All Activity

- Today

-

Hello group experts. I moved in July and the movers broke the take up arm on my Juki Lu563. I had a local company repair the machine paid for by the moving company. $730 repair cost. I got the machine back and it doesn’t seem to be sewing properly. hook is too close to the needle, hitting it going forward and appears to be slightly off going in reverse . I spent hours in the past getting this machine to perform flawlessly using help from this forum. Unfortunately the arm that was installed appears to be shorter and does not have the same lift and extension as the original arm did attached is a pic of the new arm installed on the machine I am sure that the old arm at least extended to the front edge of the flange guard to the left of the arm and the new arm does not extend out that far kind of like a Juki lu562 arm and upgrading to a 563 arm when doing a big bobbin conversion am I right ? Is this the wrong arm? thank you richard richardf1969@gmail dot com 9 05 73 00 844 text

-

Seems I broke my Juki-LS-341, again... (Bobbin Shuttle)

friquant replied to Yoshi888's topic in Leather Sewing Machines

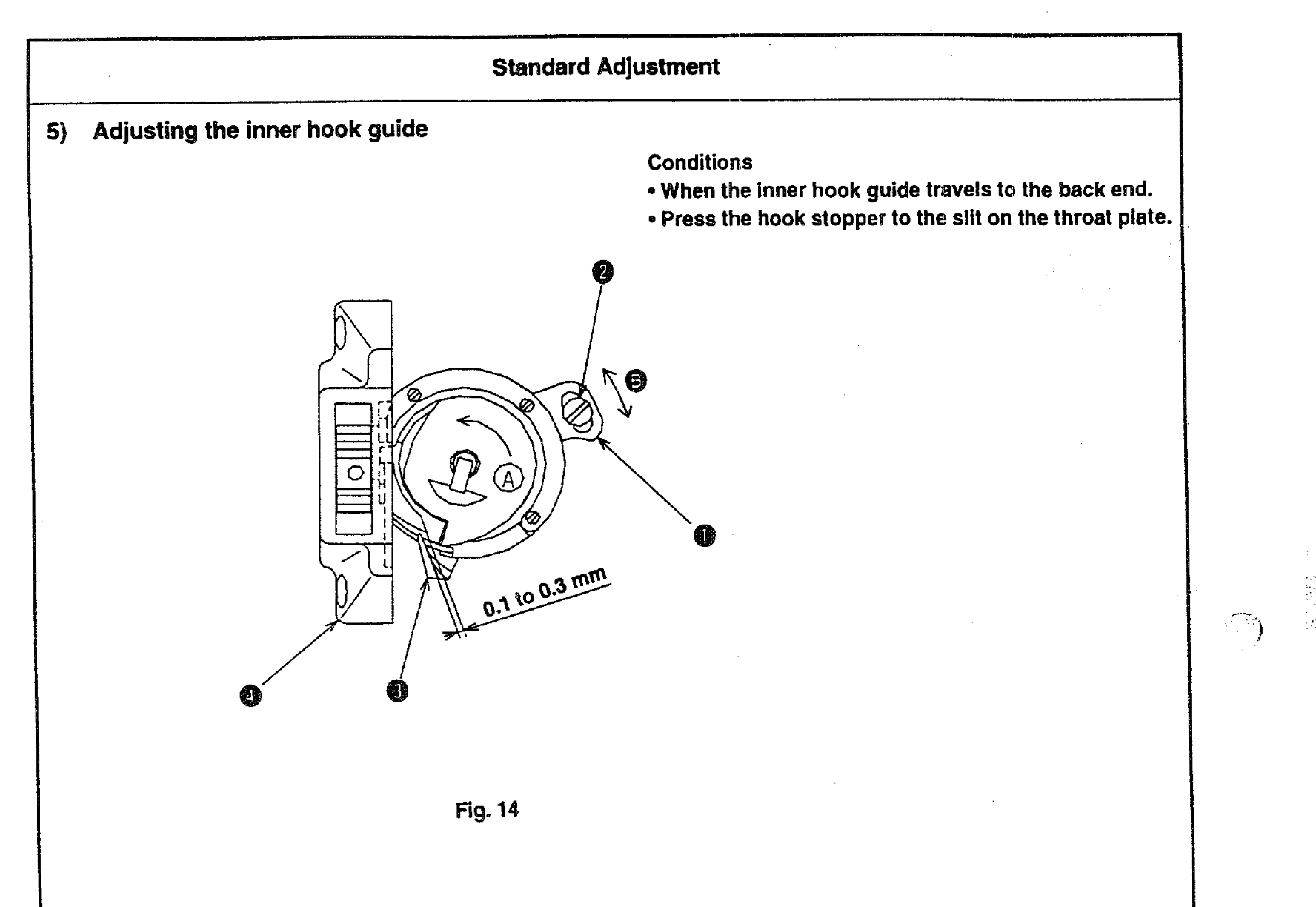

Here's the image from the engineer's manual. I don't bother with measuring this adjustment---I just make sure the latch opens far enough to allow thick thread pass through, and make sure the latch doesn't bind. By the way, it's the needle thread that goes through the latch, and the latch should open to allow the needle thread to go through as soon as the needle thread is ready. (Otherwise there will be some popping sounds as the thread gets forced through a closed latch) -

In a word - yes. With a splitter you can split down the heavier leather to have keepers that are the same tannage and color of the strap. When I was doing production belts I made loop stock from the piece I cut off straightening the side at the top. I cut all my belts down to the "break" in the side. On the remainder of the side I made one or two passes with a strap cutter in the mid area between the top of the flanks for more loop stock. My loop stock from the top was usually firm and good. From the lower hide i cased it heavy and used a slicker to run some stretch out of it before I cut the stock to final width down there. Stitch the ends (didn't have a loop stapler then) and slide them on a loop stick and tapped them to square them up and then leave them to dry in the rectangular shape.

-

Hi and thanks in advance for specific advice re: making keeper loops for collars or belts from veg tan. I don't have a splitter and just have bought veg tan 8-9oz. leather, 9-10oz., 2-3oz., maybe some 3-4oz. again soon. I assumed I would just use stock thin leather for a keeper loop for nice dog collars I'm trying to get serious about. In preliminary playing around, I noticed that the thin veg tan leather I have is noticeably softer than even Herman Oak thick stuff skived thin, experimentally with a knife. Is this an extra reason to have, at least, a small strap splitter? I mean, I guess I can wet my stock thin veg tan and dry it a few times to firm it up a bit, dye, crease or even stitch it and it will firm the end resulting loop up a bit. But I guess I'm realizing if I had a splitter I could use the exact same grain leather, a bit stiffer and, even, the same hue if it made a difference with light dye. Any thoughts confirming or denying the validity of this thinking is appreciated. Thanks! Jeff in Silver Springs, FL

-

-Sylvia- joined the community

-

Hello, I own and have yet to operate my ikonix ks335a industrial cylinder arm sewing machine. Through this website somebody told me it’s a clone of the pfaff 335 cylinder arm industrial sewing machine. It is and I can’t wait to start sewing. However I have a problem, I can’t figure out how to raise the height of the presser feet. I know I can use the foot pedal to raise and lower the presser feet. But to permanently raise the presser feet is maybe 3 or more step process and may also include tension adjustment. Can anybody please tell me or show me a video that shows me how to raise the presser feet in the best way possible. Because I even emailed Ricoma which is where I purchased the machine and have got emails back with people responding with videos of different machines. It has been nice getting at least a response back from the company but not a good answer. So my advice as of now is if your going to purchase a similar machine order one through a small company. Because your going to have questions about the machine and who better to get answers from a smaller company who sells industrial sewing machines but has people who actually are using the same sewing machines that they are selling. please help and thank you!

-

What presser feet do you guys find useful?

-

Made in Germany. Good working order. Cut down table to save space. 3 phase, setup for 8oz veg tan with steel roller: $2500 These machines are all part of a small business downsizing. They are located in San Francisco. All priority will be given to pickups. I will crate and ship only as a last resort. Alternativly you can have a local crate person pick this up and handle all the crating and shipping. This will be a bit expensive in SF, but these machines are rare. Please take a look at the other listings.

-

@noahjoshu We need the location/shipping info with this one, too. Looks like you're listing a few ads. If I notice any more lacking the above, I won't tag them, just be aware all ads need that info. Thanks for listing this stuff here.

-

@noahjoshu We need a location and shipping info to be in compliance with the Marketplace rules. Thanks!

