Rosch22

Members-

Posts

27 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Blogs

Gallery

Store

Everything posted by Rosch22

-

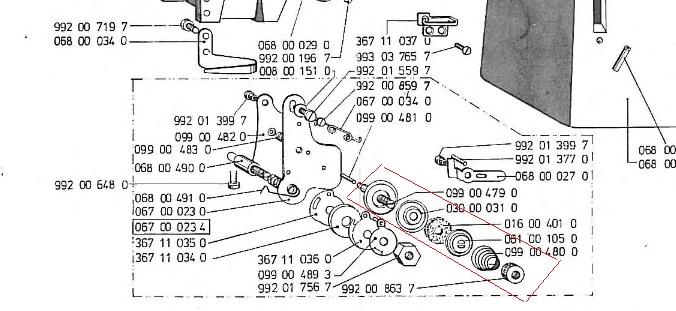

Hi Leathermans, may be there's someone out there who does have what I'm looking for desperately: I have got an old ADLER 167-373. Table, machine, belt and rest in actually good shape. The only bitter pill with it: The whole tension unit (the one we see in the pictures below) is missing! Is there any gentleman out there who has a used one in the shelf somewhere and will give it away for an acceptable amount of money? Would appreciate any offer! Thx and hope to hear from You guys soon.

-

Is This Adler 167 Tension Assembly all Stock?

Rosch22 replied to AlexanderDyer's topic in Leather Sewing Machines

Hi Leathermans, reading this thread, I thought, may be someone out there does have what I'm looking for desperately: I have got an old ADLER 167-373. Table, machine, belt and all in actually good shape. The only bitter pill with it: The whole tension plate (the ones we see in the pictures above) is missing! Is there any gentleman out there who has a used one in the shelf somewhere and will give it away for an acceptable amount of money? Would appreciate any offer! Thx and hope to hear from You guys soon. -

Aaaaaah there it is....little sucker.....hidden on the other side deep in a hole !! Thank You so much, I think I need new glasses too !! ;)))))

-

Hi Guys, I'm looking for a partslist of a Pfaff 138-6. (As shown) Normally it's sort of explosion drawing, where You can work out how parts go togehter. Or any advise how to loosen the needle bar for adjustment would be great too. Would appreciate any help. Thank You all...

-

Dear Leather related Gentlemen ;)), I could lay my hands on a very goodlooking and functional lady, a beautyful and mint used ADLER 167-373 T. Did allready some research and I would think, that the T is standing for textiles, because leathermachines are often marked with L. Does anybody of You guys do own a ADLER T versions and what are your experiences? And: Could I do leather with it all day long ? Thanks in advance for Your kind help. Regards Roland

-

Dear Leatherworkers, a few days ago I looked at a used DA 205-370, which is a cloned ADLER 205-370. It was offered on an online marketplace. Sadly, the way was far, the owner was a miserable character and salesman and the place a horrible run down building with tons of dirt, empty beer bottles and lots of smell. The machine was covered with nasty dust, the price too high and my fear great, to import this horrible smell of this ramschakle-hut into my workshop, which always smells nicely like leather So I decided quick to leave it behind and left the place quicker, than I arrived. Unbelievable, how some people live ?!! Later on I looked again at the differences between the 205 and 441 machines, but I can't make a decision. Both do the job very well for sure. What else are the differences, what do You like on the one, and what do You miss on the other ? Would appreciate Your opinion!! Keep Your needles always sharp ;)) Kindest regards

-

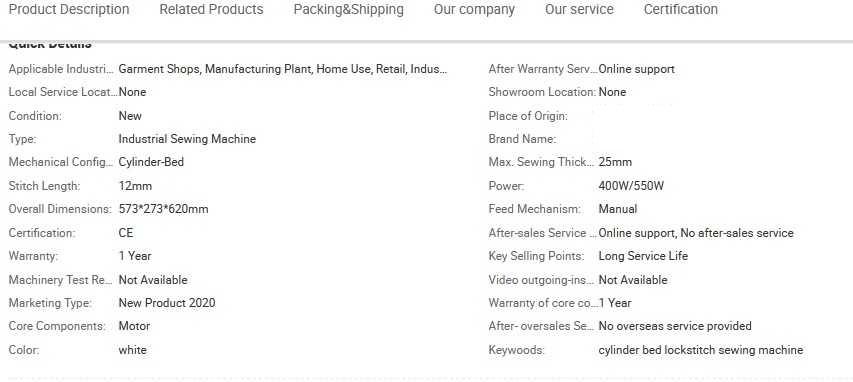

Dear Leatherman, I'm busy getting something new into my workshop and I'm stuck now a little bit. I learned, that Hightex offers 2 different types of TSC 441 small arm clones: - Hightex CB 3200, max foot lift 18mm, - and Hightex CB 3500, max foot lift 23mm, other technical top and bottom insides then CB 3200. Does anybody here has experience with this two different types of machines ? Thanks for Your help and keep allways Your needles sharp ;)))))) Foto by Frank Brunnet

