-

Content Count

10 -

Joined

-

Last visited

Posts posted by Hypomelanistic

-

-

@Handstitched I don't have a plan for the table yet but I think the original is too far gone.

-

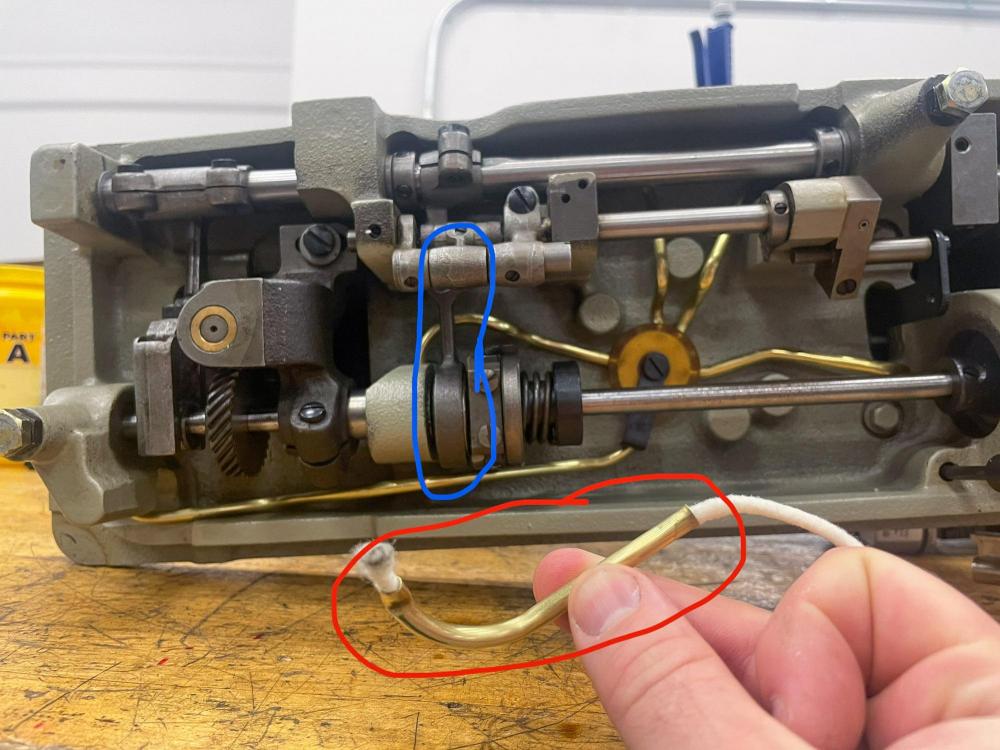

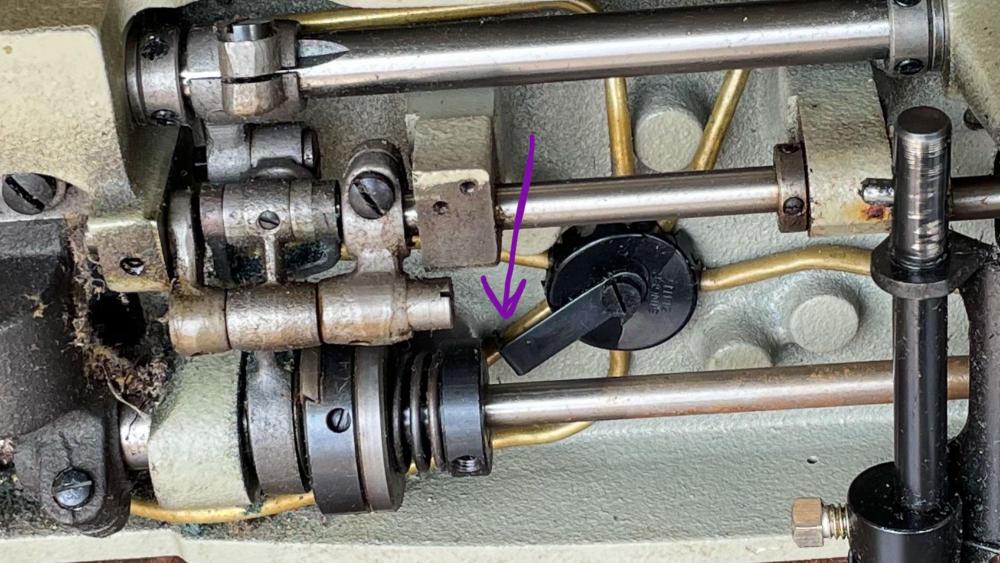

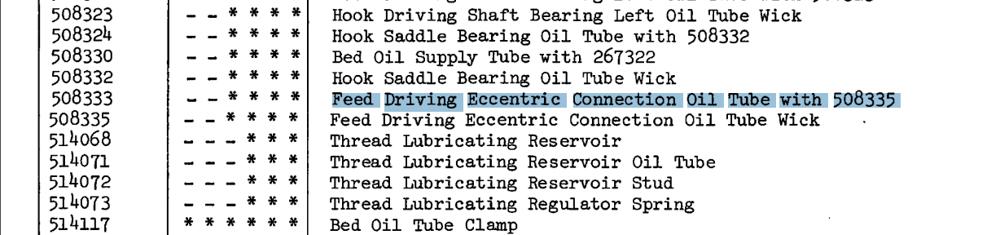

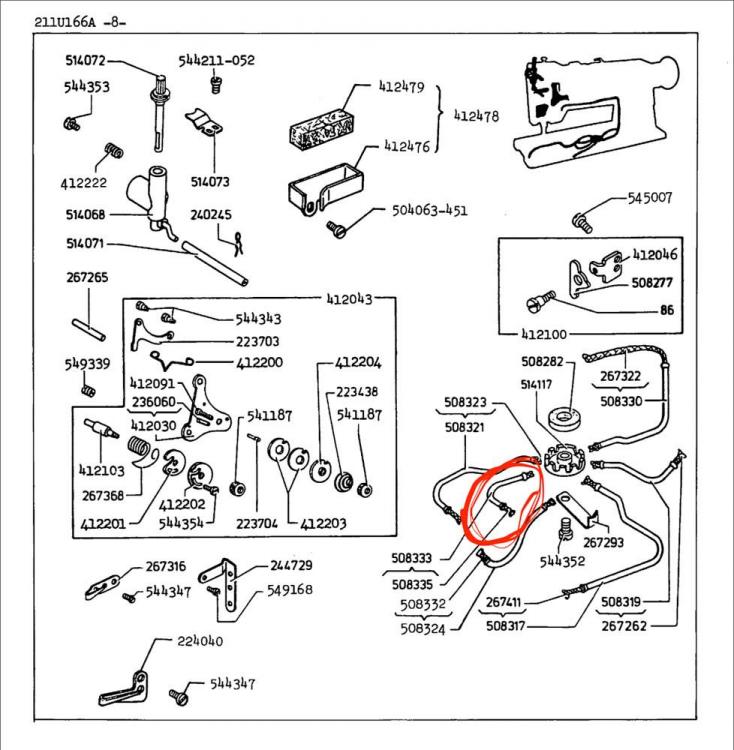

Hi Arjon thats awesome I am glad you enjoyed the pictures. I have a question for you (or anyone else who might also have a similar machine). Do you happen to know where the "Feed Driving Eccentric Connection Oil Tube" hooks up on the bottom of the machine? Mine was falling apart when I got it so I am not sure. The "Feed Driving