davemac2

Members-

Posts

16 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Blogs

Gallery

Store

Everything posted by davemac2

-

Found it. It's not easy, so I'll upload it here for anyone else looking. cheers, dave Consew_CS-1001.pdf

-

Looking for this CS1000 manual also. Does anybody have a PDF or instructions on programming it? thanks dave

-

JUKI 563 thread snagging on bobbin case

davemac2 replied to matcanada's topic in Leather Sewing Machines

Are you sure the hook timing is correct? The tension on the thread seems fairly tight going around the bobbin like the take up lever is going up too soon, upper thread tension too tight, or maybe the take up spring is not adjusted properly? The take up spring on the upper thread tension assembly should be at its stop and applying NO thread tension once the needle has reached the fabric on its downstroke. Also check for any burrs on the bobbin case thread slot there which may be catching the upper thread. -

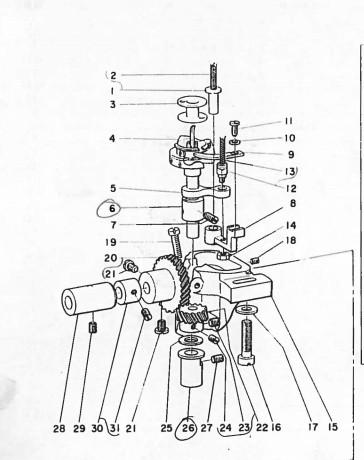

Ya those bushings look ok, but the upper could be slightly off. Someone would need to compare against another lu562. So that leaves either the hook is the wrong one (doubtful) or the #5 bobbin case opening lever link is not seating fully onto the eccentric of the hook shaft, or it is the wrong part maybe and is too thick? What happens if you don't put that link onto the hook shaft and just seat the hook shaft fully against the upper bushing? Does it meet the slide plate clearance then? The other thing is that with the bolt (#16) and washer (#17) that secures the hook frame to the machine frame, you could add shim washer above #15 in the diagram to drop the whole hook assembly a little down below the top slide plate to get your clearance, but then that might throw other things off such as the proper gear meshing on the hook drive.

-

Also check to make sure the upper hook shaft bearing sleeve (#6) and the lower one (#26) are seated fully into its mounting. There is a set screw there I think that secures them into the frame. See the diagram.

-

Popular & Affordable Used Machines for making Bags?

davemac2 replied to JC2019's topic in Leather Sewing Machines

JC2019, if you are in the Sac or Bay area, there are a few decent used machines on the market. examples: https://sacramento.craigslist.org/tls/d/roseville-consew-227-sewing-machine/6892644382.html https://sacramento.craigslist.org/for/d/carmichael-tacsew-t111-industrial/6890120621.html https://sfbay.craigslist.org/nby/for/d/rohnert-park-consew-industrial-walking/6893547783.html https://sfbay.craigslist.org/sby/for/d/san-jose-walking-foot-industrial-sewing/6892821480.html https://offerup.com/item/detail/643878972/ https://offerup.com/item/detail/664448029/ -

Canvas and Leather Sewing Machine

davemac2 replied to YanceyCravat's topic in Leather Sewing Machines

here is what appears to be a cobra 5110 post machine for $1000 https://us.letgo.com/en/i/brand-new-industrial-sewing-machine_8924627d-7274-4763-a17a-f4868385fb2c -

Canvas and Leather Sewing Machine

davemac2 replied to YanceyCravat's topic in Leather Sewing Machines

there are some other machines around in the area. this one below is an Artisan Toro 3000 that would likely meet the saddle repair criteria. It's been listed for more than 8 months though at $1200: https://offerup.com/item/detail/418162317/ There are a few LUx Juki's and a Consew 206rb5 (medium duty) around in the Bay area too for canvas/light leather work with about a 1/2" foot lift clearance: https://sacramento.craigslist.org/search/sss?query=juki+lu*&srchType=T&min_price=500 https://sfbay.craigslist.org/nby/tls/d/consew-sewing-machine/6722035616.html -

Greetings again folks. Continuing to tune up my singer 111G156. I have noticed a lot of play in the upper hinge joint at the top of the need bar rock frame (see pic, red arrow). It came to my attention when trying to adjust the presser bar spacing adjustment of 19/64" at zero stitch length. Is that something that can be reduced by making an adjustment to the hinge stud/set screw, or is it excessive wear in the needle bar rock frame itself? The play looks like about 1mm side to side.

-

singer 111G156 removing the handwheel

davemac2 replied to davemac2's topic in Leather Sewing Machines

Just a follow up for others with a similar situation. I did receive the consew specific parts yesterday. The set screws appear to be the same (with the exception of them not being a cone shape tip but more conical) and I put the extra one into my handwheel without issue. However the consew shaft end bolt does not fit the singer shaft at all. I've seen other postings on the forum here from some of the experts that have said this bolt is not really necessary, so keep that in mind. I will have to check my existing taps to see if one fits or maybe I'll try to thread one of the set screws into there to see if it is the same odd 15/64-28 thread size/pitch. -

Hi guys, I'm tuning up this machine I acquired a year ago. It's well used. Some of the adjustments from the service manual state to set the stitch length to '0'. However, '0' does not show up on my stitch length indicator. It goes from 5 thru 32. Can I assume that '0' is basically the max SPI past 32 or turning the handwheel past 32 until it stops while depressing the stitch length adj. button on the base? When I do that, it still looks like there is a very small back and forth movement of the feed dog. I have not tried running something in it yet at this setting, but I will to see. Just curious why there is no actual '0' on the dial.

-

singer 111G156 removing the handwheel

davemac2 replied to davemac2's topic in Leather Sewing Machines

Yes I'm certain now these set screws are 15/64"-28 threads. I found what appear to be equivalent consew 206RB parts and ordered those from SouthStar Supply rather than re-tap the handwheel. Consew Parts: Set screw 10576 Set Screw 10579 Balance wheel adjusting screw 19505 thank you all. -

singer 111G156 removing the handwheel

davemac2 replied to davemac2's topic in Leather Sewing Machines

Ok, success! Came right out after a few wacks with a pin punch, some heating with a heat gun, a little wax and one of the new flathead drivers on an impact . Now I need to figure out what thread these set scres are. Can I assume all the nuts and bolts on this old Singer machine are imperial and not metric? The set screws seem to be a 1/4"-28 thread. I want to make sure before I put a tap down the holes to clean them up. Actually I just did some research and these set screws may in fact be 15/64"-28, Yikes! may need to re-drill and retap to 1/4-28 I guess. As well, anyone know the thread size for the pulley end bolt that goes into the upper shaft? thanks -

singer 111G156 removing the handwheel

davemac2 replied to davemac2's topic in Leather Sewing Machines

ok thanks guys. I'm going to give it a shot this weekend. I have a set of these driver bits coming in this Sat which should help with tapping it to shock it. -

Greetings folks. Fantastic Resource here. I have a singer 111G156 machine I acquired a year ago but have just started to use it. It is a well used machine but is running decent so far. However the timing belt is very old and cracked and will likely break any day now. I have a new belt and was going to change it but discovered that the position set screw and the upper shaft end bolt on the handwheel (bolt secures hand wheel I guess) are missing, and the only thing holding on the handwheel is the pointed set screw which I cannot budge. It seems seized or someone put red locktite or something on it. Any recommendations on getting this loose? I was going to try some heat with a heat gun for a few minutes and then try a 1/4" impact driver in reverse with a hardened flat bit on the set screw. Maybe I need to be gentler to avoid destroying the set screw? As well, does anyone know of a source for the missing set screw and bolt? part #'s (I think): set screw 350541C position screw 350540C end bolt (adjusting screw?) 350419X thanks Dave Mc

-

I need this video too. I have an older, well used Singer 111G156 I acquired last year that is suppose to have a max stitch length of 5 SPI. I can get that if I adjust the reverse cam screw underneath, but then my reverse stitch length becomes much shorter than the forward stitch length. It's a compromise for now but I suspect the eccentric unit is not adjustable to its full range or there is something else limiting the range. I'm wondering if the stitch indicator adjustment on top or something else can limit this range, but I don't think so?

- 10 replies

-

- juki

- adjustment

-

(and 1 more)

Tagged with:

.jpg.d60258221c476480a6e073a8805645bb.jpg)