-

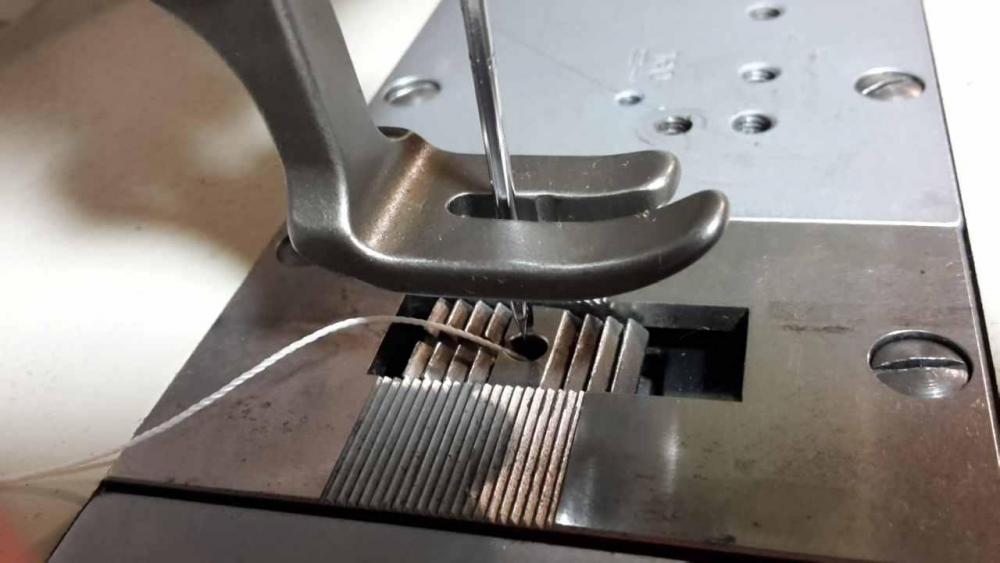

Hi folks, have been busy looking around, to serve my problem and contacted also a pro for a hint ;)))) ! He send me a link for the adjustments of a Pfaff 545, which has about the same features as the ADLER does. Now what I finally did was, bringing the small pressure foot a few millimeters more down (look at picture, that can be adjusted by those two screws, when the needle touches the needleplate with feet up), which has the effect, that the bigger presser foot moves those millimeter higher in walking mode, the smaller then a bit lower. If brought into a usefull relation, all is fine and at WORKS finally very well ! ;)) Have a nice weekend all together ! !!!

-

Hi Michiel, thank You for the information, but this I went through already. This adjustment regulates the height of pressure foot when lifted with lifter. The movement while sewing is too low. So it must be adjusted along this movement.

-

Yes, thank You....that feature I know. But if I move the wing nut from bottom of the " banana" to its highest poition, not much happens to the hight of the presser foot. I need one step deeper into the materia.

-

Hi guys, have a new project with higher material. But the presser foot of my ADLER 167-73 is too low to handle the thickness. The specs out of the books say max foot lift 7mm, but I'm quiet away from those 7mm, means less (in fact 4,5-5mm). Anybody has a technical hint to fix that and reach at least the 7mill ? Thank You in advance.

-

Suppi...Danke !!!!

-

Dear fellows, I rescued a nice little machine called Pfaff 138 short before it went to the scrap yard. The special on this thing is, that it is driven by an 250 watts moretti motor, which sews like a bee flying over flowers, so smooth and nice, driven just by transport from below. With a dial in the middle of the top, a switch from straight to Zigzag sewing is possible. The only flaw I can find is, that the hook is missing some stitches, which could be solved quiet easily, if there wouldn't be that feature, that also twin needles can be plugged in. So I would like to do the timing by the books. Does any one of You guys own a SERVICE MANUAL for this machine ?? Thank You.

