AWORKOFMARC

Members-

Posts

52 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Blogs

Gallery

Store

Everything posted by AWORKOFMARC

-

Stiffening Crazy Horse leather for a sunglass case?

AWORKOFMARC replied to AWORKOFMARC's topic in How Do I Do That?

I suppose I could always sandwich some sort of stiffener used in garment making in between a liner layer and the crazy horrse.. but that's way more invloved. -

Stiffening Crazy Horse leather for a sunglass case?

AWORKOFMARC replied to AWORKOFMARC's topic in How Do I Do That?

I heard that wax is a method but not to do it bc it has a nasty habit of leeching out and permanently staining whatever it was on -- like car seats, furniture clothing etc. -

Making a sunglass case for a friend....Anyone have some experience in stiffening Crazy Horse leather? Can it even be done? Cold water soak? Resin coating?

-

No idea why the zipper would turn South me, but after getting one side of the internal dividers completely sewn together, in trying the zipper before moving to stitch the second side internal dividers, it hangs badly over one section requiring some yanks to get it past. Without the dividers in the zipper glided along quite smoothly, zero hang or resistance any where.. So Im fairly sure its the design and not my zipper... I had zero instructions on how to assemble this pattern, so I went with what the lady at the Tandy store suggested for the pocket dividers leather's width (1mm) plus watching sev. different YT videos. Guessing 1 or 2 causes: That divider leather is too thick depth wise so when stacked (closed) causing the hang AND/OR the design itself is hinky. If it were me. I would'ave designed the internal dividers 1/4" inward on each side, so the vertical leather sides of the divider weren't flush against the inside of the zipper. I have 2 options, completely cut stitches and remove the 1 center divider thereby making it 2 pockets instea d of 3(making a thinner depth) OR slice a 1/4 to 1/2" piece all the way out of the middle section, sew the 2 sides back together, (making thinner width overall horizontally of the divider section. Or both. Any ideas?

-

American Leather Splitter. Nicely refurbished

AWORKOFMARC replied to AWORKOFMARC's topic in Old/Sold

No longer available. -

What a very fine gentleman you are for walking me through this --all the while you did not feel good. Well... I hope my pain helped take your mind off your pain hahah. Seriously.. I learned a ton here and I now know how they operate. It's good guys like you make these forums worth it for us retardo-noobs. If I had known the splitter was specifically made for the stiffer leathers it would have saved all of us. But. Here we are. I hope this thread lives on because your guidance has been incredibly generous and patient and there's a lot of good info for the next guy.. Feel better fast Sir! If there's anything I can do lmk. Marc

-

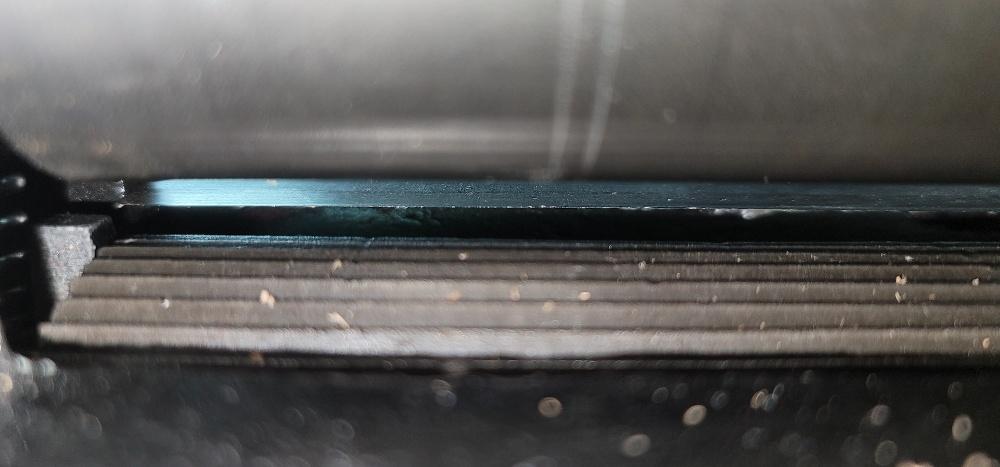

So at least it splits leather... TY Bruce! This is where I am -- it seems to split --kind of. I'm sure it comes down to now finessing the settings to get more even splits. the first attempt after making the adjustments was the best --the tan color longer split at the right side. The rest after that got mangled as you can see. I dunno if that's because they're pull up more oily or why..