-

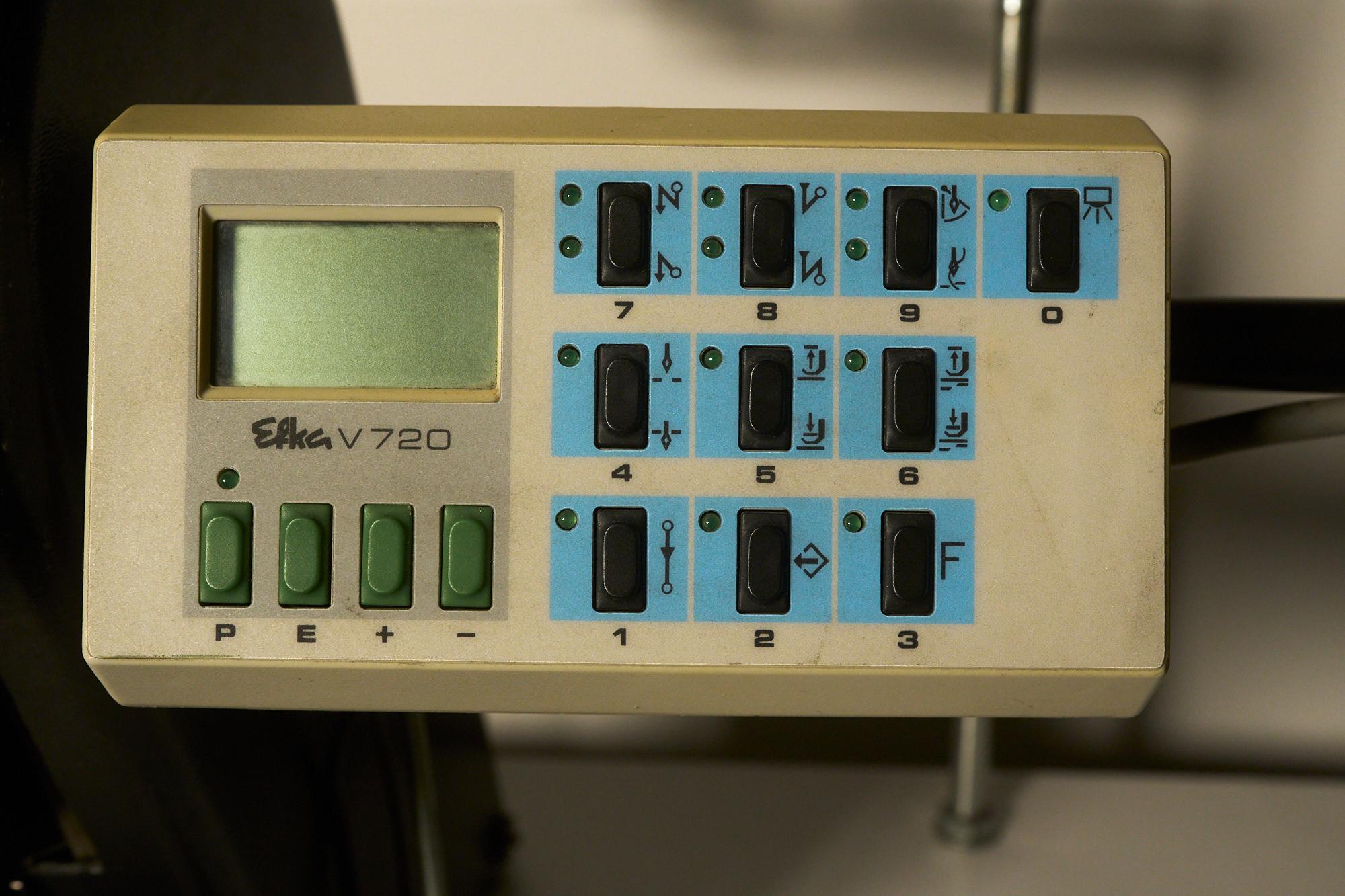

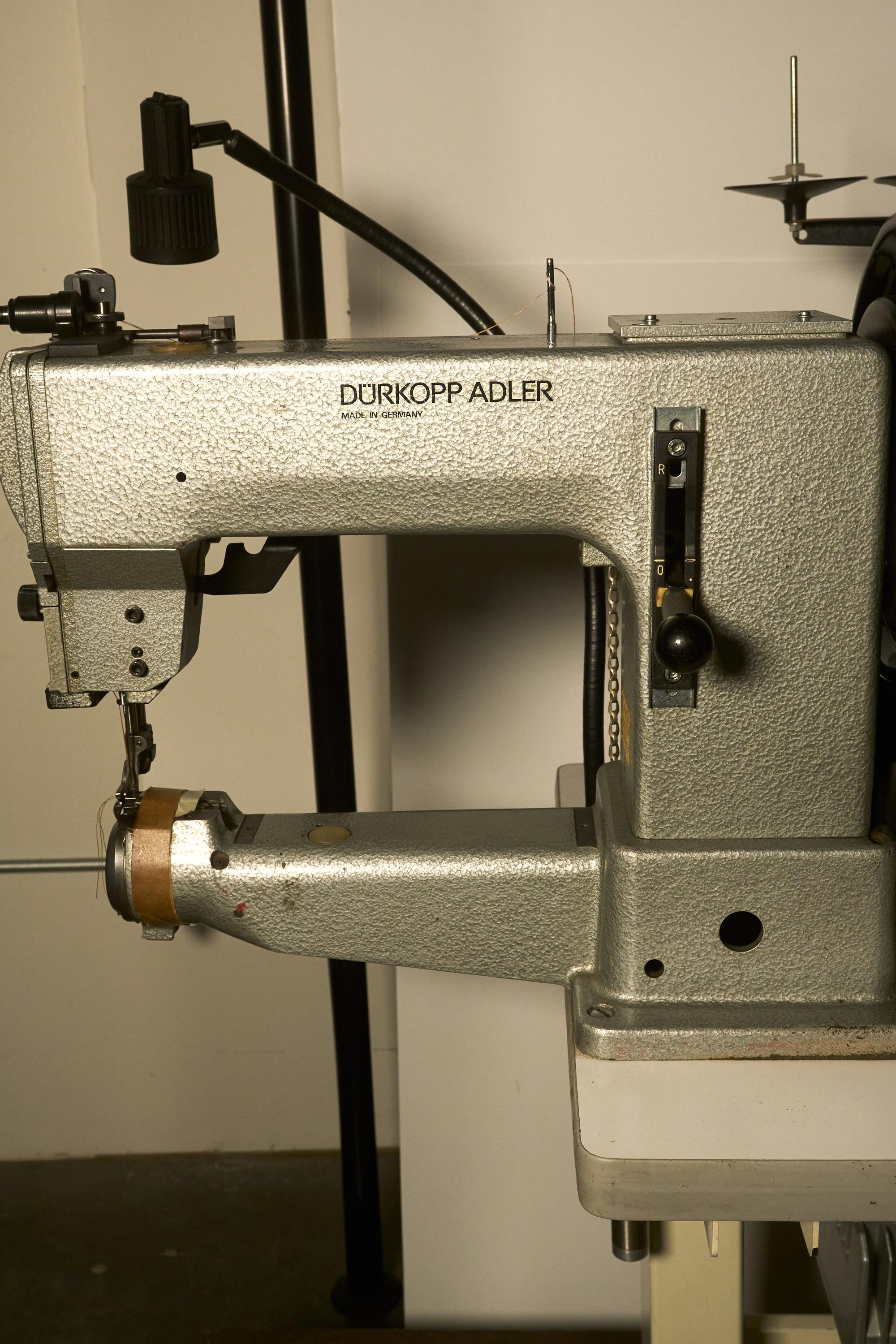

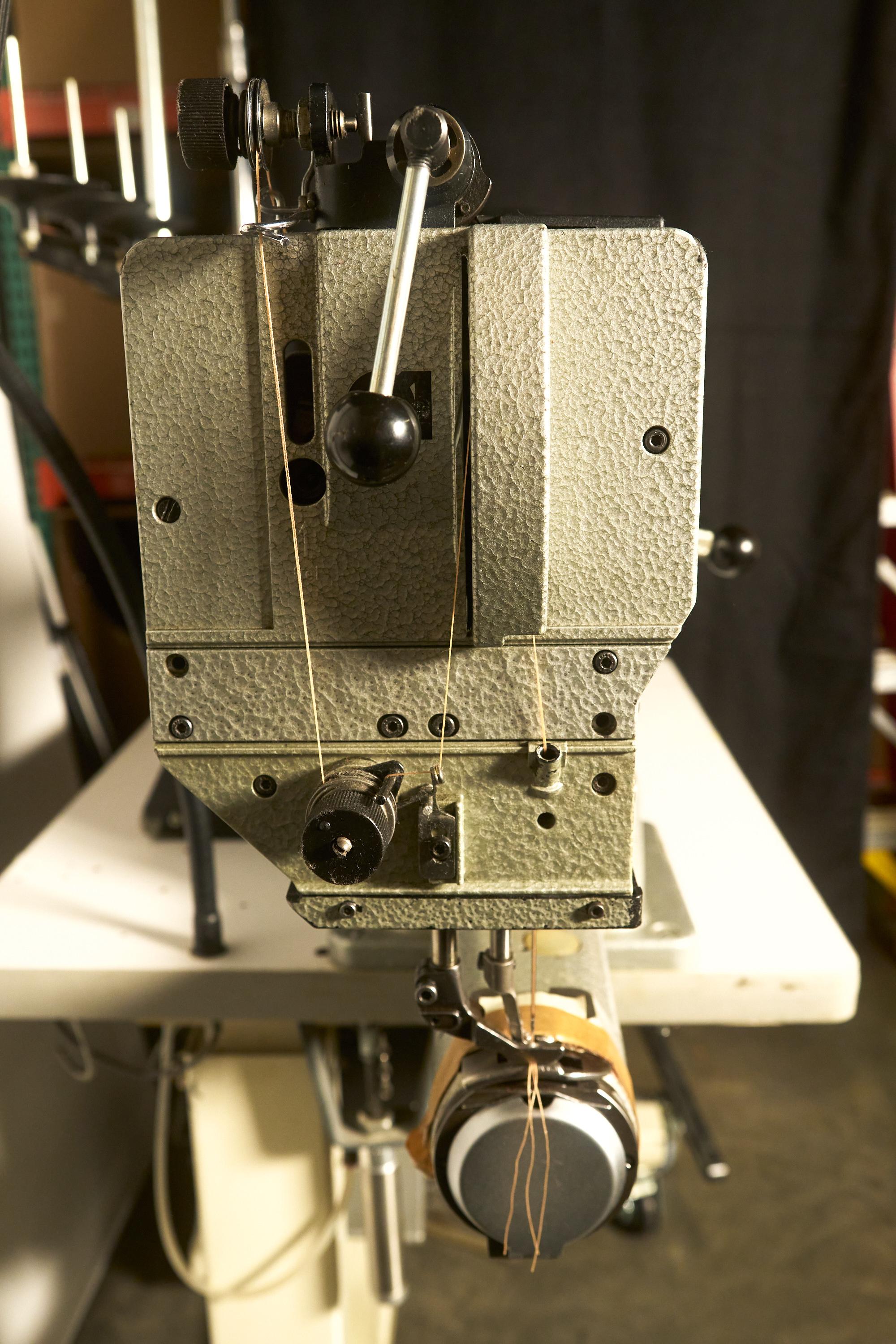

Single Needle small cylinder bed walking foot machine. This is both for binding and sewing leather in tight corners such as wallets, bags and upholstery. Comes with a Efka needle position motor and Kessler sit stand legs with power. Motor and machine made in Germany. Legs in the USA. 220v single. $2200\

-

1-3/4” wide 95% cotton, 5% nylon, olive drab, treated with mildew resistant. NOS 1969 - 50 yards per roll. $40 per roll, minimum 20 rolls. These machines are all part of a small business downsizing. They are located in San Francisco. All priority will be given to pickups. I will crate and ship only as a last resort. Alternativly you can have a local crate person pick this up and handle all the crating and shipping. This will be a bit expensive in SF, but these machines are rare. Please take a look at the other listings.

