Dave4

Members-

Posts

44 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Blogs

Gallery

Store

Everything posted by Dave4

-

Need info and advice on presses and dies and things.......

Dave4 replied to Dave4's topic in Leatherwork Conversation

A little more follow-up: I bought the ebay press linked by hobbledcobbler above. It's a nice press, better fit and finish. It has a 8x1.25 metric thread where you screw the upper die into the ram. It has a 12mm hole for the lower die stud. The Goldstar press and dies are also a 12mm lower die stud, but they have a non-standard thread on the ram and upper die: 6mm major diameter (2.38") x 24tpi (approximately 1.06 on the metric pitch scale). So the measured specification of the external diameter of the screw on the Goldstar upper dies and ram is 6x1.06. It's just different enough that you cannot run a standard 6x1.0 metric screw into the ram. You can however run a 1/4" x 24tpi screw into the ram if you can find such an animal. The ANSI spec for 1/4" screws is 20 and 28 tpi, not 24. Bottom line: Goldstar is providing a press and dies with non-standard threads, apparently to ensure that you cannot run their dies in someone else's press, or their press with someone else's dies. The Goldstar upper dies definitely do not fit the ebay press. The dies from Goldstar are high quality dies and the selection is fairly comprehensive, so their kit is suitable for most purposes. Their component selection is thinner than what you will find at other providers, especially for colors other than brass and silver and for components with shorter stems for use in thinner materials, but the Goldstar rivet dies do work with metric rivets from two other providers we have tried. I'll find out this week whether the Goldstar grommet dies work with standard #3 and #4 grommets from other suppliers. The Ah Kwok grommets do not match the #0, #2, #3, #4, and #5 standard grommet dimensions. They are high quality grommets and are a good fit for our uses (smaller diameter flanges for a smaller overall footprint but still having a hole big enough for our straps), but it is apparent that you will need their dies to set their grommets. I'm trying to obtain the anvil stud and upper thread specs for their dies, to know whether they will fit anyone else's press. schwew! -

That's exactly what I was thinking when I saw it. Many thanks for the procedure Gregg. DS

-

Hi Ferg, I saw a 2010 thread where you mentioned a smooth needle plate for a 206RB machine. Did you ever find one?

I have occasional projects with 5-7 oz leather with both sides "finished side out", therefore I'd be interested in any tips you can share on setting this machine up so that it doesn't leave serration marks on the leather. I just got the machine a week or so ago, and I'm currently getting set up. I'm following a lot of Wiz's suggestions from over the years, but thought I'd ask you about your experiences.

Thanks!

-

Thanks Eric, I have those manuals: both Instruction and Parts. The adjuster's section of the Instr manual is handy, but if there is an actual service manual floating around, I'd love to have a copy. I finished the clean-up yesterday. Waiting on a few parts. I must have found 15 different fasteners that were loose. Set screws, pinch screws, etc. I'm seriously considering taking this thing apart so I can check the 20 or so screws you can't get to without taking it down, but I hesitate to just start ripping stuff off without a true service manual for parts specs and reassembly. Maybe I'll just bend that presser bar spring a little and see how it goes. Thx, DS

-

Awesome, thanks guys, I really appreciate it. More questions: 1 - My check spring stop has a notch where the spring hits the stop. Is that notch supposed to be there, or did it get cut by the spring? 2 - See photos. My presser bar spring made a black dent in the paint where it hits the casting when the presser is down. Is that normal, or is my spring wore out? Maybe something else is out of whack? I also noticed the regulating screw doesn't line up with the notch on the spine of the spring, but I'm not sure if that's important. 3 - Who sells a service manual? 4 - Who sells a pedal kit to convert the presser lift to pedal-chain? Thanks!

-

Thanks Floyd, it's pretty smooth, maybe I better go out and check if it's still going from the last time I cranked it. I have a User and Parts manual, would love a 206RB service manual if one is floating around. I do have the Navy Chapter 4 225 service manual, 1541 service manual, and an "adjustment procedure" manual for 145/545, so I'm not completely in the dark. Those manuals don't help with the questions above. Thx.

-

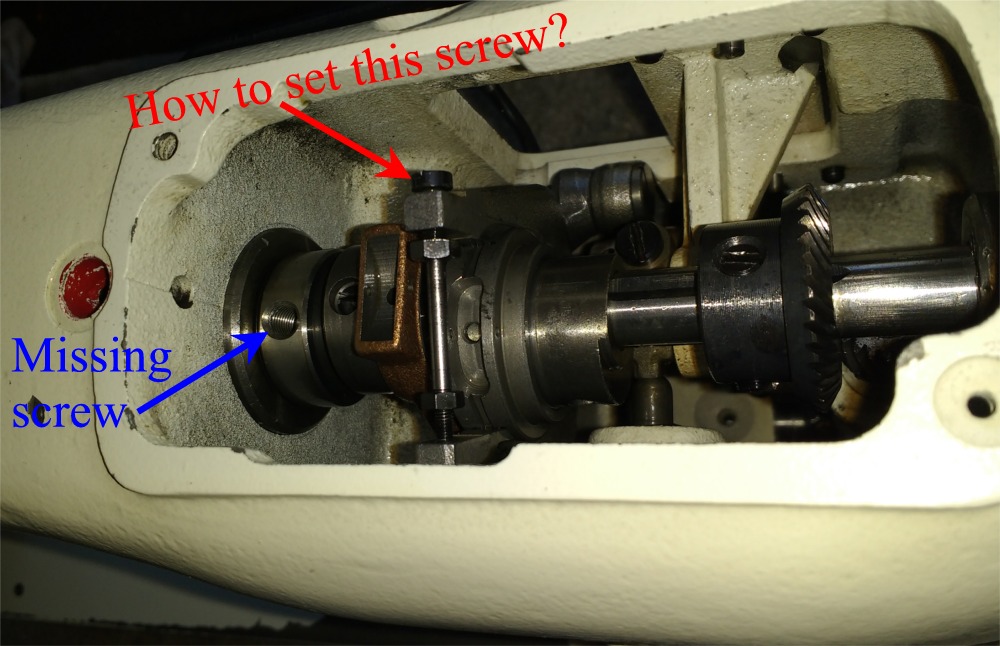

New to me 206RB4, from a wildland firefighter apparel factory. Came with servo table. I bought a smaller motor pulley. I initially thought it was a 3, but it's a 4 TH. It was well oiled, but really dirty. A lot of the wicks were clogged or torn. I removed covers, plates, and wicks, then rolled the head around in a tub while hosing it with kerosene from a deck sprayer, then blew it out. I looks much better inside than I expected, rolls really smooth. Apparently, fasteners come loose over time in a factory machine. The nut for the oil wick clamp fell out of the upper rear window while I was cleaning. One set screw for the arm shaft bushing collar is missing. A set screw for the lower shaft gear had come loose, backed all the way out until it hit the inside of the gear cover BANG broke the gear cover and then hung up in the excess grease. I bet that was loud. No telling how long ago it happened. Lucky that screw didn't get caught up in the gears. The set screw and hole and gears are fine, i cleaned and re-used the set screw. Gonna need a new gear cover. See photo. Moral: it might be worth checking the 8 set screws for the 4 gears periodically when you service your machine. I have multiple diameters of new felt I can use to cut & replace wick pads. I took photos of the long wick routes. Most of them look like easy installs except for the one that routes leftward into the arm shaft area. Questions: 1 - This machine will be used for slow-speed work, only 5 hours per week average. In this environment, are the long wicks even necessary? I'm pretty good about oiling my machines, and have some nice long dispenser tubes for my oil cans. Thoughts? Don't get me wrong, I fully appreciate the engineering and convenience of the oiling system, and a full set of wicks is less than $20, I don't mind going either way. I know that my work environment is less demanding, I have a machine maintenance day every month, and I know how to oil a machine. Just curious if anyone else has relevant experience. 2 - I pulled a couple of pretty fat felt wick pads out some pretty small holes. I anticipate some potential swearing getting some of those back in place. For future reference, are there any wicks or pads on this machine that are typically "never removed because you gotta take something apart to reinstall the wick"? Any tips or tricks for reinstalling any certain wicks? 3 - On my machine, the long wick that hangs down from the right side of the upper oil reservoir was torn up and dangling inside the tower, so I don't have any reference as to routing or destination of this wick. Way down inside the tower, I see the dime-sized concave-dished oil hole on the upper surface of the casting that holds the lower shaft bushing between gears and clutch. Mine was blocked with lint and dirt, but it's totally clean now. How is that hole oiled? Was the torn wick supposed to reach that far down? If so, routing? I can reach that hole with an oil can extension tube, but I like learning how it was supposed to be from the factory. 4 - There is a long screw with 2 lock nuts spanning the top of the big feed fork. It's loose, not really doing anything. It is apparently some kind of reinforcing pinch screw to stabilize the top end of the big fork. What is the procedure or spec for setting this screw? See photo. 5 - I'd love to find a source for the big Consew sticker that goes on the front of the arm. Mine is long gone. Are these still available? That's it for now. I'm sure I'll have more questions soon. Thanks for your help! DS

-

Need info and advice on presses and dies and things.......

Dave4 replied to Dave4's topic in Leatherwork Conversation

Wrap-up of my personal journey: If you're new to rivets / grommets / snaps, it is a mild shock to discover the incongruity of this particular arena. Hand-setting with a hammer and appropriate punch and anvil can be a good & fast fit for workflow because you don't have to move anywhere, you just grab nearby tools and whack your piece. Hand-setting can also be loud, unhealthy for joints, and even inconsistent in terms of quality and appearance of set, at least for mortal craftsmen, and especially when you start setting large components. Advance planning is good. If you can order needed parts 1 month prior to project start, you'll have time to recover if your ordered parts don't work as expected. A 10 day advance time period can be plenty if there are no surprises, or it can frustrate you to no end if surprises occur. (Nothing new here). Presses are a moderate investment. Dies for the presses are a bigger investment. Not all dies fit all presses. Even worse, not all components fit all dies. Rivet stem length is an important variable. You need to find rivets that have stem lengths that match your project thickness. A too-short rivet stem will make a weak or no set; a too-long rivet stem will be crooked or weak because of excess stem material curled up under the two halves. An eyelet is a grommet. Some grommet providers limit their selection of grommets and dies to #0, #2, #4. Like rivets, some grommets have longer stems than other grommets of the same ID. Some good vendors will sell multiple stem lengths for the same size rivet or grommet, for example: 8mm rivets with either 8mm or 6mm stems, etc. If their products fit your dies, then you are good to go. If their products don't fit your dies, then you need to buy their dies or find another components vendor. Sometimes the only solution is to use 4 different vendors to get the components you need, and the difficulty of this task is compounded by the fact that not every vendor's components will fit your family of dies, unless you have a huge cross-component family of dies, which translates to big money. Example: you cannot set an http://www.ahkwokbuckles.com/grommets.html 14mm grommet using a goldstartool #3 or #4 die. ahkwok is a great vendor for excellent components at great prices, but they only offer a handful of dies, and no hole-cutter dies, and their dies won't fit other companies presses. Goldstar is a great provider for presses and any die you could want, but their selection of components or colors is smaller in some areas, and their dies or presses won't fit presses or dies from some other companies. See more comments on other companies in posts above. Self cutting grommet systems are for thin projects. I haven't yet found a grommet setting die that has it's own cutting action. All of the cutting from self-cutting systems is done by the grommet itself. If you work with thick materials, pounding thin-walled grommets through tough material is not a recipe for craftsmanship. You need hole-cutter dies to pre-cut the holes. Ring snaps are strong and usually "plainer" snap systems. Their primary retention feature is a single split steel ring that is contained in the female side of the snap. I'm pretty sure that rings snaps are the most commonly used snap in leatherworking. Spring snaps are not weak, are more eloquent, are usually available in more decorous configurations, and can certainly be used for leatherwork, but they seem to be steered more towards lighter pieces. Their primary retention feature is 2 parallel wire "bars" observable on one side of the snap assembly. There are other specialty snap systems available. Ultimately, for me anyway, presses and die and components are a lot like sewing machines. You need to put some money into them to get what you need, so newcomers should just plan to make some products to sell to make some money, and work their way slowly up to the ideal shop for their goals. Or, inherit some money and buy a 1st class set-up on day 1. I realized last night that I had fallen into a whining paradigm, brought on I think by exasperation at my inability to quickly identify and buy exactly what I need for rivets and grommets and snaps for less than $500. I think they call this "being new". Today, I contacted Dave at Goldstar and explained my problems with my original purchase, and i also provided a list of additional equipment I needed to purchase now (#3 grommet kit, #4 hole cutter, 20 ligne ring snap kit). It took Dave 2 minutes to address and resolve all of my problems, without hesitation. Bang. Done. I admit, I was pretty pissed off back in July, but that seems like a really long time ago. IMO - Goldstar and Green Grizzly offer the most bang for the buck in this arena. They have extensive lines of dies and components. If you are in the states, GG purchases will be accompanied by moderate shipping costs and overseas transit times. I live in a west coast state. Goldstar ships free and UPS ground is 2 days. They stood behind their product line when I had problems. So my plan is to expand my die and components family by staying with Goldstar. Thanks to everyone for their comments. Hopefully my wrap-up will save the next noob a little time. -

dikman makes an important point. When I was shopping for a compound feed walking foot flatbed machine, i narrowed the field with the following considerations: Singer 111w155 - the original design, no reverse, parts are fairly easy to find and inexpensive. Singer 211 - newer version of 111, has reverse, some parts are shared, others are hard to find. Seiko STH-8BLD into the current generation 3, and Consew 206RB through generation 4 with a TH serial number - these are basically all the same machine with only minor differences, they share many parts which are all easy to find and inexpensive. These are japanese machines, very well made. Today's Consews and perhaps even the Seiko are now made in Chinese factories, but there has been no huge slide in quality according to most dealers. I also looked at Consew 225/226 and 255 style machines, which are capable and have available and affordable parts, but I chose to stay with a 206 style machine. Juki LU 562/563 and 1508/1541 - Japanese manufacturer, very good quality, same type of machine, parts are easy to find but a little more expensive. Pfaff - 145 / 545 / 1245 family - same type of machine, very good quality, parts are hard to find and very expensive. There is a TacSew machine that belongs to this family and probably shares many parts, but I did not research this machine so I don't know anything about it. National 300N - same family, worth mentioning, but I don't know anything about it. IMO, these are the machines to keep an eye out for. They will do anything you need up until you start sewing over 3/8" of material. I really thought I'd bring my 26 home, clean it and start sewing, but the farther i went into it, the more little parts and screws I found that were missing or needed replacing. I ended up needing about 15 little things, but they were easy to find online and inexpensive to buy because my machine is a 206RB and not a 545. Good luck!

-

Need info and advice on presses and dies and things.......

Dave4 replied to Dave4's topic in Leatherwork Conversation

Hi Tom. Yes, it was Dave. I'm learning more: the style of grommet die in my photo above is for self-cutting grommets. The upper die captures and holds the grommet inverted. You wedge it into the spring-bound outer ring and it just sticks there. The lower die holds the washer. The grommet edge cuts the material as you actuate the ram. The die itself has no cutting action. The grommet OD must match the upper die exactly, or the die won't capture it. The other type of die used with self-cutting grommets is a cylinder with a protruding split (forked) center pin. You pinch the split pin halves together, place the grommet over the pin, and release the pinch to capture the grommet. My personal progress is realizing that i don't need either type. I just need standard grommet dies, because we think that a hole cutter die will be necessary for our thick pieces, rather than trying to cut each hole with the grommet edge. What i still need to learn more about is neck length. If the compressed material thickness is 3mm, how long a neck can you run before you simply have too much neck length? We succeeded with a 7mm neck, but the grommet size we want has a 9mm neck from some vendors, and i'm reluctant to buy them without trying to first learn whether 6mm of excess neck will simply be too much. Tandy doesn't have dies for grommet sizes we use, and their die prices are just too dang high. Their grommet dies max out at 1/4" size grommet. We need 7/16"+. Thanks for the link though, I did check it out. The Tandy press looks the same as the campbell randall HP1 press linked by the hobbled one. I'm studying on whether it runs a standard 3/8 base die, and if so, what other die families might fit the sale-price Tandy press and allow you to get away from Tandy components and dies. Hob - your ebay link doesn't look like the exact press i got from Goldstar. To me, the ebay unit looks much better. It's good to know that the GS dies fit that press. Press price is good, but my current need is not finding another press for the same die family. Bopp - agree. In fact, the tandy press throat also looks stingy. Photo attached. Rivets heads have a very shallow dome, and rivet dies require only a very shallow concave shape to keep from crushing the dome during the set. If you get the light at a good angle, it is very easy to distinguish between a concave and flat die face. The concave faces have circular machining marks and make a prevalent "propeller" ghost in the light. Flat die faces just look flat. Single-sided rivets can be set with a double-sided die, but not vice versa, as the one flat face of a SS die will mar the dome on one side of a DS rivet. The photo shows my GS rivet dies: the incorrect 9mm die that was labeled "double sided", the replacement 10mm DS die, and the original and proper 14mm DS die. Is this photo what you needed? I'm open to more feedback and advice. My goal is a decent press with dies for 6mm, 8 or 9mm, and 12 or 14mm SS and DS rivets, also setter and hole-cutter dies for #3, #4, and #5 roll crimp 2-part grommets in antique brass and nickel colors (this is the 7/16 to 5/8" ID neighborhood, or 10 to 15mm), also snap dies for good snaps, which I need to learn more about, such as which snaps are most prevalent and why. Thanks! -