-

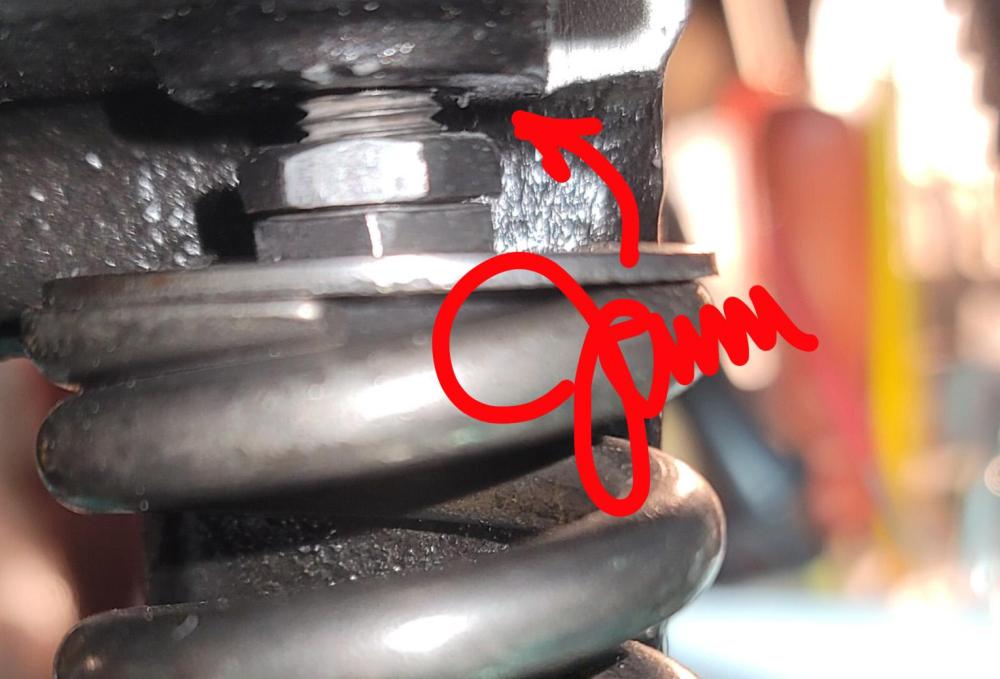

Here's from the back side -- using the square bolts to bring the bottom roller up. the leather still drops down and comes out the bottom --nothing thru the top. So I tighten the gap a wee bit more and then the leather won't even come through as if it's not being gripped enough by the bottom roller to push it through the bottom or top.... but then if I turn the square bolts and bring the roller up too far it seems to meet the blade and not allow the handle freedom to turn and I'm being baby gentle with this bc I don't want to damage the blade.

