PhilC

Members-

Posts

12 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Blogs

Gallery

Store

Everything posted by PhilC

-

I got a response from Okada, the plane is japanese white oak, and the knife handle is japanese magnolia.

-

-

Hey everyone, i just got a 36 mm tuchime leather knife, mini bean plane, and thread nips from Okada Tools https://okada125.com/store/category/tools/. You can use google translate on the site because its japanese. The knife and plane blades are aogami super blue steel, and i think the nips are aogami #2. Holy crap, these are nice to use. The knife can shave off layers so thin that they break apart when you try to pick them up, i'm really impressed. I'm using the bean plane for my full edge shaping so i dont need to sand anymore, and it makes a nice fully convex edge instead of a flat edge with two knocked off corners as with my normal beveler. It takes more time though, multiple passes for the shaping - def not a high throughput method. They were very responsive while the tools were on the way from japan, but i havent been able to get a reply fro them as to what type of wood they used for the plane of the knife handle. I want to start making tools some day myself so i'd like to know what im working with, anyone have any idea what types of wood these might be?

-

As many have mentioned, acrylics are only going to be optimal for smaller areas that aren't going to see much contact because they are not rub-fast. If the customer isn't the type that is buying this because they expect longevity but more for fashion, which some are, maybe you can use acrylics. Looking at https://fiebing.com/product-color-charts/, it looks like the closest Fiebings dye to light blue would be the turquoise Leather Dye, but keep in mind this stuff is pigment based and has a reputation for drying out the leather and some issues with rubbing off color if its not burnished and sealed correctly. Strangely, theres a light blue Leather Dye on their website that isnt listed on the color chart, might be something to look into https://fiebing.com/product/leather-dye/. Keep in mind that many of these colors are going to turn up darker than expected, especially if multiple layers are applied, and you can dilute them with an appropriate base to make them lighter.

-

Also, i found out that if you are careful, you can apply the dye to the flesh side and it will penetrate everything besides the very top layer of the veg tan, so you get a two toned effect. I am assuming this is how Niwa got this very top layer with the light brown and then purple beneath it! I bet it would work even better with a resist on the grain side.

-

Well i tried Pro dye on 2 mm veg tan, if you put it on the flesh side, it drinks up the dye and soaks right through to the grain side. Its just really dark, so ill try some dilutions and see if i can get full penetration with a decent color to it! Im still interested in hearing about everyones experiences though. My goal is to make some stacked edges with alternating colors like Niwa does, but without having to buy expensive leather like Pueblo because i'm still practicing.

-

Does anyone have experience or know of resources related to dyeing veg tanned leather all the way through? All i have been able to find from my digging so far is that tanneries do it by using a drum. I'd be interested in learning how to do this in small batches, specifically what types of dyes are used. Is it possible to get full penetration on thinner leather like 1 or 1.5 mm with just several applications of alcohol dyes, or would that make the leather too brittle? Thanks!

-

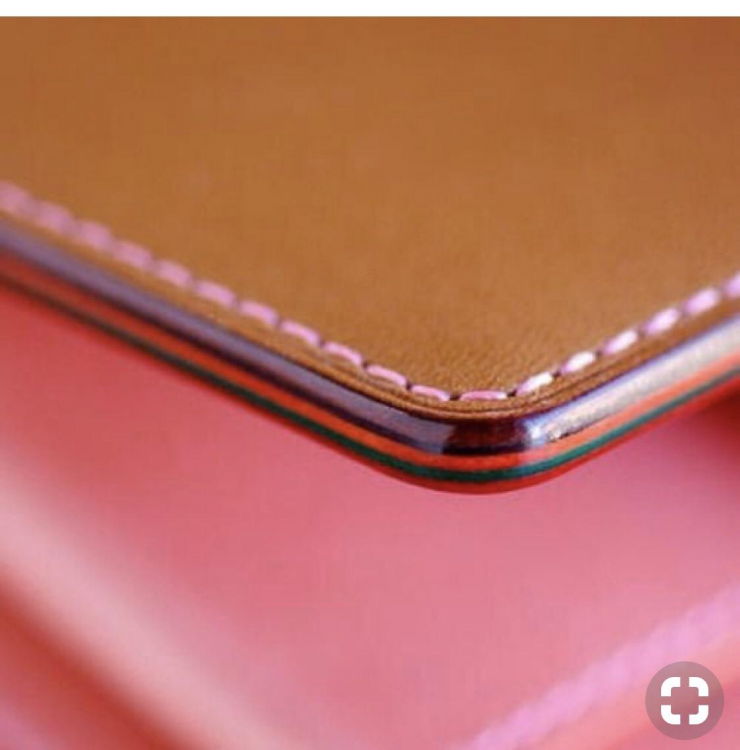

I want to try making a card holder with alternating colors stacked on the edge, like Niwa He uses leather that is already struck through completely so that he can cut/sand/burnish the edges. Does anyone have any experience or know methods of dyeing thinner veg tanned leather, maybe 1 mm, all the way through on a small scale? I cant really afford to be practicing with expensive Pueblo or the likes quite yet... I was thinking maybe if the leather was wet, my Pro Dyes might penetrate further, and maybe it might go all the way if i dye from both sides. Or possibly dyes in an alcohol carrier like Pro dyes might not be the right kind for something like this...i have no idea. Any insight is greatly appreciated! Thank you!

-

pre-neutralised vinegaroon

PhilC replied to Nny's topic in Dyes, Antiques, Stains, Glues, Waxes, Finishes and Conditioners.

I'm unfamilar with vinegaroon, but i recently discovered this leather marbling technique that uses potassium carbonate and ferrous sulfate to make really beautiful marbling patterns on calf leather https://www.hewit.com/skin_deep/?volume=15&article=1. I am going to try it out soon. The recipe dissolves ferrous sulphate in water, so it may be applicable to this discussion.- 5 replies

-

- neutralize

- vinegaroon

-

(and 5 more)

Tagged with:

-

I have been going nuts looking into cool ways to dye and texture leather. I was looking into marbling leather using acrylic or oil paints/dyes when i found the original method of marbling leather (https://www.hewit.com/skin_deep/?volume=3&article=2) used in bookbinding. It uses potassium carbonate and ferrous sulfate in a reaction that etches leather in really beautiful ways(see calf tree marbling http://scholar.library.miami.edu/bound/bindings-page6.html). It is insanely beautiful. He mentions that it has a reputation for deteriorating leather, however. Other sources say that its only an issue if you use solutions that are too concentrated. Has anyone had any experience with this technique, or have some input on ways that might be implemented to neutralize the leather after marbling to prevent or slow down any additional deterioration? I have all the materials on the way to start experimenting. Thanks! By the way, those hewit.com skin deep articles are a treasure trove of traditional leather marbling techniques, most of which were used in the old days of book binding. Additionally this book which you can apparently view online with this wiki https://en.wikisource.org/wiki/The_Art_of_Bookbinding/Chapter_22 has sections devoted to texturing and dyeing calf leather for bookbinding, mostly from very old texts. Check them out!

-

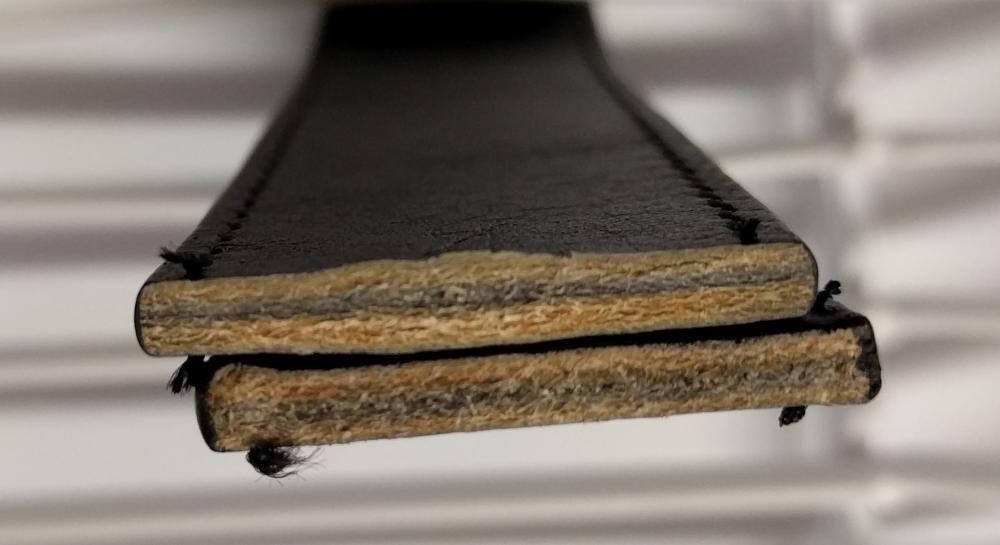

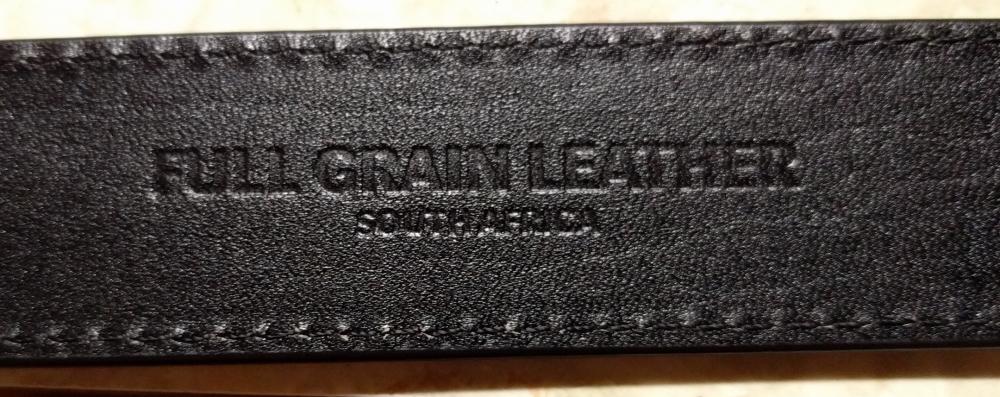

Hey everyone, First post! I came here for your opinion on a recent purchase - a full grain leather belt from a company called Slidebelts. I made this $85 investment hoping to get a belt that i can take care of and maintain so it will last me a very long time. When the belt came, i noticed it appears to be two pieces of leather glued together with two light layers separated by a darker layer in the middle that i am assuming is glue (see pics). I was expecting one piece of leather, although it does not specifically say its one piece in the item description... Based on the picture, am i looking at 2 pieces glued together, is this common practice for a full grain leather belt, does this defeat the purpose / decrease the longevity of the belt? I'm feeling like i may have been bamboozled and would like to make this a learning experience. Thanks for your insight!

- 3 replies

-

- belt

- full grain

-

(and 1 more)

Tagged with: