175-33 (button sewer).

-

@jrdunn yeah me too. So many places closing up. However, the aim is for it to be both story telling and working. I have restored most of the machines back to working condition, and have hopes to do more workshops, including ones for children using the domestic hand cranks. We had a machine restoration workshop last year. It was a blast, but I got too tired doing it over two consecutive days. I had hoped that some of the people at the workshops would return to help me, but that didn't really happen. I confess to not know much about making shoes, and most of the leatherwork I've done is horse tack and sewn by hand. I do use the other machines in the "Shirts and trousers" section to make stuff like jeans and aprons though. I've got a 4 needle chainstitch coming, and will see if I can add a folder for waistbands and potentially bag handles..... then I'll get the kids sewing shoulder bags from recycled material .....maybe!! I don't want to clutter things up though, trying to stay with the leather work focus.

-

It has been a while since I posted. I've been steadily working on a display titled "Clothing the workforce" at Westland Industrial Heritage Park, in Hokitika NZ. Here are some pics of the "boots and shoes" section. I recently got gifted a set of wooden shoe forms, and the ledgers shown in the "office" are from a local shoe shop and date from around the 1930s. Locals have enjoyed looking through them to see what shoes their parents and grandparents purchased or had repaired. I have also been given various tools, and we have a pile of cast iron forms for repairs. So far the machines are a Singer 107G2, a couple of Singer 29K (2 and 13), a Pfaff post bed, a cup seamer for fur and a Singer 31k19 kick foot. I also have a Pfaff triple feed, a Singer 7 and an early Pearson but they are displayed in the upholstery and heavy leather sections. I have pending an alternative fur sewer (the existing on is on loan) and some local history from the possum fur shop which is retiring after 50 years in business. I'm curious as to what, if any items I should keep an eye out to add?

-

Interesting topic..... I have what I think is a Singer model 47 coming. Don't know the subclass as it went straight to storage and I can't see it in the pics. It currently has a roller foot, but I want to look into if I could get it darning. Was wondering if anyone has modified a domestic darning foot...... there are a few different ones that might work perhaps......

-

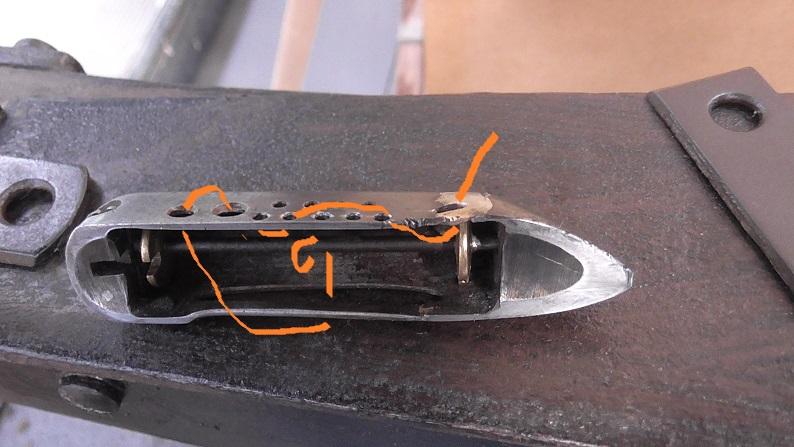

Sorted. It turned out to be the usual things - grease was a bit dirty, but the main issue was lint and broken needles in between the feed wheel and the hook, and also a heap of thread wrapped around the base of the hook assembly! So the same issue as most of the domestics I've worked on, but just looked more complicated.

-

A friend recently got given a bunch of machines, including a Pfaff 191-5. it looks like it has been sitting for a few years. The needle system and hook timing are now working fine, but then I noticed it was sewing in one spot..... it appears the drive shaft the runs the continuous wheel feed is not moving. If I hold the stitch selector button down, I can't move anything, and when I let it go it just disengages. I have doused the gear train in kerosene and PB blaster, and will let it sit for a few days. The worry is the condition of the shaft - to me it looks like an aftermarket part, and has blueing showing partway along..... would removing this shaft be the first step to track where it is jamming, or could there be something more obvious I am missing? I did open up the cover plate over the main vertical drive shaft to check, and the grease is not hard. Sorry I didn't take images of the top end, I can do that next time i am at the workshop.

-

thanks for that- i had a quick look on their website, but contacting them is an option. You are totally right on the cost front. it may be another machine pops up in the future that I can gather parts from....... there seems to be all sorts hidden away in old sheds!! It will be interesting to see if it works as is - makes me wonder if the system was replaced with a standard presser bar. I am not that familiar with them as yet. Part of the issue with contacting Mayfar would be I haven't figured out the part numbers I'd need to ask about! I have the manual, but it is a bit tricky working out what the parts look like!!

-

Hello! A friend recently acquired a Singer 31-19 as a tag along to a bunch of other machines. I've freed it up, just the bobbin case to clean and then I can check the timing and see if it will sew. Sadly it looks like most of the kick foot assembly is missing- see pics. It currently has a standard high shank foot instead. Does anyone know if such parts are still available? We are in New Zealand.

-

-

those two pics are perfect, exactly what I need. I couldn't quite see it properly on your earlier image..... thanks heaps!!

-

Just wondering if your 7-5 has a spring mechanism that returns the foot forward after is is pulled back by the action of the feed dogs..... the foot has a tiny hole in the back, and then there is the L shaped bit, as if there could be a compression spring on a pin nestled in there to do the job. Tried a coil spring and it worked great but restricts the movement backward. A ballpoint pen spring will be the net thing to try, but would like to see pics of what it SHOULD have in that spot...... and does the thread run through there, or should it come from the take up lever through the slot and skip the tab thing?