Eccentric Connection" (i circled in blue) of course moves depending on the stitch length. That makes me think if i hook the felt to it (there is a hole on the top of it that maybe the end of the felt could be stuffed into) it might eventually break because of the movement. Any insights? Thanks a ton for the help.

-

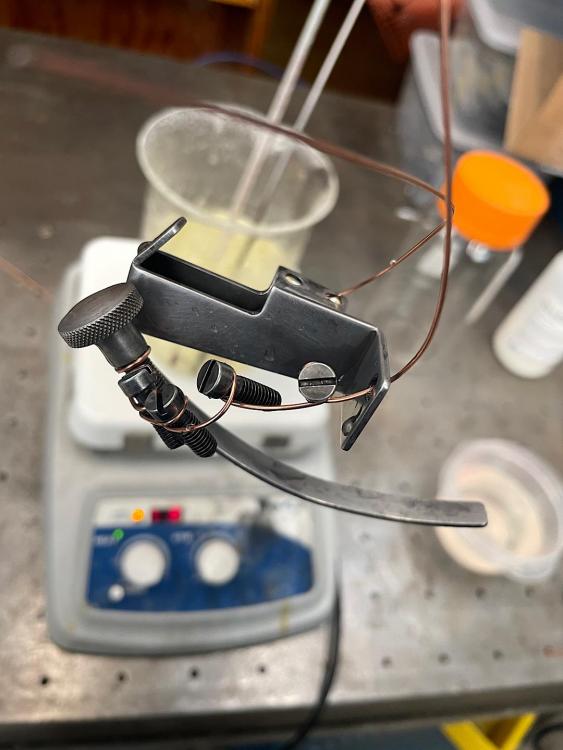

8 hours ago, shoepatcher said:Nice job. Electrolysis on the rusty parts?

glenn

I used Rustoleum “Rust Dissolver” on the rusty parts which removed the rust but still leaves the pitted surface. So after that I hit them with some sand paper and scotch brite so they would have a smooth finish under the black oxide.

