CowboyBob

-

Posts

3,263 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Blogs

Gallery

Posts posted by CowboyBob

-

-

The manual for this machine is very close to yours.

-

Yes,it is a needle feed that will sew 5/16" using 138 thread max,your holsters would have to be on the very thin side for this machine to sew them.This model is for thinner leathers for sewing wallets,credit card holders.

-

As far as it's backed off I really doubt the tension is the problem,my guess is look for it to be binding ( or getting caught) somewhere between the spool & machine.

-

I have them,give me a call.866-362-7397

-

I've done it before on Landis 12F using a 2-wheel cart fits between the motor & side perfect.It's alittle top heavy so don't tilt back too far.

-

Just get some oil on the parts & it will free up on it's own!

-

53 minutes ago, Tigweldor said:

Re read this posting.

the little round holed lever to take pressure from the thread tensioning discs is mounted on the other side of the head between 2 lock nuts.

You can move the lever up by loosening the top lock nut and tightening the bottom lock nut - thread sticking out the top is about 6mm = 1/4 inch on my machines.

Greetings

Hans

@Tigweldor The older 29-3 doesn't have this adjustment.

-

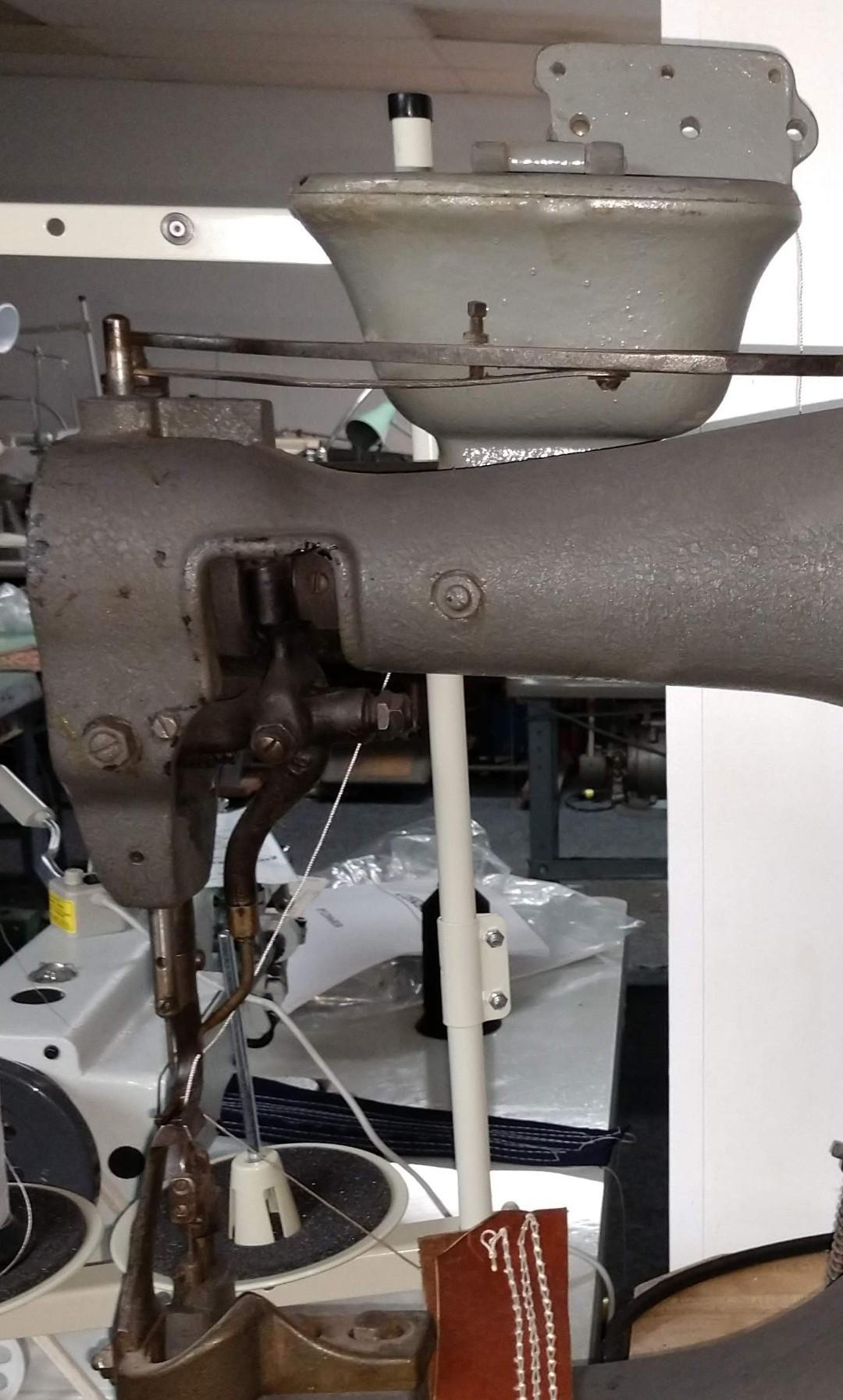

The manual doesn't show threading just some adjustment tips. Here's a pic of one threaded. You go through the tension & then take off the brass piece holding the rubber stripper (at the bottom of the lube pot) run your thread though the rubber & then to the thread throw piece by the needle.

-

Looks Great! You might want to get a smaller (45mm) pulley on the motor for better slow speed control.

-

Yes,there's not many different types of feet out there for a needlefeed.It would be best to file it.

-

If your bobbin thread is showing on top it has nothing with the #23 needles,we have people using that size all the time.I would suspect you need to tighten your bobbincase tension spring to get it to pull down.If that doesn't work you should get a new bobbincase spring.

-

16 hours ago, FDC said:

Hi All!

I'm hoping that someone might be able to steer me in the right direction regarding a 62 tooth metal cleared timing belt for a Singer 51W56. The Singer part number is 234003.

I am interested in the OEM style belt OR a modern alternative and source please.

Any help would be greatly appreciated.

Chris

