nylonRigging

-

Posts

463 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Blogs

Gallery

Posts posted by nylonRigging

-

-

On 6/21/2024 at 11:29 AM, LimaZuluTango said:

My problem is mainly the tensioning.

OK, Not sure if proper routing ? . just throwing ideas out there .. but from your Pic. it looks like you not utilizing full benefit of your larger tension-disks/knob on that thread routing . Look like it needs to be using more tension surface area. As it is right now, looks like you only using maybe 25% surface of that main tension knob .

But right now, your not getting much thread surface on that main Tension Knob Disks with routing that you doing . I don't know why ? , it not with what choices given you on that machine . If yiu look at a Pic. of a Durkopp Adler 269 . The thread routing goes over around the Top and down around of main Knob tension .

Is it possible maybe ? , to take that routing as it comes around that main tension knob . Take that thread over more L-side to the 'thread guide' . To then take thread routing down to the Take-up spring routing .

I Not sure if that Thread Guide that is above your take-up, has 2 holes, or it just open wire guide ? . Route .. Main Knob --> L- to tension guide --> down to take-up --> then back up threw thread guide .

.Or ? .. can you ( flip-over ) that thread guide that is above your take-up . From pointing Left , to pointing Right ?

Then come off that main tension knob with thread . to thread guide . down to Take-up . Then come up from ' take-up spring' routing thread up threw the other thread guide that is below the safety guard .

. -

Dont understand ? you say ..." can’t get a stitch to stick! " are you talking about tension ?

Might try a Titanium plated needle, as they tend to be slicker surface and better for sticky and needle stays cleaner.Are you sewing threw that really sticky ( peal and Stick ) Velcro ? that adhesive backing is pretty gawd awful 'GUMMY' especially that 3M brand . in general almost never buy and avoid that adhesive Velcro product, and just use rolls of sew-on . I would suggest not even using that sticky-back Velcro.

I always sewing Velcro and keep hundreds of yards always on hand of different size/color. Like you saying, the fluffy 'Loop' side sews easy, looks good . but Hook is different animal, Going sewing around the boarder edge of Velcro Hook always looks great, But In general though anytime you sewing right on Top of Velcro Hook is hard to make look good because your feet are on-top of tiny 'unstable' flexible pillars .Stitches never look consistent pretty ..

-

On 6/18/2024 at 7:01 AM, HeatherMom6 said:

Yes it is one large feed dog. Whatever this foot is, it is bolted with 3 large bolts up into the head of the machine plus a large hex wrench screw into the front. When I first got it, I did get the foot off, but after thinking about order of operation and the set up, I put it back on bc none of the other adjustments to the needle bar, hook timing etc could be done without this foot on. Second picture is the only identifier I can find for this foot. I have 2 other pics that I will try attaching.

-

The 211 parts to covert back is easy found,and cheep to do . but me.. I wondering what material stitching the original 112 owner was doing with this set-up ?

That a sham to just toss aside the prefab. foot/dog setup work that is on it. It was built and added to do a specific job on the old 211, and 'probably does it very well' .

. -

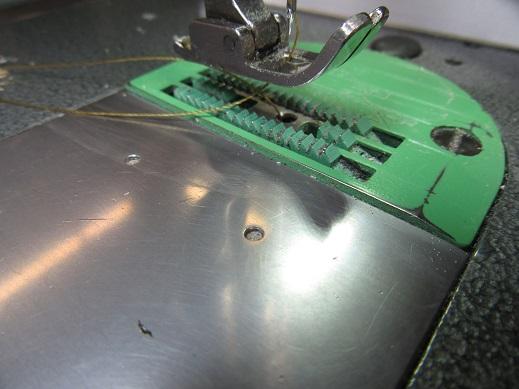

Cant really see the feed-dog . Is that just one large dog ?

Is it a Needle-Feed / drop-feed walk ? . I never seen a heavy large single-needle foot setup like that before on a 211.

