-

Posts

1,025 -

Joined

-

Last visited

About TomG

- Birthday March 17

Contact Methods

-

Website URL

http://www.legacyleathercraft.com

Profile Information

-

Gender

Male

-

Location

Buford, GA

LW Info

-

Leatherwork Specialty

Belts, and Bracelets, Dog collars and leashes

-

Interested in learning about

Anything for improving my skills

Recent Profile Visitors

The recent visitors block is disabled and is not being shown to other users.

TomG's Achievements

Leatherworker.net Regular (4/4)

-

Yeah, spammers are a real pain. I did the reply method that you advised on. Thanks

-

I put a Python skin in the For Sale area and want to reduce the price. I can't see any way to edit my post. Can anyone show me the light? I thought messages used to have an EDIT button

-

This is a home made knife, slightly larger that the Tandy round knife. This blade actually cuts as well or better than my commercially made knives. Ther4 handle can be replaced by pretty easily. I just never had the need. Comes with the slide on cover shown. $40 plus shipping.

-

This knife is in good condition and is very sharp. It has no name on it, but looks like a clone of Tandy's Stohlman knife. $45 plus shipping.

-

I have 2 of these that have little to no use on them except for stopping. $50 ea. plus actual shipping costs.

-

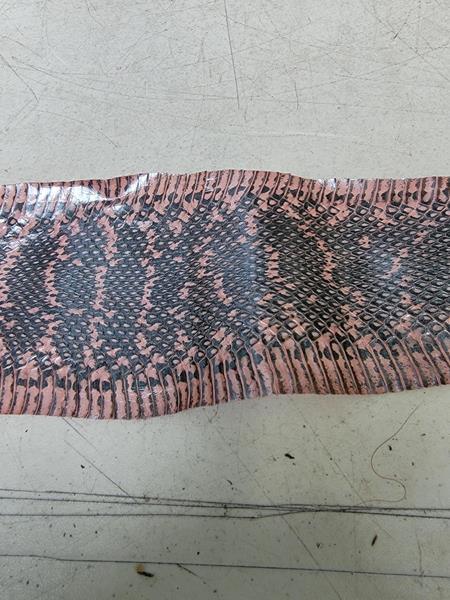

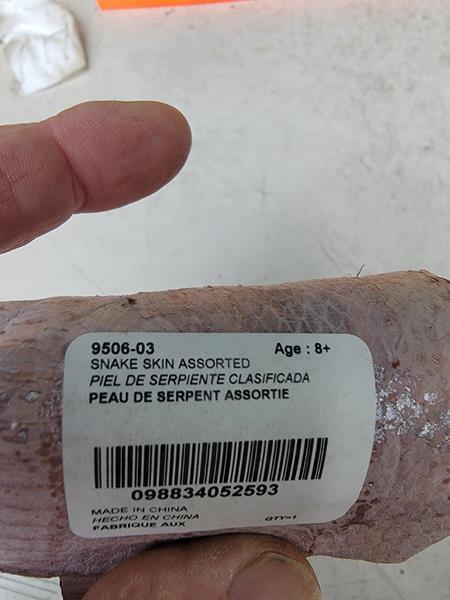

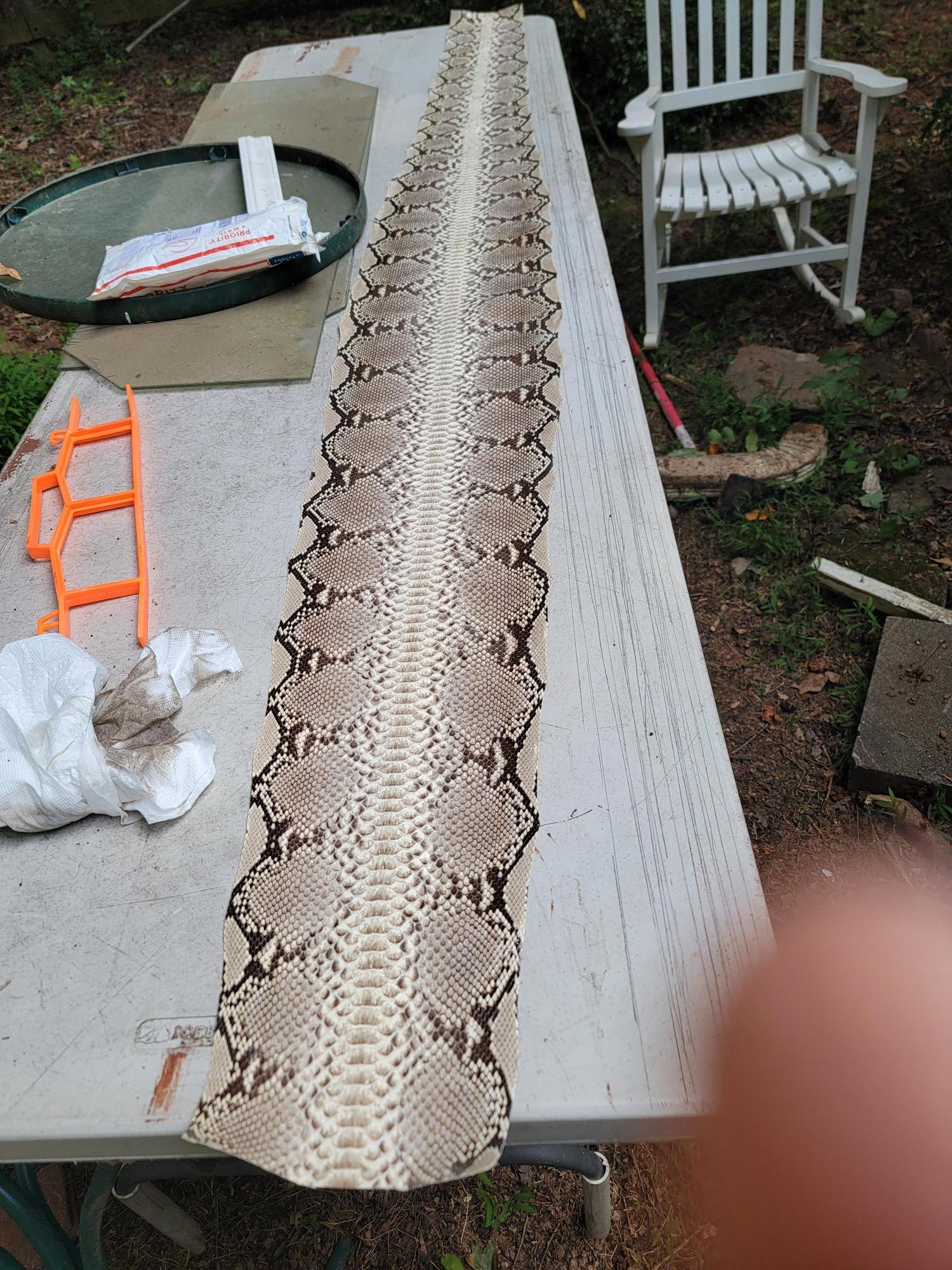

