Damas

Members-

Posts

105 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Blogs

Gallery

Store

Everything posted by Damas

-

This place is amazing ! Thank you all for your answers ans precious détails ! @Cumberland Highpower I do love drop down guides but as said by @CowboyBob hard to find a spot on the cb3200 to place one... And I agree with you, it would have been so great to have that possibility I will buy the outlaw guide, it's available here in France at a fair price : https://www.decocuir.com/products/guide-pour-machine-a-coudre-cowboy-outlaw

-

Hi, being in France it's not easy to find parts and accessories for my CB3200. Does anyone here can tell me if the cowboy outlaw heavy duty roller guide will fit my cb3200 ? It's this guide https://www.buckleguy.com/heavy-duty-sewing-guide-for-bg-cowboy-outlaw-hand-operated-sewing-machine/?srsltid=AfmBOoonU5cm1FmPj1-4sV5qAnFb-FzI4iHyXL9UsjM42GdepeDWoSZ0

-

I have the same Fortuna splitter. That’s the way I do with mine to remove the main belt Regarding pulleys and grinding stones issue do you have pictures ? Different systems exist on same model /type

-

This would be great ! I send you a pm with my email address

-

Singer 45K online - weak points and what to avoid?

Damas replied to TonyGreen3455's topic in Leather Sewing Machines

So true ! -

Cowboy CB3200 and its "performance"

Damas replied to TonyGreen3455's topic in Leather Sewing Machines

I have the CB3200. It's definitively not a hobbyist or semi-domestic machine. It's sturdy, solid and perfectly finished. No plastic nor alu. And it's very big and heavy. All is smooth in the mecanism. I bought mine second hand from a hobbyist who hardly used it because he was scared of it, too big he said It's main limitation to my opinion is it's capacity under the foot, no more than 15mm which is easy to reach when working with veg tan for instance 8 hours a day is just huge, by "profesionnal manufacturer" I understand factory, industrial working process. Many professionals here, are just craftworkers, they are not 8 hours a day on the sewing machine That said, between a CB3200 and a CB4500 or even a CB3500 I would have chosen bigger. Buying second hand, I did not have that choice -

I did the conversion this morning. I had to lower the needle bar of 6mm so from 23,5mm clearance to 17,5mm (from base of needle bar to top of feed dog) Prior to this, I set the stitch length to 0 and position the machine to BDC as recommended by @Wizcrafts It's the only change I made I did tests using three layers of veg tan leather, total thickness being 12mm. It's not the max cb3200 can take (specs say 15mm) but it's my usual max I used terko satin thread (Coats), tkt 025-tex 105 on the top and bottom I tried 120, 140 and 180 sizes and it was perfect ! I'll give it a try in real working conditions for the next few weeks and report here

-

Singer 45K online - weak points and what to avoid?

Damas replied to TonyGreen3455's topic in Leather Sewing Machines

Here, on this pic from internet, I circled what seem to miss on the eBay one (at this price I wouldn't mind, just be sure the part is available) : -

Singer 45K online - weak points and what to avoid?

Damas replied to TonyGreen3455's topic in Leather Sewing Machines

Thread guide on face plate seems also to be missing or not ? It’s a little different on mine… -

Singer 45K online - weak points and what to avoid?

Damas replied to TonyGreen3455's topic in Leather Sewing Machines

I have a 45k25, I love it, but I just bought a cb3200 similar to your first link. You can’t beat a triple feed and smooth feed dog when working with leather… -

I sure will, hopefully I already have a bunch of them, using 328 system on both 45k and 132k

-

Thank you ! I also found this post which suggests the opposite conversion with some interesting hints from @Wizcrafts :

-

I do get your point, but I am doing fine bridlework, all by hand, saddle stitching french style so far. In order to be more competitive, I would like to extand my price range and offer machine sewn articles without changing the overall look and style of my production This can only be achieved using more light thread and needle association CB3200 by design accepts smaller needle sizes, 794 is available down to 110-120 range but not in LR point

-

Very good point @Constabulary, I didnt know, I will have to check that on the sizes I'd like to use (120-130-140)

-

Hello, I would like to do a conversion on my CB3200 from 794 needle system to 328. The reason why is the following : - 328 needles are cheaper, more easy to find and available in a variety of sizes that are currently no more available in 794 system (nothing under 160 in LR points) - CB3200 is not maint to sew heavier than 15mm, so longer needles such as 794 are not really an advantage here Did I missed something or this conversion would only be avantageous to me ? And what other steps would be necessary apart from lowering the needle bar ? And would I lost the timing by doing so ? Thanks in advance for your answers

-

Good to know, thank you !

-

Thank you both for your suggestions and answers. I was thinking about both the stirup and the holster plates (raised ones) which are used without the feed dog according to my understanding, as the slotted one mentionned by you @CowboyBob Also good to know that the standard plate can do all

-

Hi All, I just bought a second hand hightex CB3200 which is working like a charm. It came with very little to nothing accessories (standard needle plate + narrow needle plate and the double toe harness foot) and I am in search of what could be added in order to fit to my main activity which is basically light horse tack (bridles, halters, etc), holsters and knife sheath so I started to look into what was available and I have several questions to people who actualy have an work with this machine. - what feet/needle plates are essential for that kind of work : light horse tack (bridles, halters, etc), holsters and knife sheath ? - will chinese needle plates tagged as "for durkopp adler 205-370" be compatible with a CB3200 ? Thank you very much for your answers

-

Hello, I found an old fortuna leather splitter. It has not been used for years but looks ok so far. Electrical wiring will have to be remade and belts are dead but regarding the mecanical part, where should I start and where can I found a user manual ?

-

Yes, sure. But I already took a close look and some does not have any… As said by @Constabulary probably custom made.

-

Upholstery, according to the people I got the machine from. It originally belonged to a far relative, who died about 20 years ago. They have now decided to sell the house and everything had to go. Yes, I have been lucky on this one ! I am very happy !

-

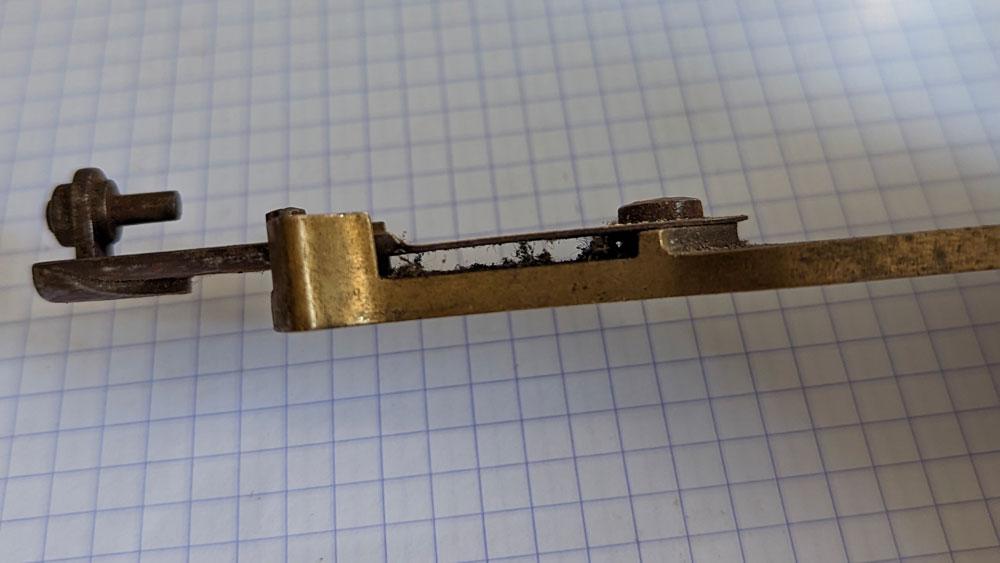

Attachement N1. It looks like it has to go under the foot... with what looks like a needle hole in the center But I might be wrong. I really need your help on this one. Top Bottom : Side view : Attachement N. 5 This one looks like a piping maker from my understanding. You put a string in the center, and you wrap a piece of leather around and voilà ! Foot N7, any idea ?

-

I found a 45k this weekend and its drawer was full of things ! I wanted to share with you and I will also need your help to identify and use some of the attachements it came with. It came with a roller foot too ! Several hooks and shuttles and some Pfaff feet too... I have not yet started to clean it, just took of the front plate and shuttle race and shuttle and hook in order to prepare it for a good clean. Here are the attachements (I will have to clean, derust, etc) I know Number 2 is a binding attachement because I have found previous topics here that talked about it. But Number 1 and 5 are more mysterious to me... So does one of the foot too (7). Some close up pictures to come ! And the fun part, the badge above serial nb says "Rental machine, unseizable and non-transferable property of the Singer company"

-

132k5 Help needed to adjust clearance between needle and hook

Damas replied to Damas's topic in Leather Sewing Machines

Sorry for late answer, I have been away for a few days. So I compared both machines and the bushing is moving on my 132k10, in both direction, when gently taping on it, once screw #4 is loose. There isn't any second screw. The second hole is where comes the bobbin case retainer ratchet I had to remove in first place in order to access screw #4. Both machines are identical twins for this mechanism. So my guess is @Constabulary is right, probably some rust I will have to stress with heat to unlock that bushing. I'll try that and keep you informed. -

That's funny because I bought this foot a few weeks ago and I think it can be very handy in some situation where you have to get very close to a D or a belt buckle or a ring, that kind of thing. I put it on my Mitsubishi DU-105 without any modification and gave it a try this morning, see below. I found it on Ali and did a combination of the "Short head foot" small foot here : https://fr.aliexpress.com/item/4000937997235.html? And the "Horseshoe foot" that can be found there : https://fr.aliexpress.com/item/32962189517.html? Works like a charm.