It's interesting.. A different (side angle and rear ) Pic.of the feed and foot would be good to see.

.

-

3 hours ago, Rtilley22 said:

Help. I have a Singer 211W155 and had to pull the bobbin case to remove jammed thread beneath. I have managed to loose one of the tiny gib screws! Any part # or resource would be greatly appreciated! Ron T.

Those screws are tiny...LOL . If can't round one up . I got a screw can mail you.

I wont miss a screw. I replaced both bobbin assembly on my old double needle singer about dozen years ago, and threw the old in a box just for that reason of loosing or breaking...etc. 'cheep insurance' Robbing parts off the old trash.

.

-

I like the size, shape, design, the finger cutouts for 'Grab Bag' . and you should digi. pattern it.

That bag can be no-sew primitive Grab bag, or easy go different directions for the maker. It could be sewn, plus use the lacing and rivet points as added accent, or even with lining, pockets, removable shoulder strap...etc.

. -

-

7 hours ago, ThomasBH said:

Hello,

I've fairly recently picked up a Typical GC2605 Cylinder Arm machine specifically for binding the inside/raw edges of backpacks, pouches and some leather items. I'm specially looking for it to bind work pieces that are probably 1/8-1/4" thick using 1" grosgrain mil spec binding tape (5038 style).

The machine came with a binder that I think was meant for using very thick binding like leather or webbing, but even using webbing does not produce good results.

Here is a photo of some of the binders I've accumulated over the years that I've tried on this machine. Some are not meant for this purpose so I did some jury-rigging with tape to get them to mount, but alas, nothing will produce even remotely acceptable results. Most can't even bind on a straight flat piece.

https://photos.app.goo.gl/xFoaS6pCGYHb4sb56

Any suggestions or help would be appreciated!

Thanks

Setting-up Binders is never easy, and it hard to get into specifics on doing a setup to Bind with internet forum pic. and not actual seeing, and with not having hands-on the binder and machine . Getting the correct Binder, and with Binder in proper set-up . That goes with equal detail with seating-up on the positioning of Binder to the presser feet, also the shaping of the feet to accommodate the binder position to Needle for feeding materials. Plus a few other things. After that it's all about building your personal technique for Binding.

Sounds like your saying, your biggest struggle is getting the binding material of choice to track out the binders throat nice even with feeding material ? , and the Pic. of the, 1"/25mm Binder to me ?, looks like that binder is for thick edge, it looks to have a pretty tall open throat height .

your 1st choice on binding is, 1" wide, type lll grosgrain ( tape binding ) ?

( for me/just my opinion ) .. On thicker edge materials, ( exposed, finish look ) and using 1" wide Binding for a wrap. My 1st choice is a type ll, #4082 herringbone . Binders throat height around the 12mm size .

And for ( exposed finish look ) for the thinner edge binding, 1/8' and thinner edge. I always go with a 3/4" wide type lll #5038 grosgrain . also the binders throat height around the 5mm size .

.

-

1 hour ago, dikman said:

A bigger hammer!!

Just joking, looks like a reasonable tool kit, one thing I find indispensable is one of those head magnifiers - but that's 'cos I'm older than you!

Just joking, looks like a reasonable tool kit, one thing I find indispensable is one of those head magnifiers - but that's 'cos I'm older than you!

Congratulations on the job.

ya .. a nice Magnifier for sure , and also some 'soft' super-fine grit emery cloth for smoothing Hooks and also need something to remove nick's on needle plate, and other sharp spots ..etc. that you run across.

edit add:

Besides a nice tool carry box for repair and cleaning . Also I seen some repair techs. run a hang-harness/ chest mount that has a lot of common small hand tools at easy reach . Also...LOL you will be cleaning and blowing out a lot of thread and fabric Lint and oil everyday, If a machine is run for 8 hr. shifts it's incredible the amount of filth they accumulate.

.

-

Looks like ? , in the Vid. . That your outer presser foot not lifting also .

