DavidL

-

Posts

1,516 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Blogs

Gallery

Posts posted by DavidL

-

-

in illustrator I click and a box will come out asking for the length of the line, from there i type in "10 cm" and it will change that to pixels or whatever measurement is default. texas custom dies automatically creates curved edges, unless told otherwise.

-

http://leatherworker.net/forum/index.php?showtopic=50706

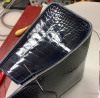

That above type of splitter will work for crocodile, a band splitter, I don't know if it goes by any other name. The specs should allow the leather to be split down to fractions of a mm. In the picture you showed the leather is probably below 1mm. There was one splitter I saw, almost like a sanding drum that the workers would pull the alligator skin through with tension to shave down the flesh. No, I do not know the name of the machine.

A splitter for vegtan is not used for flimsy type leathers. It can not reach sub 1mm and probably can't even split the leather if it is too soft, although I never tried. It is what I understand of that type of splitter.

A skiving machine only thins down the edges. Without the guard on it can split the entire alligator hide an inch or two at a time.

Ask a dealer what they recommend.

-

I prefer to prick the inside, only because its easier. The outside would look better.

If I was to make something over and over again I would measure out how many prick marks until I reached close to a pocket (outside), use a scratch compass to make a slightly larger mark to clear the pocket edge. If the stitching is low SPI in the 4- 6 SPI you may be able to adjust the pocket size so that the pricking marks can pass the edge. At 7+ SPI it may be too close to the edge and will probably rip the leather.

-

there are ways to identify real croc, or alligator.

you can split with a specialize splitter for chrome tan that can split below .5mm.

or a skiving machine done in section

-

single needle, secure the first stitch, two holes forward, one hole back.

-

I tested out some stitching on tumbled veg tan and embossed chrome tan, using a regular pricking iron but on the back side only, meaning that the front side will have the angle of a reverse iron. When stitching the stitches came out very consistent and the reg. way of stitching ( right needle on the top of the hole) is the same result as casting the thread. casting the thread towards you creates a near perfect flat backstitch, and slanted front. Corners should look nicer with this set up.

I might have to pick up an inverse iron just because its quicker than the reg. iron when casting the thread.

-

Im trying to get into a shoe making or saddle making assistant (specific part of making like stitching, cutting, assembling only) in the Toronto area. However the requirement is 1-5 years minimum to get a consideration for the new job opening.

Where does one start for shoe making or saddle making to be able to have the requirement for entry level jobs doing the tasks like aligning leather pieces, clicking leather, working specific tasks.

-

I've read about code too.

beeswax by itself will hold, code would probably be "extra strength".

machine stitching without wax by itself may last years, saddle stitch may last 25 years or more with beeswax or whatever.

Anything you choose will last a long time

-

heres something else to consider:

Pic 1(not my work)

holes are pricked before hand front and gusset. Looking closely you can make out that he uses the same pricking iron on both piece. The stitch created is the most consistent stitch hands down, its almost impossible to make a bad stitch if you take the extra time to align the leather marks, so they meet exactly in the middle. Margin of error is lower since you don't have to use your awl on thick leathers or around bends like that pic.

Doing more tests casting the stitch works even on 2.5 ounce leather, only with thicker threads like tiger thread on thin leathers does it change the stitch.

-

I prefer to do ian's way majority of the time.

https://www.youtube.com/watch?v=3zTOqJCWbfY

It creates an upward slant towards you on the backside, almost like casting the thread ( throwing the loop away from you) but it has less tension from what I noticed. Sometimes when casting the thread on thin leathers the front stitches will straighten, I have not noticed this when doing ians way.

1.Casting the thread is the best solution IMO with thick leather (upward stitch slant, back and front)

2.Putting the second needle at the top of the hole is the best solution IMO for chrome tan leathers and combination tan leathers IMO (downward back stitch slant, almost flat looking). Something about the leather closing up more than veg tan makes the stitches want to stay compacted together.

3.Putting the needle at the bottom of the hole is the best solution IMO for most leathers with the exception of the two situations above ( upward stitch slant back and front)

You can use the 3 different ways on different types and thickness of leather but thats what works best in my testing. I haven't tried using a reverse stitching iron yet, so theres still more that I could test out..

Side notes:

When done correctly all stitches should look the same on the front more or less (all three types of stitching), with the back side stitches looking different. The second solution will look the most different on the back. 1 and 3 will look the similar, on thick leathers they are essentially the same stitch. Number 3 has the ability to be used on thinner leathers where number 1 may flatten the front stitch. Number 2 is harder to get the backstitch straight than 1 and 3, chrome tan and comb. tan work well with this way.

Pulling the stitch upwards or downwards will help the thread lay a certain way. If the back stitch (left side, awl in right hand) needs to lay above angling the thread in the right hand upwards will help the thread (backside stitch) go up, while angling the left hand thread down will make the thread go down.

Last tip. If you stitched a whole piece you can always use an awl to push the thread to the correct position, sometimes this will not work if you changed the needle positioning.

At first I thought there was a way that could be used on all leathers, after a while you notice that once you perfect your technique the leather will dictate how the stitch will look. The only thing you can do is choose the appropriate stitch, awl, tension, thread size, SPI for the chosen leather. You do not choose a stitch, tension,thread,spi before hand and pick a piece of leather, you look at a piece of leather and decide on everything afterwards. Change the type of leather or thickness if you can not achieve that stitch.

The stitch may look different from one leather to the next, but very similar if they are similar leathers. The only way to know how it is done is by doing it over and over until you can see the "correct way".

-

How do you guys remove wrinkles and stretch marks in leathers like horween, or chrome tanned leathers. With fabrics there are irons, whats the way to remove wrinkles that come from the leather being rolled up?

In a video of a bag being manufactured they used a specialized machine that has two hot plates flatten the leather and steam it.

What do you do? stretch it out? Roll it up? brush?

-

saddlers needle and awl is what you are looking for. A glovers needle, is what the name implies needles for gloves. No awl is needed I believe for glovers needle - only for soft thin leathers.

Lekoza.com Email matt and he will help you out, he is also on this forum under Matt T.

-

based on the picture, I can see they do not skive it on the edges, only the entire piece. Both ways will work though.

Looking at the second picture I posted I think I figured it out. Take the notch and align that notch edge to the edge of the bag part.

-

Glover needles I think are sharp, saddler needles aren't because an awl is used. Get something that is small just enough to pull the thread through without needing to feather or skive the thread tip.

get a medium sized awl for medium stitching, large for large spaced stitching, small for small stitching. Simple enough. Vergez awls are sized in mm's for the length not the width. 32mm is a good size for 9 SPI, you can sharpen it further for 10 SPI +. 40ish mm for medium stitching, 48+ mm for large SPI 3-6.

In the video he says to use metal clippers to cut the tip, just sharpening to round it out could be better.

A pointy tip is something I want to keep around on a spare awl for overstitch and the rounded tip for pricking iron.

-

thread and thinned down leather.

The hard part is when the piping is tucked under and connecting two ends of piping seamlessly is difficult too. The picture you posted is the most difficult because the excess bulk of the leather on the inside is hard to manage, it has to be well thought out and executed for it to work.

Just a straight line is simple enough.

In my opinion this is probably one of the harder if not hardest skill to master, to get the leather to manipulate the EXACT way you need it to go.

If you do figure it out let me know.

-

illustrator Adobe or photoshop can figure that out for you. Plot out the pattern on offset the pattern by the thickness of leather (ex. add 2mm around the perimeter of the pattern), use some setting in the program to measure that line.

The other way is to do it by paper and measure using thread. I never tested this but it should work more or less, the stretchiness and stiffness may affect this?

-

What is the power output and temperature range of the soldering iron you had custom made?

-

Sona: It wasn't a dumb question, I only know it works that way because I tried it before and messed up

Another thing to consider is using a divider spaced out to 2.5mm or 3mm instead of using a 4mm pricking iron (Roughly 3mm = 1.5mm away preside from the joint). On the joint, space it out 2.5mm to the left, 2.5mm to the right (using dividers) and use an awl to pierce the holes.

To me it seems like an awl hole is less likely to tear than a pricking iron mark.

-

sona: It would look pretty bad if you skived the ring in the original picture. The edges are turned over, when you skive it its difficult to match up the two ends creating the same round edge profile.

Regular flat edge on vegtan is much easier.

-

https://www.leathercrafttools.com/shouhin.jsp?id=10153

Looking to find a usable edge creaser and using it to use edge paint with this tool. Has anyone used this tool before. Any other recommendations?

-

-

lol.... I make lots of small rings / bands I skive the ends and glue them. skive 5-8mm from each end... front on 1 end and back of the other end. then form them around a metal bar... but you can use a wooden dowel.

that wouldn't work well with the leather he is using.

-

I would think you would want it 3-4mm shorter than a perfect circle and stitch the leather while its around a mould, making sure to have the leather stretch slightly to have a tight seam. Take a hammer and bone slicker to flatten the two ends.

The leather you are using looks fairly soft, stiff thick vegtan wont be able to stretch as much as softer leathers.. play around with the leather to see the right distance to cut.

-

Do you have a springfield leather membership?

How To Accurately Design Leather Dies?

in How Do I Do That?

Posted

curved edges doesnt make sense.. curved corner is what I meant to write.