Brtz

Members-

Posts

42 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Blogs

Gallery

Store

Everything posted by Brtz

-

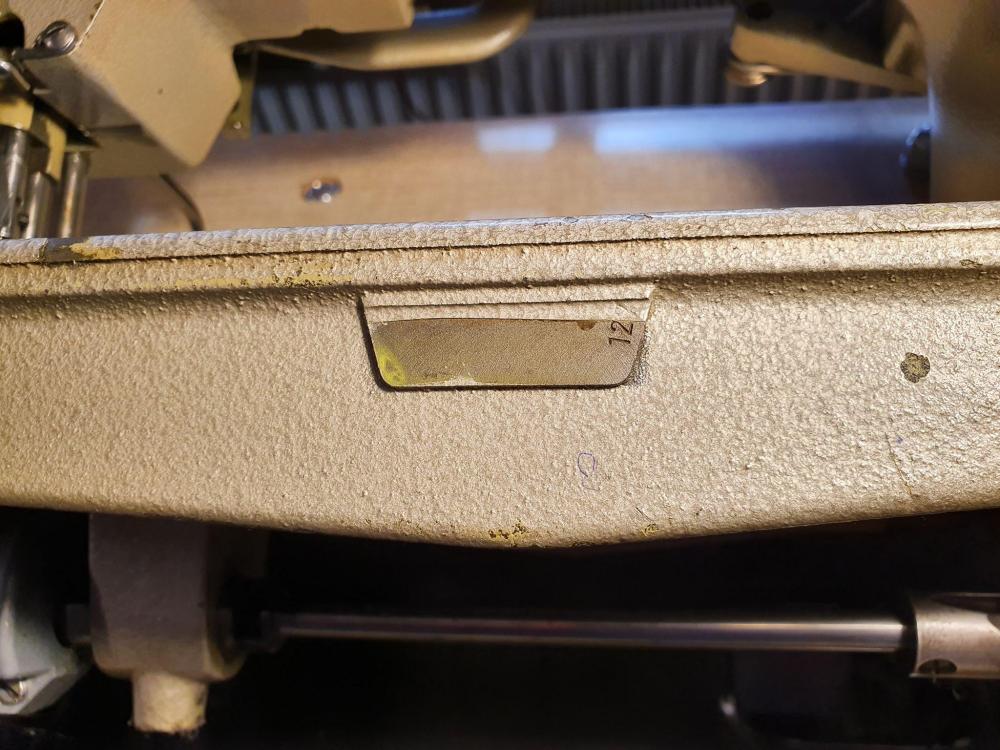

Hi, Can anyone help me to understand why SN on my Pfaff 545-H3 has been placed on the brass badge on the column and the mark on the base is empty? (no stamped number apart of small 127)? - see photo. 1. I do not understand why my Pfaff SN is 765631 while similar machines produced between 1950 - 1976 have SN from 4.000.000 to 8.788.456 (reffering to http://ismacs.net/pfaff/pfaff_manufacture_dates.html)? 2. Was my machine a part of any special editon numbered differently? 3. Which digit is "missing" in my machine SN? First or last? 4. What the small '127' on the base mean? A mark of production facility or foundry? I would be pleased to find a contact to somebody who were working for Pfaff, to know the history and development of 50, 60, 70 - Pfaff machines better. Any sources will be highly appreciated. Thanks in advance, Bert

-

Hi, Trox wrote: " Singer is not alone copying popular sewing machine models, but here I find a strange model from Singer, The 45A 92 http://parts.singerco.com/IPpartCharts/45A92.pdf It is a copy of the Adler 204 -64. In addition, Singer 45A 93 http://parts.singerco.com/IPpartCharts/45A93.pdf who is a copy of the Adler 205-64. If you look at the part lists and compare them with the Adler part list, you will see it has Adler part numbers. It is photocopies of the Adler part list. I wonder if Sewmun or anybody else has seen any of this Singer models in the US before. Trox" By searching the net I found much more readable copy of the part list of Singer 45A93 than a singerco copy linked above. Try this: http://www.supsew.com/catalogs-reference-materials/ and look for Singer 45A93 There is also very good copy of part list for Adler 205-6 (205-64) Regards, Bert

-

Hello bassplayer, We've not heard from you for a long time 1. steel balls sound CLICK CLACK when you turning the handwhell are normal. I have checked this in four pfaffs recently: 461; 463; 467 x 2. All of them sound similar. In my supplementary post above I have described what those balls are for. They are a part of a centrifugal governor which opens the oil valve when the machine is running at full speed. 2. you are welcome to ask - if I only could help 3. I do not think converting 463 to 461 is a good idea IMHO regards, Brt

-

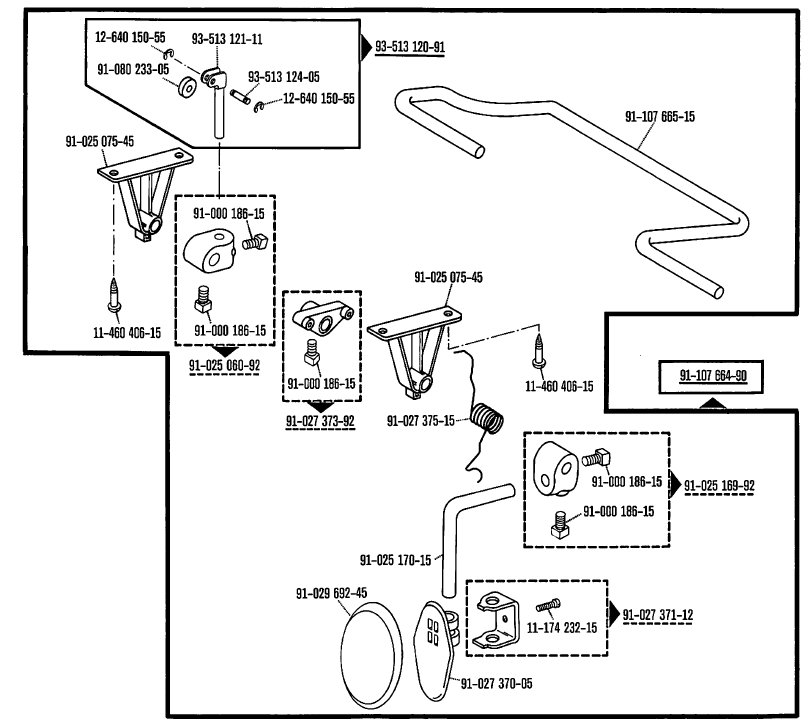

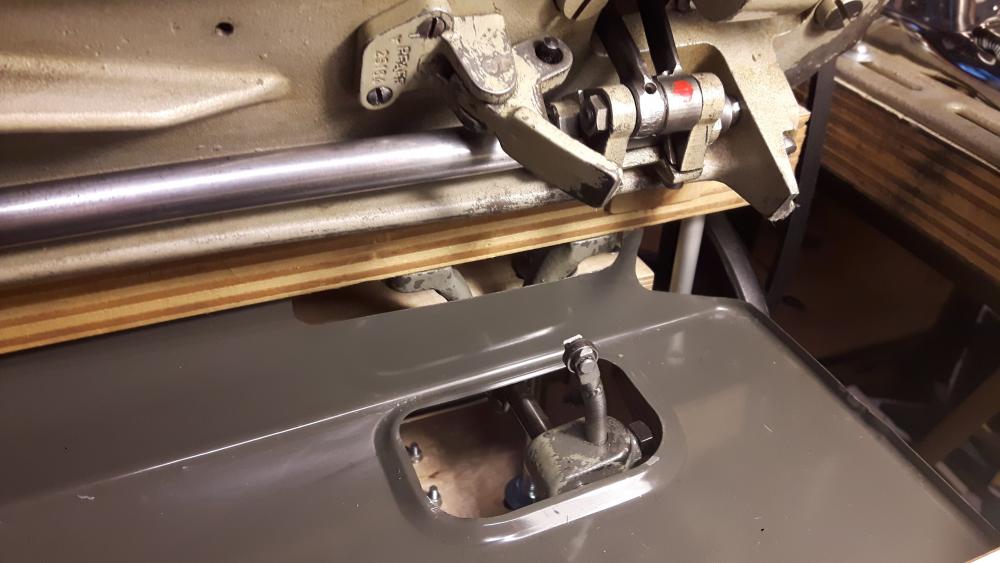

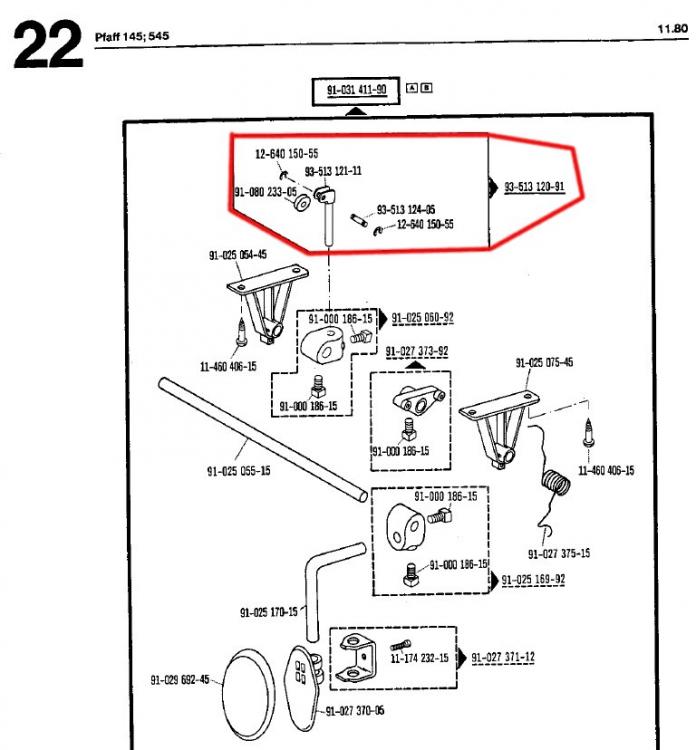

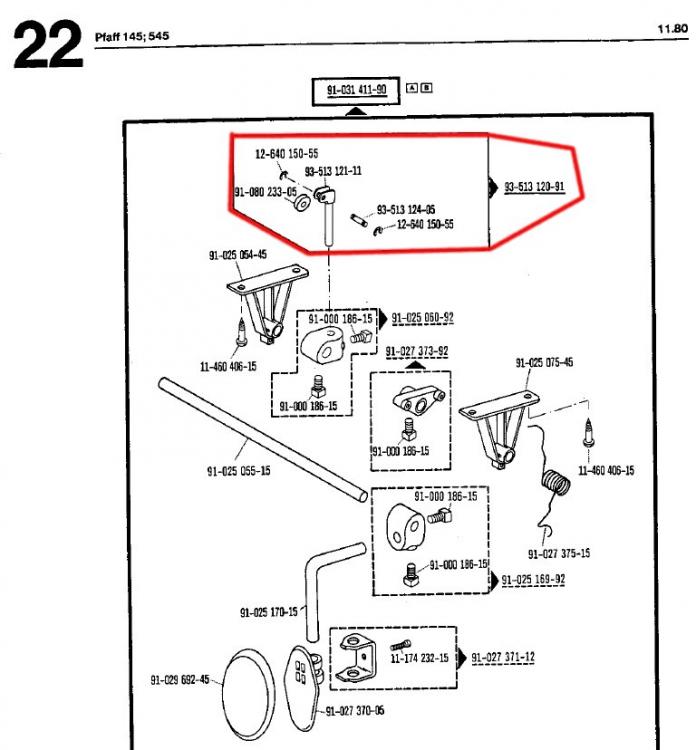

Rabaut wrote: "I recently obtained a machine which has a lift but is not working." I think the point is to make existing lift working, not to install another one. Anw, here are parts number of pfaff knee lifter for 145 and 545 Brtz,

