hackish

Members-

Posts

40 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Blogs

Gallery

Store

Everything posted by hackish

-

I've had the shuttle spring in and out probably 5 times so it is definitely clean. For the lower tension on the machine itself I can watch the tension pulley rotate with each stitch so there is nothing evident there. I've had every part of the machine I can think of apart several times. I may have reached my limit of frustration. I think I should buy a few parts I know need replacing and buy a Consew 733-5 or 733-25. The number of hours I've wasted on this machine I probably could have bought a new one anyway.

-

The thread is not the issue. I've tried 3 different cones of it and it's the identical brand and type the factory uses on the identical machine. I have fixed the skipped stitch issue, it's just the mystery loops forming on the top of the seam now.

-

The shuttle is not worn. It's a 50 year old new part that was never used. The threads are supposed to cross in the middle of the material but it's going to be a ratio between top and bottom tension. At this point I'm feeling like I should just return the machine to the seller and go buy a consew 7-33 or something like that instead.

-

Don't quite understand what you mean about the second tensioner. It's wrapped all the way around the tension disc to make sure it doesn't slip. The manual was printed in 1918. That was before nylon was invented so I expect old cotton thread only needed a single loop. The lube pot does add some tension to it but it's consistent. I expect that would be at most a tiny change while the problems I'm having are not tweaks to stitch quality, they're major problems. The thread is coated (resin perhaps) and that's what the white flaky stuff is - I could omit the pot. I can try shimming it. It would be nice to eliminate slop, but the feed dogs fit so well in the needle plate that the slop is only there when I've taken the plate off. The shuttle tension spring is not really rough but I feel like its related to the problem because it is limited on the amount of tension it can apply. I'm not sure how much is necessary when sewing such thick material. I might spend a few more hours this evening to see if I can make any headway.

-

There is a good amount of right/left play in the feed dogs but I haven't figured out how to tighten it. The shaft is in there firmly but I think the only way to tighten up the feed is to shim it since the assembly that holds it is cast. Although not ideal, I'm not feeling like that is the issue because I can feed it smoothly. It has to be something in the tension. Any suggestions on how much tension to use for the bottom?

-

The harness that I'm sewing specifies that many SPI as well as the thread and needle type. These machines are industry standard as is the needle size. It has to be sewn to spec. I've tried changing the needle. You can more or less see the thread path. The thread goes all the way around the lower tension disc before exiting through the spring.

-

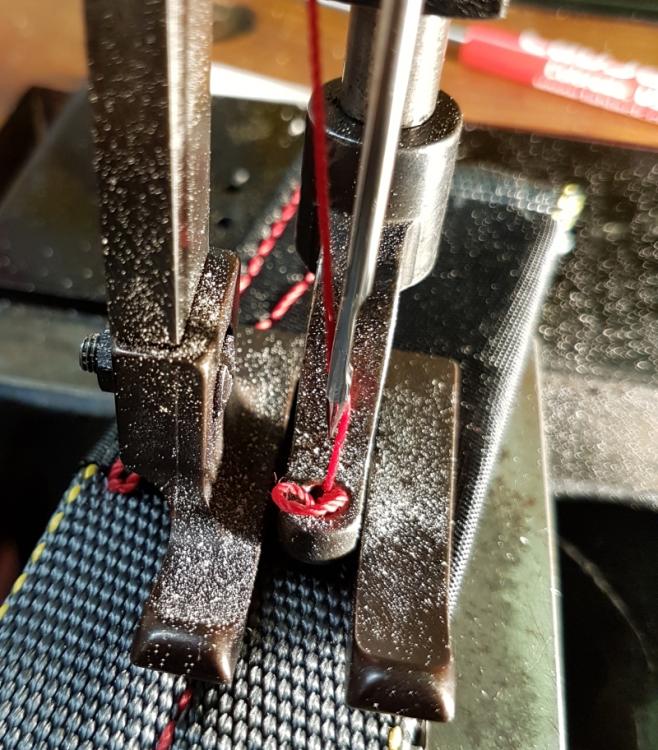

I tried more and less pressure on the foot. No difference. I re-adjusted everything including the hook. This time I dropped the needle bar so the eye of the needle is far below the 1/32" the manual says - more like 1/8" below the hook tip. It's not dropping stitches anymore but the loops forming on the top are more pronounced now. It seems to me that it could be related to bottom tension but it's like a loop of loose thread is forming on the bottom and then is being pulled through the material by a "kink" in the thread as the needle rises. I need a transparent sewing machine so I can see what's happening while it sews!

-

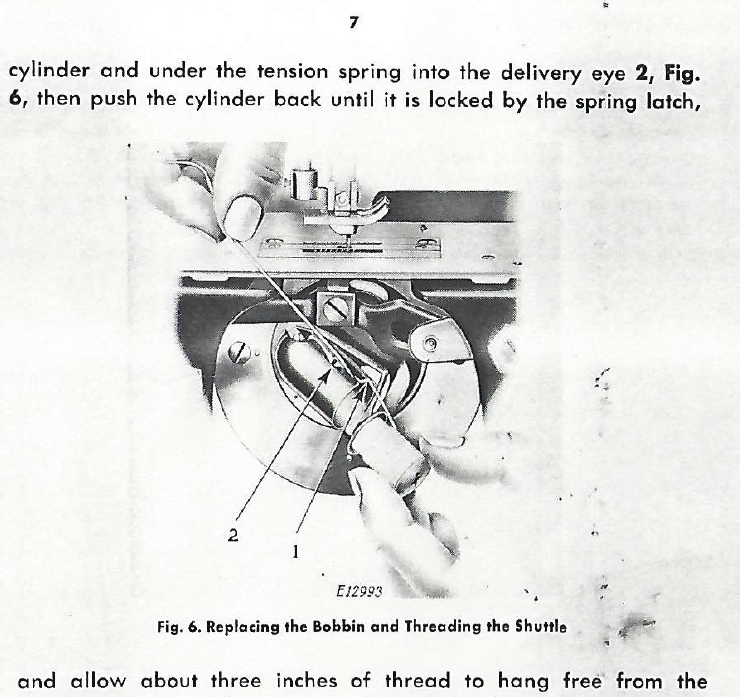

Oh so much fun! Have a look at this one from the Singer manual. I wonder which is better? I can play around a little with it reversed and see what happens.

-

I'm used to bobbins that turn in the reverse direction but I followed the manual which shows it coming off the top of the bobbin and to the carrier. Pretty sure this is correct...

-

As mentioned, I've adjusted the needle bar height a number of times but with little difference. Just spent the last 2 hours playing with the hook distance. Too close and the top thread gets cut, too far and the loop gets missed. This is the top layer and I can see no reason why the big loop is occurring - it doesn't coincide with a start/stop or anything I can see. You can also see a few where the tension is not quite optimal but the stitch is still well formed. This is the bottom of the same piece. Again, the tension here is OK and teh stitches are formed somewhere near the center of the sample. On these there is still a tiny bit of thread nicking so I may try backing the hook off by maybe 0.010". Next step, maybe I will grab my gopro from work and see if I can record the shuttle to see if there is anything catching or jamming. -Michael

-

I bought a 7-33. It's actually for stitching harness webbing. As soon as I try to stitch heavy material it will randomly skip stitches or make giant loops of top thread on the top of the material. This happens even when slowly hand-wheeling it and the bottom thread is not pulled into the material when it happens. I've never seen this sort of problem before. I replaced the hook with a real singer one and adjusted the spacing so it barely touches the needle - reduced but didn't eliminate the skipped stitches. I think the problem is in tension. Since parts are hard to come by I've started machining a few new parts to try and correct the problem. Although helpful the only supplier I've been talking to is really hard to buy from. I've probably spent 4h trying to get through on the phone to give a visa number! The original upper tension assembly was bent to hell and the sewing thread was catching the metal threads slightly so I made a new one using a junk chinese mill. I'm not proud of the result but it's serviceable. Thread is 348 weight using an organ #27 needle. Needle size and thread are well established standards for sewing this material as is the machine. The timing is not adjustable and there is nothing to indicate it's grossly out. I've played with a lot of needle bar height settings without making any progress. Any insight into what else I should be looking at? -Michael

-

Talk to Giroux sewing in Cornwall. Paul is the owner there. He has a ton of parts and usually originals for a good price. If not, he can usually tell you which aftermarket ones are quality and which ones are junk.

-

I Need To Tell You How Much I Hate The Consew Servo Motor...

hackish replied to JimC's topic in Leather Sewing Machines

Wish I had time to play with it. I'm sure I could build a controller but it would take $25,000 in R&D time and $10,000 in up-front production to have 1000 made. I have found a few servo controllers on ebay. Seems you can buy an industrial one for $250. I should order one and see if I could coax it into running one of the motors I have. $375ish still isn't that bad for a good working servo setup. -

I once ordered a timing belt and pulleys from stock drive products to solve a situation like this. In most cases the pulleys are simply installed on a standard sized shaft so you can order practically any set of standard toothed timing belt pulleys as long as the ratio matches - no need to stick to an end of life original setup or low quality asian knock-off parts when you can make commonly available industrial parts do the job.

-

I Need To Tell You How Much I Hate The Consew Servo Motor...

hackish replied to JimC's topic in Leather Sewing Machines

I'm joining in this conversation because I've had a similar experience with servo motors. All the ones I've found are simply chinese re-brands of the same junk. I've opened 1/2 dozen motors from $120-$300USD and they innards are identical. Some of them advertise 500 or 750w yet have exactly the same motor and controller boards inside. They also seem to have fake UL labels on them considering basics of electrical design are not followed (high voltage floating grounds on the synchronizer for example!) In other words they seem to tell you what they think you want to hear. I disassembled a needle positioner and installed it in my 20U but the Consew CSM1000 does not seem to ramp the speed up and down very nicely so it does not start/stop smoothly and depending on the position sometimes flies past the top/bottom sync and does a double stitch. I also have a CS1001 on my double needle machine and it suffers similar problems. I have not yet had a chance to do the pencil mod inside. At this point I want to buy a servo for my class 7 machine but given all the problems I'm considering buying a non-sewing industrial servo motor driver and programming it to do what I want. It would be interesting to syncrhonize it but I know these little junky controllers would never be able to stop/start a heavy machine with any reliability. If I had infinite time I'd just design my own controller for the cheap motor kits so they could be setup safetly to do what we want and just plug a USB device in and program it as you like.