Thadrick

Members-

Posts

164 -

Joined

-

Last visited

Profile Information

-

Location

WY

-

Interests

Almost everything guns

LW Info

-

Leatherwork Specialty

Holsters so far

-

Interested in learning about

Leather finishes

-

How did you find leatherworker.net?

Stumbled into it

Recent Profile Visitors

The recent visitors block is disabled and is not being shown to other users.

Thadrick's Achievements

Member (2/4)

-

It's been a minute since I've posted anything

Thadrick replied to DoubleKCustomLeathercraft's topic in Show Off!!

If you ever do get a chance to stop in there remember the good stuff is in the back. It's a landmark business and building and the people are nice. I get a veterans discount too. Makes me 😊 -

I took my first spike with a 500 about 25 years ago when Smith first started making the frame available to the public. I really liked that pistol but I was still young and used it for barter because I was a poor boy. Always wanted another but just can't justify. The picture sucks because my step daughter was running the camera even though she took several pictures of the land owners dog which turned out great. As you can see, I hit about 2" to the right. The processor said the bullet lodged in the front shoulder so I lost a lot of meat because of it. My friend at work has an unported snub nose 500 that his father left him and it really makes the hand sting! I'm sure at $5.00 a shell I won't be spending a lot of time shooting it anyhow. Oh, the buckle is a used buckle I have been looking for a place to use it.

-

Chiappa Rhino 60DS drop holster (stange situation)

Thadrick replied to DoubleKCustomLeathercraft's topic in Show Off!!

I like it. Beautiful! -

The best part of valentines day is when i became single 11 years ago. That 500 will have lots of canvas for tooling on the next holster. Thanks.

-

Had a new toy follow me home so had to start a new leather project. I always do a trial holster first to ensure my pattern is good so now that test fit is good I can start a bling bling holster.

-

It's been a minute since I've posted anything

Thadrick replied to DoubleKCustomLeathercraft's topic in Show Off!!

I found some really nice Buffalo at Montana leather company. I prefer to go up there and choose the sides in person but be sure to bring your entire savings because they have some really nice stuff and you won't get out without having to sell your first born. I always come home with way more than I had planned. I think I have the other side to that Buffalo. It's nice and easy to work with. Nice job -

I made a set a few years ago. 12x12x4 Funny how I never seem use them? They just sit here over the back of my couch on display. I planned to hang them over the seat in my truck but figure someone might break my window to steal them?

-

first pancake holster

Thadrick replied to Thadrick's topic in Gun Holsters, Rifle Slings and Knife Sheathes

Thanks guys. I got bored after that holster and started a cowboy style holster for my Lil GP100 and made it half way through the project before realizing I made a rooky mistake. I made it left handed. Couldn't help think that if I was making a pancake style I wouldn't have mattered. -

first pancake holster

Thadrick replied to Thadrick's topic in Gun Holsters, Rifle Slings and Knife Sheathes

I plan to put a leash over the hammer. Thanks for the compliment. -

I watched a friend shoot a buffalo three times through the lungs with a 4570 and it didnt even grunt. Then the herd started running and we had to take it down with a 338 ultra. So if your buffalo hunting, head shots are where its at. Sorry, Im just remembering the good ol days. LOL

-

I have no idea if I did it right but this is my first. It was very easy compared to other holster styles ive tried so has me wondering if I did it right. Took me about 2 hours not including time waiting for dye to dry. Still needs sealed but I need to let it dry a little longer. Let me know if Im doing it wrong please

-

Looks a lot better than mine. Those big boys are awesome! I've had two now in 44mag and even my g daughter loves shooting them. My newest lever action is a rossi in 454 casull and it's a kick in the shorts but the rossi isn't that impressive when it comes to feeding. The Henry feeds so much better.