.

-

I have never seen anyone with branding a Machine head with sales name 'Mach3 ' as logo ? Only cross reference in the name . if type in general search , ( Mach3 sew )

The only thing that I could see connected to sewing was Longarm Quilting machines, and Mach3 software stitch/pattern programing.I seen that machine you asking about advertised in the craigslist/salem OR. , their asking 2500-$. it looks clean and head is a complete set-up w/table and drive.

It is/looks like any other 441 clone, and i have noticed asking/pricing is all over the place right now on used sew machines. 2500-$ is little high for used but not unreasonable ' if ' you are real close to area for you to easy pick-up . also price not unreasonable if has a lot extra's with the machine ? feet, Dogs/needle-plate set-ups, or binding or other attachments ?

You saving minimum about 700 to 800-$+ over buying new . ( this for example ) , if you buy new from dealer on west coast here, You are in WA. like from artisansew down in bay area CA. you going to pay 3000-$ and change, and plus at least 200-$ 4'x4' pallet truck shipping up I-5 N. to a shipping hub for you to pick-up.

. -

Sounds like the machine was misused and monkey mechaniced by the previous owner . If all is in time properly . The going Slow is Fine, and the Fast RPM is Bad on thread could also mean simple problems .

Maybe some needle strikes. Check real close for a Burr or a Nick in your Needle-Plate, smooth-out with fine emery . Check for Burr in the Hook, take piece of cotton ball or Q tip and run it across Hook. If any snagging, smooth it out.

In my life I have even run across/pulled-out a couple new Needles out of the Pack also that had a 'sharp Eye' inside-edge that would also shred Thread .

. -

56 minutes ago, LiftPig said:

I have some oil and whatnot I can bring when I look at it. That's a great suggestion.

Wiz, do you know what motors shipped w/ those back around that time? I'm guessing I'll probably end up replacing the motor and I'd also bet there's no speed reducer (just a hunch) so that'll have to go into my calculations. Right now the figure I have in my head is if it runs okay I'll offer up to $1000, get an ACF-681 motor (~$500 shipped). With that 1,100 watt motor I shouldn't need the speed reducer, right?

should be similar/same watt set-up as this older Artisan 3200 I have had for several years, good watt, programmable servo and added reduction. mdl. ( ACF-622 b brushless servo )

-

-

-

On 1/18/2024 at 11:18 PM, lilbax said:

Thanks for sharing. So the when you say I can tune it to those size needles is that just buying them and they will swap out or are there other adjustments that need to made for that different needle to have correct timing etc?

On my immediate grab list will be:

Thread 69 text/thread

Needles 135x5 or 135x 16/17 size

Heavy Tooth dog and needle plate

Roller presser foot

Play with the tension

————

I’ll see how that goes and get a servo controller after if I don’t have enough control. Does this sound like a good start and I can do some leather projects on it?

Your machine should be a 135x5 needle right now ? , Your machine is pretty common. just figure out what DB Model MITSUBISHI, that is looks like and go from there for info also .

Needles like 135x5 is perfectly fine. Your machine isn't doing any bigger than #69 thread anyway. 135x17 offers a little bit bigger needle thread hole for larger thread, but you wont need it.

It a good learning experience for you and changing out a few things on this bottom-feed machine, and will be good basic knowledge, and be pretty helpful when you moving-up to a better machine latter on. 'Basic stuff ' like this translates over down the line.

You changing out Needles , Dogs, needle-plate, Feet ...etc. that is real economical ' for your machine . Just go on Ebay for presser feet, or a roller foot . If just using standard presser foot, just buy both a Large and a Medium Dog and needle-plates to play around and see which feeds best to what you doing . You might not even need to go to the largest tooth Dog .

--------

Your machine will stitch thinner leather . It is just that a unison-feed, or a drop-feed walk has far better feed and needle control.

I threw a couple Pics. in to show you. I cut a piece of old scrap leather/deer . It is average @ about 1.33 mm thick. it still fairly supple but Old.