-

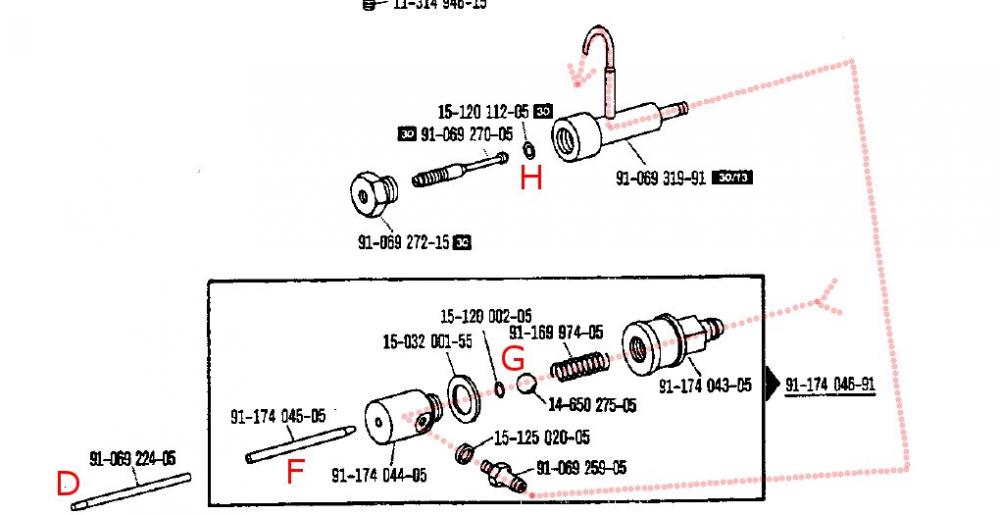

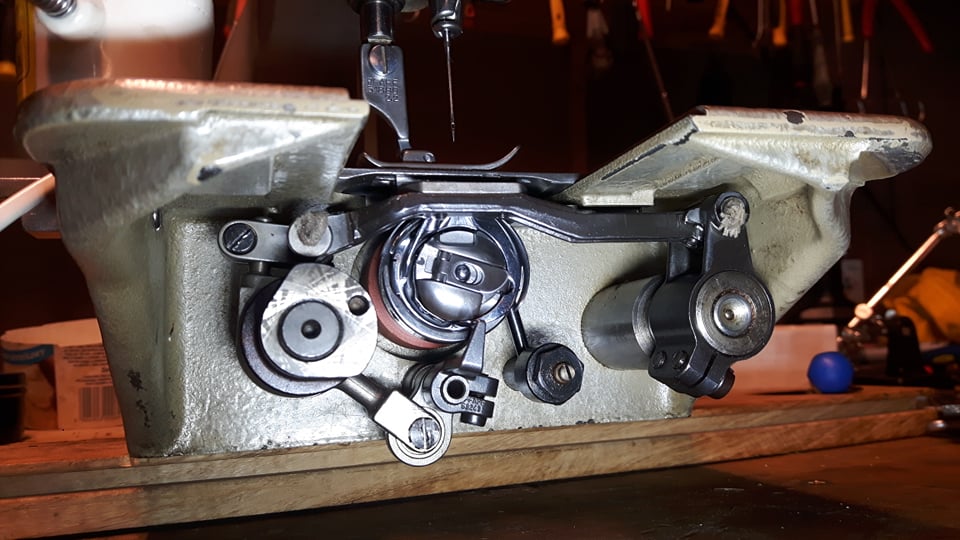

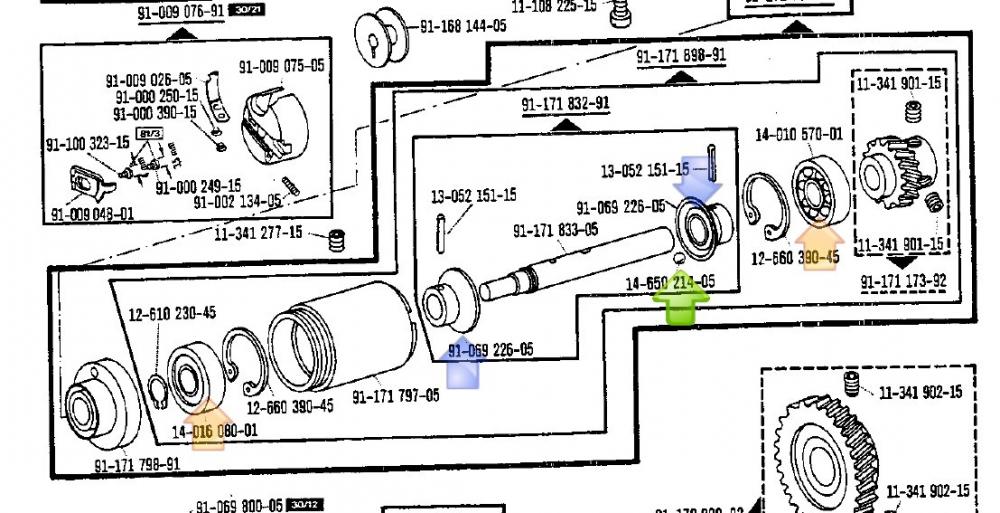

SUPPLEMENT: In my previous post I wrote that steel balls 'probably help in spreading oil to the bearings'. This is not entirely true so I try to describe more precisely my understanding of how hook lubrication works in pfaff 461; 463. (see pics below) Cones are mounted on the hook axis. The cone [A] is fixed permanently on the axis by pin [a] which is passing through the transverse hole [a'] in the axis. Mirrored cone is mounted on the axis with the pin passing through the oval hole [b'] in the axis. This oval hole allows cone to move along the axis to the right. The force moving the cone along the axis arises as a result of the pressure of the steel balls [x] which move freely between the cones. Those balls make a 'click-click' noise when you turn the handwhell slowly. Now, when the axis rotates at high speed, the balls [x] are ejected outward and open the cones. This is a mechanism very similar to the flyball or centrifugal governor used for the first time by J. Watt. The cone moves to the right together with its pin , which pushes the rod [D] out of the oblong hole in the axis of the hook. Rod [D] then presses anothre rod [F], which opens the valve [G] with a ball and spring and allows the oil to flow through the tube (dot line) to the hook through the additional valve [H] which can be adjusted by a screw. You can see how centrifugal governor works here:

