-

Posts

423 -

Joined

-

Last visited

About Rod and Denise Nikkel

- Birthday July 24

Contact Methods

-

Website URL

http://www.rodnikkel.com

Profile Information

-

Gender

Male

-

Location

Valleyview, Alberta

LW Info

-

Leatherwork Specialty

Saddle Tree Maker

Rod and Denise Nikkel's Achievements

Member (2/4)

-

I thought we would share our new website - https://westernsaddlefit.com/ - with the Leatherworker.nt community. We have put together a 67 minute video we call Western Saddle Fit - The Basics and have it for sale on our website. We have footage for a much longer one we will be working on called Western Saddle Fit - Well Beyond The Basics that will hopefully be finished later this year, but we'll see on that. We have a 7 minute video on YouTube called Western Saddle Fit - The Essentials. And we have also compiled and organized a lot of our blog posts about saddle fitting and have a section on our website with links to them: https://westernsaddlefit.com/articles. This is a new venture for us, since we are no longer building trees. If anyone one is inclined to share the links on their social media pages, please go ahead! Publicity is great!

-

We also agree that roughing up the tree is less than desirable. The varnish is the water proofing and scuffing will remove that even if the rawhide isn't damaged, which it often is. Finding varnish that glues will adhere to well these days is another story... Also agree that the back of the stirrup groove is the weakest point of the bar, and we've seen too many trees where the rawhide was scored there as well, and that removing the back stirrup groove (making the bar the Arizona type) will increase the strength there. However, so will increasing the quality of wood and rawhide used, and we will not make Arizona bars because of the negative effects on fit for the horse. Removing the back stirrup groove has more effects than just increasing strength. We have explained more in the past here: http://www.rodnikkel.com/content/saddle-tree-blog-from-shop-and-desk/of-arizona-bars-and-why-we-won-t-make-them/ (I am not trying to promote our website, but I just don't want spend a lot of time rewriting what we have said before, more than once...)