-

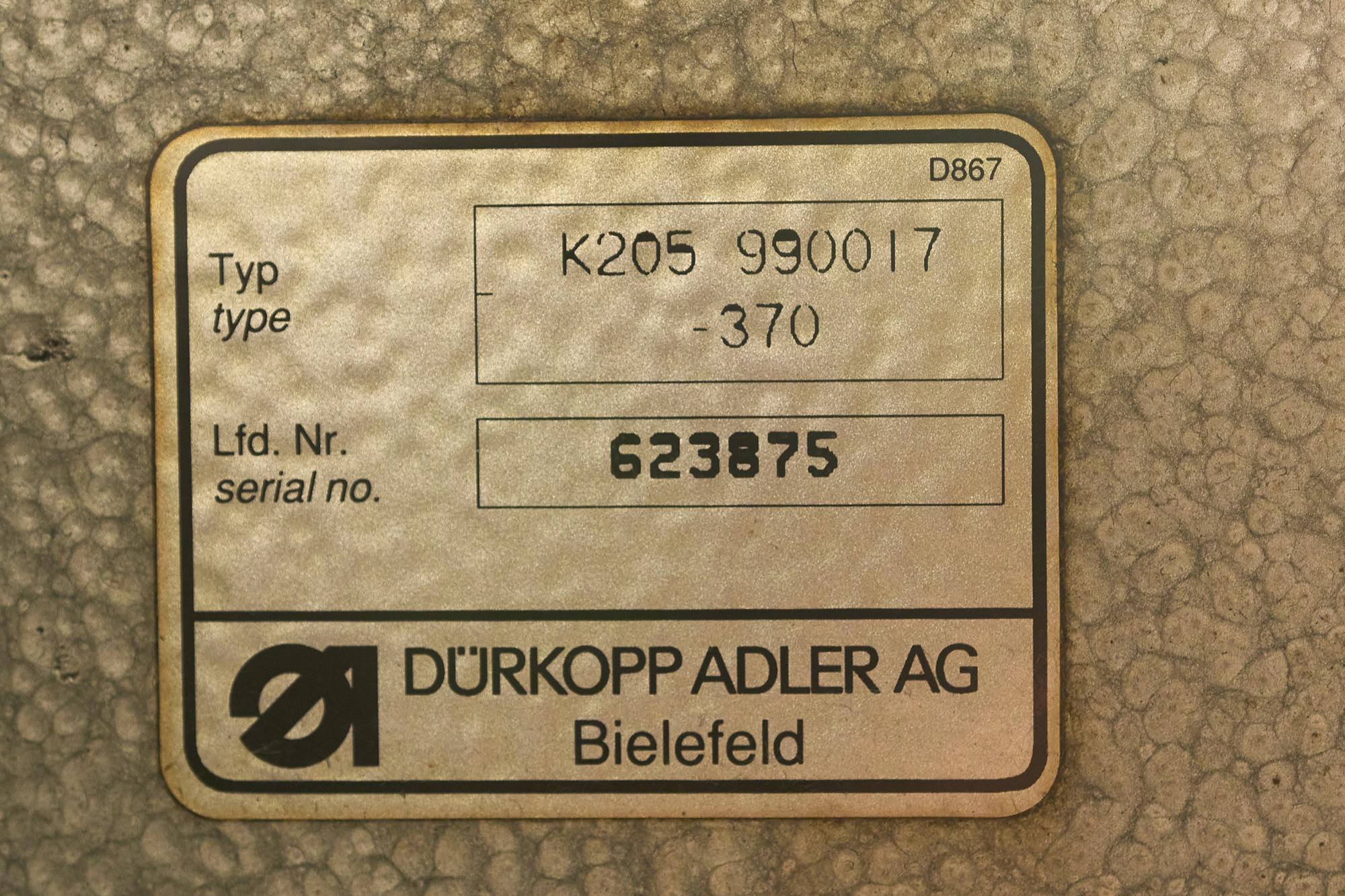

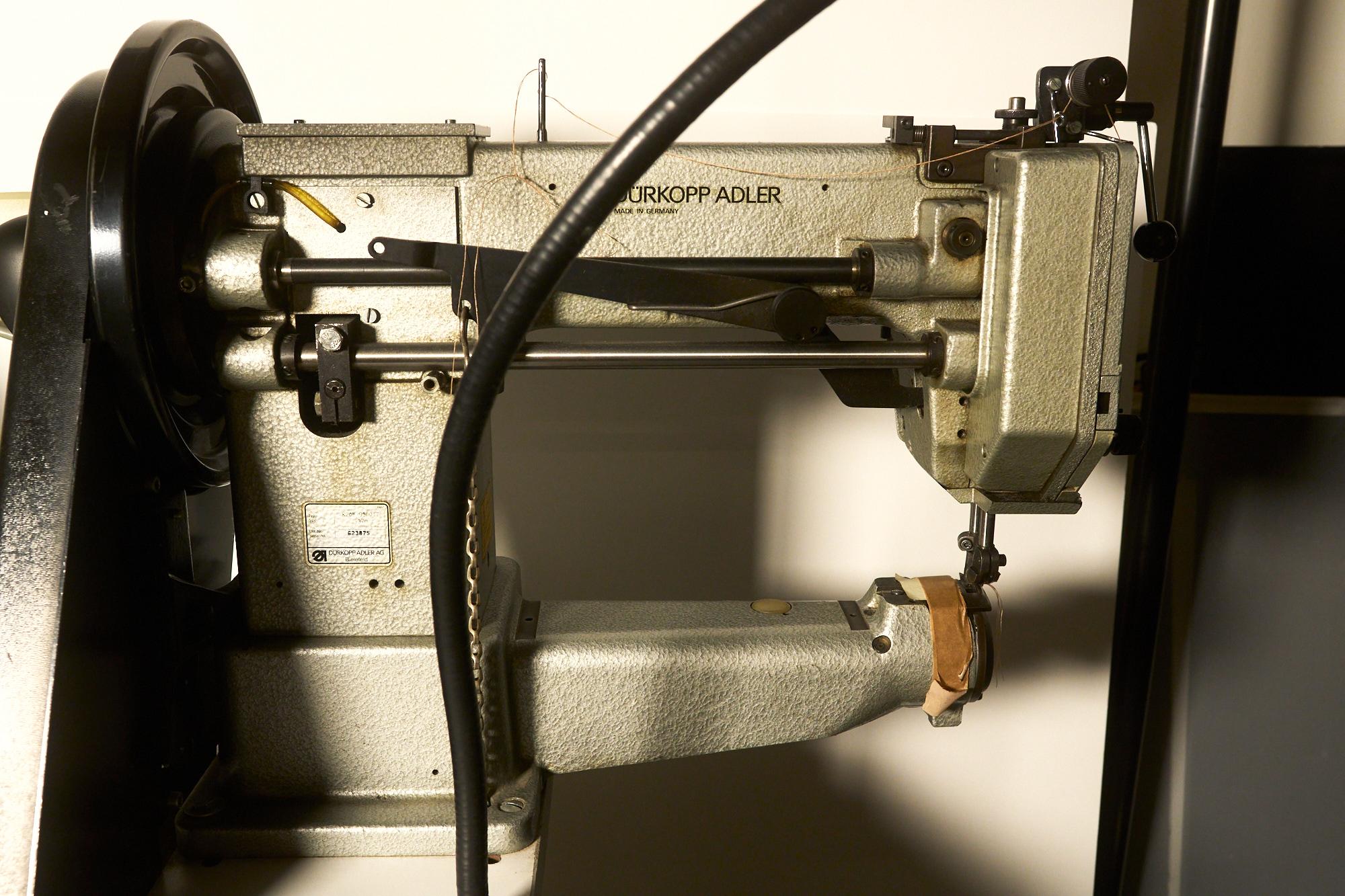

Adler 205 made in Germany New needle bar, all parts in excellent working condition, ready to sew Efka needle position motor with pneumatic foot lift - made in Germany Efka control panel Kessler motorized sit stand table 3 phase 220 $4500 These machines are all part of a small business downsizing. They are located in San Francisco. All priority will be given to pickups. I will crate and ship only as a last resort. Alternativly you can have a local crate person pick this up and handle all the crating and shipping. This will be a bit expensive in SF, but these machines are rare. Please take a look at the other listings.

- Yesterday

-

Im in Texas. I did manage to get the manufacture to add a 50mm pulley to Amazon. So I have one on the way.

-

This is a medium to lightweight Rossley kick press that has been outfitted to attach solid brass arches to various materials. It comes with the brass arch and the brass post rivet that holds it in place. Great machine that can be adapted to other uses. $400 complete with arches.