-

-

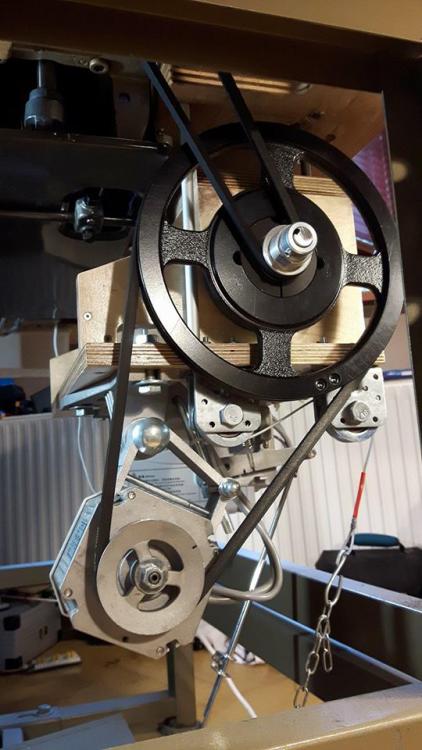

Hi, Here are some pics and a link to the short video showing pfaff knee lifter working. regards. Brt. https://www.dropbox.com/s/c3a6p0ukcic1fnb/working.mp4?dl=0

-

-

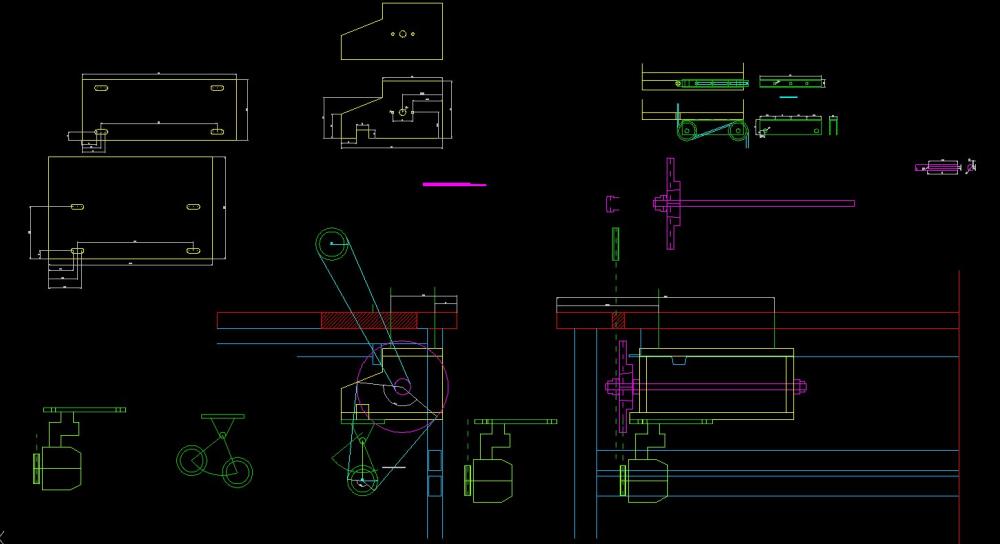

Welcome to the forum Bassplayer! A weird sound that you hear and identify with a damaged bearing comes from the steel balls (green arrow) that move loosely between two baskets (blue arrows) mounted on the hook axis. I came to this during the last pfaff 461 repair. See the drawing. The purpose of these balls is probably to distribute the oil, which is transported from the oil pipe to the hook through the axis with the oblong hole and then transversally to both dry-secured bearings (orange arrows). Bert,