Dom - For starters, stay optimistic! Coupla months ago, I drove 4 hrs to Bend to buy a 31-15 for $80. It was in an old solid wood clutch table. It was cheap because the machine had no paint. I cleaned it and shot it with duplicolor black auto paint and cleared it with shellac over a Keeler decal set ($11) installed wrong so nobody could try to claim it was original. I sanded the table, stained it with leftover pecan, routered out the dual belt window, shot leftover black oil-base on the frame, and shot the table top with shellac. Then I talked to Bob. He spewed $1 million dollars worth of Singer 31 info in 12 minutes, then I could never get ahold of him again. I figured he went to New Zealand. I put a $110 servo on the table, bought a $19 small motor pulley on ebay, and built my own bigger handwheel pulley. I bought a $20 shuttle race assy (which you need because they wear out, which i learned from Bob), and a $20 set of (3) wheel feet with a single-row dog and plate, and also a $8 teflon foot. I got some 69 and 92 BN thread at a thrift shop for $2 a spool. So I got a total of $280 in this thing, and it is fine! Wife digs it. Can you blame her? It looks great, and sews even better. Check out the cig marks on the right. There were actually twice that many, but I sanded half away. I left the remainder on purpose to preserve a little character, and also in case i decide to start smoking. Here's what we learned: if you run 69 thread in this machine, it sews like butter. If you tension 92 properly, it sews but it grumbles. If you properly tension 138 in it, it sounds awful. We only tried that once. Several weeks ago, I talked to Gregg about used Cornsews. He spewed just over $600,000 worth of 206 info in about 15 minutes. I sent him an email a day later to clarify exactly what I would get for the $800 price for a refurbed 206 head only. No response. I called, got the answering machine, figured he went to Guam. I drove to Bend, bought a 206RB3 in a table converted to servo (FS) for $500. Should be done cleaning it up by Tuesday. I needed cornsew feet, so I emailed Ohio, got no response, checked with my man ngosew in Salem, got R&L zipper, regular smooth, left toe smooth, inside raised toe, 3 sizes of right-side guide feet, a bobbin case and 10 bobbins for $93. Good to go. Last week I called around looking for 135x16 needles in LL (NTW) or S (NCR) or DIA tips because i didn't want to be confined to just using TRI or RTW or NW points, because the S and LL points make straighter stitches than just about any other tip, where the S or DIA is a really open stitch, and the LL is really tight and closed. I even called Ohio to make inquiries, and Bob answered the phone! He said he'd look into it and get back to me, but I never heard anything back, assumed he went off to the Northwest Territories. I called Abe at Diamond, he was brisk but polite. I got his girl on the phone, she was the best. I bought 600 needles from them (a very small order for them, and I'm glad they tolerated my small order), so i now have DIA and LL points for leather in 16, 18, 22, 23. BTW, if you are still reading this and you have always wondered what LL or DIA points will do, but you didn't want to drop $45 to get 100 of one needle, mebbe you should send me a PM. I have more than I need of LL18, LL22, LL23, DIA16, DIA18, DIA23, all Organ 135x16, new in unopened 10-wrappers. Mebbe I'd sell a set of six 10-packs, one of each needle type listed above, 60 needles total, $35 delivered conus. Mebbe I'd do this as many as 4 times, not in any other configuration than what i described just now, unless you want all 120 for $70, or 240 for $140. KISS, etc. I digress. Dominic, if your material is only two layers 8mm total, either one of the machines mentioned above will easily do everything you need, and they can be found for reasonable prices. The 31 is just a fast oversized bottom-feed SS machine with a nice motor and some style points. There are other non-compound feed non-walking foot industrials out there that will do your job. If your piece has a "hump" anywhere in it, where you have to sew multiple layers and the bottom layer has a stitch line or edge that creates a "hump", it seems to me that a needle feed is the minimum requirement to consistently sew over that hump without skipping or making an irregular stitch, but I'm fairly new and you can get better advice from others here. My message for you: stay optimistic and patient. Good deals come along, even for people like me who live in counties where cattle outnumber humans by 3x.

-

A few months ago, I bought a Goldstar press with two double-sided rivet dies (9mm & 12mm) and one #4 grommet die. $125 delivered. The 9mm set was actually a single-sided set with a flat bottom die. See photos. I sent these photos to Goldstar and asked for a replacement. I got a very quick and very short reply: " xxxxxxxxxx! So I placed several phone calls and sent more email and photos (unpleasantly worded). I literally had to teach the owner and his employee the difference between a double and single sided rivet and associated die set, because they absolutely had no idea about the significance of flat-faced vs concave-faced rivet dies. Not kidding. They had no idea. I asked for a quick overnight replacement because their mistake had bottlenecked our run. They did ultimately ship a replacement, but in 10mm size, because they didn't have double sided sets in 9mm, they only had single-sided sets in 9mm that were packaged in bags labeled 9mm double-sided. They shipped the 10MM replacement ground, arrived 5 days later. Nice. The hinge pin for the press was a loose-fitting threaded bolt. I replaced it with a 6" x 1/4" steel rod (nice tight fit), then drilled a wood dowel and drove the dowel onto the rod, creating a handle. See photo. Ultimate outcome: a week late, we were finally setting rivets, although we were using a 10mm die to set our 9mm rivets. It worked, so we just did it. Yes - we were frustrated by the whole experience. Fast forward to today: we tried the #4 Goldstar grommet die (designed to work with Goldstar 28x15x9mm grommets) with our pre-existing supply of Ah Kwok 23x14x7mm grommets. Unsurprisingly, and through no fault of Goldstar, they don't work. This is actually what led me to post today, I guess everything before this point is just FYI stuff that is fair for me to share with the board because it might help someone in the future. I'm at a decision point: I can abandon Goldstar completely and buy a different press with the rivet and grommet dies I need, or I can buy some Goldstar #4 grommets for the dies I already have and also some additional Goldstar #3 grommets and dies, because my next project requires those. If I abandon Goldstar, I gotta spend ~$300-$500. If I stay with Goldstar, I only have to spend $150, but I have two potential problems: 1 - who knows what they will ship me once I place my order; 2 - Goldstar grommets in #3 and #4 size have 2 or 3mm longer necks than most other vendors. It seems like a 5 or 6mm neck is common, they are selling 7 or 9mm necks. My fabric thickness is not super thick; I place grommets in 2 or 3 layers of 12oz linen, or one layer each of 4oz leather and 12 oz linen. Am I correct in thinking that Goldstar grommet necks are just too long for most applications? What happens when the neck is too long? Will it still curl away nicely, or will it pile up and look like crap? Faced with many decisions, I started reading. A lot. Woe the lack of standardization in rivets and grommets and snaps and dies and presses! What a freakin mess this is. Below is a photo of the Goldstar grommet die. It is unlike most grommet dies you see from other vendors. Fasnap shows a similar die set here for $218 (wow). Is this style of die a dual function hole-cutting grommet die, intended to cut the hole as well as press the grommet? Or, is it just a different design that is still mainly intended to press grommets into pre-existing holes? Goldstar sells hole-cutter dies. I'm not sure whether I need hole cutter dies with this style grommet die. Goldstar won't know. So I gotta ask here. If you buy a dual function hole-cutting grommet-pressing die, does it require the accompanying use of self-cutting grommets, or does the die do the cutting work all by itself? IMO - with thick fabrics or thin soft leathers, the best approach would seem to be a 2-stage process of cutting the hole with a hole cutter die, then placing the grommet with a grommet setter die. It seems to me that self-cutting dies and/or self-cutting grommets may be well-suited to thin stuff, but will likely struggle in thick material. What is your experience? Is there such an animal as a 12mm or 14mm self-cutting grommet-setting die system that will work effectively in thicker material? Vendors I looked at: Fasnap - can't afford it. Weaver Little Wonder - good press, but $350. Die sets are $30 to $40 each. For me, it would be $500 for the press with 4 die sets, no cutting die included. Ohio Travel Bag - press is $165, 3-piece grommet die sets (cutter incl) are $60 each, only 2 available sizes of rivet dies available, no clear distinction between ss vs ds rivets (you use the same die for both), only 2 sizes of snap dies available. For me, it would be $480 for the press + 4 die sets, cutter included. Harbor freight arbor press - $50, customize it to fit whatever die system you want; perhaps overlap several 3/8 "American size" die systems. Not as handy as a simple "squash it" press because you gotta manipulate the slider handle, but adaptable to just about any die and therefore any component. Anyone here done this? Tips, advice? What dies are you using? Photos? Green Grizzly!! - UK, nice looking cast aluminum press with complete die sets sold in very affordable package deals, plus good selection of colors and sizes of rivets, grommets, and snaps. Here is a press with 19 die sets for less than $300 delivered. The press looks pretty decent. Anyone using this? Tips or advice? Anyone discovered crossover compatibility with other brands of components or dies? Goldstar - pretty full selection of components and dies, but uncertain whether you will get what you ordered, mild language barrier, no product knowledge, not the greatest press. I think I'm leaning towards Green Grizzly, but would like to hear from the hive. What else is out there? I need to learn more about crossover compatibility of dies and components. I need to learn if ladies hate the arbor press approach, because I'm married to a lady who will be using the press. Sorry for this massive post, but I just got to that point where I have way too many hours invested in trying to get a simple rivet and grommet press system set up, and my brain is no longer functioning effectively, so I wrote a summary of where I'm at and I will look at it again tomorrow. I chose to save my summary here because you can get some really good help and advice on this forum. :D

-

Singer 31-15 bed dimensions vs other machines

Dave4 replied to Dave4's topic in Leather Sewing Machines

great info, thanks Gregg! -

Singer 31-15 bed dimensions vs other machines

Dave4 replied to Dave4's topic in Leather Sewing Machines

Many thanks! -

Quick question : Which, if any, triple-feed flatbeds can drop into a table for a 31-15? I'm looking at the consew 206 / juki lu563 / Singer 111 / Pfaff 545 family. I'm away from home right now, so i can't measure bed dimensions etc on my 31-15 table. If the 31-15 bed doesn't match, are the triple feeds a bigger footprint, such that i could router my table to make them fit? Many thanks!

-

Hey - thanks for the replies! I can include international prices whenever they are provided. So far Mike, it looks like all your machines were less than $600. brmax, i see your point & thanks for the feedback. If I buy a machine, I intend to use the board and other resources to learn about it. I don't think a shopping list for newbs will interfere with the learning process of those who still wish to learn. 4-yr old thread: http://leatherworker.net/forum/topic/40710-fabric-sewing-machines-for-leather/ : Sylvia sews 4oz with an easy feed on a Brother; Cheryl 15-91, CowboyBob praises 15-91 and 31-15, Nick 201K, Spinner Husky 315, Anne mentions 15's, pfaff 30's, 1950's Jap, Art says 15, 31, 201, 66, 301, and a few others will work fine for lite duty up to 10oz of chrome or soft handed veg sewing with up to 45 and sometimes 69 thread, Wiz talks 15-91, Hooligan echos +201. 7-yr old thread: http://leatherworker.net/forum/topic/20945-singer-201/ : guy asks about a 201, Art says NO!, Wiz recommends $1000+ rigs, guys asks about budget machines, Wiz sez 111, Art says "There are literally 100s of posts on this very subject on this forum.", Wiz writes an excellent essay, Particle says 'We need a sticky because these are very common questions', etc. So people have been asking the same questions here for at least 7 yrs. And lots of people have been buying various old-iron machines at yard sales for $100 and dropping another $200 into them and then sewing their butts off on garment or upholstery leather and making cool stuff and never thinking of spending $1500 on a machine. That's what I'm after. As a newb, I have no idea what to look for on craigslist or at yardsales. No newb does, but they always ask. Let's make a list! What are the 1950's Jap machines? What brand, what model, what color, what size, what the heck are they? What's a 15, 30, 201, 111, 211? What's a 78-3? What's a 144WSV33? 145W103? Which pfaff's? What are they? What else is out there in old iron that can be used for light-leather? What are the big ol WF industrials to keep your lucky eye peeled for? Take your time. Pick one machine, spec it out, I'll add it to the list. Wait a week, do another. Colt - thanks for a great start! SPM, not spi. How fast are you running it? Thanks everyone! The spreadsheet link is at the bottom of the OP. Just click the link.

