-

Posts

62 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Blogs

Gallery

Store

Everything posted by AlizabethThomas

-

It was time to deal with the interestingly disgusting motor with it's chemically time-melted rubber pads. I couldn't tell quite how the pads fit into the mount mechanically since they were more of a substance than a material. Best I could figure is that they were bolted to the motor body against the contact plates that were part of that sandwich, and then the cradle mount had separate rings held to the cradle body that then dig into the rubber, sort of pinning into it to prevent rotation. I've seen canvas/rubber composite ones of these where both parts are bolted directly to the material. This one seems to apply two pressure points to the material's outside, over a disc. If the tips of the bolts went through holes in the padding material, there would be metal-to-metal contact, and we wouldn't want that. So I guessed my way through this one, it seems to work. I used leather instead of the shoe making rubber material I had originally thought I was going to use. It will probably squeak, I will probably then oil it. It has the fibrous strength I would be getting out of a canvas/rubber composite, and made from parts of the hide that were going to just end up stitching test scrap anyway.

-

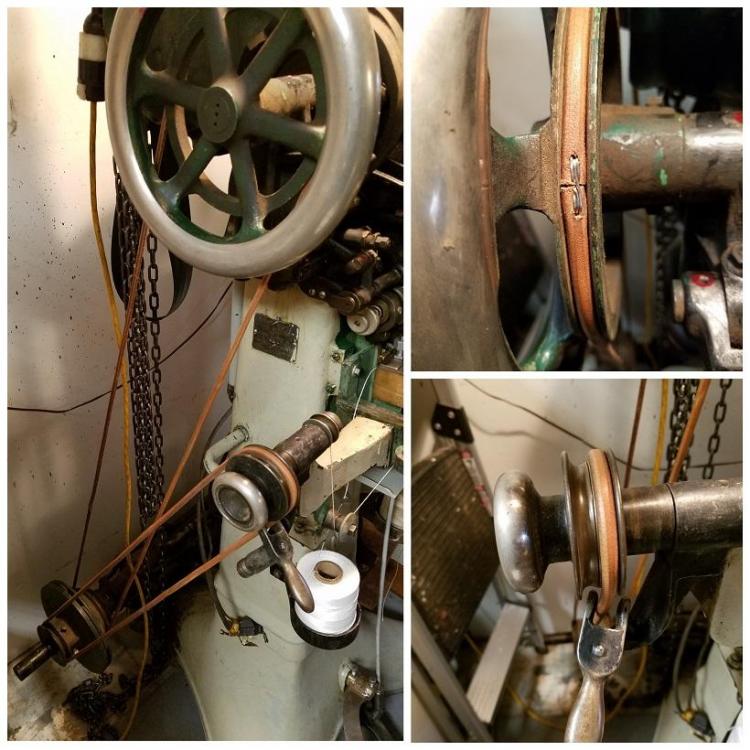

I made some new belts out of the round belt material that came with the machine. I sttiched it together with a 1/8" hole being drilled 1/2" from the end and stainless steel wire I have passed through the holes twice and then an L shaped end tucked in and all pounded flat. The main machine belt stretched enough that it was slipping and loose later on. I cut and re-stitched it an inch shorter to make it tight again. I might have to get used to the re-stitching a few times before it settles. The glazed over, hard one originally on there showed no elasticity left. I started anew because it seemed like it was going to be slippery. I'm not sure how much of a factor belt slippage is for regular users of these machines. I ended up using some spray adhesive to maximize traction temporarily, but it still slips some. Not sure if there is a belt dressing for leather belts, or a giant o-ring sized right for this machine. It has a lot of weight and rolling momentum that seems to like a certain speed and a pulsation of power to it seems to be the best way to keep the speed in the lower range, I later realized.

-

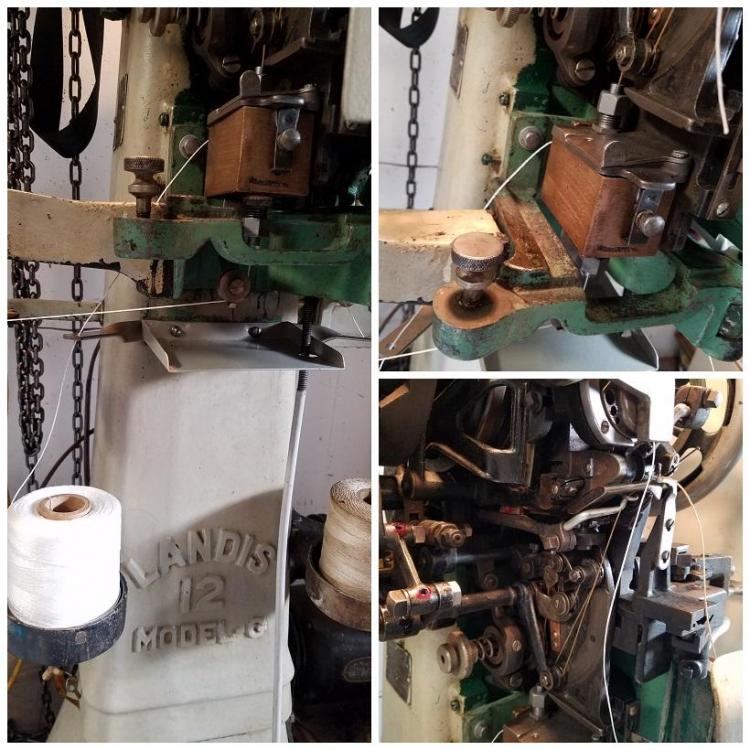

I had ordered a new left thread holder. The one that had come with the machine was snapped off and re-drilled, and had a piece of whittled down broomstick as the center post. I just couldn't live with it. I saw one for sale on Ebay and snapped it up for about $30. It was now time to re-thread the wax pot and adjust the strippers. This is still an ongoing process, the rubber is going to compress, and I still have to figure out how much to tighten it over time as a factor to thread tension.

-

Haha, I was wondering what was with this "make sure you GIT that one wit' yer oiler" as I was interpreting it earlier. I was especially confused to see that your location was Wisconsin with that kind of talk (lived there 5 years). So thanks for the clarification. I made the effort to inspect them and they are indeed genuine, original Gits Bros. brand oil cups bearing that mark!

-

While I had the touchup paint mix perfect, I took the time to prep and paint a few things mainly for the front of the machine like the table and tombstone cover. All that's left to do is secure the motor and it's belt to the clutch shaft, make some leather drive belts, and thread the machine. That would render it ready to be put into motorized service, and may require some slight troubleshooting to make it run perfectly.

-

I got to work on reconnecting all the heater wires. These are insulated with asbestos. Mmm, genuine asbestos. I had to heat shrink some tubing on to where some of it was crumbling. These little resistor pack heat pads providing 200 degrees to this cast iron all these years made the whatever part of the wire that holds the asbestos together get crumbly where the heat was. Hopefully I won't need the heating circuit now that I'm using cold liquid wax, but if the machine still needs to be warmed, hopefully all the heat shrink tubing will do is shrink or get soft. If I blow a fuse, I could add some modern fiberglass sleeves to the ends where I applied heat shrink. Note that the small black thermostat wires are not in the right place. There was another conduit box that was later swung into place that had a carbon resistor inside, and unlike the other heating pads, this one wasn't in contact with a part of the machine near thread handling. The heat is to keep the wax melty. The placement of this box out in the open with the resistor block that din't look like the heaters, along with the fact that the ring terminals on these flexible black thermostat wires fit the large threaded studs which were much bigger than the little machine screws that hold wires to heating elements led me to conclude it's the hanging junction box where the thermostat wires belonged. I knew I would figure it out right when I took it apart without taking pictures. I usually just ask myself, is this part of the machine different enough that it has a best correct fit that is different from the other places it could connect, if it could matter?