-

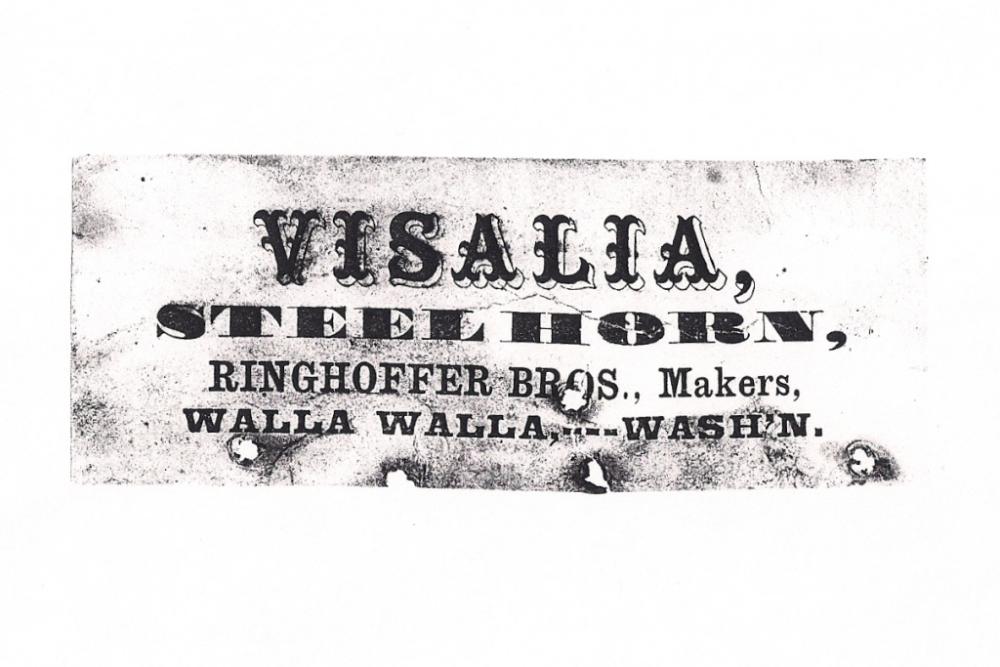

Another post to respond to a few things in previous posts, just because… When you use real bullhide of good quality and thickness, you don’t want a double covered tree. Good thick hide on its own will be 1/8” thick, and ¼” of hide is real overkill… The only reason to double it is if the company uses relatively thin hide. Then it may be worth it. We would have to disagree with this. Every tree maker we know attaches forks and cantles solidly to the bars. Even if it is with nails or staples, they mean it to be solid. It doesn’t matter how close your joints are, if you don’t attach them solidly, all the stress of pressure is on the covering, and we want the wood to take some of that stress as well. The whole thing together is what makes it strong. We agree that if you drill a hole through something and attach a bolt, you have weakened the wood and it is more likely to fail, but we can’t see that using screws rather than nails or staples would make it fail catastrophically. We’d be interested in what kind of testing led to that conclusion. If the wood is so poor that it would break by screws pulling out of it and, then the nails or staples would have been long gone . Nails and staples will pull out easier than screws, but they don’t go back in again. Then you have a loose tree where the bars can move relative to the fork, and that can hurt a horse (different angles, pinching, etc.). If the idea is that something solid will break where something that is loose will withstand the strain, we have to disagree. We screw everything together with top quality screws into good quality wood. Additionally we also glue our forks & cantles, so there really is no movement possible. We have yet to have any fail catastrophically. In fact, if the bronze horn gets bent in two directions and all that happens is some cracks in the wood, nothing broken through, we figure they are plenty strong enough… http://www.rodnikkel.com/content/saddle-tree-blog-from-shop-and-desk/we-told-you-it-would-be-good/ Totally agree with you oltoot! Thanks for the referral to our website, Northmount. Just wanted to note that the way production/factory trees turned out in high numbers and the way our trees are built are quite different. Here's a few videos we have found that shows trees being made in various ways. We don't understand Spanish but we sure would be interested to understand what is being said! Especially at the beginning is where the tree construction is being shown. I believe Precision Saddle Trees builds the trees for Circle Y saddles. Here's a couple short ones that say they come from Steele Saddle Tree Co. And here's one showing Ben Swanke and K.T. Monson hand making saddle trees very similar to the way we do it.

-

Interesting discussion, and Rod and I had a good conversation about it. For those not wanting to read a dissertation, you can skip to the end for the short form of our opinion (for whatever it is worth) on the matter. Here’s the long version. First, this isn’t the first time this has been discussed on this forum. This old thread from 2008 has some pretty good thoughts in it and is worth reading. http://leatherworker.net/forum/index.php?showtopic=3313 The picture that is now gone showed Robin doing the test he describes and the tree flexing to touch down. He describes that tree as having thin bars and lightweight rawhide. He also said he didn’t feel it was a good thing in a roping tree. None of our trees will do this, nor do we want them to, but it shows (showed) that it can be done. Second – does a rawhided tree flex? Sure. So does a fibreglass covered tree, tall buildings, steel beams and concrete. Everything flexes to some degree, though often it takes very sophisticated equipment to measure how much. To figure out what really happens on a horse may very well be impossible. However, there are other questions about this that maybe should be considered. Do we want a tree to flex and if so, how much? If the question is bend or break, then yes, we would want bend. (I’ll get back to that one.) But if the question is flex to move with the horse, our answer is no, we don’t want that. We haven’t changed our thoughts from what we wrote six years ago. How can something that flexes enough to “move with the horse” not sag under the rider’s weight, putting excess pressure in the center of the saddle? The advent of the “flex trees” has shown this is the case. Here’s a blog post with the proof of that: http://www.rodnikkel.com/content/saddle-tree-blog-from-shop-and-desk/checking-out-a-flex-tree/ Do we want a tree to flex when roping? The idea that the tree will take some of the stress and not transmit it to the horse may sound good, but you don’t want a lot of flex then either. Good bars are designed to have edge relief, etc. so there are no high pressure points on the horse. Now, if the tree gives, where and how much pressure is it putting on the horse? Something that flexes a lot when the cow hits the end of the rope could have a lot of “dig” on the edges of the bars in the direction of the pull. That is NOT when you want your horse to be reacting to pain! You want that pressure spread out as much as possible over the entire surface area of the tree. But when you hear experienced saddle makers like Pete Gorrell talking about how they see problems with the ground seats being pulled away from the fork in well used saddles, you realize that there has to have been some movement over time for that to happen. So, assuming the wood component of the trees were identical (which is an impossibility because every section of every piece of board is different), which covering would stand up to repetitive strain best? You can’t bend fibreglass very far or very often before it breaks and loses all strength at one time. However, you can bend a piece of rawhide back and forth and back and forth and back and forth, etc. etc. etc. for a long time before you see wear on it. And it loses strength gradually with repetitive strains. It takes a LOT of pressure to totally rip it, if it is good rawhide of a decent thickness. (We grant that “chicken skin” tears much more easily…) In fact, people sometimes don’t realize their tree has broken because the rawhide holds it in place. Here’s the description of what we discovered on a tree we had in to duplicate where the rawhide had held the bars together when the wood appeared to have been broken for a while: http://www.rodnikkel.com/content/saddle-tree-blog-from-shop-and-desk/things-to-see-on-a-broken-saddle-tree/ Now, do you want to be riding a tree like this? No. It will “flex” in the middle and those broken bar ends will put a lot of pressure on a horse’s back. But is that better than having the whole thing disintegrate underneath you when you are holding a bull? You better believe it. Just don’t ride it again the next day… Another example of how well rawhide on its own flexes is our experiment in driving over one of our trees early on in our tree making career. It was a tree we decided wasn’t up to snuff and we weren’t going to send it out, so we decided to see what it would take to break it. The front end of a half ton didn’t do it, but the front end of a loaded five ton moving truck driven over the center of the bars flattened them to the ground with nasty cracking sounds. After the truck drove off, those bars were back to their original shape. The stitching had given in a couple of places on each bar, and it was scuffed all along the bottom edge of the bar, but it was back to normal. And push and pull on that tree as we might, we could not make it budge. (We soaked it for a few days to get the rawhide soft enough to remove and discovered that the yellow poplar we had made the bars from had cracked longitudinally in three places on one bar, twice on the other, through the screw holes where the bar attached to the fork where the wood is thinnest. The cracks didn’t extend all the way to the back of the bars.) The rawhide had flexed down to the ground and come back to shape, and still was more than strong enough to hold its original shape. Fibreglass would have been broken and finished. So yes, in cases of extreme stress, we feel that rawhided trees will tolerate more flex than fibreglassed trees. But, can you honestly compare between trees? Not really, because every piece of wood is different, every piece of rawhide is different, and there are multiple kinds of fibreglass and other synthetics which are all different, and how they are laid up makes a difference to how they hold up as well. It honestly comes down to the quality of the materials – wood and rawhide or other covering – and those vary dramatically between makers. We believe that rawhide will hold up longer and better than the synthetics. We know that rawhide can hold up for over a 100 years (lots of old saddles with rawhided trees are still around) but it will take another few decades to know if fibreglass stands up the same… So for those who skipped to the end to read - we don’t believe good quality wood/rawhide trees should or do flex under regular riding, though rawhide does have the ability to withstand long term, repeated stress (ie. heavy roping) better than fibreglass coverings do. At least, that is our opinion on the matter, and so that is what we will continue to use.