-

I got another step further today - I had trouble with getting the tapered pin that holds the foot in place back in, and just had a thought that maybe I had the presser bar 180 degrees out.... so pulled it around and it went back together perfectly. I had a friend helping today and we developed a better take up spring. He also questioned why the foot wasn't travelling the whole distance, and we decided maybe there should be a spring in there too, so the foot can flick forward properly......got all that sorted and wow, we suddenly have perfect stitches!! If anyone has a 7-5, I'd love to see a pic of what the two springs actually look like LOL

-

The Singer 7-5 has graduated from the intensive care ward onto her own bench. 2 oak headboards and what looks to be an old steel industrial sewing machine frame that was kicking about in the Engineering shop. Now I know it will look OK, I'll stick the frame into the electrolysis tank and give it a clean up. It is a good height for standing up at. This shows the machine with a single coat of rustoleum flat black. I'll probably do the frame in the same way, and leave the wood light coloured.

-

Gordond helped me out and sent this (see "Singer 7-33 under restoration for the whole thing - I couldn't change the title, but it shows my rescue of the 7-5). I'll look up the Adler plate. This machine takes a 7x1 needle, is that the same as your Adler?

-

Who uses a Pearson #6

MariaMS replied to T Moore Medicine Hat Saddlery's topic in Leather Sewing Machines

ta. I'll get in touch with them. -

Brilliant!! Thanks so much!!

-

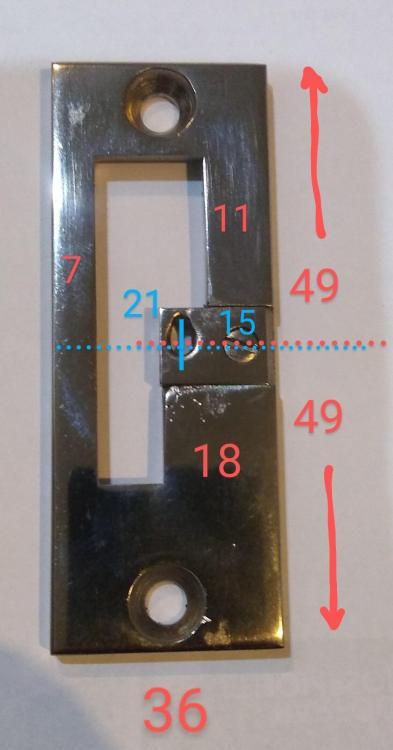

Hi I'm still trying to get dimensions for the 7-5 needle plate so I can make one - I asked in a new post but no responses so far...... any chance you would have time to do a measure up and add to a photo? We managed to make one OK but I think the needle hole was maybe a bit small (1.5mm) and was super close to the edge, which may mean I need to adjust the feed dogs more to the left to get a bit more of a margin so the hole can be a bit bigger.... I ended up breaking the needle as the tip caught the edge.

-

We managed to get a plate roughed out, but the needle hole looks closer to the inside edge than it should be, which could be to do with the feed dog adjustments. I noticed today there is a slight slop sideways, so I will have a go at adjusting them slightly further left, which would give more metal between the edge of the plate and the needle hole. 2 questions, what size is the needle hole usually, and does anyone have a plate they could measure up for me? it would make a repeat plate a bit quicker to make.....

-

Who uses a Pearson #6

MariaMS replied to T Moore Medicine Hat Saddlery's topic in Leather Sewing Machines

What a beauty!! Nice history too. DO you know of anyone selling needles for the BUSM #2 machines in New Zealand? I only have one - it would be great to start using it more often on the various bits of harness in the Livery, but I don't because of the lack of any spares. -

it isn't the dogs that are the issue, they cleaned up fine..... it is the plate that covers them that I'm wanting to make a new one. The other was so rusted I thought it couldn't be saved, so cut it off to gain access to the hook assembly. Rewelding it could be a possibility if I still have the other bits perhaps, currently I only have the ends with the screw holes.

-

Who uses a Pearson #6

MariaMS replied to T Moore Medicine Hat Saddlery's topic in Leather Sewing Machines

excellent - great to see the inner spring. I tried ours out today, but the spring has sharp edges rather than rounded - I found it is an issue when the bobbin is fully wound, as the pressure is so high it causes the thread to jam and pull into itself. I unwound it a layer and it was heaps better, managed to get quite a stretch of a reasonably tensions row of stitches...... as usual forgot to get pics.... will get net time I am up there. -

The Singer 7-5 I'm working on had a feed dog plate I thought was past rescuing, so I made up a set from wood. I'm going to have a try to making one from 3mm MS today but I'm not sure my skills are up to the task..... does anyone happen to have, or the skills to draw up a laser cutting file for these? I do have my Verniers to do a measure up if my "drill holes and wear out a few files" approach is a complete failure..... at least this time around I know to get the plate fitting at the screw holes first up, and THEN mark the needle hole!! Then again, maybe I need to beg some lessons on how to use the milling machine.....hmmm that could be a fun learning curve!!

-

Who uses a Pearson #6

MariaMS replied to T Moore Medicine Hat Saddlery's topic in Leather Sewing Machines

-

Who uses a Pearson #6

MariaMS replied to T Moore Medicine Hat Saddlery's topic in Leather Sewing Machines

I got as far as this https://en.wikipedia.org/wiki/British_United_Shoe_Machinery so somewhere between 1900 and 1910 possibly. Unless it is a date - 6/2/18 -

Who uses a Pearson #6

MariaMS replied to T Moore Medicine Hat Saddlery's topic in Leather Sewing Machines