miker

Members-

Posts

81 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Blogs

Gallery

Store

Everything posted by miker

-

Thank you! The machine is the SE22 model (https://www.atom.it/en/prodotto/se-series/) . The machine i have is single phase from the factory! It's not modified. The limitations are, it takes more time to reach the working rotation speed and you have a led light to indicate when you are overdoing it. So i guess, somewhere the machine have a leak in hydraulics. Now the question is where?

-

Hello everybody! I recently got a an Atom clicker press model SE22 single phase! The previous owner told me that the machine have a small problem! Normally when you turn off the machine the arm move downward! When you turn on the machine the arm start to move upward till it take the working position. On my machine the arm moves down on turn off but not upwards when turn on! You need to lift the arm with a crowbar or before turn off have something under the arm to prevent it from moving downward! Anybody had the same problem before and knows how to resolve it? Thank you!

-

Typical Typical GC0302 sewing machine shredding thread on reverse

miker replied to miker's topic in Leather Sewing Machines

today i test another thread! I sewed perfect! So i guess the thread is no good quality!!! I am curious to check if the same happens to other machines with this specific thread! -

Typical Typical GC0302 sewing machine shredding thread on reverse

miker replied to miker's topic in Leather Sewing Machines

I am using tenax Polyester thread! I will try another type and i' ll be back!!! -

Typical Typical GC0302 sewing machine shredding thread on reverse

miker replied to miker's topic in Leather Sewing Machines

Not always! The last couple months! -

Typical Typical GC0302 sewing machine shredding thread on reverse

miker replied to miker's topic in Leather Sewing Machines

I will make some photos later today! The needles are always the same! The thread is another type! I will try another thread to make a test just in case! -

Hello again! Maybe someone knows and can help me a little! I have a Typical sewing machine model GC0302. A classic walking foot machine! https://all.biz/ar-en/typical-gc-0302-cx-g125091 My problem is that the machine keeps on shredding the thread only when i sewing in reverse! What can cause this behavior ? Thanks!

-

Computer Drawing Software For Making Leather Patterns

miker replied to Blackey Cole's topic in Computer Help

FreeCad is another option + it's free! I am considering to try Rhino for a while! -

i use a cad program, sketchup!

-

i have tested the wire but it's no good! Lot's of smoke and not perfect cut!

-

Hello! One question! ( Not quite sure if this is the right place to post! ) Can such an industrial electric scissor cut also foam or sponge? https://www.alibaba.com/product-detail/Electric-Scissors-For-Cutting-Fabric-Nylon_1483441585.html. Normally you use this one https://www.aliexpress.com/i/32893964157.html but i am curious if the other is also capable for cutting foam/sponge? Thank you!

-

Does anyone knows an EU site where i can get spare blades? Thanks!

-

The machine is ready! The only "problem" is the motor! I used an old i have from a sewing machine. It is a fast one! 2800rpm. I am looking for a smaller pulley to reduce the speed.

-

Computer Drawing Software For Making Leather Patterns

miker replied to Blackey Cole's topic in Computer Help

Guys make a new thread for guns! I am using sketcup to make my patterns. It's ok but. Recently i see some videos from fusion 360! I like it a lot but the fact that it's cloud operating cad is very disappointing! -