These have been discontinued many yrs ago,I sure hope you can find one as I have 5 machines here that need them ,I've been looking for at least 10 yrs.

-

@cadet4x4 Here's another manual 111w Navy Repair manual - Copy.pdf

-

12 hours ago, Tigweldor said:

Yup - it sure is.

This is a picture of the defective but crudely repaired part.

If I were to live 20 klicks south of Timbuktu where no spare parts are available, I might have tried to weld up the missing piece inside the ring and then try to grind it smooth.

BUT : time is also money - so why bother, when I was in the position to buy a complete "parts machine" for 20€ - with a singer treadle table to boot for that small price ?

Not only that - I wanted to point out that the Singer 29K51 head fits 1:1 as replacement for the Adler30-7 head - the only difference being that the foot pressure spring on the Adler is external on the back of the machine (spring bar) where as the 29K51 has a coil spring right inside the head to accomplish same thing.

I thought to have pointed out all of this in the answers before - but then again, English is not my mother tongue so it may not have come across clearly.

The part in the pic has meanwhile landed in my scrap metal bucket, as I have no further use for it - with not a single tear lost over that act.

needs a plate on top to enlargen the table though, because the "footprint" of the 29K-33 is a lot larger than that of the 29K-51.

You can use 2-pieces of angle iron,I use old bed frame cut the length of the legs to extend the mounting surface on the short top.

-

11 minutes ago, GerryR said:

I'm working on a project, just for my amusement, where I changed the needle stroke (I'm presently using the 135x16 needles) of the machine. Because of this the added stroke causes the shoulder of the needle to just enter the leather on 16 oz and and above, widening the hole at the needle entry point. I read that the 328 needles have a 1.98mm shank diameter up to size 140 and a larger shank(s) after that. the 135x16 needles have a 1.98mm shank. If the 328 needles have a slightly longer blade, I could cut the shank to get the same total needle length (~45mm) and keep the shoulder away from the leather. This is part of my conversion project of a Chinese patcher to using M-style bobbins. If the total length of the 328 is near 60mm, as Tigwelder indicated, then maybe I chose the wrong system to modify. Like I said, just amusing myself.