-

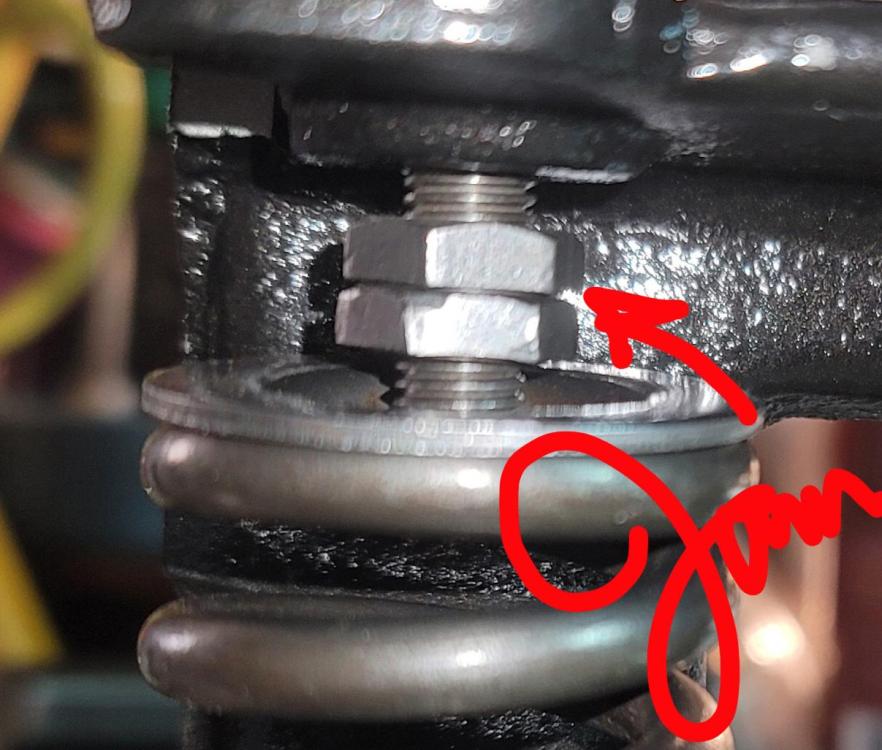

Part of this is just not knowing what tabs on blocks are or jam nuts or stops... and not having a diagram that spells it out. I haven't found any manual. So. that said. Here's some pics I've positioned the blade forward to meet those little square tab stops and then backed of just a hair so the blade is not touching. The Jams (or what I think are jams) are not actually against the bottom of the frame as seen in the pics. How do I bring the bottom roller up --proper? By turning the square bolts? Or the jams? I was able to make it move up and down using the square bolts -- so is that how I close the gap properly to 1/16th inch between the blade and the roller by using those square bolts?

-

Bought this a day ago in a splurge spend. I'm just a hobbyist and it's easier to just buy the right weight leather, I am never going to be that busy. Blade is super shape. All parts seem to operate as they're supposed too. Screws screw, bolts turn, lever works well, rollers roll and rise and lower appropriately. My loss your gain $1,400. Los Angeles area if you want to pick it up --otherwise there's a shipping cost.

-

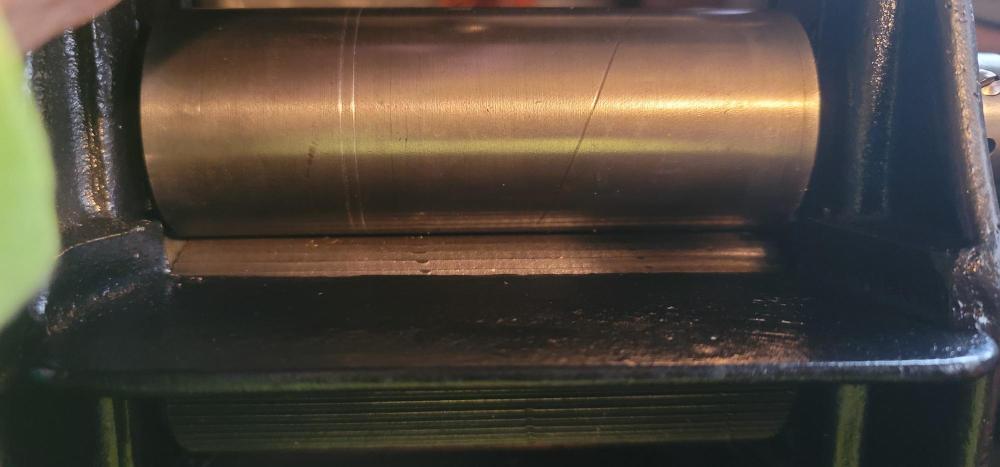

This is the blade all the way forward. Not sure what back up screws are. The more I am into it everything on this appears to work flawlessly mechanically. The gears glide smoothly, all parts move as they're supposed too. The blade is extremely sharp so it comes down to t0otal NOOB operating ignorance. I haven't the patience. I'm just a small hobbyist and this was a splurge spend. It's easier just to buy the right weight leather to begin with and I'm not seeing myself ever being so busy this is a necessity ---so that said.... Coming up -- One nicely refurbished American Splitter for sale $1,400.

