NeilMott

Members-

Posts

118 -

Joined

-

Last visited

Profile Information

-

Location

Chicagoland

-

Interests

watches, chess, leather

LW Info

-

Leatherwork Specialty

working on watch straps

-

Interested in learning about

watch straps

Recent Profile Visitors

The recent visitors block is disabled and is not being shown to other users.

NeilMott's Achievements

Member (2/4)

-

Cobra NP4 Leather Skiving Machine - bad presser foot mechanism?

NeilMott replied to NeilMott's topic in Leather Machinery

I got my new part today and installed it. It's 95% smooth with a slight hesitation at the bottom, but it goes down each time. I'll continue to lube and adjust the pressure plates. Glad to finally have this back in working order. It's a shame it came damaged but LMC was prompt and was great to work with overall. -

Cobra NP4 Leather Skiving Machine - bad presser foot mechanism?

NeilMott replied to NeilMott's topic in Leather Machinery

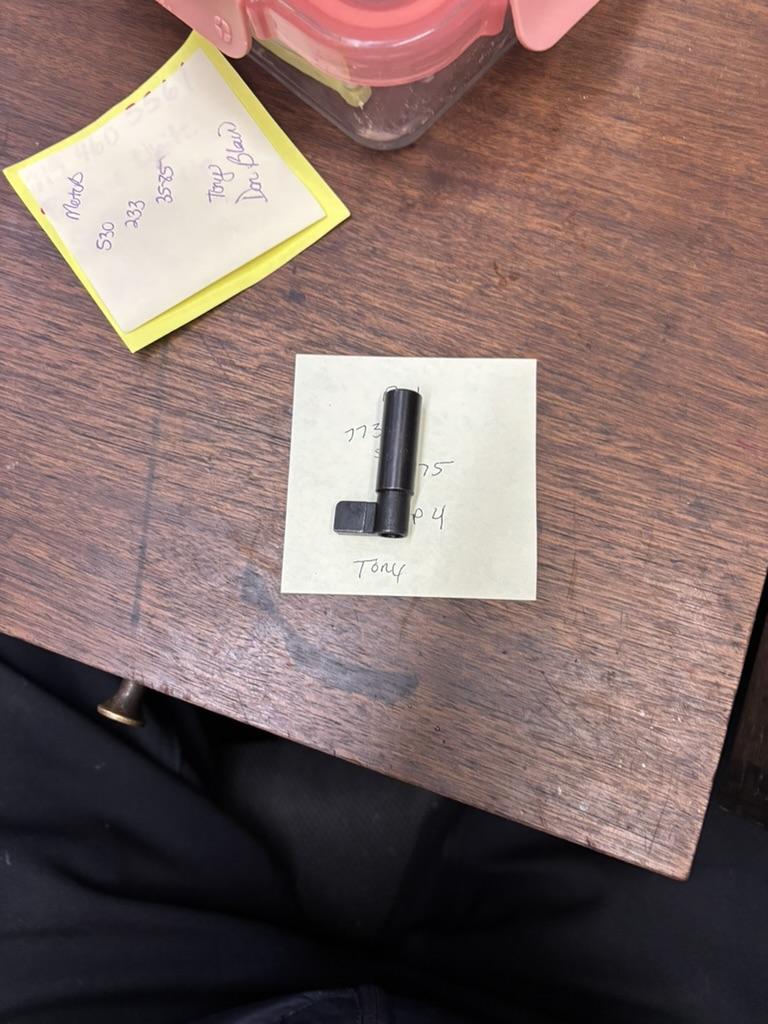

Given what I've taken apart, the guy at LMC thinks it's this part that's bad (bent) They're mailing me this top part of the assembly. They said it's not uncommon that this part can get damaged in shipment, bending the internals. I find that hard to believe given how stout the box is along with the hard styrofoam holds things in place, but they are really trying to make this right. -

Cobra NP4 Leather Skiving Machine - bad presser foot mechanism?

NeilMott replied to NeilMott's topic in Leather Machinery

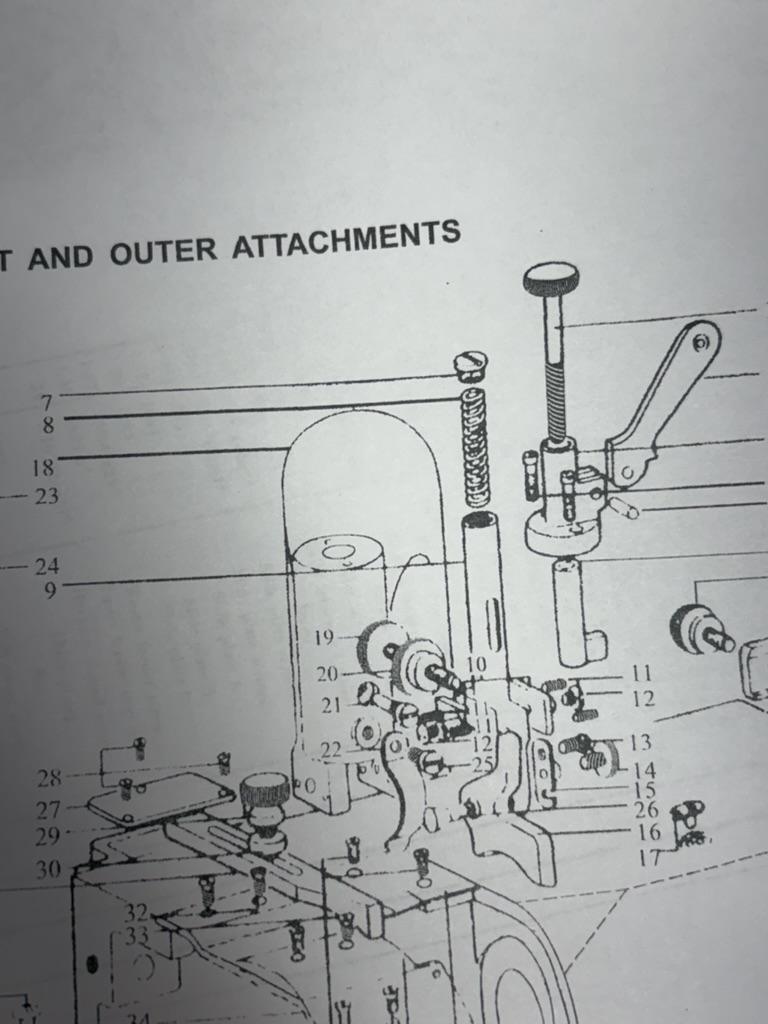

After some phone tag, I got some guidance. I loosened the Allen screws on the sides and the black screw, but it didn't help. I didn't think anything was in those holes. I was told that if that didn't work, then it probably needed a new bushing and was to take the top mechanism off. Well there's no bushing, just a screw that covers up the spring. As fas as I can tell that's it in the tube. I put everything back together and it worked better for about 7 pulls then started binding up again. Less than before but still not right. This is the schematic. I'm going to call them again tomorrow. I'm quite frustrated and am done repairing a new $2000 machine. -

Cobra NP4 Leather Skiving Machine - bad presser foot mechanism?

NeilMott replied to NeilMott's topic in Leather Machinery

Just tried to call and they're closed until Monday. Yeah, it's frustrating because it shouldn't happen on a new machine. It seems like they rushed this out the door. There's no way this worked properly when they tested it and then doesn't now. To me, it seems like air is getting into the mechanism because after I pump it a few times, it'll go down smoothly. I'm definitely not going to play mechanic on it. -

Cobra NP4 Leather Skiving Machine - bad presser foot mechanism?

NeilMott replied to NeilMott's topic in Leather Machinery

My friend who's been advising me on fixes also has a Techsew SK4. He said that his feet didn't need any polishing. He has another machine from LMC and also thought they'd be very helpful. At least I kept the box in case I need to send it back. -

Hi all. I recently purchased a Cobra NP4 skiving machine and received it right before I went out of town. Now that I've had a few days to use the machine, I think there's a problem with the presser foot handle. When I pull the handle down, it stops about half way. If I do this 3-4 times it will then go down once. After that, it's another 3-4 times before I can bring the foot down to skive. A friend with a similar skiver recommended that I lube a few areas, which I have done, with no change. Of possible note is that when I received the machine it was pretty filthy, which I thought was odd. It took a few wipe downs to get it clean. There is also a lot of grease at the top knob and where the handle rotates around the pin. The other issue is that the foot is leaving marks on the leather, so the foot isn't polished to the degree it should be. I haven't tried the other feet yet. Here's a link to a video of the presser foot handle in action: I emailed the company that I ordered through but haven't heard back from them. I plan on calling Leather Machine Co tomorrow, but was hoping to get some insight so I don't get the run around from them. Thanks in advance for your time. Neil

-

I think you hit on a couple great ideas to fall back on. Glove leather makes a thick wallet. I'd want to really be mindful of that. I'd plan on using the glove for the outer shell, of a bifold wallet for instance, then line it with normal thin leather. As for skiving the edges and also for the french seam, I saw a baseball glove wallet maker use this type of skiver. It is a pain to skive used glove leather to be sure! https://www.ebay.com/itm/294552741372?epid=17019894518&hash=item4494b625fc:g:XncAAOSwXoRhk2PZ&amdata=enc%3AAQAHAAAA8N88rBVyUSTaZveVBzGZQe7qJG7iKd%2BdRX3KJRlSmK%2BF99WD3f63P4jKKpxdEsKE5kPhfh7rDdbEMxFh9S7zFvnjP%2F4fUuYJo7ZZ8IuGrH6Ny1hDtIpbLknrrrCw300BEMv%2BVcnBiljvZgpddSza6214wLD97%2FkNP9uJl3vjXnwxpSzKdh653StLxTCBlPCj5NouuBX2ElW52yDJggREnEmFa6qsL2XVh8HbcSoc2p4UFSURyGPL%2FRMr9YwzRqN0k1hY1jMQbRaHtcR4js6%2F7HYcqfxfqa7uVbc2wN8DXod39%2B3WORBCwouXLs2BOT56BQ%3D%3D|tkp%3ABFBM-oS7oONg I think this is a knock off the original Scharffix, which I think is around $300. Neil

-

Hi again. Hoping to gain some traction with some different questions. As I look more and more about how to put these together from small gloves, I'll probably need to do a french seam (felled seam) on some to piece parts together, and so a lining leather would look the best. Plus, it's hard to get the flesh part of a glove really clean. As far as thickness, what do you recommend? One maker said 1 ounce leather, Walpier Buttero. 1 ounce seems pretty thin, but this guy makes a lot of them. As far as type of leather, some makers are using Steerhide. I've got a few smaller sides of oil tan leather from Springfield in tan that may look the part as well. Not sure if it'd be too stiff. Thanks, Neil

-

Belt Punch Dies - Looking for a die maker

NeilMott replied to BeefSupreme's topic in Leather Machinery

Hey all. Not exactly what is asked for, but here's a hole punching tool I found a little while back. I may take a bit of the stress out of punching holes. https://www.etsy.com/listing/997280427/beltstrap-center-punch-guide?click_key=ee43145a07339bf4032e0768de24c10ece9f67ea%3A997280427&click_sum=a20898a9&ref=price_range_narrowing_module_market-3&frs=1&sts=1 They also have their own site as well. Neil -