-

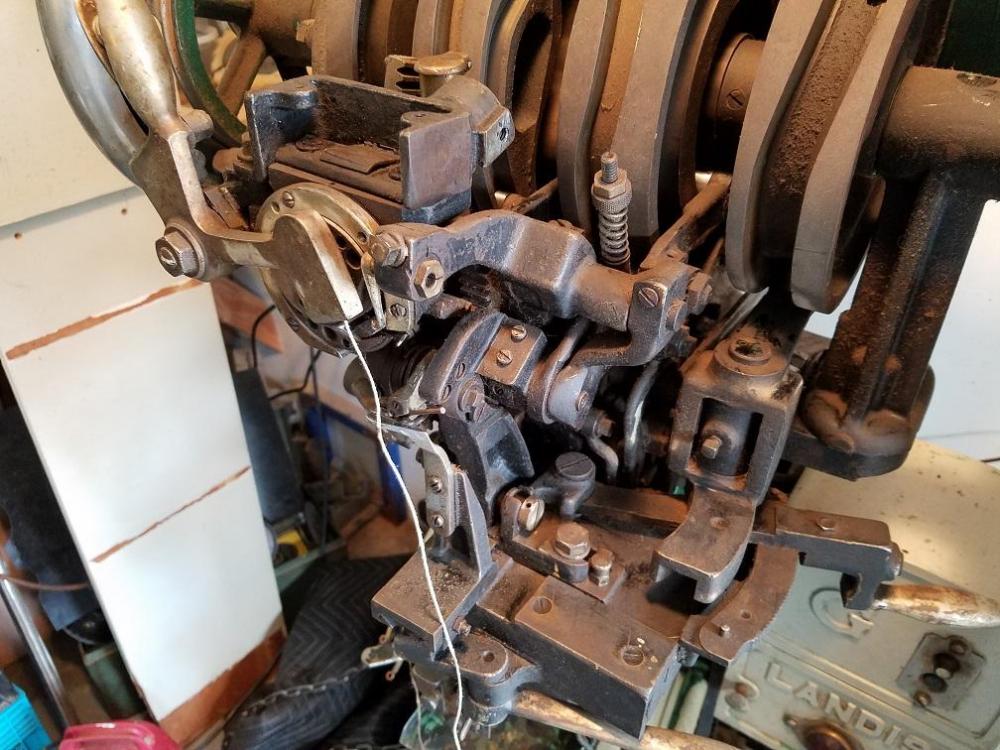

Spent some time cleaning the moving parts to make sure I was finding all the oiling points. Turns out I had missed some in the back. I cleaned them all off with acetone and used some red nail polish to mark them. I would have liked to use something brighter for visibility, but I think red is tasteful and simple for the age of the machine.

-

I bought new wax stripper rubber bits and nuts for the wax pot. But before I could thread that up, I started to realize all the touchup painting and some of the small parts I wanted to color match repaint were in that area. So I bought some small tins of black and white rustoleum to go with my rustoleum brown. This was an interesting shade of grey with it's brown oil staining and probably some UV darkening. So I got to work tinting some paint after I took the little drip shelf and thread bracket off and started stripping them and the conduit that provides heating electricity to the shuttle case area. Mainly using the dinged up base to match and play with my color. Spent quite a while on this. I shouldn't have used a whole spoonful of black, because I had to add all the white. When the brown made it too red, green colorant added was the answer. I got it about perfect color wise and then it dried a little darker so I added some of the non-green-tinted to lighten. Still dried darker, but after all that, the two batches were going to go back together in the can anyway, and it was fantastic compared to before.

-

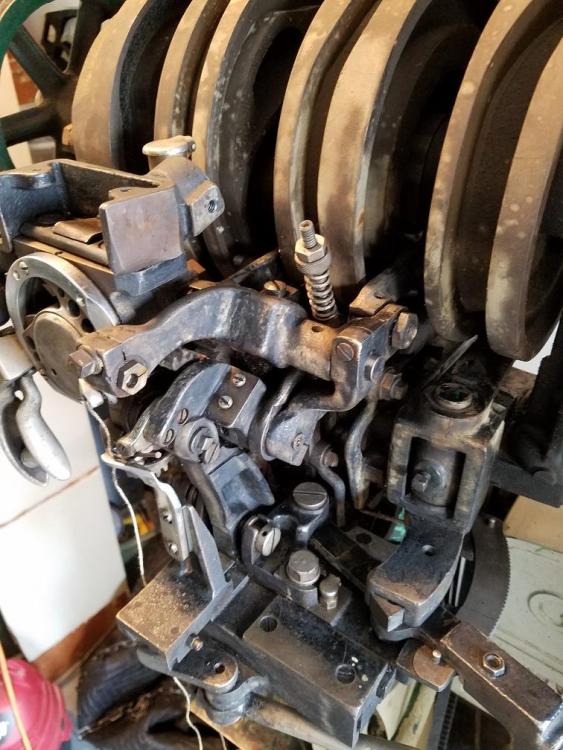

The Landis has turned it's first line of stitching in probably decades. Just hand crank for now. I have to take a step back and finish reassembling all the little things or I'll never get around to them. With cold wax, I shouldn't have to be running the heating circuit, but that's just what I'm hearing so far, and in case I do, I'd like it all assembled. I want to get the machine as close to original mechanical condition as possible and reinstall everything it came with. Nobody has documented the details of the guts of any landis online that I could find yet, which is why I started this thread. It could use a new awl, and I sure have to build momentum in that part of the cycle to keep the presser foot from bouncing way up and get it to punch through swiftly. It's struck somethig hard and has a dulled/damaged tip. I just need that square nut driver Steve has in the video. I've messaged his company about getting one of those and a set of wax stripper bushings and possibly nuts, and some stitcher machine oil, just using zoom spout oiler oil like on all my other sewing machines for now.

-

The wax pot all cleaned out and filled with Sellari's liquid wax. Both cones of thread in place on their holders, threaded through the pot and into the machine. I don't have new wax strippers (rubber bushings under tension from a barrel nut to squeegee off excess wax) but these will work ok for my tests and probably even longer until I obtain newer ones. No leaks so far, but the nuts seem to be specific to each ferrule. I'm not winding bobbins just yet, but I have the thread for that going through the wax pot for when I get the bobbin winder cleaned, installed, and figured out, including any parts it may be missing. So the bobbin thread, which is 6 cord thickness, is just holding it's place in the wax pot, so it doesn't leak, since that ferrule comes out the bottom of the pot. I have one metal bobbin wound with old linen thread, but I am using a 6 cord polyester prewound bobbin thread for now, I bought just two. Ideally when the worldwide linen shortage catches up (2020-21 pandemic era) I'll be using pure linen on the bobbin side, but I bought a cone of the polyester anyway. The top thread is linen, original to the time when the machine was last used, and is typically a 7 cord thickness thread.

-

A first wet scrub with mineral spirits and thorough wipe down, and breaking up crusty wax pot contents. I've seen shoemaker's wax made with wax, lard, and rosin, and am not sure what this old wax contained. I have a block of wax that came with the machine that is yellow like beeswax but harder and may contain other ingredients. The wax left in the pot looks very crystalline like rosin, dark, and almost green. The wax pot looks like it's made of aluminum, but this greenness almost makes it seem like a bunch of copper corrosion. I don't know, it's nasty and gets scraped clean, and then I will see the condition of the rubber bushing "strippers" that wipe the thread of excess wax, be it liquid or hot melted, from the threrads, both in bobbin winding and in stitching processes. There is one pointed out, and another hidden at the bottom of the wax pot out of view.

-

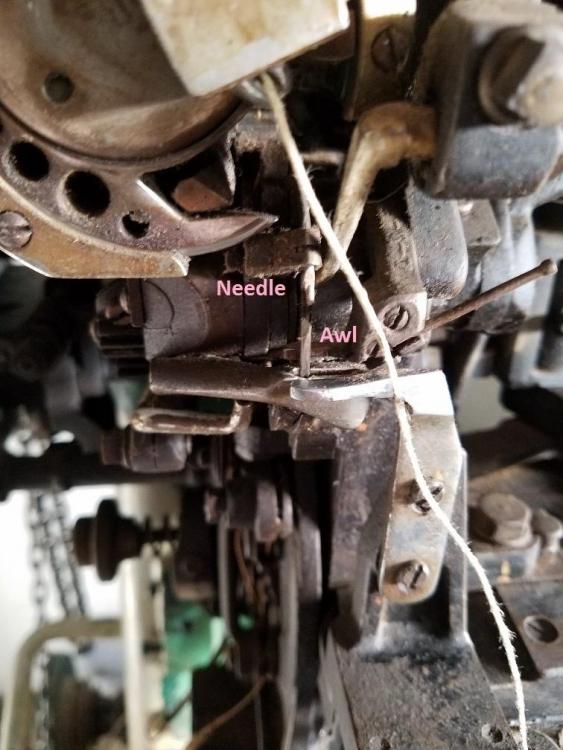

much earlier in the process, i had gotten nervous about whether it was all there or if it were missing parts. Here you can see I have gotten to the point of rotating it through a cycle (it was gummed up slightly and all the oil had basically dried up, dripped off, wicked out into the dust). I not only was able to remove the bobbin to verify that it was present in the machine, but also see the needle and awl present, and figured out that the handwheel rotates away from the user at the top, that is, clockwise viewed from the right side of the machine, the opposite of most sewing machines. Unsure if I was seeing that wheels-spinning-backwards effect video sometimes has on wheels like in car commercials, I could verify this opposite rotation because the awl has to make a hole before the dull needle can travel through the material to hook the thread from the looper below. Here you can see the two tip-to-tip in the hole making. thread-hooking-from-below part of the cycle.

-

It's finally got it's head back. I need to start looking into wax stripper/nut assembly at a supplier. I like Gateway in Illinois. They've already hooked me up with an original foot pedal for $60 shipped, and one of the main techs there has the only comprehensive video (or only video at all) on youtube about threading, wax, cleaning, and lubrication, Steve Mueller is his name. Here's a neat old '90s video on the landis stitcher. A K model is shown, but it's still a 12 like mine. All these have the same basic heart of the mechanism with little improvements and changes to the things around the outside edges of the machines as the alphabet progresses (there is not a Landis 12 for every letter, but I know of an F, G, and K). The discombobulated narration is an acquired flavor. https://youtu.be/h3EhvqTIBhY

-

Taking small bites. Today I lifted the base, removed it from the cart, and placed it on the ground as far to the side as possible. Then I lifted the head almost all the way to it's position next to that, placing a moving blanket and then a plastic bag between the two. I did a basic cleaning of the back of the head where it will sit towards the base to remove the major grime. I wasn't going to bother getting it spotless, that's more of a disassembly cleaning job. Just some mineral spirits, scrub brush, and paper towels. I did get a lot of crud out of there, and it's reasonably clean. The rest of the gunk can be reached from the sides and front as I reassemble the small parts I removed to separate the head, clean up the moving parts in preparation for oiling, internal cleaning of the wax pots, threading, and the addition of liquid wax. Almost ready to mount the head!