-

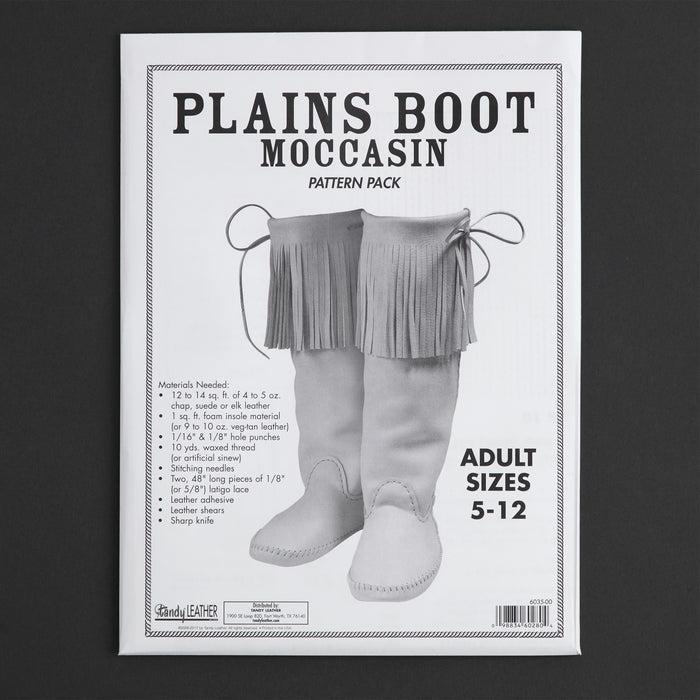

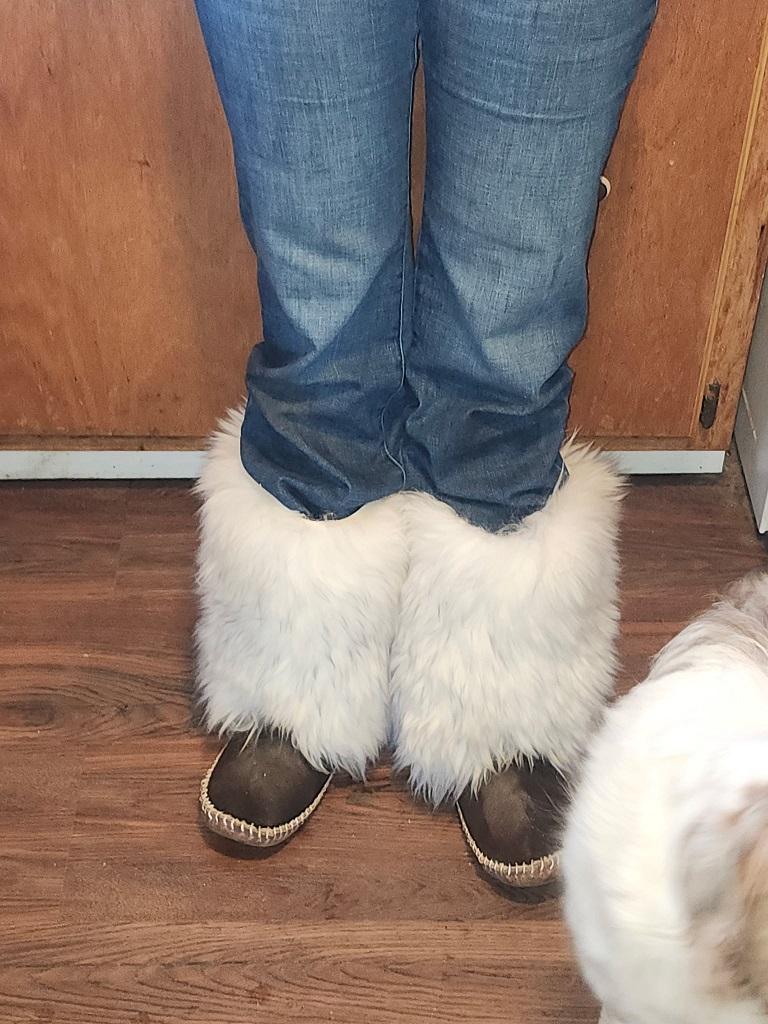

Well, long story. I purchased a plains boot patern from tandy thinking I could alter the design to fit my liking. Basicly a pair of booties to wear inside my tent when camping in deep snow. I altered the pattern so they would be triple warm for my aging feet. I wear a size 10 logger but knowing I would be using bark tanned wool inside for insulation I decided size 12 would work. It didnt. They were very tight... So... I gave them to my gdaughter. SHE LOVES THEM!!! I guess Ill have to try again but go larger yet to fit my feet? anyhow, this is the pattern and these are the booties I made. Bark tanned inside the lower portion and long hair wool on top . I bet her feet stay warm?