Look @ the 190 system of needles it measures 1.98mm shank & 44.50 mm from top of needle to top of the eye hole making it approx 6mm longer than a 135x16

-

The best way is counter-clockwise.

-

4 hours ago, kgg said:

My take without seeing any photo's:

With a crack that severe there are three questions that need to be answered.

1) Does it move freely and sew? If not it there are more then likely internal damaged / misaligned parts.

2) What parts are damaged / misaligned / bend inside. Parts for Durkopp Adler in general can be expensive and depending on the age of the machine they maybe difficult to get.

3) Welding can be done on case iron but and it is a big but can the machine be welded properly so nothing internally warps. If the crack could be repaired it does beg the question why hasn't the repair shop had it done?

Personally I would consider this a parts machine so it's worth is next to nothing except to someone with the same or similar model. As for the repair shop well I would would be very wary and probably consider finding another repair shop.

Since you are looking at cylinder arm machine I have two suggestions:

1) Set a realistic budget. My rule of thumb if I'm looking for a used machine for myself I am willing to pay 60% to 70 % of the cost a new machine if it is owned by a hobbyist.

2) Determine the class of machine that covers 90% of what you plan on sewing. As a quick reference: i) The Juki DNU-1541S and clones for Flatbed needs. ii) The Juki LS-1341 and clones for Cylinder Arm needs. These machines in general cover most needs.

If it is going to be your main machine I would suggest a cylinder arm machine with a flatbed attachment and probably go with a new machine. Clone machines and there are many are a cost effective way.

kgg

Here's one we welded years ago & he's still using it.But every repair is different.

-

20 minutes ago, DavidMM said:

Hi I have just purchased a 29u171, and need a manual, and also if possible where I can find some info on on the machine. The serial no is UY80401014

Many thanks

David

-

-

-

1 hour ago, Trucker said:

Thanks for that!

That's the detail I need to understand the mechanics and settings of how these things work.

One thing to check before you do any timing,turn the stitch length to "0" & make sure the feed dog in centered in the slot.

-

4 hours ago, Trucker said:

I've just purchased the Cowboy 6900, (4800?) the first electric machine ive ever used. Been quite the learning curve! Mainly teaching my left foot... Had an Outlaw for several years but found its limits with bag making and thinner leathers. I have made 3 or 4 bags quite successfully and am loving it so far. So much easier and more accurate with 2 hands holding the work

Problem is I had a jam that tripped the clutch. Mistake learned! Reset it but now the stitch length is way too short for the dial numbers and it's not walking the material thru properly. Looks like the dog is sitting too high and maybe not timed right, seems to grab the material and pull it back to the front. It stitches okay so hook timing is good, but a 6 on the dial is only about 2 or 3mm on the leather now.

Something has shifted.

Watched and read everything I can, but not sure what, where and how to adjust to make it right. Help please?

Here's an engineers manual on the theCB341 that should work on this model too.

-

@SkullzandHides I have some dark brown (Chesnut) in 415

-

9 minutes ago, Southerngunner said:

I tried that several times and it doesnt move at all when engaging the lift. Where might be the best place to order one , and are they different between the 1 or 2 models since I'm not sure if mine is a 255-1 or 2

Give me a call,we stock them,both 1 & 2 take the same part.They are a real buggar to install.

Sewing machine safety

in Leather Sewing Machines

Posted

Hope you heal up quickly,just remember to use it once in a while to keep the blood flowing,LOL!! Had a guy in here one time that got one in his thumbnail,had pics & x-rays to show me,said it took 3 hrs operation the get it out(went into the bone)Closest I've ever came was a needle broke once hit me in the cheek,felt like it stuck in.Glad I have to wear glasses & recommend safety glasses when sewing.

Stay safe!