-

Posts

70 -

Joined

-

Last visited

Profile Information

-

Gender

Male

-

Location

HK

-

Interests

leather craft

LW Info

-

How did you find leatherworker.net?

internet

Recent Profile Visitors

2,759 profile views

DANDTON's Achievements

Member (2/4)

-

www.lzpattern.com www.leathercraftpattern.com Welcome!

-

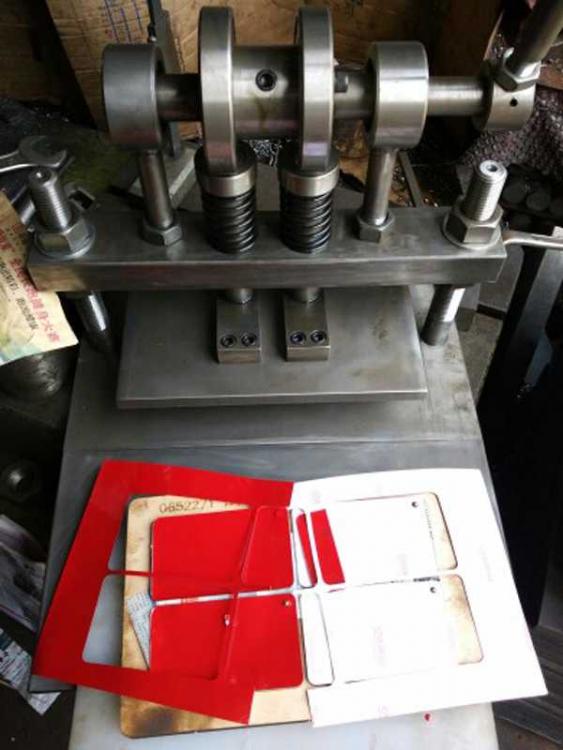

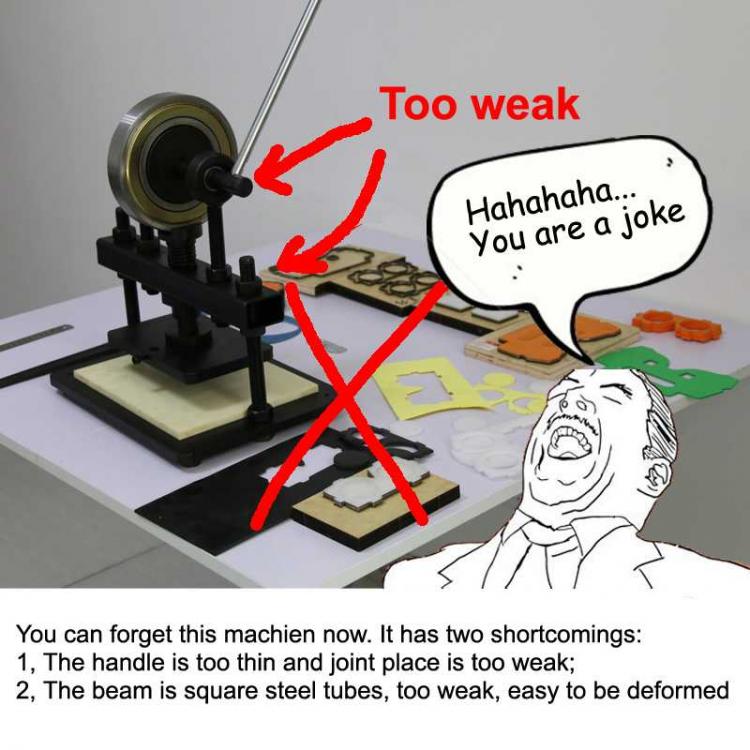

Hello everyone! Please allow me to introduce this machine to you,compare with the old version, it was improved a lot, the old single bearing one is really a bad design, easy to be deformed. This machine offer about 8 ton+ pressure. easy for you to cut any leather that you want Leathercraftpattern.com design and improved! You can get it here: http://www.leathercraftpattern.com/leather-cutting-machine

-

Tutorial On How To Make Steering Wheel Sleeve Easily :)

DANDTON replied to DANDTON's topic in How Do I Do That?

Sure. Absolutely right~ Thank you Cradom! -

Tutorial On How To Make Steering Wheel Sleeve Easily :)

DANDTON replied to DANDTON's topic in How Do I Do That?

I didn't try Tshirt, but it must be a better way use duct tape I gusse, especially that kind of metal foil duct tape, the tape may stronger enough to form a hard pattern. -

I am a professional leather pattern designer. Different steering wheels have different pattern, you can't follow its update steps. Let me show you a kind of special way to get the pattern from your steering wheel with old newspaper and scotch tape, this kind of way is used by shoe smiths a lot. Do notice: you must wrap the tape firmly Steps: 1, wrap the tape and newspaper on your steering wheels firmly, the more the better, a thick pattern is easy to be tracked by pen. 2, cut off it, along the inner side. 3, track it on thick paper or kraft. 4, you can try to punch some small holes with your chisel or awl. 4, sew your sleeve. Nothing is easier than that This way is suitable for all kinds of steering wheels.