I bought these many years ago and never got around to using them. The large one is Back Cut Python and is 8 feet long and approximately 9.5 inches wide at my hand span. The smaller Tandy skin is probably 2 feet or so. The product number is no longer listed in Tandy's ever-changing catalog. But a fellow user ID'd it as probably Whip Snake, or similar. $180 for both, (+shipping) Shipping will be at my actual cost. mod edit: See next post for New Pricing!

-

Can you roll the leather up as you go to get those middle holes?

-

I found that running the spindle cuts down on the punch getting stuck in the leather after the punch. On the Latigo, I also would lube the punch occasionally by running it down into a big, plain candle briefly.

-

Here is a small set of single hole punches that are made for the drill press. I used to have a customer that I made leashes for and each required 8 holes punched into 10/12 Latigo. They saved my life and sanity. https://www.harborfreight.com/6-piece-hollow-punch-set-67030.html

-

Thanks

-

Any idea of the value? I have done a little checking on some website, but the pricing seems to be all over the place. I'm sure it's just me not knowing which to look at.

-

I bought these many years ago and don't even remember what kind of skins they are. The large one is 8 feet long and 9.5 inches wide at mt hand span. The smaller Tandy skin is probably 2 feet or so. The product number is no longer listed in Tandy's ever-changing catalog. In the near future, I am going to be selling off stock that I no longer need. Can anyone tell me what I have and the possible value?

-

I'm sure most were in the $200 range. I was thinking about $10-$15 depending on the width. All at Latigo and in the 10-12oz range. I mainly make 6' + leashes out of them, so when they get down to less than the lengths I need to make say, a 5 footer, they are not really usable for me.