-

Puuh....my school english is too lousy to catch up in full what You wrote. Or is it Your PC ??;)) Can You say it in other words please ?

-

Dear Constabulary, I thank You for looking so well after me, but the world isn't so difficult as You see it. At least facts tell the truth. For sure I would have my own agent, who will take over the shipment as soon as it is on european land. Salestaxes are also no problem, because that will be charged directly by customs as the import taxes will be, which are just 3,7% for industrial sewing machines (in my case about 45 EUR). Nobody will take me to jail for this amount of money ;))? @DRY Thank You for Your report. That was the sort of information, I was looking for. Every year just Germany imports goods, machinery, tools etc. for 77 BILLIONS EUR from China. If they would sell shit, those numbers would be different. I thank You all for Your posts and for me I will take a long walk and think about all that. It's great and a privilege to have You guys around to chat about those things.

-

Hi leathermen, Thank You very much for Your all times good arguments. You all look very well for my wellbeing. I like very much the expression of "Juki shaped boat anchor" !!! ;)))))) We have some guys here selling those machines, but I don't feel comfortable with any of them. Its sort of swimming with the sharks. A 441 with stand and a normal cheap clutch motor no extras takes 2.400 EUR plus shipment, which is quiet a piece if compared with the prices in the US. If You like a 1Phase Motor (servo) with a speed reducer instead, we talk about 3.000 EUR plus shipment. A COBRA takes more than 3.500 EUR plus shipment. The chinese head only deal would be 1.200 EUR (saving on EUR $ exchange) door to door all inklusive. No further taxes or duties are charged. That is checked. Thats why I was thinking about it in the first place !!

-

Hi there, I've a very nasty chinese salesgirl from Alibaba on my back, who really wants to sell a TSC 441 Clone to me. The problem is that her offer is very good and transport is cheap. She works for a big manufacturer, so I'm really tempted to go for it. If there wouldn't be that little tentative voice sitting on my shoulder, whispering to me that this chinese girl will not only take my money but also my peace of soul and send me a 441 clone, which was found last year in a corner when cleaning up the workshop, looking for a new stupid owner, who has the money and passions to get it sewing straight. Anybody out there who went through this and can still sleep ? HELP !!!! Kindest regards to all leatherman Roland

-

Hi leatherworkers, some days ago I was on the road and visiting a company busy in all leatherworks. Had a look on the machines, all brands, all types and old as usual, like Adler, Pfaff, Singer....! The ladies working with them did not, to my surprise, hold the thread while starting to sew, they just let the presser foot down and here we go. If I would do that with my Adlers, not holding the thread tight while starting, I could phone the mechanic straightaway to bring the big spareparts bag and start repairing the whole lot. I asked the owner, he said they have a great mechanic who is perfectly setting the machines to highest use and comfort. Wow, anybody of You works the same ? All tips (also the secret ones) are wellcome ;) !

-

Since school I had trouble with physics. And here it strikes me again. Thanks for Your tip. Makes lots of sense!!! Thanks for the idea. I will try.

-

Hi leatherworkers, my adler 269 is a real great machine. Only problem is, if I try to sew paralell close the edge the material moves out to the left side, away from feed dog and presser food. It slides out of line. Even if I hold hardly against it. What must be adjusted to avoid this ? Thanks

-

Hello Leatherworker, just bought a good Adler 269 and I'm looking now for service instructions and all other technical information. Anybody around with a service manual for this machine ? Thanks a lot for any input. Keep save and healthy. Regards Roland

-

Hi Gregg, wasn't here for some time. Found Your post just now. Well, its more than I expected. Thank You so much !! Best regards To Philly Roland

-

Dear leatherworkers, I have a real nice ADLER 204-64 which is fitted with a TEXI Servomotor. I do leatherbelts with it. These days I was cleaning and servicing it and wondered, if the feed dog timing is right ? My thought is, needle enters material, feed dog pushed up, both transport material, needle leaves material ? Is this right so ? Have made some pics for You to check. Pic1 is the whole, Pic2 needle enters feed dog, Pic3 needle deepest point Pic4 needle leaves feed dog Thanks for You help.

-

Hi leathermen, Looking for all manuals or infos about Pfaff 145. Couldn't get hold of any around here. Would appreciate Your help. Thanks. Regards Roland

_s2.thumb.jpg.b3179bdf3054f8fb0ab7e43623f1009e.jpg)