-

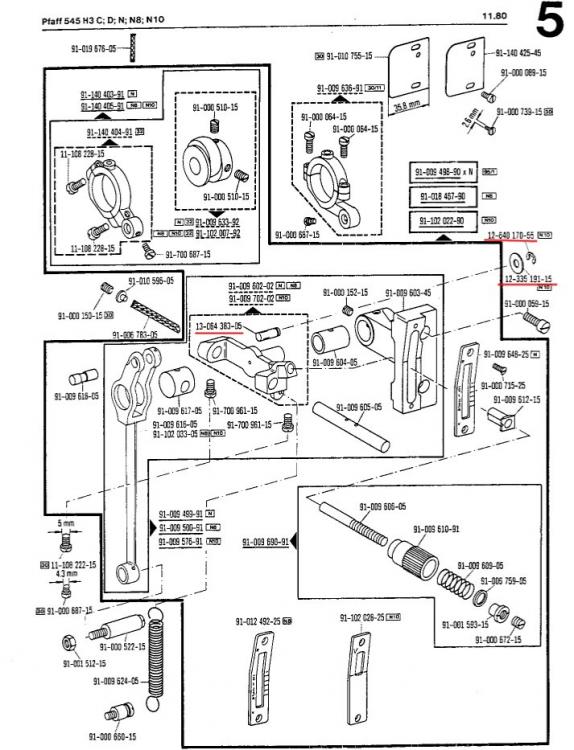

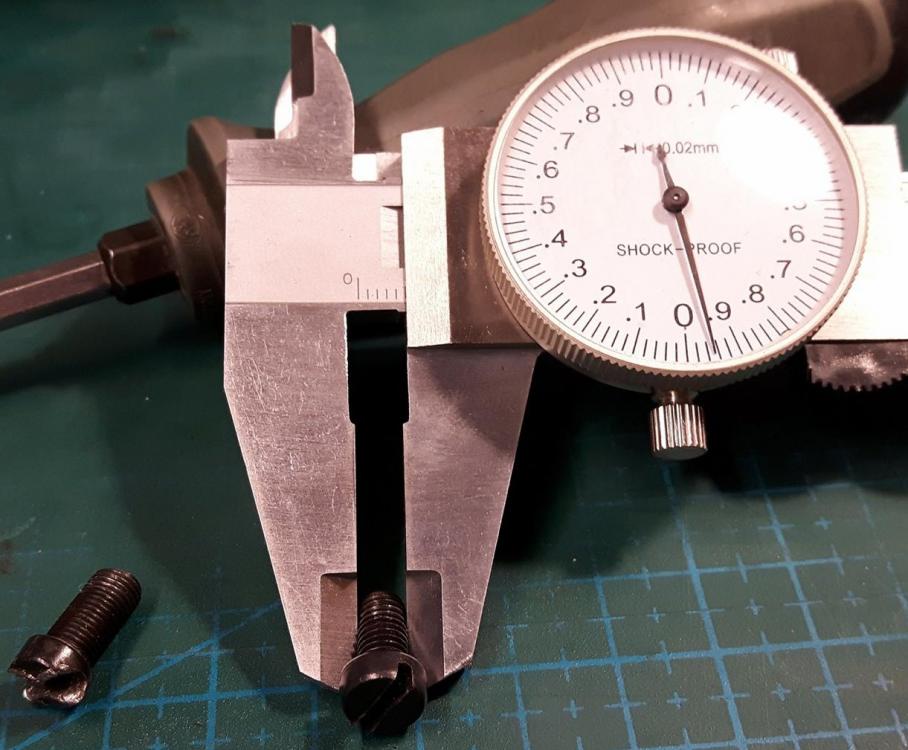

BINGO! This weird screw for the horizontal bar in pfaff 145; 545 is NOT 11-108 225-15. It is 91-000 560-15! you can check it temporarly replacing this screw from the feed dog lifting axle, as I marked on the picture. mine fits perfectly. Regards, Bert

-

Ah, OK! manually backtacking by turning the good - thanks all of you! Bert,

- 4 replies

-

- union special

- union special 63900 a

-

(and 1 more)

Tagged with:

-

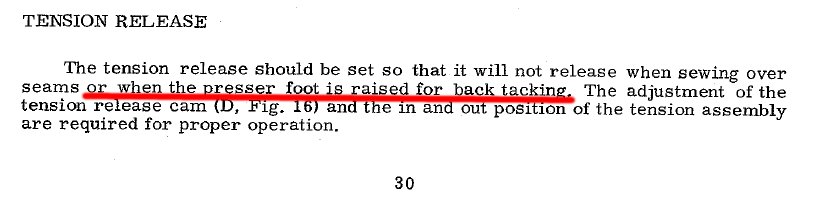

Hi, I found Union Special 63900 A yesterday. As its price was about USD 40, I couldn't not buy it. It seems to be in a good condition for a first view. I know it's for light or medium fabrics, not for leather but need to ask about backtack feature of this machine. I read in the adjusting manual: '... the tension release should be set so that it will be not release when sewing over seams or when the presser foot is raised for back tacking...' Does it mean that this machine can backtack? I can neither find any lever or button to switch the machine to the reverse feed nor to find in the manual how to backtack. Regards, Bert

- 4 replies

-

- union special

- union special 63900 a

-

(and 1 more)

Tagged with:

