-

Posts

2,277 -

Joined

-

Last visited

About Ferg

- Birthday 01/21/1934

Profile Information

-

Gender

Male

-

Location

Southwestern Ohio

-

Interests

Anything I can do with my hands and mind

LW Info

-

Leatherwork Specialty

Everything that is unusual

-

Interested in learning about

everything

-

How did you find leatherworker.net?

Web

Recent Profile Visitors

35,437 profile views

Ferg's Achievements

Leatherworker.net Regular (4/4)

-

Left handed Shoemakers insole/channel knife made by Tina of Germany. Sells new for $219.00 I am selling new out of box for $175.00 plus shipping New TEKTON TOOLS Nipper/Tack puller Made in USA $20.00 plus shipping NEW - LASTING PLIERS $40.00 plus shipping NEW - BRASS SMOOTHING TOOL. Used for smoothing leather toe area of shoes and heel area. I paid good money for this tool. $25.00 plus shipping More later

-

Top photo is of an Osborne six inch round knife. I bought this when I was in the Navy Circa 1954. Number embossed in blade doesn't come up on Google. It has been ground professionally and cuts leather like butter. There is a slightly flat spot at the top of arch. I do not remember why that is there. $50 plus shipping Round knife at bottom of photo was custom made for me by Terry Knipshield. Three and a quarter inches tip to tip. This is a top of the line blade. I used it to skive leather and cut intricate pieces of leather. Blade is scary sharp. $200 -=SOLD=- plus shipping. I will not take less for this blade PayPal or Postal Money order

-

Buying A 227R What I Have To Check The Most?

Ferg replied to BodegaBrasil's topic in Leather Sewing Machines

Bob and Bobbie are not only great at their business, they are great individuals and will give you a good deal. As Wiz said, they have rooms full of everything -

I have eight more hides of this LAMBSKIN leather varying in size from about 6 sq ft to 7.5 sq ft. All same color and thickness. Anyone wish to have more than the three or if you wish to buy only two, I will give you a good deal. Just let me know.

-

4.5 sq ft x .8mm LAMBSKIN #3 Nice hide the bright streaks in photo are my leather room lights reflecting. I used this leather for lining purses, making pockets for purses, and inside wallets and card holders among other things. I had taken some cuts from this hide $25.00 plus shipping We take PayPal

-

7.5 sq ft x .8mm LAMBSKIN #2 Nice hide the bright streaks in photo are my leather room lights reflecting. I used this leather for lining purses, making pockets for purses, and inside wallets and card holders among other things. $50.00 plus shipping We take PayPal

-

6 sq ft x .8mm LAMBSKIN #1 Nice hide the bright streaks in photo are my leather room lights reflecting. I used this leather for lining purses, making pockets for purses, and inside wallets and card holders among other things. $50.00 plus shipping We take PayPal

-

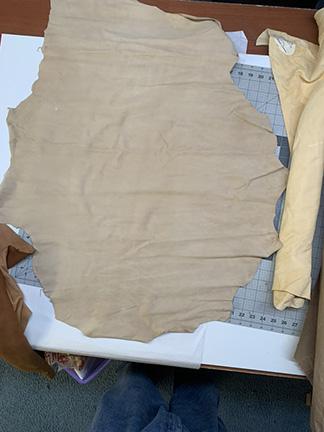

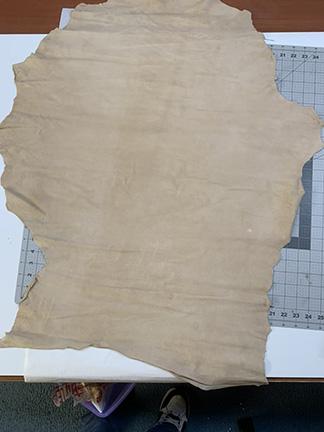

Approximately 4 sq.ft. Great for gloves and small clothing accessories etc. Approximately 4.5 sq.ft. Great for gloves and small clothing accessories etc. Almost 5 sq.ft. GARMENT CHAMOIS LEATHER. Great for gloves and other small clothing accessories.etc $20 each or all three for $55 plus shipping. These are good grade chamois. Wrinkles can be pressed out easily. These are not intended for polishing your car but could be used for that.

-

Heads Up:I am going to sell most all my leather "stuff"

Ferg replied to Ferg's topic in Hand Tools-Leatherworking Tools

Kangaroo leather will last forever I think. I have made many small items from it as well as wallet insides. -

Spent five days in hospital up to almost Christmas. Too many things going on to elaborate at this time. I desperately need to get rid of lots of leather tools etc, I have including hides. Going to hang onto my electric sewing machines. I have quite a few Kangaroo hides of different colors. Will try to list them as I can get them suitable for photos. It has been a long journey for me since 1953. It has come time to make it possible for someone else to enjoy what I have been blessed to obtain. Will try to make the items attractive in price without giving away the house. Ferg

-

You should be able to play with your settings to minimize the charring. I keep a box of what would be throwaways for trial and error work. lol

-

Chuck, Advantage I see? I keep the laser file, engrave to leather anytime I wish. The engraving should take about 30 to 60 seconds. The drawing is precisely the same every time.

-

You can get a trial version of LightBurn and you won't have to do all this fiddling you guys are doing. Yes it has a learning curve. I find anything worth doing is doing it with the right program or tools. Personally, I hate InkScape.

-

Neila, You are a true artist, in leather and artwork. Ferg