-

Saddlemaker's Benefit Auction

Rod and Denise Nikkel replied to Rod and Denise Nikkel's topic in General Saddlery Discussion

Ken, They set up a bank account for the benefit that I believe is open for a few weeks. I will PM you the contact information of the organizers and cheques made out to Saddle Maker's Benefit and sent to the organizers will be deposited and go toward them still. -

Second Saddle

Rod and Denise Nikkel replied to Rod and Denise Nikkel's topic in Saddle & Tack Maker Gallery

Thanks everyone. -

Saddlemaker's Benefit Auction

Rod and Denise Nikkel replied to Rod and Denise Nikkel's topic in General Saddlery Discussion

Thanks Bob. I sent you a PM. -

Second Saddle

Rod and Denise Nikkel replied to Rod and Denise Nikkel's topic in Saddle & Tack Maker Gallery

Rod - all Rod!! I (Denise) watched and was happy to see it happening. And no, we're not going into saddle making as a business. (Too hard to make a living that way... ) This one is for us. So was the first one - that he built ten years ago. He sold it this past fall so had the chance to build another one. I think he did a wonderful job on it. -

There will be a fundraising auction on July 13, 2013 to benefit two saddle makers who have suffered severe damage and losses due to the devastating flooding in High River Alberta in late June. Steve Mason (a member on here under his own name) and Stan Groff both live and have shops in High River. For those of you who know Steve or Stan and want to know more, or who are willing to donate goods or money, please contact us and we will give you more information. (The organizers don't want everything open on the internet but prefer information to spread more privately.)

-

Here are some pictures of the second saddle I have made. I have my list of critiques and things to do better next time, but all advice and suggestions are welcome.

-

Saddle Tree Blog

Rod and Denise Nikkel replied to Rod and Denise Nikkel's topic in General Saddlery Discussion

Late 70's, early 80's - from what we understand that was the time a number of saddle makers started building their own trees because they were so unhappy with the quality of trees they could purchase. Wonder why things went so far downhill about then? While a lot of people talk about "the good ol' days" we have heard other comments to the effect that there are more good saddle makers and good tree makers around now then there probably has been at any time in history. It is interesting in looking at trees made by different makers. You can often see the "genealogy" of who taught the maker by how the tree is made and what it looks like. We've never had the chance to see one of yours. The pictures we have seen have all been fibreglassed. Do you still rawhide some? It is also interesting to see how different people go about making their trees. Some like hand tools. Some use some equipment, but each piece is individually made. Others go the duplicating route. Depends on how you like to work, your business model, how many trees you want to build, if you want to have employees, etc. etc. "Every tree maker does things differently" - but we all have our reasons for doing it! -

New Rough Out Association

Rod and Denise Nikkel replied to cac's topic in Saddle & Tack Maker Gallery

Really nice job, Clyde. Clean work. Good lines. Glad you liked the tree. I knew it was rough out but had a hard time seeing that in places. How did you get it so smooth?

b.thumb.jpg.3597b72d8e22f504bc2107d6392b109c.jpg)