-

16 hours ago, RockyAussie said:I am curious how you do the process black oxide? That is some very nice looking work on the servo motor attachment

16 hours ago, dikman said:

16 hours ago, dikman said:Good question. The common way that most of the restorers on youtube do it is to either heat them and drop them in oil or use the gunblue stuff that is used for cold-blueing on firearms. I'm interested if there's another way.

I used EPI ultra black 400 and their E-Tec 512 rust preventative. This requires you to boil the parts in the solution at about 290 degrees Fahrenheit. My understanding is this is a more industrial product than cold bluing. I have never been able to get something that looks factory with cold bluing stuff I’ve tried so I went this route.

-

3 hours ago, dikman said:Some nice work there. If it was me, though, I would have made the handwheel bigger as it will help give better control and torque. How do you intend controlling the servo?

I was going back and forth on handwheel size. I ended up at 5" diameter. I forget the size of the original but the new one is a little bigger.

I made a pedal with a rotary encoder that talks to the motor. I dont have an actual picture of the pedal right now but this a screenshot of the model.

-

14 hours ago, trash treasure said:Did you do the machine work on the handwheel? If so - Very nice work.

I did. Thank you. I am thinking I will anodize it black to match the rest of the machine.

15 hours ago, Handstitched said:Seeing the machine collapsed inside the table is a sad sight to see. Looks unloved

Good luck with the build

HS

Yeah it was a sad sight. Previously owned by our state government.

-

23 hours ago, kgg said:Nice job, I really like the nice clean servo setup.

kgg

Thanks

-

-

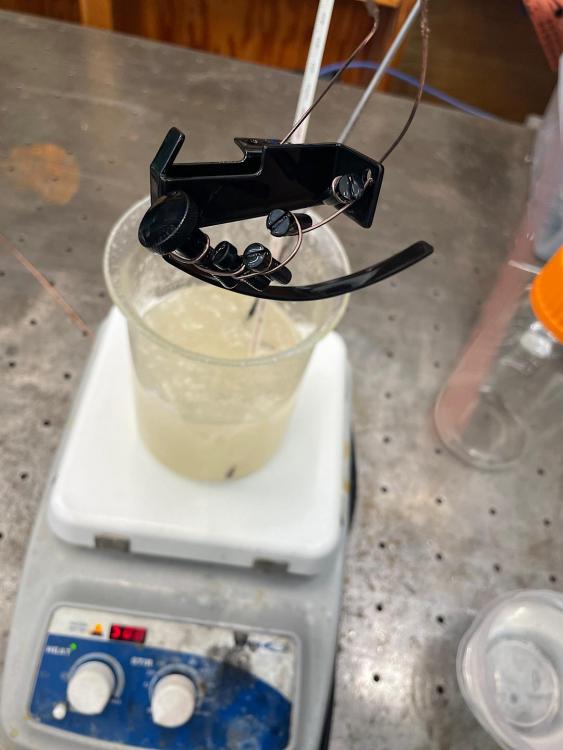

Hello all,

Last year I bought a pretty ratty looking Singer 211U166A from a local auction. Throughout my tinkering I have found a lot of interesting information on this forum. I am far from finished with the work on my machine, but I figured it would be worth starting a build/progress thread. Hopefully someone finds these pictures to be helpful on a project of their own.

So far I've redone the black oxide on a lot of the rusted screws, added a machine mounted small (but still 0.44hp) servo motor that is designed for a CNC machine tool, and replaced about half of the oiling felt.

If anyone has any questions or suggestions I would like to hear them. I am new to the sewing world so I dont really know what I'm doing.

Singer 211 Restoration

in Leather Sewing Machines

Posted · Report reply

@Handstitched I think you're right about the water damage. I have some maple butcher block table tops I got at an auction that I think I will use.

@Scoutmom103 The felt wick I used is McMaster Carr part number 8767K21.