-

Posts

2,234 -

Joined

-

Last visited

About Ferg

- Birthday 01/21/1934

Profile Information

-

Gender

Male

-

Location

Southwestern Ohio

-

Interests

Anything I can do with my hands and mind

LW Info

-

Leatherwork Specialty

Everything that is unusual

-

Interested in learning about

everything

-

How did you find leatherworker.net?

Web

Recent Profile Visitors

33,820 profile views

Ferg's Achievements

Leatherworker.net Regular (4/4)

-

Ferg started following Leather punching with complex shapes? , Scissor Sharping , Bob Park- Creating Western Floral Designs and 6 others

-

You are putting wrong angle on blades. Sharpened area should be no more than one or two mm back from cutting edge. You have filed the edge at least 60 degree angle when they should be right at 30 degrees. Fine grade file that is new and finish with about 600 grit stone.

-

One of the finest individuals I never met in leather work. I think I may have spoken to him on the phone once but most likely e-mails. He never declined to answer any of my many questions. I wish him and family the best. Hard when losing your mate.

-

That's funny. I needed your response to that post after a not too great past week!

-

-

Did you ever bite the bullet and get a CO2 Laser? Or are you cutting these with a Diode? Nice work anyway. Ferg

-

-

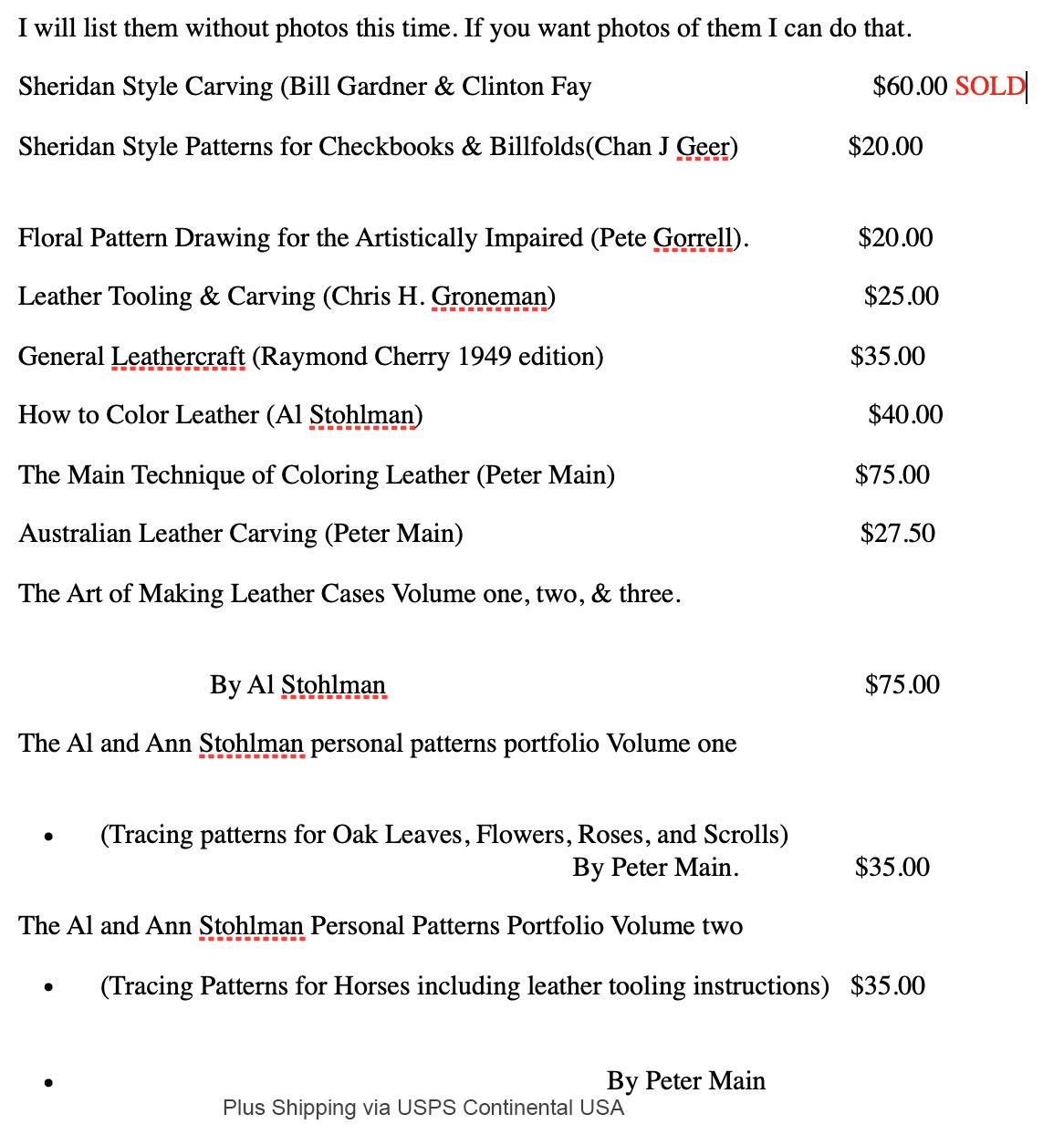

As I have said many times, "I have been at this a long time." There are probably as many ways to do this as there are folks trying. That said: I run the tap water so it is moderately warm. I hold the leather under the faucet until there are no bubbles emitting from leather, turn it over to opposite side and do the same. Use an old terry cloth towel or old clean T-shirt laying it flat on table, lay the dampened leather on top of the cloth and roll the towel and leather together. Leave overnight. When you unroll it next day it will be damp and a little darker in color than when dry plus very pliable. Lay the leather out on your stone you use to engrave and stamp. Allow the leather to dry enough you can see it begin to change back to original color. It is ready to work. Naturally it will dry out as you work your stamping. Use a large cellulose sponge that is wet, not dripping, to go over the leather piece. This will replace some or most of the moisture you started with. Continue your carving or stamping. When I am finished with the engrave I make sure the piece is laying flat and place the towel over it overnight. You can do what ever finish you wish at this time plus the leather will take an impression with a personalized stamp with ample pressure. Hope this helps. Remember one very important thing. Take your time with casing the leather. Do it correctly and you will never regret your results. Photo is of a piece I carved over 40 years ago after using above tempering method. Ferg

-

Awww! Woman Repurposes Mom's Singer in Her Memory

Ferg replied to Sheilajeanne's topic in All About Us and Off Topic

What a delightful story and fantastic woodwork. Have often wished I had saved my mom's old Singer -

Machine Man looking to become a better Leatherworker

Ferg replied to mbnaegle's topic in Member Gallery

You have had a very interesting life. I have worked with leather for over 70 years, not a lot recently with too many physical limitations. Most of my life's work has been in residential and light commercial building plus over 40 years of manufacturing wooden commercial cabinetry and decorative items for the home and children's wooden puzzles. I have always felt woodworking and leather go hand-in-hand. Stick around. We all learn new things every day. -

I have an unrelated/related question for the OP. Why on earth are you soaking your leather overnight or longer? Do you know how to "Temper" leather?

-

I forget where I got those punches. I placed colored leather on the backs of the leather I filigreed. I have been at this a long time and learn something I missed every day.

-

I have a set of 39 filigree punches I will sell for $125 plus shipping. A little difficult photographing them unless I done them one at a time.