Japi

Members-

Posts

11 -

Joined

-

Last visited

Profile Information

-

Location

UK

-

Interests

Everything

LW Info

-

Leatherwork Specialty

Yes

-

Interested in learning about

Everything else To stop learning is to die.

Recent Profile Visitors

2,210 profile views

Japi's Achievements

Member (2/4)

-

-

You should look for a knife that you can use day in day out for all the jobs that come along. There are many different one's to chose from. All knife makers want to stand out from the crowd. In the old days there were knives that did everything. Long cuts, belt cuts, skiving, shaping, curves, straight lines, etc. etc. Knives were tools for workmen. They used them everyday to make their living and they were expensive. When they found one that worked for them they kept it. I know an old saddle maker who only ever used two knives. They did every job he needed to do and at the end of the day he left them in the workshop and went home. Nowadays people have collections of knives. They use a different one for every job they do and they have several that do the same thing in different sizes and styles. I started like the saddle maker, mainly because there were not many knife makers when I was young, and because they were too expensive to have one or two just lying on the bench not doing anything. Now I have boxes of them. All kinds from hand made to worn out veterans of the 1800's. The main thing is what kind of stile do you hold it? Thumb in centre or thumb in corner? Blades that are fat and have a ground edge are not so good for grip. It is good to be able to look along your thumb and see the point that the blade meets the cut. With a fat blade it's like having to look round a corner. The blade should not bend or be too thin. Learn to sharpen your own knife. It should really be stropped after every few cuts and put to the block at least once or twice a month. If you look after your blade, it will be safer for you. The most dangerous thing is a blunt knife. Osbourne make nice knives, Terry Knipp does too and they are both in America. What ever stile you choose remember it is a knife not a screwdriver. A screwdriver can be used and put back in the drawer for years without much ill effect but a knife requires a little looking after and respect. Do that and it will serve you well for many years. First picture is thumb invented with hand over handle, second she's thumb in corner with hand under handle. This grip works better with larger sized knives. And then there are Quarter knives.....

-

When the Englishman first designed and started selling his burnisher, he did a deal with the people that helped developed it and they sold the burnisher and power source as a unit. Needless to say, it was all a con and the power source was a cheap generic brand , phase 1, two shaft machine that ran at 3000 rmp. Intended for a 150mm wheel power was 370W, Volts 230v- 50Hz and Amps 2. Having developed emphysema, I am no longer able to burnish anything much and nothing well I have used this machine with it's 2 1/4" outside diameter burnishing wheel since I got it, a little before I joined this site in 2016. I don't post much but I try to help. Take care and remember to have fun

-

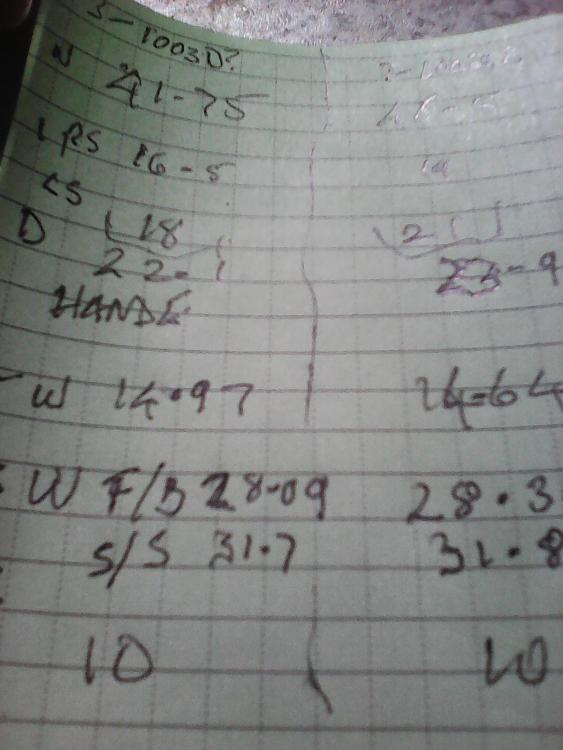

I just bought a skiving knife on e-bay. It was sold as a Verges Blanchard and looks like a 3-1003D but it has a sort of hammered finish on the top face of the blade. I have a 3-1002-2 which is to all intents and purpose the same knife with a rounded blade instead of a slanted one but there are a lot of little differences. If you want the figures I did pics but if you can't read them, please ask. The only thing that is the same in the length of the handle but they are, as I have said, differences in size and weight and of course, they are made of different wood. The main cause for my concert is that the logo is almost impossible to see. The dog is unrecognisable but you can see something and the word BLANCHARD is underneath it. I also bought a set of black steel with red handles frog mouthed pliers which the guy swears are Blanchard but they have no logo. He says he bought them more than ten years ago but there is nothing like them in the current catalogue. I think one of us got ripped, can you help me to find out if was him or me? Thank you in advance for your help

-

There are two types of 'snaps' (we call them 'press studs' just go ahead and laugh) There are one tool snaps and there are two tool snaps. As long as the size of tool or tools matches the size of snap it should work although I understand that there are snap makers with a brand out there who are working to stop that occurrence.

-

The Koreans use a knobbled parallel sided 4inch steel bar handheld turning on bearings within a handle. They use different sized knobbles depending on the viscosity of the edge paint and also whether it's gloss or matt. I have two. They have served me well for many years.

-

Use a good quality stitching iron to mark out your holes first. A groove can help but if you stitch "English" style then marking your stitching holes across a feint scratch line made with a marking awl, a needle, knitting needle or a bent prong of an old fork accurately will be all you need. Just make sure that whatever you use to do the marking is sharp. That goes for your awl too. Look out for Nigel Armitage's YouTube lesson on how to sharpen an awl. Then it's just the same as getting to Carnegie Hall. Practice, practice, practice.

-

You could try "Edgeflex" made in Italy by Fenice. www.Fenice.com. Put it on with a proper edging roller or a cocktail stick in thin layers, two or three should do the trick. If you put it on too thick it will dry in a lump and either hang over the side or come off in bits. This gives a sort of shiny edge that's kind of hard to the touch. If you want a more rubbery, plastic feel try "Maxedge" also from Italy by Giardini. www.leatheredgepaint.com. Don't you hate this autotype feature that keeps respelling words as you type. It always puts a full stop after you type out site addresses, puts gaps in them and keeps respelling Fenice as Venice for me. Ho hum, the technology we have to put up with!

-

Try "Edgeflex" made in Italy by Fenice www.fenice.com. You could also try "Maxedge" by Giardini. www.leatheredgepaint.com. I try!

-

You should check out the Giadini website! www.leatheredgepaint.com. I think this looks like the nearest thing to the real deal you or I are going to get.

-

Chemico sell rubbing paste and cleaning compounds in the UK, what did you say the web site was?