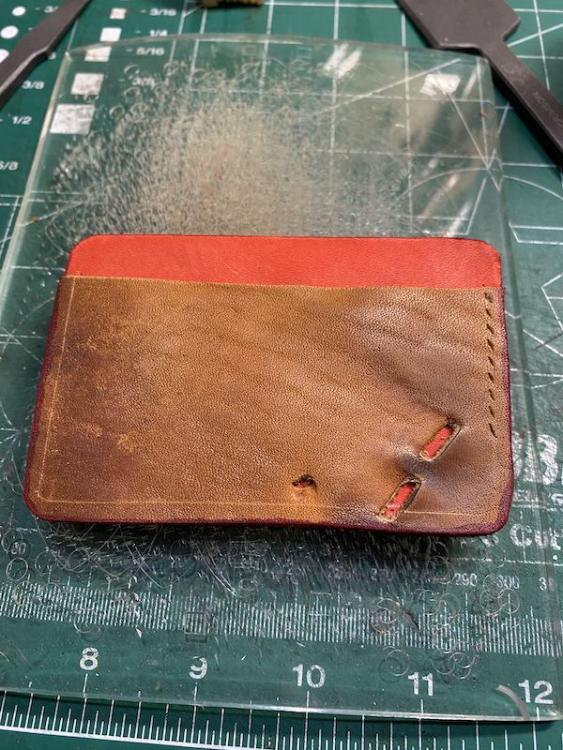

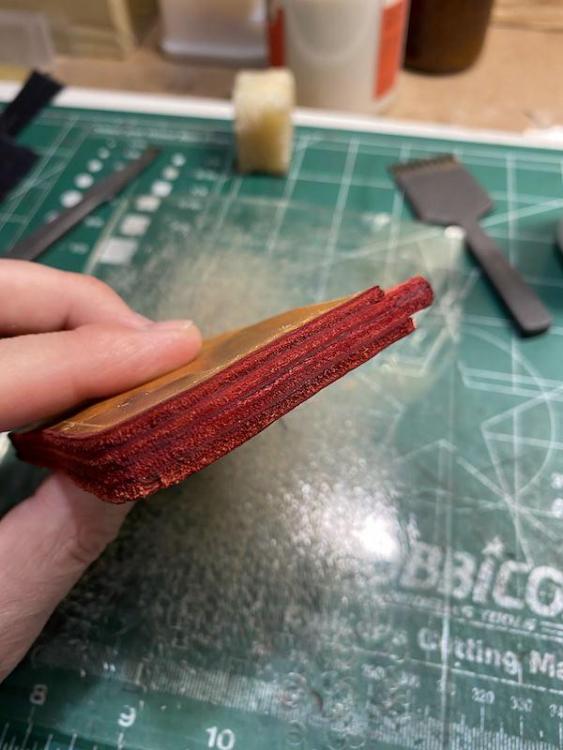

Hey all. I mainly make watch straps from baseball gloves. Lately I've bought some really old gloves with logos of baseball players in action. The logos are too big for a strap, so I thought about making wallets. Unfortunately, I'm new to wallets. So, after a lot of google'ing of designs, I tried to make a 3 pocket wallet. I used some beat up glove parts from a catcher's mitt and some red Horween baseball glove leather. I kinda threw it together to get a feel for it. I did some things out of order and forgot a few things. I was going to finish the edges with Tokonole after stitching, but I couldn't get my irons through the wallet since it was so thick (10mm). After looking at a number of designs, it seems the big issue is how thick glove leather is, which I found to be the case on my sample wallet. I find glove leather to be 2-2.5mm thick. So, either the wallet will be made of entirely glove and be small, or the wallet has a shell of baseball glove and the lining and other bits being new/normal leather. Recognizing that gloves don't provide a lot of leather, I'm hoping to have a small card wallet and one that's a bit bigger. For both, I'd like to have some place to store bills. For a money clip, I'd prefer to use this style: Here are a couple designs that I like. http://www.leathercove.com/bifold-card-wallet-pattern-pdf/ https://fcgoods.com/collections/wallets/products/bifold-card-case-money-clip Thanks in advance for your thoughts, Neil

-

I make watch straps mainly out of baseball gloves. They're soft and thick, but I wear big watches mostly. For conditioners, try Bicks 4. I use it when any of my leather is too stiff (from an old glove for instance). But in general, there is no reason a watch strap should come to you stiff, in my opinion. Walpier Buttero is a good leather to try for a watch strap. I'd say any leather described as medium to soft hand should work. Also can depend on hole placement how it feels. If you're too tight or too lose, try a different size watch buckle. Neil

-

Oil Tan leather for Valet Trays (catch all's)?

NeilMott replied to NeilMott's topic in All About Leather

thanks! really like how they turned out. I've got a few more in process and will post when they're done. I also just ordered more shackles in bronze, steel and gunmetal . Neil -

Oil Tan leather for Valet Trays (catch all's)?

NeilMott replied to NeilMott's topic in All About Leather

-

Valet trays

NeilMott replied to RichBliven's topic in Purses, Wallets, Belts and Miscellaneous Pocket Items

Rich, these look great! I bought the template from Makers Supply and have tried out a few. I'm wondering what leather you find works best - size and tannage. I'm looking at a few oil tans because of the great pull up. One is 3-4 oz (1.6-1.8mm) thick and the other is 4-5 oz (~2mm thick). If you have a source and size for those shackles, that'd be appreciated as well. Best, neil -

Hey all. I'm thinking of making leather valet trays and found some amazing looking oil tans on Springfield's site. Wondering if this type of leather would be good for valet trays. I don't plan on wet forming them, and understand I couldn't with oil tan leather. I bought a valet template from Maker's supply and would probably stitch in a different leather for the bottom to make it more formal and add rigidity. Here are the oil tans I'm considering: https://www.springfieldleather.com/Vintage-Gold-Rush-Buffalo https://www.springfieldleather.com/SLC-Oil-Tan-Cowboy-Collection?quantity=1&color=206 (probably the vintage and oxblood). As a side note, I'd probably explore using these for watch straps, as that's the main item I make currently. Thanks! Neil