-

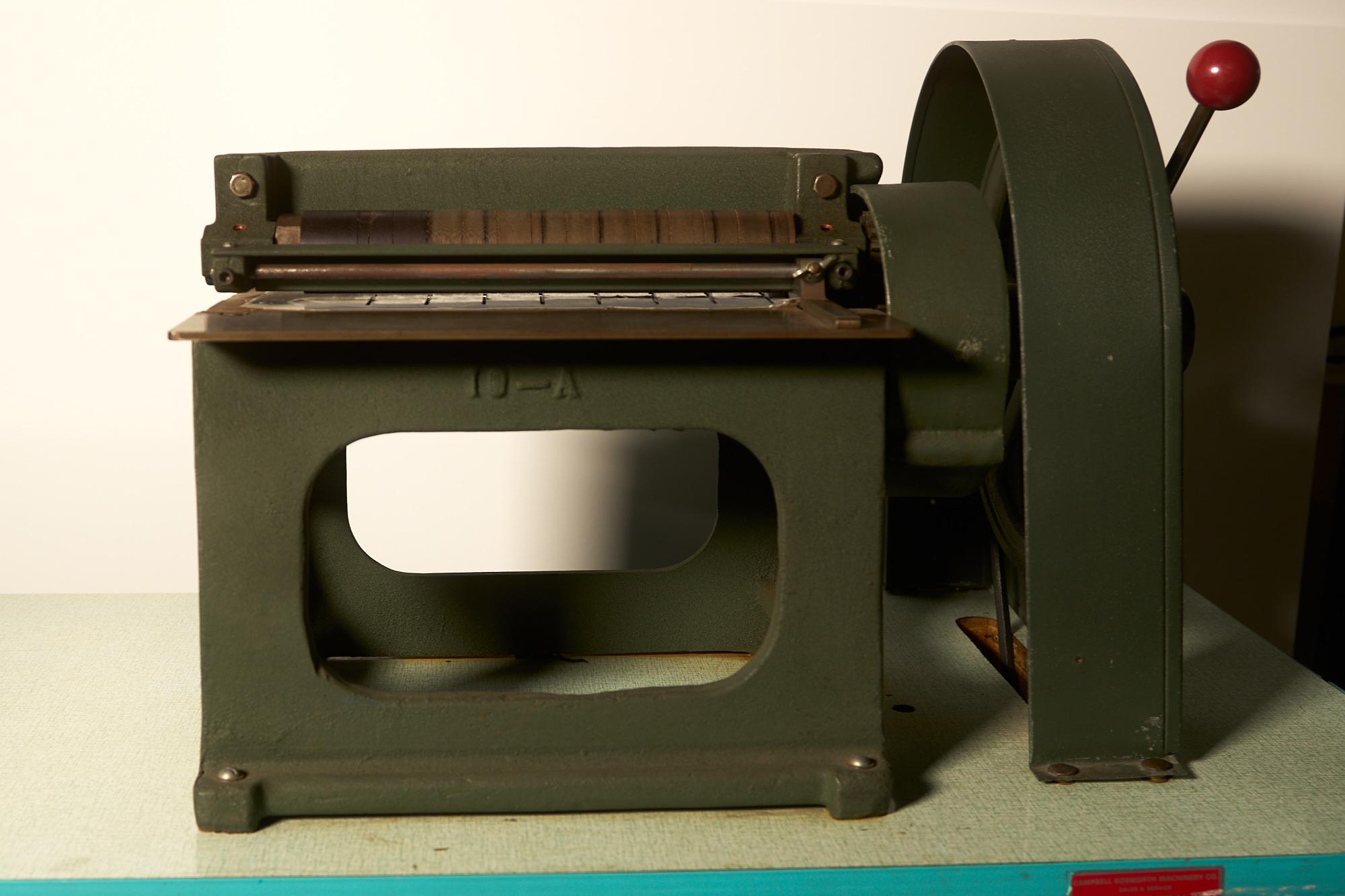

This is a strap combiner, made to fold leather strap of different gauges together. Can be set on a table and motorized, or used by hand. $100 These machines are all part of a small business downsizing. They are located in San Francisco. All priority will be given to pickups. I will crate and ship only as a last resort. Alternativly you can have a local crate person pick this up and handle all the crating and shipping. This will be a bit expensive in SF, but these machines are rare. Please take a look at the other listings.

-

Leather strip cutter or belt / strap cutter. cuts leather into different widths. Comes with knifes and a bunch of spacer - THE WIDTHS COORDINATE WITHT THE DAN RAY LEATHER BINDER I AM ALSO LISTING FOR SALE. so you will have a 1" binding and a another width. 220v 3 phase (can change motor easily) $1000 These machines are all part of a small business downsizing. They are located in San Francisco. All priority will be given to pickups. I will crate and ship only as a last resort. Alternativly you can have a local crate person pick this up and handle all the crating and shipping. This will be a bit expensive in SF, but these machines are rare. Please take a look at the other listings.