-

Sorry, sucks that you don't feel well, so doubly thank you for taking the time. What kind of leather are you trying to split? As a test 5/6 oz leather - but really anything. The main idea was to have a machine I didn't have to arm wrestle with like the hand splitter where you're pulling it through by hand. Which seems to work fine for anything less than 2" wide. I wasn't aware this American would require finessing micro settings manually. This guy in the video at the bottom made it look so easy stating "Split to 25 thousandths of an inch" How big is the gap from the blade edge to the bottom roller? I've varied that using the 2 square spring bolts at the bottom. When I first got it that bottom roller was so far up it didn't allow the top roller down enough to thereby allow the level gauge all the way to the end/thinnest setting. By lowering that bottom bar and moving the blade out as far as it allows it allows the gauge to move more to the left/thinnest. If you move the top adjustment to thinnest setting, how far apart are the top and bottom rollers? Pics attached to show where it is now. Big gap a little less than a quarter inch, blade all the way out. Is the blade all the way forward to the stops inside? No all the way out. Loosen the hold down clamps and center screw and slide it forward. It should hit the stops at both corners of the blade. Back off the back-up screws about 1/4 to 1/2 turn. I'll do that now. The back up screws are...? The 2 sideways top facing forward in front of the blade? You mentioned "off-kilter". Which roller or both? It appears the off-kilter was due to the bottom roller one side being slightly higher, with a slight adjust to one side of the the square spring bolts corrected that. I took the blade completely off to inspect. Despite there being a couple flea bites on the cutting edge, I was able to knife slice a piece of 4mm leather like butter so I know that's sharp. So we can rule out a dull blade. Let's get you splitting here Thanks for taking the time.

-

Please forgive my noob status and ignorance. I just bought an American leather splitter, beautifully refurbished. But I am unable to split the leather --i must be completely retarded because I thought all you had to do was set the gauge for the thickness and crank the handle, feeding the leather in from the back. No matter what lever/gauge setting .. and I've tried several, right down to the tightest. I see the roller moving well in conjunction with the thickness level but the 5/6 oz leather just feeds through, coming out the bottom entirely unscathed, must less split with any finished split piece coming out the top. When he showed me the machine in the back of his truck there was a piece of sample leather, already having been fed in the machine to show me the thinness --it was about 1mm form an 8/9 oz sample.