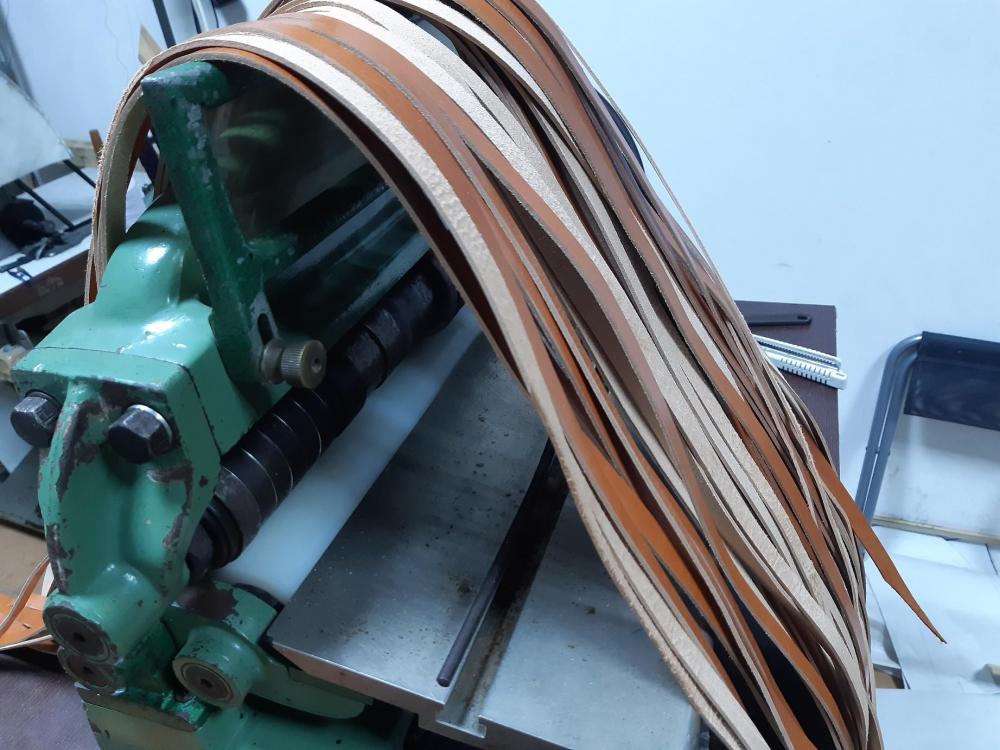

The plastic cylinder i think is ok. I tightened the screw seen on image 1. I will do some work and i will be back with more pictures and questions!

-

The 2 shafts are indeed connected with gears. Right now this plastic cylinder is not fixed with it's shaft. I believe it should be fixed and not freely rotating. I will make a few more picture and I have to order some new blades.

-

Hello everybody! I just bought a used strap cutting machine! My question is about the plastic cylinder! Is it supposed to freely rotate or when i turn the flywheel? The blades are tightened on the upper metallic cylinder and turns only when the flywheel is turned!

-

i have made some adjustments and it seems ok now! I will make one more video and post it again!

-

a little help will be appreciated! I don't know what are the strikethrough words? according to the service manual Adjustment feed dog follow-up movement 1. Set stitch regulator lever to maximum forward stitch length. 2. Rotate handwheel until the take-up lever has reached its highest position. 3. In this position rotate the handwheel further. The feed dog should now advance by one tooth before it sinks below the throat plate (with normally toothed feed dog). Fig.1. Correct as follows: 4. Slacken screw 51. Fig. 2, page 204. 5. Rotate cam 52 as required. 6. Retighten screw 51. Feed dog height adjustment 1. Rotate handwheel until the feed dog has reached its hi- ghest position. 2. In this position the feed dog should be above the throat plate by the height of one tooth. Fig. 3. Correct as follows: 3. Slacken screw 53. Fig.4, page 204. 4, Rotate crank 54 upwards = _ feed dog moves higher | downwards = feed dog moves lower. 5. Tighten screw 53, Feed dog lift adjustment Please note that with the following adjustment you will not obtain the feed dog lift movement as shown in Fig.1 but an approximately rectangular movement (Fig.2 ,page 205). The lift movement shown in Fig.2 is necessary in order to ensure that the pre-set stitch length is actually carried out by the feed dog above the throat plate 1. Rotate handwheel until the needle enters the needle hole or the feed dog has completed its follow-up movement as set according to page 12. 2 With the feed dog in this position it should sink vertically below the throat plate when the handwheel is rotated fur ther, and, on completion of its return journey it should also emerge vertically from the throat plate. Please note that this vertical lift can be only approximately obtained by means of the round cam. Correct as follows: 3. Slacken- screws 55. Fig. 3, page 205. 4. Rotate cam 56. It is advisable to hold the cam by means of a tool (screw- driver or the like) and to carry out the adjustment by rotating the handwhneel. 5. Tighten screws 59. why the say "Please note that with the following adjustment you will not obtain the feed dog lift movement as shown in Fig.1 but an approximately rectangular movement (Fig.2 ,page 205). The lift movement shown in Fig.2 is necessary in order to ensure that the pre-set stitch length is actually carried out by the feed dog above the throat plate" Isn't this kind of movement the correct one? Those part are the same on 168 and 68. Only the number for the various screws are different

-

here are the photos!

-

I also have this manual! Only in german damn it! I have some german friends and i will ask their help to translate. I will make the photos tomorrow! The funny thing is that the machine came like this from a service center

-

according to the international service center in Germany the machine is ok! I will keep it as it is but i still believe that it's not perfect!

-

i saw the the difference! The 168 is not a walking foot machine!

-

is the class 168 similar to the 68? Because i have a detailed service manual for 168! As i can see from the exploded views the 168 have a shorter stick than 68-4563L and the position of the hook is from the right side of the needle, on the 68 is from the left side

-

The new video! I hope it's ok now!