DavidP

Members-

Posts

16 -

Joined

-

Last visited

About DavidP

- Birthday 03/11/1970

Profile Information

-

Gender

Male

-

Location

Montana

-

Interests

Everything, old machines, camping, hiking etc.

LW Info

-

Leatherwork Specialty

Custom boot maker / boot repair

-

Interested in learning about

everything

-

How did you find leatherworker.net?

Internet

Recent Profile Visitors

2,462 profile views

DavidP's Achievements

Member (2/4)

-

James, Thank you for the pictures. I have the piece that covers the gears. To my reckoning my machine is complete. I don’t have any paperwork on it, do you have a book? What size thread do you use? I have a pack of needles that came with machine. David

-

Hello, Can I assume that this still for sale? If so, have you considered shipping? I live in Montana. David

-

Hey folks, a few years back I bought out a bookmaker and he had a lot of spare parts and machines. It’s time they moved out of my garage. The numbers will correspond with pictures #1 Landis 1. Complete and in working order. When I got it I cleaned it up, oiled it and it sewed well. #2 shuttle and bobbin for Landis 1 #3 Head of Landis 12f #4 Motor for 12f #5 Landis 12f FOR PARTS ONLY #6 spare Landis 1 head and parts. This is the nicest one. He may have had it refinished. I have 3 spare heads, 3 spare bases plus parts. I am located in Montana, am open to traveling to deliver. Shoot me a line and we can discuss prices. David

-

This is my machine. I will look over the book for the dn86 McKay stitcher for the basic operation of the machine but in order to make sure it is complete if anybody has a book would be helpful. There was a gentleman (19th century boot maker) on here back in 2012 that had one but he hasn’t responded yet. Thank you for the help on resizing. Had to make 15 different copies of 1 picture together the right size. It’s funny, you change the size of the picture from 2500x3200 to 400x600 and it doesn’t change the size of the picture. Figure that out. Anyway, any information would be handy. David

-

Setting Up A Mckay Stitcher

DavidP replied to 19th century bootmaker's topic in Leather Sewing Machines

I know this a long shot, but did you ever get any help with this machine? If you happen to have a book for it sure could use a copy. -

YinTx, I have tried resizing on my iPad down to 3:5 and even 2:3 and they are still too big. I will keep trying but may have to email pictures if anybody wants them. I guess I don’t understand the photo requirements of this site, when I hit choose files and pick the photo I want, it gives me a size of the photo (1.3 and 1.4 MB) Even if I add them one at a time they are below the 1.46 MB required limit?? And it still won’t load because it states the size is too large. ‘If anybody wants more information I can send more photos via email. As of right now yahoo does not limit the number of photos or size of attachments. Thanks

-

Hello! I have recently acquired a McKay stitcher to use in a local living history museum. I am hoping to get it running but have no resources for it. It appears to be 95-99% intact and moves as it should. I was hoping to get some of your knowledge and maybe a contact or 2. I will try and upload a picture or two, my phone does not like my computer right now. I have also reached out to museumLA in Maine as they have a similar one. Any information anybody may have would be more than greatly appreciated!! With the size restriction on photos I am not allowed to upload more than one photo. If somebody from IT could assist me in uploading more photos. The photo I did take is the brand Thanks in advance David

-

This may be a dead post but,,, I have tried all the links to parts and needles and none of them work. Does anybody have current information on parts and needles for Gritzner and Frobana? I have a gritzner and want some spare parts on hand. Thank you

-

Thank you, I will research cadmium coating in my area.