-

This board gets a lot of threads where newbies ask about budget vintage light-leather starter machines or budget vintage WF machines. I'm one of them! With so many machines on the planet, knowing what to look for is half the battle. Especially for newbs! If I've learned one thing here already, it's that this board has a lot of folks who know models and specs and capabilities of sewing machines! It'd be great to have a list assembled in one place of viable budget starter leather machines with relevant info and comments for each. Perhaps two classes: Non-WF models that can be made to work, and purpose-built WF Models that sometimes pop up at lower price levels. A few possible examples: 15-91, 31-15, old Japanese makes, etc. WF's - 111', etc, etc. Non-WF models: Brand & Model, Years Made, Type and Thickness of leather that can be sewn, Even-feed or WF available?, expected Clearance Loss from installed WF, Clutch-Motor?, Servo-Motor adaptable?, Needle Size range, Thread Size range, expected Price to pay at a garage or estate sale, expected Cost for Modifications (WF, Servo, etc), Comments on duty-level, Top-3 Items to check when first looking at the machine, SPM Comments, Other Comments. Older WF models: Brand & Model, Years Made, Type and Thickness of leather that can be sewn, Feed Type, Clutch-Motor?, Servo-Motor adaptable?, Needle Size range, Thread Size range, SPM Comments, expected Price to pay at a garage or estate sale, Other Comments, Top-3 Items to check when first looking at the machine. Let's limit the total expected machine cost to a range of $100 to $600, including mods. Let's exclude the TuffSew genre. If the membership is willing, fire away! I'll compose and maintain a pdf chart of the info provided, and link it right here on this post. Also, please suggest changes or additions to my spec list. It was compiled by a newb! We will assume that machine buyers will take responsibility for learning about required maintenance & lubrication after purchase, and will start new threads to ask about parts or repairs. Thanks. All input or feedback is welcome! SewRev1.pdf

-

Thanks folks! Too bad, I was hoping the 245-4 might be workable. Thanks for the list Constabulary. I think we're just going to have to keep reading and learning.

-

Hello, new member here. Great site! We're newcomers to leatherworking, but not sewing. We're hoping to find a bargain on a starter machine that is suitable for 2 layers of leather up to 5/16" total. Our projects are bags and straps. Some bags may have seams joining heavy canvas or denim to leather. Our leather material range is 3oz to 8oz. Maybe occasional work with 10oz (maybe). I've read Wiz's big thread (thanks Wiz!) and many others. It's a lot of info to take in but we're beginning to get an understanding of some of the important factors: walking foot, needle size and thread size compatibility, stitch length, sewing speed, servo vs clutch control, etc. My questions: 1.) For nylon or polyester threads, what is a typical range of thread sizes used in our range of materials and projects? Is 69 to 207 a reasonable range, or should I be looking smaller or bigger? 2.) Photos attached: a machine we found in our area. Singer 245-4, straight stitch. Located a few hours away, haven't seen it in person yet. That doesn't seem to be a walking foot in the photo. Am I correct? Pulley sizes suggest reduced speed. Correct? Clutch-type drive, correct? Anyone know what range of needle sizes it takes? Is this a good candidate for a starter machine? If so, assuming reasonable condition, what would you hope to pay? Please share any comments you have on what may be needed to make a good leather sewer out of it, parts availability, add-ons, etc. Thanks!