-

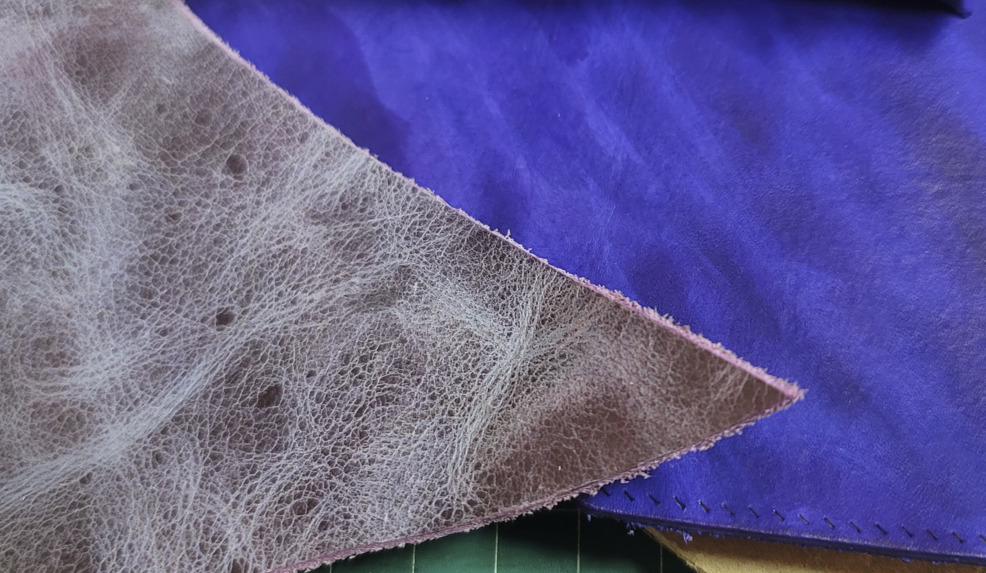

So in dying some veg tan (right side) for the inside compartments of a zipper wallet I used Angelus purple... I like the mottled look but it's not a good match to the outside leather seen left of it. Any suggestions on how to repair the inside color to something less of an assault to the outside side? I'm resigned to probably dying it black now --but thought I'd come here and ask the pros first. :(

-

Thanks Gents! I'll look into Kanga.

-

So I modified a wallet pattern and while I love the look on the outside --the 4 rows of vertical stitching on the inside bill fold section is a bit much. I want to line it with something and I have zero experience lining anything. I got some "salpa" which, in my experimenting, took the dye well --but I'm not sure I should use that as a liner or would I be better off going with something like card stock paper thin goat skin? The vertical rows are what's going to be covered and the horiz. dots are where my liner stitch will go.

-

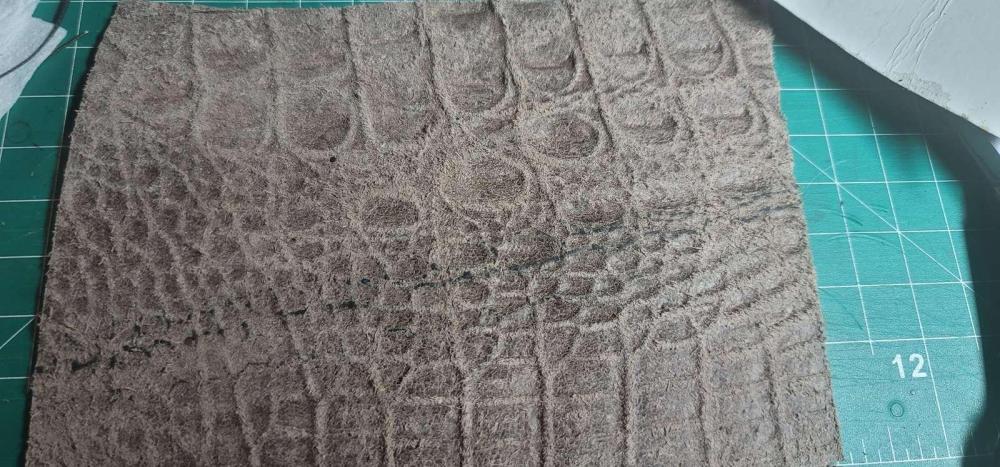

Came across some alligator...seems a tad thin and I need to conceal the flesh side on the inside of the wallet I want to make... With what might work best? Duck canvas or a thin piece of leather?

-

Sadly this was an expensive lesson. But thanks again guys.. so much good info I just learned here.

-

Here's some pics of the piece I have (paid $125.) --then before I started working with it I decided I better buy another strip -- that's the second $125. out the window and it hasn't even gotten here yet. which is going right back.. I'm going to get screwed on shipping but whatever.

-

Crazy depressing. I've spent $250. on leather now that I can't use to start making wallets and I can't return...

-

Ah.. thanks. I'll look into the stuff. see if they have any smaller sizes. Update. Nope. So does that mean this leather was split? I am feeling now like maybe I got a little taken --with my novice stupidity not knowing good form bad? The distressed side looks beautiful --but if they're selling split leather w/o being up front --that's pretty shady no? This is the stuff I bought -- but I bought a whole side. https://www.ebay.com/itm/266400282454?hash=item3e06b1b756:g:P6cAAOSw-rxk9kkE Thanks everyone -- new to the forum so it's nice that you all are so helpful!