-

One of my guest change the construction a little and send me a tutorial, let me share you here Look at the pictures in the attachment, I named them as aaa bbb ccc ddd eee fff ggg hhh ggg, so you can follow the alphabet order as the steps.

-

Our New Website And Customization Tool

DANDTON replied to Astinos418's topic in Marketing and Advertising

It is a wonderful website I think! And the products are very charming! I like it very much! -

Sewing Machine That Can Look Like Handstitched?

DANDTON replied to KelseyR89's topic in Leatherwork Conversation

Hi Ferg, Thank you very much for your honest comment especially from an old experiential leathercrafter, I think we have the same viewpoint: Sewing machine is not as Hand sewing, just "very like". I born from a sewing machine family, mother father and grandfather are old leathercrafters, but they work in factory and operate sewing machine. grandfather "play" sewing machine about 50 years as you, mother more than 20-30 years. They are skillful leather machine operators. I learn a lot from them, include repair and adjust all kinds of sewing machines sewing machine can't offer perfect "chisel holes", I will show you two pictures of what the chisel I am using, you can compare the effect with other chisels and machine holes. The reason why the machine sewing doesn't like hand sewing because lots of reason: 1, the hole shape. Sewing machine can't offer prefect hole shape as chisel, I used hundreds of needles to compare, needles from German is perfect, it likes but not perfect that chisel. 2, the thread you use. for sewing machine, you use silicone oiled thread as “nylon thread” (nylon 6.6 or 6), it is not wax thread or “flaxen wax thread”, so when you sew it on, you will see the thread will be a little loosen or tighten, I don't know if you can understand the meaning, but you if you hand stitching, you will see that. 3, you said "Machine sewing gets a bad rap some times. When done properly it has a fantastic look and can outlast hand stitching.", the reason why Machine sewing gets a bad rap some times because the coordination system of upper thread and bottom tthread, sorry for my translation, you know what they are. If you loose the upper one and fast the bottom one, you will get very smooth rap--Very,, not sometimes, but all the time. Anyhow, as a young guy, I accept your comment modestly, and Merry Xmas! Yours, Daniel -

Sewing Machine That Can Look Like Handstitched?

DANDTON replied to KelseyR89's topic in Leatherwork Conversation

Hi Kelsey, Yes, the cyclinder machine's stitching like handstitching very much, but if you check it carefully, you will see the difference. The stitching line is wave. The shape of the machine stitching line due to what kind of needle you use and the distance of each stitching, if you use No.23 needle, and set the distance 3.5-4mm, it like handsewing very much, but if you set the distance as 2.5-3mm, you will see it absolutely sewed by machine -

About the machine, there are 3 different kinds: First: cookie cutters, as thefanninator said, you need make knife mould, and the machine press on the mould, then you will get a cutted piece, the advantage is: You can cut lots of layers of leather one time, because the mould have heigh. But the shortcoming is the cost of moulds are very expensive. Second: Laser machine, this machine can cut only one layer of leather, you can design pattern in our computer with AUTOcad, PDF, AI and so on, the machine will cut along the vector line you designed. The advantage is: You can cut the leather quickly after design without waiting for making knife mould, but the shortcoming is: If you can't adjust it well, there will be black edge (burnt by laser), the black edge is about 0.5mm-1mm, the newest machine will reduce the black edge enormously, but no matter how, there will be black edge. So it was used only on crazy horse leather or chrome tanned leather with dark color, natural color vegetable tanned leather is not OK. Third: Rolling knife machine, this kind of machine can only cut a layer of leather one time as Laser machine, but it cut the leather buy rolling knife, so there is no black edge at all. But the shortcoming is: 1, you should change your knife frequently; 2, the price is very high because its complex construction, about 5-6 times than laser one, 7-10 times than cookie cutters.

-

Let me draw an instruction picture to show you..... Actually the fabric lining was glued on the flesh side of the front leather, and when you sew the lining's two sides, it forms a card back....I wish you can understand the instruction picture. You can use a whole piece of fabric or cut them into pieces, both are OK.

-

Hello handsw, I know the tech that harder the leather with wax, but it is now very old tech...actually nobody use it now. You can buy a kind of leather treatment named: Leather hardening agent(I don't know whether my translation is OK or not), it is a kind of liquid that when you paint it on the surface of the leather, it will be harder.

-

Use Arbor you will meet this problem, you can add a piece of steel board to enlarge the plate area. I made a machine to do this job...I use jack, it can offer 10 Tons pressure, I use this machine to press big logo(very big, as large as palm), make leather by moulds and so on. Take a look and Merry Xmas!