-

Posts

25 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Blogs

Gallery

Store

Everything posted by Claykan

-

Hi Allen, I'm sorry to hear this. I've been a member of the IILG for about 20 years, which is where I learned most of my leather working skills. There, and a place called "Trial and Error". :-) Met a lot of great leather crafters VIA the IILG. Even ran into you a time or two. I think it was at a Topeka leather show and then at the Okmulgee round-robin training courses. Good times. Maybe we'll bump into each other at another show. Fred Probst

-

Thanks Jim. Your belt making tutorial is the cat's meow. I've tried using the customer's belt to get the proper measurement, thinking that it would be right on. But between stretch in the old belt, and the curve that that it forms after a lot of use, I had a heck of a time getting it right. Finally started using a tape measure, which was a little better. But some of them had a tendency to suck in their gut when the tape went around their waist. Using your belt sizer I can let them cinch it up, then make some small talk with them until they finally have to let their breath out so I can get the right size. :-) Thanks for sharing, Fred

-

Tony, I've had a Boss for several years and it is still going strong. But, it does have a learning curve, so I suggest that you read the manual carefully. Also, the Tippmann website has numerous videos on it's care and operation. Once you understand how it operates you will be very happy with it. Some things that will cause you problems are; Using the wrong size needle or thread, or not having the proper thread or presser foot tension. When I first started using mine I had trouble with the thread knotting up and skipping stitches. I finally sat myself down, watched the videos and reread the manual. Took my time and properly set the tension, used the proper size thread for the needle I was using, set the proper stitch length, and ensured I made a full stroke with the stitching lever. After that it was a joy to use. Good luck, Fred

-

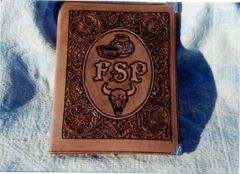

From the album: This and That

-

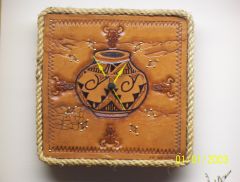

From the album: This and That

Made for SASS member. -

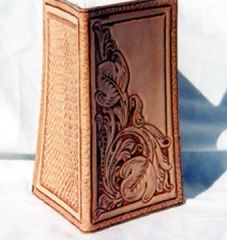

From the album: This and That

Made for SASS member -

From the album: This and That

-

From the album: This and That

-

From the album: This and That

-

From the album: This and That

-

I have dealt with both Nigel and Stefan. Nigel has some great videos on his site, which show the proper way to hand sew leather, with the proper tools, and how to maintain the tools. Thanks to him my hand sewing has improved in quality and is now much easier to do. Ordered my harness needles from Ludlow Leather and have been very pleased with them. Great quality. Fred

-

Springfield Leather is a great place to shop and their website is full of how-to videos. Have dealt with them for about 10 years with no problems at all. http://springfieldleather.com/ Good luck, Fred

-

Good deal. Let me know if you have any questions. Especially when it comes to a head knife or round knife. You should only do half the blade at a time. I'll explain in detail if you plan to sharpen one of those. Really simple when you set it up correctly. Fred

-

Hi Troy - In answer to your questions: No, it will not sharpen a swivel knife blade. The blade is just too small to work with. The good news is, if you don't drop or otherwise damage your swivel knife blade, all it should need is stropping. If needed, there are special guides made just for swivel knife blades, which can be purchased through a leathercraft supplier. Sharpening a knife with the blade beveled on just one side is no problem. But since the system is designed to work with knives that have the blade edge running along the long side of the blade, I think you'll have to use a bench stone for a skiver. I just looked at Lansky's webpage and wow, they have really added to their products. A lot more to pick from now. The Deluxe 5 stone system for $49.99 is the one I have, but it may not be right for you. If you're going to be using it to maintain blades that you buy new, the 3 stone system is all you need. If, like me, you buy some used knives, then probably the 5 stone system is the way to go. I bought some great, 100 year old C.S. Osborne head and round knives off of ebay. Great steel, but over the years the blade edges were in terrible shape and it took all five stones to make them right. But brother, do they slice through the leather. Lastly, if you plan to sharpen knives for others, or your work load is such that you'll be using the system weekly, then you might think about getting one of the higher grade systems. Let me know if you have any other questions. Fred

-

This works for me, so thought I'd pass it on. Not to say that it's better than what has already been posted, just another angle to look at. First off, I run a black Magic Marker along both sides of the edge. This allows you to easily see if the angle you are trying for stays constant. Then I use a Lansky sharpening system for sharpening my cutting edges. This goes for regular knives and round knives, but we're talking round knives here. You can set the Lansky system for 17, 20, 25 or 30 degrees. I prefer 17 degrees for my round knives since they are only used to cut soft material, and I like them sharp. The system I purchased comes with 5 stones ranging from 70 to 1,000 grit. I think there is also a 3 stone set you can purchase. Basically you attached the guide, which has slots for the 4 different cutting angles, to the blade. Then you select the stone you want to use, depending on the condition of your edge. Each stone has a steel rod attached to it. The rod is inserted through one of the slots on the guide, which will keep the angle of the stone constant, and then start working the stone across the blade. A word of caution! You will be moving the stone against a very sharp and wide blade. Be aware of where your fingers are. I have sharpened my round knives with this system for about 15 years now and can still count to 10. Just pay attention, as you can get the blade to be Scary Sharp! I haven't looked, but I'm sure that by now there are "You Tube" videos out there where you can watch the system in action, although I doubt it will show round knives being sharpened. If you have any questions let me know. Fred .

-

If you take the Tippmann Boss out of the box, install a needle and thread, and start sewing, you're going to be disappointed. But, if you take the time read and understand the manual, you're going to enjoy the Tippmann Boss. Viewing Tippmann's instructional videos will help also. Check out the videos on Youtube of the leathercrafters using the Tippmann Boss to sew holsters and sheaths to see them in action. Good luck,

-

Thanks to all for the information. Dirt Clod - I had not thought about a chest strap, but certainly see the merits in one. Thanks for the suggestion. Camano - Since this is going to be a set up for one person, for one purpose, I was going to sew and rivet the suspenders to the belt to cut down on bulk. Tree Reaper - Thanks, I'll check out the Duluth Trading site and see what they have. No need to reinvent the wheel if I don't have to.

-

I'm making a tool belt that will carry enough weight to warrant suspenders being attached to the belt. My question is, does anyone have any thoughts on attaching the suspenders to the outside of the belt vs the inside of the belt? I've given this some thought and see merits for both attachment methods. I just don't want to get this rascal tooled and constructed and then see why I should have done it the other way. - Thanks, Fred

-

The design in the picture looks like a stamp that a silversmith might use. Take a look at "Things Western", www.thingswestern.com. Look under "Products" and then click "Silversmith Stamps". I've purchased some silversmith stamps from Joe to use in my leather work and they work fine. You just have to be mindfull that they do cut sharply, and they are not chromed so they may rust, although mine haven't. His stamps are $7 or $8 dollars and he has 50 or 60 to choose from. Since he makes them himself you might even be able to have him make the design you're after. Hope you find what you're looking for. - Fred

-

Thanks to all for the welcome. Kate, I remember your work from the IILG Group. I see that you're still producing awesome work. I live just outside of Wakefield. Maybe we can meet sometime and you can show me the secret to your masterpieces. Fred