-

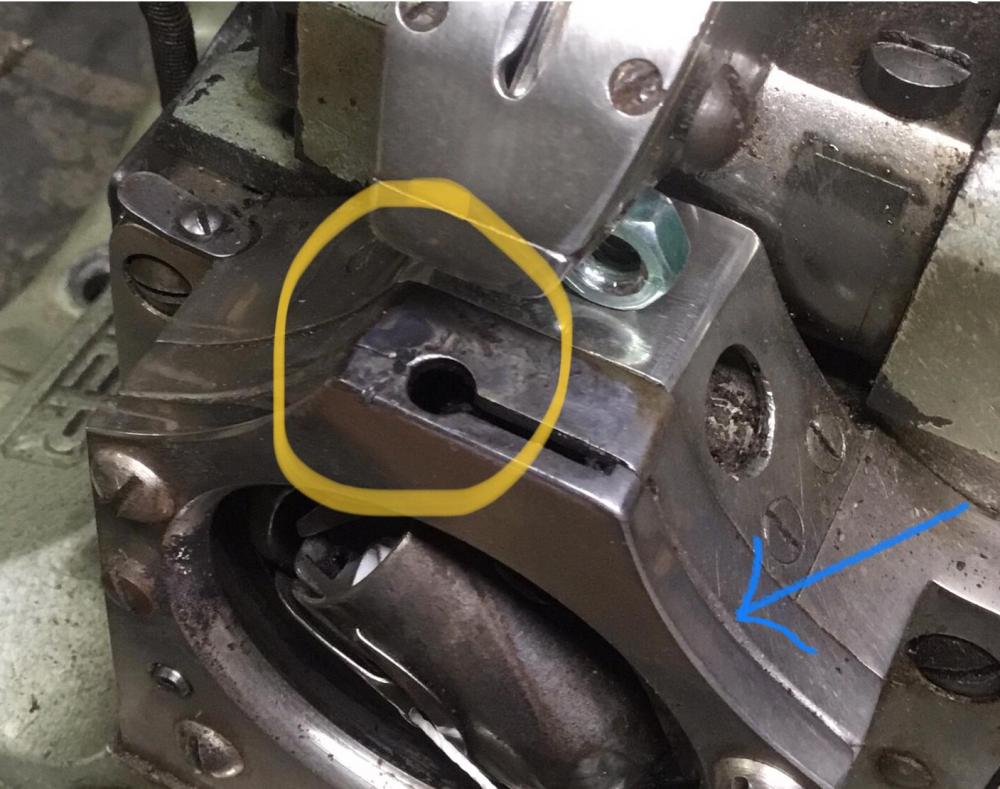

If it works here is a picture of the part in question. The circle is the spot that needs fixed and the blue line is where the 2 pieces split. Any thoughts or suggestions?

-

Hello all. Short and quick question that I know won't have a short answer. I have a Gritzner sole stitching machine that works like a charm. When stitching the wet leather sole, the chrome face plate is turning my leather sole black (chrome worn off). I am wanting to rechrome the faceplate but wanted to get everybody's opinion first. Has anybody successfully had parts rechromed for sewing machines? Would it be cost effective or would the tolerances be out of wack by doing so. The reason I want to rechrome is the wonderful world of google returns nothing as far as Gritzner or Frobana new parts. If anybody has a good source for parts I would be equally interested.

-

I would sure appreciate a copy, leathermoose@yahoo.com

-

Original Price Of Singer/adler Shoe Patch Machines?

DavidP replied to PonyEdwards's topic in Leather Sewing Machines

I know this is an old topic but I wanted to let people know that yes the price varies. The prices for said Singer machine in my area are running $1200-1500. These machines have been sitting in a closed up shop or garage for some time. I would like to say shop around but I will not buy a machine that I cannot visualize and sew on first so that knocks out buying over the internet. Thanks for listening.- 11 replies

-

- singer shoe patch

- 29k

-

(and 1 more)

Tagged with:

-

I know this has been a while but I have a question. In the manual it states the needle and awl should be about 1/16 of an inch apart, isn't that a long distance?? I also read somewhere in this forum(can't find it again) that somebody said the needle and awl should be about the thickness of a fingernail apart. Any input?? Also in the maintenance manual it pairs the 23-47 needle with 23-45 awl. I have 22-50 needle with 23-45 awl, could this be why I am having problems with my machine working correctly?? I bought the machine with this needle and awl combination. If anybody could help would be great. Thanks

-

The machine works fine when moved by hand and when no shoe on the rest. I can run it all day long when it is empty. I have come to the conclusion it is just operator error and inexperience. I think I might be pushing the boot too hard into throat of machine, as it is the stitches are only about an 1/8 inch from outside edge of leather. I am going to play around with different amounts of pressure holding a boot in place. As for the groover, it was not pushed down to the level of the leather. I will get it lowered and give it a try. Thanks for your help.

- 4 replies

-

- curved needle

- bent needle

-

(and 1 more)

Tagged with: