Damas

Members-

Posts

105 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Blogs

Gallery

Store

Everything posted by Damas

-

From the album: Damas album

-

From the album: Damas album

-

From the album: Damas album

-

From the album: Damas album

-

From the album: Damas album

-

From the album: Damas album

-

original_f2eae614-b86b-4c75-b554-3f325f457b40_PXL_20251001_091623765.jpg

Damas posted a gallery image in Off Topic Pics & Videos

From the album: Damas album

-

From the album: Damas album

-

original_c64a4adc-d059-489b-9f3f-7334d88ce3a3_PXL_20251001_091635928.jpg

Damas posted a gallery image in Off Topic Pics & Videos

From the album: Damas album

-

I'll do that today, sorry

-

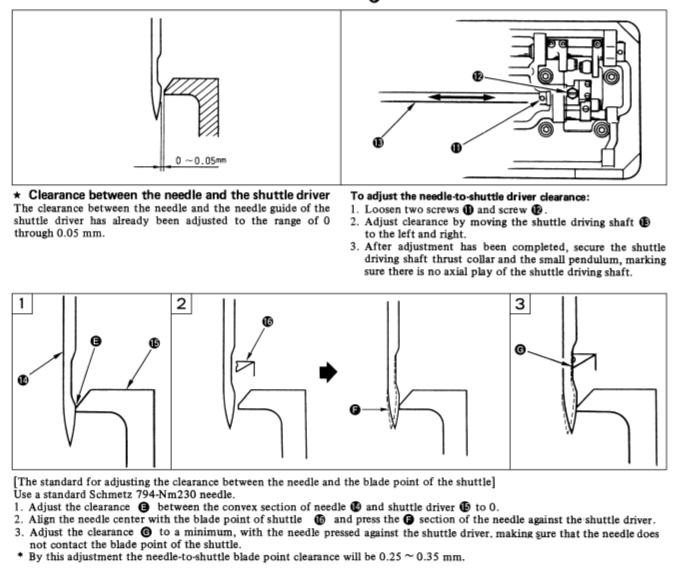

To All, thank you so much for your help. I asked a manual from Hightex EU and they sent me the attached leaflet (CB7243 is the other name of CB243)... Also, I took pictures and made videos of my machine, I hope it will cover all the pics you asked for, but in case not, I will take some more ! In order to ease overview of the machine, I did an album : Here is the local album link 7243.pdf

-

I'll do that tomorrow, the day is over on this side of the Atlantic and I am no longer at the workshop

-

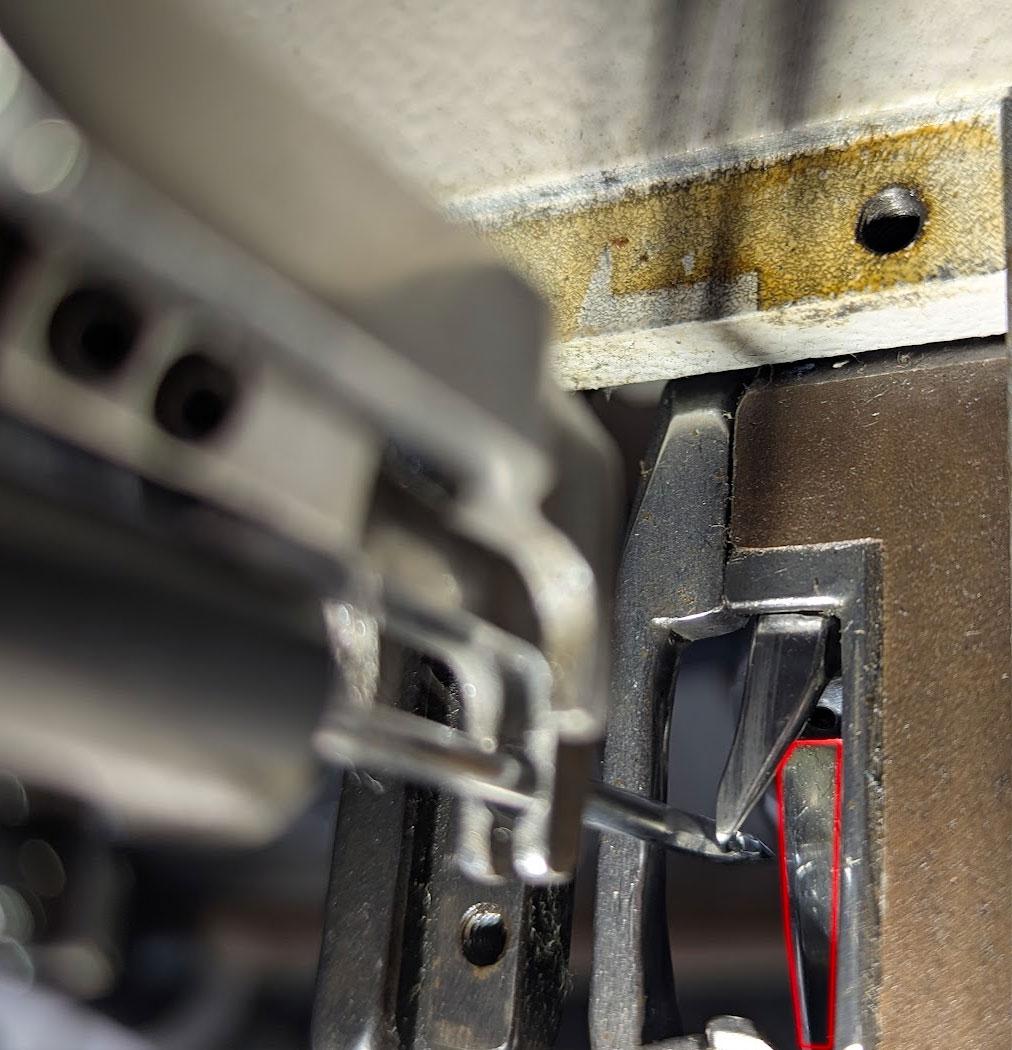

@AlZilla It's in the post below the one you mention that I am wondering if it's bent or not (post is still visible on previous page). I cheched it and can not decide if it's bent or not... It's hard to tell when you have nothing to compare to so I ordered a new one but won't get it before two weeks Meanwhile, I put a 230/26 needle in the machine (I normally use 160/23), as asked in engineer's manual and needle was rubbing on the shuttle point so I set "needle to shuttle clearance" accordingly, it's not rubbing anymore I am now trying to set up "needle to shuttle driver clearance" but I am confused trying to understand what I have to look at. Is it the part of the shuttle circled in red in my pic ?

-

Actually I just noticed feed dog seems to be bent on that pic... Maybe it is and I should buy a new one before trying any other ajustement !

-

@friquant thank you so much ! I had a different version of the manual that did not show this adjustment @AlZilla true, I confirm and cheked. I added a picture with needle plate in position showing that issue clearly comes from feed dog placement

-

Yes, that's the point. I need either to move needle bar or feed dog, depending on what is ajustable on this machine to have everything in line I just don't know how to do that. This is why I came here and asked

-

Hello CowboyBob, thank you very much for this documentation. The needle to shuttle clearance seems fine, I believe the needle to hit the feed dog, as I can clearly see impact marks on the feed dog and also if you check on picture you can see that needle is too much on the left when going through feed dog hole Also, mine being a flat bed version, so I believe adjustments will involve parts that might differ

-

Hello, I bought a second hand HighTex CB243 which I believe is a Juki TNU-243 clone. The machine stiches great, timing seems OK but I keep braking needles again and again... At a point where I am reluctant to use the machine It looks like either feed dog, either needle bar is off and I believe this to be the origin of my braking needle issue... I looked into TNU-243 service manual because machine did not come with any manual and it does not show how to move from left to right the feed dog or the needle bar.

-

Who uses a Pearson #6

Damas replied to T Moore Medicine Hat Saddlery's topic in Leather Sewing Machines

Hi, in case you don’t find help here and you are on Facebook, there is a dedicated FB group for pearson’s owners I am pretty sure there is a bunch or NZ people on this group -

That won't solve your issue but here in France, we are doing backstitch by hand on expensive leather bags/items sewn with machines

-

Thanks @dikman ! I took a look and they don't seem to offer shipping to Europe/France... I'll ask them

-

@RockyAussie I sent you a PM, I would love to get a narrow needle plate + feed dog too for my CB3200 !

-

troubles with cb3500 threading on upper tension

Damas replied to TonyGreen3455's topic in Leather Sewing Machines

I had the very same problem with my Hightex CB3200 recently. It came from the thread... It was making pigtails when unspooling and when the pigtail arrived in upper tension, the thread was popping out... Try with a different thread and see if that was your issue