-

I noticed the driving pedal was missing, and none of the boxes of stuff turned one up. I turned to the FB group for cobbler equipment for sale, and got a couple responses. One company, Gateway Shoe Machine had one but it was $132. I told that guy "that's a lot", he justified the price, I said, I know, I get it, but I know how to fabricate too. Another couple of guys had some, one was in Canada, so that was a long shot. The other one in Colorado, for some reason I didn't see or get his response on price until after I had built mine. I really wanted someone to stop me, I was at the metal yard and then to the hardware store, frequently checking my FB from my phone to see if anyone had commented. I spent the rest of the day on the pedal build. Lots of grinder work. $28 in supplies, mostly in the set screw locking collars ($10.69 ea.). Nice compound curve on 2 pieces. Fully welded rib underneath. When I got back to find out I could have had one for $70 shipped, I felt like my day was a little less valuable than the time before, but I just thought the other two guys also wanted close to $132 plus shipping after I mentioned that price and said "I already have a headache from the mineral spirits!". I have since trimmed off that rib segment sticking out the back and smoothed the edges underneath. Might accelerate the rust to match the other one. The proportions are pretty exact, it doesn't reach out quite as far as the original in the picture.

-

Front looking good, now to rotate and get the sides and back. After that, I'll have to move on to the construction of a miniature gantry hoist frame, about the size of a large door, and tall enough to at least get the base off the cart. That will also be tall enough to get the head on after that. Putting the head on while it is still on the cart would be taller than I need, the finish on the concrete in here isn't great, and the machine can be scooted around on concrete, I found. If I had known that prior to setting up the purchase, I could have spent $200 on a forklift rental and put it in the door, but I still would have had to move it off the pallet, necessitating the setup I am about to build. I also could have transferred it onto the forks and slid it in the door that way, but I can't think of a sure way to not have a slippery accident, so I'm doing fine on efficiency. I'm glad I cleaned between the head and base, anyway.

-

Cleaning is underway, mineral spirits and some nylon bristle brushes of various stiffness. I bought an unrelated product in a spray bottle as it was the only form available, so I repurposed that bottle to apply the low odor mineral spirits. It is much faster than my dipped brush application, and necessary for the stiffer brushes as they don't hold very much liquid when dipped.

-

Using a ladder with a couple of pipe spacers for the ladder rack, some reinforcing angle iron and a chain hoist with seatbelt straps I sewed, I was able to somewhat safely(?) lower the base and the head. Building one heavy duty cart for the heavier base with (4) 330lb. casters, and utilizing another prefabricated one for the somewhat lighter head, I was able to get it all inside over the course of 10 hours, with lots of leisurely breaks, but no breaking of a sweat. Except for a bit of a cramped hunched back, I felt fine.

-

I got it unloaded in my workshop building's bay using the hoist and figured out what needed to be disconnected in order for the head to come off. I had looked at a more recently operable machine locally for $1500 while buying other equipment so I was able to talk shop a little with that guy, so I knew about the two big bolts holding the head on. So I disconnected all the heater wires and found out how to remove the conduit routed through the center of the main cam under the cover. I reached the two smaller bolts connecting the "chin" to the front side, and the giant bobbin winder bracket also came off. The foot pedal linkage was removed. After that, it was hoisted back into my truck to drive it to my workshop in the back of the building's lower level.

-

After a few months of looking, I found an ad on FB Marketplace from the daughter of the owner of a Landis 12 G outsole stitcher. There aren't a lot of these for sale in my area because Oregon is just pretty sparsely populated. He got it from a neighbor who was basically a hoarder from his description. It came with a bunch of other parts including both shafts from an old Landis line finisher. There aren't a lot of forum posts with details on how they come apart or how to move them and what to plan for. I hope to provide the online shoemaking community knowledge base with a chapter on getting an outsole stitcher into your shop. Here's the machine before it made it's way to me. The father, owner of it was coming down from Idaho to get a full beef order from a rancher, and so out of state delivery became possible for just $800 for all the stuff.

-

Will do, just waiting on that roller foot to complete the setup!

- 14 replies

-

- and many more

- singer 153w

-

(and 4 more)

Tagged with:

.thumb.jpg.b723bd2cf7cd28cb888ee0aa2e7b9ca4.jpg)

.thumb.jpg.9e4fd02441e614fe9510dea1388f9c41.jpg)

.thumb.jpg.63423d1f8ab30b19e85aaf062bce4a85.jpg)

.jpg.c99bfd91addc87ba45d722f1ba346c52.jpg)