I doubled 2x thick, and it was about 2.70 mm thick . . then tripled 3x thick to about 4.50 mm thick .. then 4x thick to 5.04+ on the Caliper .

I did Little effort on my end, I just used what #69 that was already strung-up on the machine and the 20# needle hole round point fabric needle . It just sewed it all on the 1st attempt, no practice scraps before I took the Pics.

I keep an old DB-170 Mitsu. and I worked it over to Feed heavier cordura/webbing with a better servo drive,and 135x17 needle, higher tension . 69/T-70 is the limit on thread size.

-

-

-

13 hours ago, Synicsel said:

The stiffness and softness you're experiencing can be due to their individual properties. Bonded Nylon tends to be softer and more pliable, which can make it prone to fraying. Bonded Polyester, on the other hand, is usually stiffer and more durable.

Nylon is structurally stronger and more abrasive resistant than Poly . Poly is more UV resistant than Nylon . Both Nylon and Poly have there versions of ' satin soft ' threads.

.

-

It sounding like you have zero, or very little knowledge of sew machines in your Post. So It a 1st time, low budget machine, if just starting out learning .

learn some machine stitching basics, needles, thread, and machine working mechanics with using it...---> Save your money and work on getting a Consew 206, or Juki 1541 for future expansion of your skills .

That is a pretty common Mitsubishi cast head, used on many brands, and is a Drop-Feed ( bottom feed ) . it a light-Med. duty sew machine.

OK.. It will 'can' sew leather . at a minimum expectation it can do some decent stitching on thinner softer leathers. 'if' you change a few things with it. But you need to put some time 'sitting behind' getting to know the machine. Also the machine ( it is , What it is ) you got to recognize it's limitations.

It takes easy to find selection of Feet, Dogs, needle plates, Needles, and also will take easy to find presser roller-wheel. The Roller Foot, is an easy swap/change-out, and it also can do some decent stitching . You can tune it for 135x5 and 135x 16/17 size needle. It will use #69/text 70 thread . it has small bobbins . It does have Reverse, but you will 'try and try' to adjust, to get it to sew same SPI in reverse, but it Won't ever never be satisfied with stitch quality in reverse .

It is set-up in your picture for Fabric Stitching . For sewing Leather. You need to get needle control, slow it down, get a quality servo. or a cheep servo drive with using a reduction pulley . You going to have to change out the Dog and needle-plate, to a Med. or Heavy tooth, and get rid of the fine fabric toothed Dog . put in a little heavier tension coil spring on top thread. experiment with the presser-foot tension. use a smooth/slick chrome plated press foot .

. -

3 hours ago, shoe said:

This one looks so nice. Can they still be effective for today's work? I'd love to have one to use at show and sell's.

-

Looks good for it's age. 450-$ is not a bad price at all for machine in Pic. as long as it sews . There is a reason people still buy and sell them. Patchers can reach in, and stitch were no other machine can get into.

and ( Yes ) they are handy/effective to have in your machine stable . ( for me ) It one of those machines you don't use often, but when you do use it.. You REALLY Need It, and glad you got one sitting in the corner.

.

-

14 hours ago, toxo said:

Anything upholstery, Cechaflo is THE maestro. If you can't find what you need here I'd be very surprised.

That guy is a magician with a sew machine.

Have you seen the Vid. of him making his own piping foot set for French Seam ? . Cut out of a hunk of scrap metal with hand tools, for his twin needle Durkopp&Adler 268 FA-373French Seam piping, Scrap Metal Feet set

-

-

Sailrite did a couple good examples, on doing two turn-corner techniques with French Seam.

-

-

I have paid that and more-$$, for older machines , BUT ( My opinion ).. I would never pay 575-$ for a machine in that Poor condition, of that age . I can imagine how the drive looks ? , and It my lay down a Stitch, but that head and table look like it has ' already seen it's better days ' about 20 years ago .

. -

New to industrial sew machines, and buying that 1st machine that is double needle ? Sounds like you want double the frustration on your learning curve ....LOL

The double needle maybe a good buy, and you can use it for certain stitching . But it would be better for you to pair the Double-needle as secondary station, with a good Single-needle machine as your primary, as the single needle will be the one you sit behind the most hours for a daily workhorse.

. -

26 minutes ago, nycgirl said:

Some, but I am not looking for a binding machine. Thank you for letting me know.

I think you are right! It's H3 not 113. Do you know what the H3 means?

I pretty sure that the ( H3 ) is factory designation on the dedicated binding feed model of 335 . I would not mind finding a good deal on a older clean little 335 H3 head for tape binding . I for most part use needle-feed flatbeds for binding, but I have one cylinder arm unison feed right now set-up for binding also .

So seller only selling you 335 Head only ? no table or drive ? . If you buying the 335 head from seller just take your time and string it up and turn it over by hand on some material to make sure it feeding and lays down nice stitching before buying.

.

-

4 minutes ago, Wizcrafts said:

If that machine is a binder machine as built, there will not be any way to get 4 way motion on the feed dog. That motion is caused by cams that would likely be missing on a binder machine. It was not intended for normal sewing operations. I was offered a Pfaff 335 for a couple hundred bucks at the same time I bought a long arm big bobbin Singer patcher (over a decade ago). After seeing how strange the feed operated, I declined the Pfaff.

If you haven't bought the machine yet, ask the seller if the feed dog has normal up/down/forward/backward motion, or just forward/backward? It will be one or the other, not both..

I just now noticed it say's H3 on the provided Pic. from OP . I think that the clue to dedicated binding model ? .. is that -H3 ?.. or is it a -113 on the plate #'s ???

-

-

-

1 hour ago, nycgirl said:

Is the 335 I have in the picture a binding machine?

I not into pfaff's much . I thing that a G model does not necessarily make it a 'factory set-up' dedicated binding set-up on the 335 . You need pay attention to the feed dog movement, and if the needle-plate set-up, and feed dog, binding swing plate witnessed to move together .

The dedicated binding pfaff 335 has unison feed, but the feed dogs only move horizontal back and forth motion, with No Up Down oscillation moment.( I think ?? ) that if it is the normal unison feed 335. you can just change-out needle plate, dogs and feet to fit your needs .

.

.jpg.89005894e75d0303a2b82c7cad528a2c.jpg)

Sieck 269-373 Tension trouble

in Leather Sewing Machines

Posted · Edited by nylonRigging

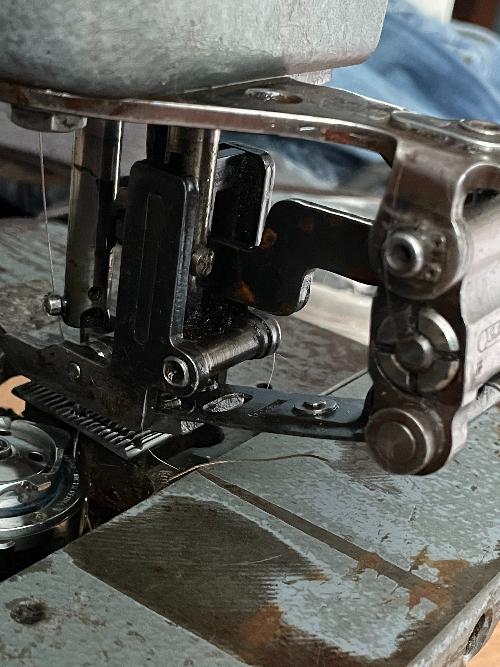

Ya there something funny going on there with the routing choice that machine is giving him .

If you look at a Pic. of a Durkopp Adler 269 . That this machine copies . The thread routing goes over around the Top and down around of main Knob tension, and makes WAY better use of the main tension.

.