-

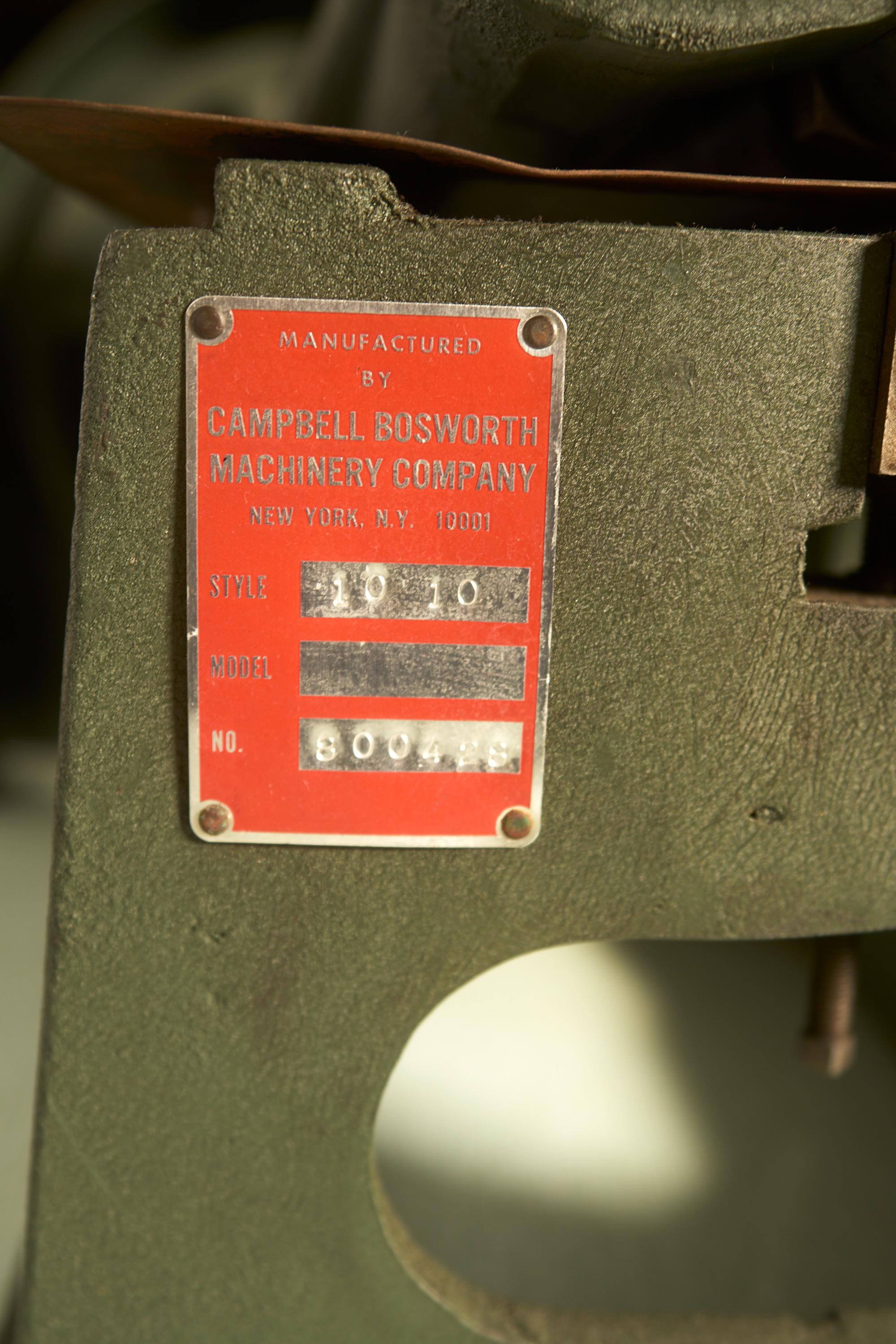

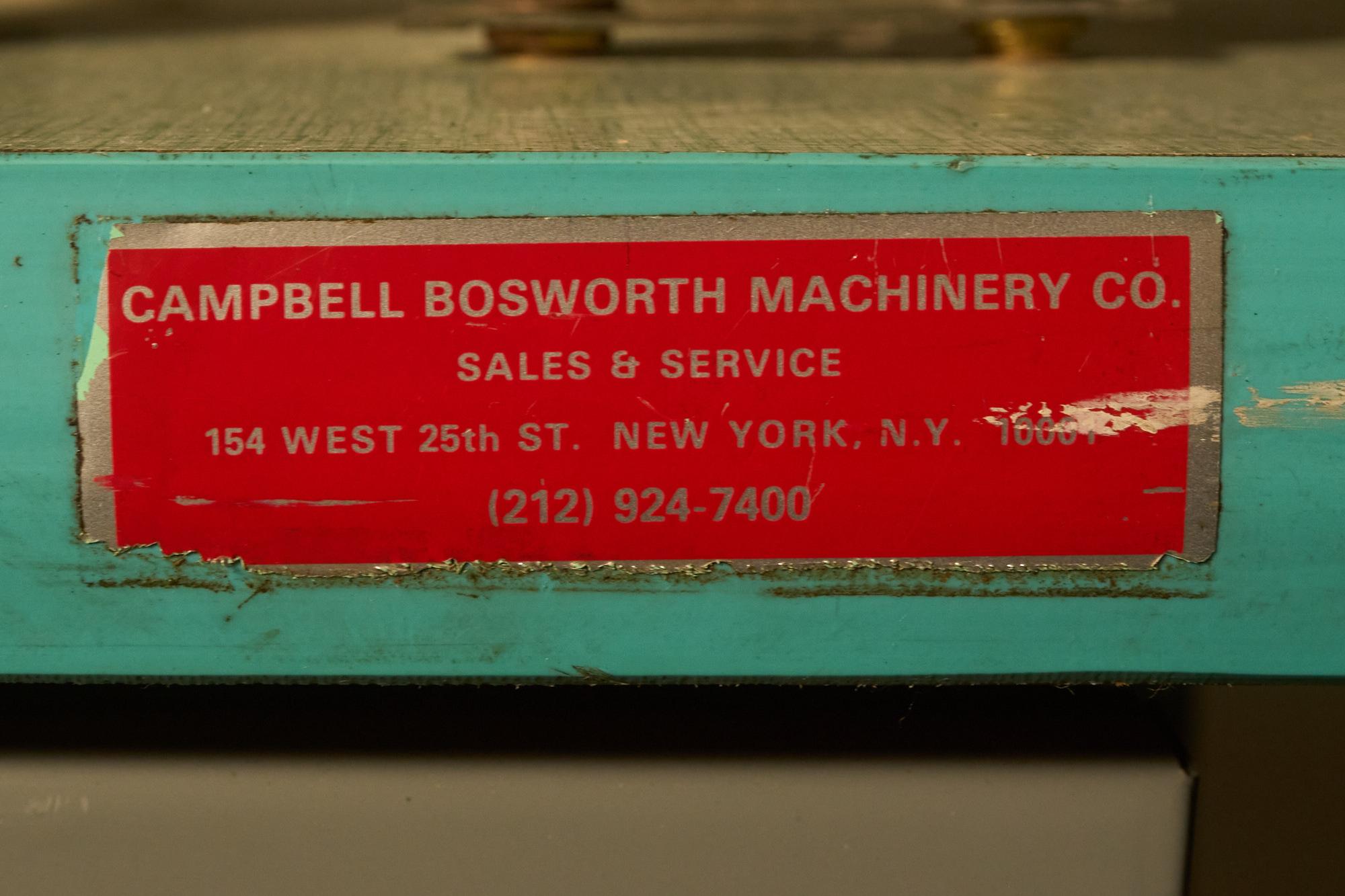

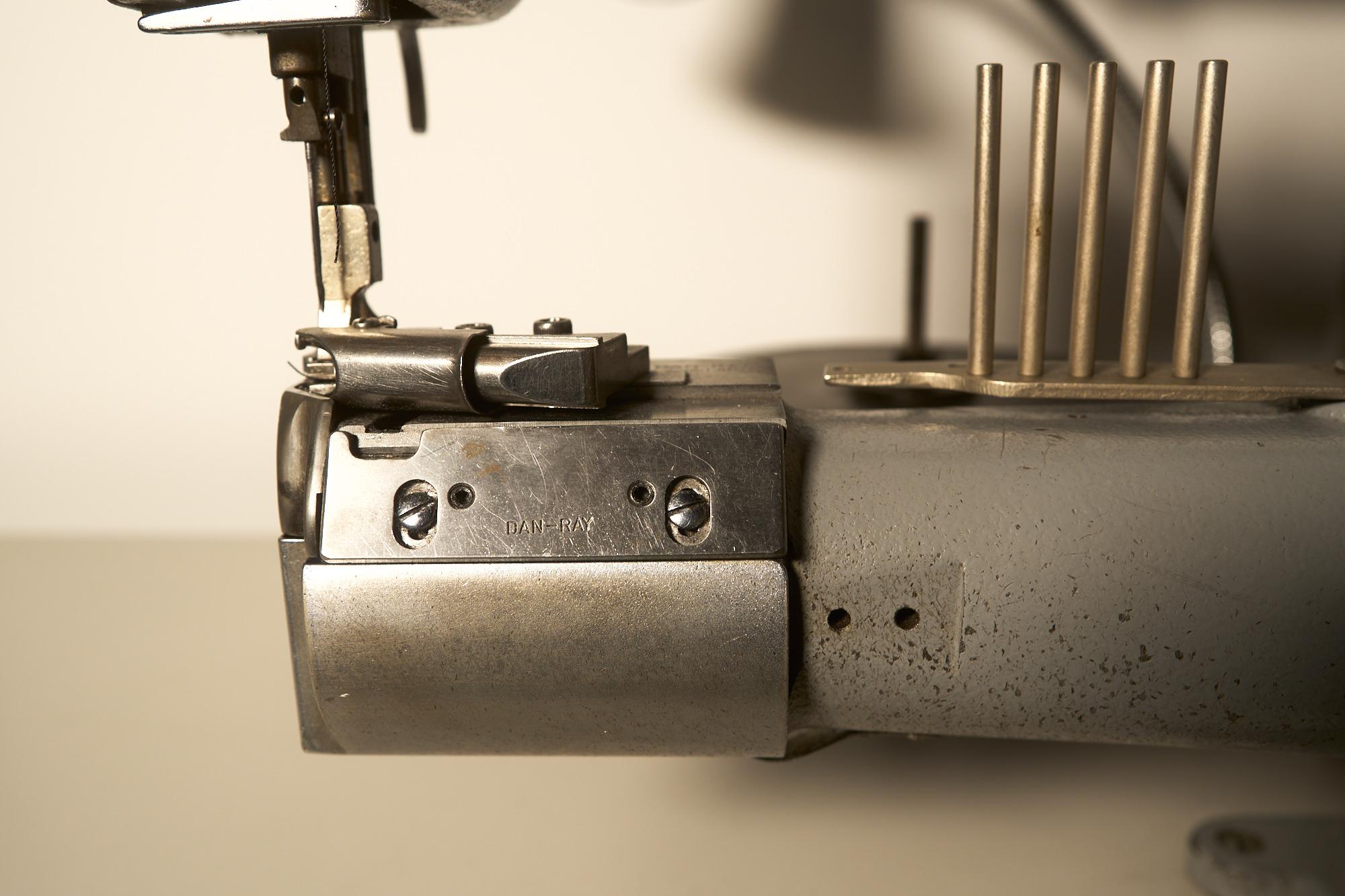

Dan Ray leather binder/edger. This is a custom setup machine for leather binding such as done on Coach bags in the 1980-90's. Needle position Efka motor. Made in Germany: $1800 (you will need the Campbell Bosworth 10 10 leather cutter that I am also selling to go with this machine) These machines are all part of a small business downsizing. They are located in San Francisco. All priority will be given to pickups. I will crate and ship only as a last resort. Alternativly you can have a local crate person pick this up and handle all the crating and shipping. This will be a bit expensive in SF, but these machines are rare. Please take a look at the other listings.

-

.thumb.jpg.327685d8c1787fa894323fed9a6b2dac.jpg)

Desert bighorn holster is finished

DoubleKCustomLeathercraft replied to DoubleKCustomLeathercraft's topic in Show Off!!

Thanks chuck. I'm happy, the client is even happier. It's a win- 15 replies

-

- desert bighorn

- holster

-

(and 1 more)

Tagged with:

-

-

Lisa J joined the community

-

I would tackle this problem with a munltimeter...

-

Seems I broke my Juki-LS-341, again... (Bobbin Shuttle)

Wizcrafts replied to Yoshi888's topic in Leather Sewing Machines

That part is known as the "latch opener." It should be set to pull back on the bobbin case as the thread goes around it, then let go after the thread knot is pulled up past the notch in the throat plate. There is a small amount of wiggle room in that cutout for the little tab on the bobbin case/shuttle to move forward and backward. Pulling it back at the right moment frees the thread to go up without hindrance. It should not be set to pull back hard against its stopped position. Leave a tiny amount of clearance at the pulled back position so you don't break anything or wear out the pulled parts. -

Desert bighorn holster is finished

chuck123wapati replied to DoubleKCustomLeathercraft's topic in Show Off!!

that came out really nice!!- 15 replies

-

- desert bighorn

- holster

-

(and 1 more)

Tagged with:

-

Man, that must suck having the knowledge right there and not being able to get to it. With your natural talent, your work could get much more refined easily.. Keep up the good work!!