-

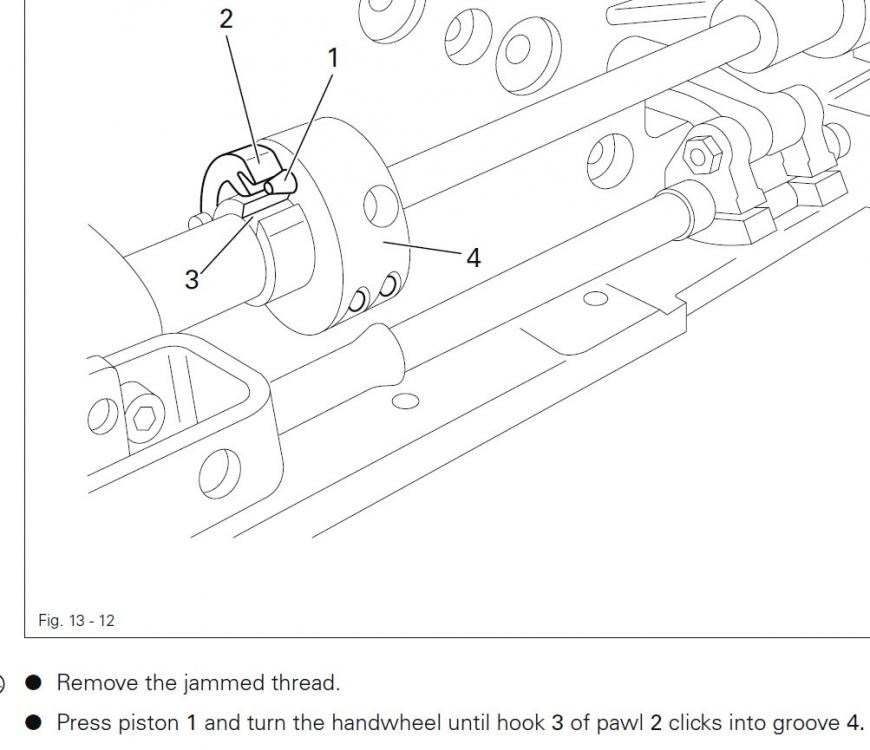

It was very helpful, thank you Uwe! It appeared that the regulating spring in the safety clutch of my machine was set to maximum force, so I couldn't release fearing not to damage it. It works now the same way as on your great videos. Btw - in the manual of the 1245 they call the latch - a 'pawl with a hook' And I apologise for improper naming of the parts in my introducing pdf. Best regards, Bert

- 10 replies

-

Can anyone could help me to understand how the safety clutch in pfaff works? I described an issue in the file below. Regards, Bert HOW THE SAFETY CLUTCH WORKS IN PFAFFS.pdf

- 10 replies

-

I am impressed. Nice job! Congrats! Brt

-

I decided to make it cause I am using a slightly different diam bobbins coming from two machines. If the axle is spreaded enough one bobbin is fixed properly but another is too small - and the opposite; when the first bobbin is too loose. Both bobbins are cutted on the inside edge so the wire spring solving the problem. Does original bobbin winder have the spring?

-

Can anybody help me understanding how the bobbin winder spring should be fixed on the axle? I did a hand-made fix and it's working but I am not sure if it's ok with the original idea. Regards. Brt

-

I am trying to find these werid screws somewhere in Europe. Maybe UK, so I'll let you know. If not - I am wondering about producing several dozens of them locally. And I am happy that the bolt is for H10 subclass only. I was afraid have a some spring missing. Thanks Uwe. I will also show you a home-produced roller bar for a knee lifter soon Brt,

-

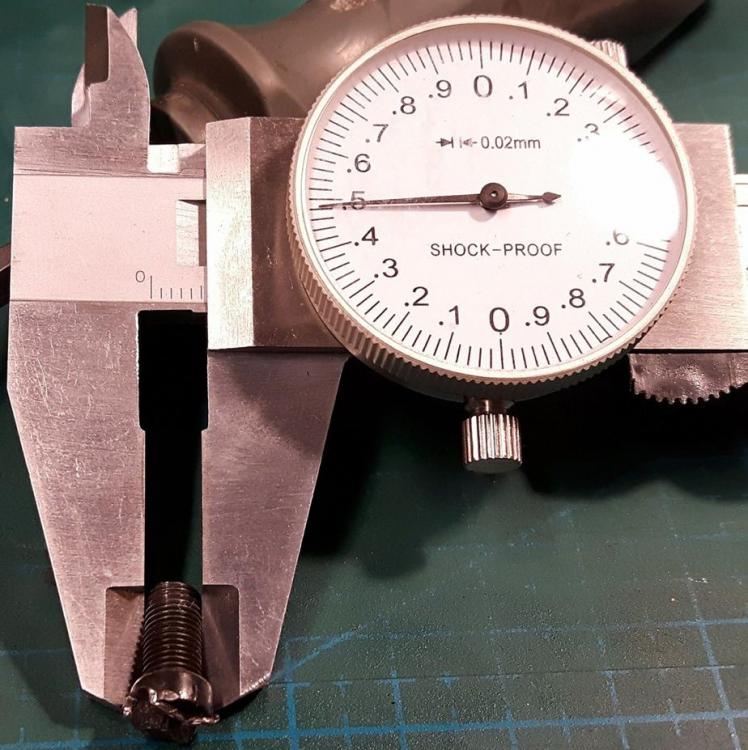

Hi again, Restoring my 545_h3 'barn' and have two problems: A) There is a horizontal bar and two levers fixed to this bar with a pair of screw each side (see pic). Two left screws are almost dead so I ordered a new pair. I ordered part no 11-108 225-15 as descibed in the parts list. During the replacement, after unscrewing them it appeared that two left screws are different then two right, however in the parts list all of them have the same part number. (see photo). On the left side I have fine thread (40/inch) diam 5,49mm screws. The right one are normal thread and diam 4,95mm. I believe that the right one are 11-108 225-15 part no but cannot recognize the left one neither in the parts list nor anywhere else in the machine. Can anyone can help me to identify these thick left screws and where I can buy them? bB) What is No 13-064 383-05 bolt for in 545? (it has a washer and a cotter in H10 version). I cannot recognize its function in the machine? Regards, Bert

-

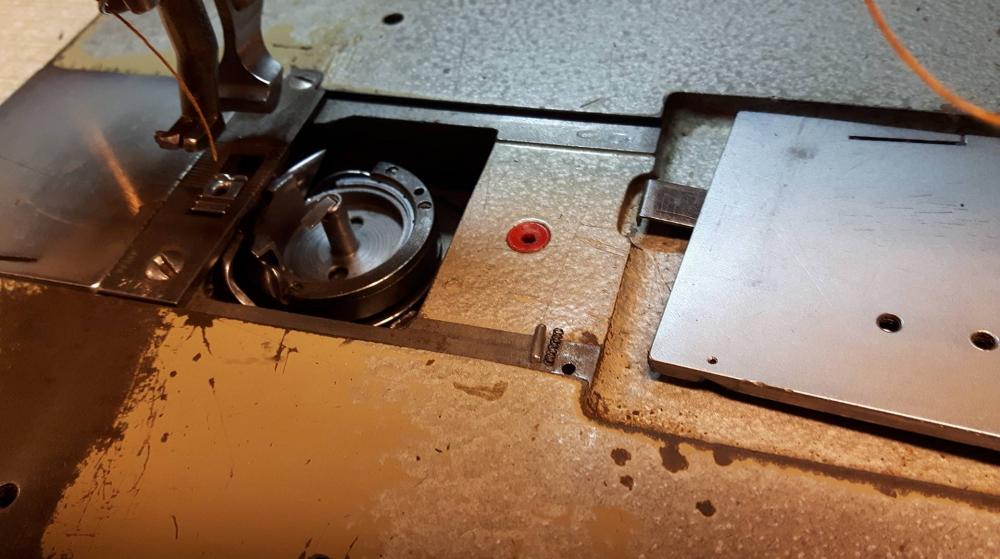

Of course I take into consideration making an 'ersatzteile' of this roller tip. I even found where to buy a kind of wrist joint (photo). There is a plenty of small rollers availiable but I think using this 'fork' may be better because the roll has two fixing points for its axis istead of one on the side. I think this roller has to be strong as the transmitted forces are pretty big. Anw I decided to ask for an genuine part first. Thanks Uwe. Btw, Did you know that the left slider (cover) of the bed has a small lock - a pin and a spring? I was surprised yesterday discovering it. There is no single word about it in the parts-list (or I missed this). See photos. Finally I also have an used genuine needle bar for replacing :). Greetings and a Happy New Year for Everyone! Bert,

-

-

Does anyone know where I could find a knee-lifter part No. 93-513 120-91 I attache some pics below. I temporarly replaced this missing assembly of my lifter with a piece of steel rod but it is not 'aclear' solution... It works very stiff My local suplier said Pfaff stopped producing this part and I also cannot find any used one... ps. Uwe thanks for the manual regards Brt,

-

Have no SM neither for 545 nor for 145. If you have one it will be highly appreciated. The only SM I have is for 1245 - http://www.pfaff.com/SiteMedia/PFAFF/Products/Machines/Support-manuals/pfaff_1245_1246-manual-EN.PDF Bert,

-

I am going to replace the needle bar for a genuine one, but used - not new. I have just bought another 545 which is damaged and uncomplete. It was only 50usd but it has probably a lot of genuine parts in a good condition. I decided to buy an extra spare-parts shop in that way. It is coming in one week, so meantime I did a stitch lenght ffd and bckwd calibration using Uwe's patterns (thanks!). And I am also ordering a genuine, new screws for my machines. Regards, Bert.

-

This missing tiny thread guide is probably something like that one which comes from Singer... I think I'll replace whole needle bar for a new one...