-

Posts

104 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Blogs

Gallery

Store

Everything posted by Silky

-

I've been looking at "Tackers" lately and am wondering about the mechanisms. Regarding the mechanical type, does the feeding actually stop while the needle is in the material ? And the electronic type, same question. Or is there something that allows continuous movement of the material ? A "wobbling" effect ? (if you will). I imagine an X / Y axis set up with servo motors but these things run so fast, I cant imagine there being a pause at every stitch ! I have the resources, is it feasible to build a CNC style x/y feed bed for one of the heavier tackers to use with leather ? Thanks

-

The ones I have came with the machine, so I just use them for play, practice and plan to use them to make mock-ups for some upcoming outdoor fabric items. They are quite old (nylon) and some are too tight on the post. I just chuck those in the scrap bin. Probably not worth the time to bore them out. Should check though, might just be a burr in there. They are quite handy ... till they're gone. Thanks Bert.

-

That is what I am doing with the 111W. Also have a small shirt pocket magnet that works OK. Thanks Wiz Hi Bert, I also have a bag of prewounds that are thicker than the metal bobbins, There is no room for anything in the case with them. The overrun doesn't bother me, just wondering if the original washer (or spring) is actually necessary after slowing these machines down for leather work. I guess its original, and only purpose was to create a little drag .... similar to the felt washer under the spool on my little 99 domestic. The overrun there can loop around the post and ...eeeeek. I use a washer cut from that soft, spongy checkerboard material commonly used for kitchen drawer liners on it. Works perfectly. Thanks again Gents,

-

Yeay, I'll assume that should also lift the bobbin a bit when opening the lever so I can better get ahold of it ! Thanks

-

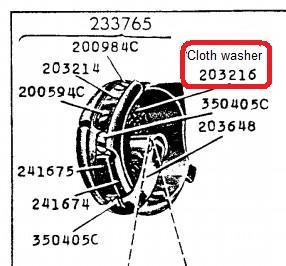

My 211G had some remnants of washers under the bobbin. 2 thin ones, IIRC. The 111W has none which also makes it difficult to get the bobbin out as it sits below the edge of the case. Is there anything critical regarding the fabric type / thickness of the OEM washer ? Is it something I should get from a supplier ? or just cut some out of ? ? ? ? ? material ? I think I saw somewhere where the washer acts a a sort of drag brake to keep the bobbin from coasting forward when all other motion is stopped abruptly. Thickness, friction, oil and the smoothness of the bobbin surface would all contribute to the lower thread tension as well ... I'm guessing. I appreciate any input, thanks.

-

guess I'll just have to order some from different outfits till I get one that fits. (hope they all don't come from the same mfg.) thanks

-

Thanks for the tips. The more I look at it, the more I'm liking the top myself. IT"S ALIVE ! Ran 3 bobbins through and it never skipped a beat ! Even on the slow pulley, its too fast for me. I stitched the belts together ... but they still click. The top one is a V belt and the bottom one is a round leather one. I am putting a parts list together, then I will contact Bob. I just put a new belt on it and it looks awful sloppy loose. I don't like it. I've inquired in another post. If no response, I guess I'll have to get on the phone or email. You guys ever put one on these similar models ? Regards,

-

Hi folks. I searched and read related posts for over an hour and never saw mention of tension. I just got a new timing belt and installed it, all went well .... but. I assumed that the belt would be tighter than it is. I expected it to just barely fit with the upper bearing removed, then be right at taught with the bearing housing back in. Are there variations in the new belts ? Some junk ? I use this type of belt in many other applications and NEVER run one this loose. Granted, this machine does not reverse, but still doesn't look right. The pulleys cannot be worn THAT much, they look good. Just doesn't look right to me. I can get a pic if needed .... and share the seller info. Thanks, nearly ready.

-

I'm pretty sure this one would have had a step pulley on the motor as there is no way to easily move the motor to tension the belt at different positions. Its bolted on rigid in slots. Its a Ridgidframe, Delco Appliance motor, 1/3 hp. and runs good. The wiring was cracked up though so I replaced it. I'll probably just choose the most comfortable ratio and stick with a single pulley at the motor ... like was evidently done previously. I put a DC gearmotor w/controller on my 211G and it is a treat to run. That drive combo is pricey to buy new, worth far more than the typical servo, but I had it on the shelf. The table is nice but has a 3/8" twist in it from one end to the other. Probably set into it from setting on a dirt floor in a barn for who knows how many years. Otherwise, it is quite nice looking. I scraped the nasty finish off of it and hit it with a belt sander then put a quick coat of polyurethane/stain combo on it just for kicks. Pretty patina ... if that's what you like. It is a pale, very soft, light wood. Not Poplar or Pine, maybe Basswood. The only welds on the frame are at the 2 horizontal pieces at each leg assembly, all the rest is bolted together. And, it is only 16" wide, not 18 as stated earlier. More questions to come, I'm sure as I get it back together and, hopefully, running. Thanks much !

-

Hey thanks, I'll check with him later today. Another question .... or few. Does this stand look like it may be original to the head ? or older ? Maybe these were cobbled together over the years ? I am considering restoring the stand and top and also maybe the knee lift, reduction pulleys and such. It has a neat clutch/brake built in. I will need the missing step pulley from the motor shaft. I guess they were cut for round belts as they are a true V with no flat in the bottom. I like the size of the table too. It is only 18" wide. NIce compact unit. I'll ask Bob about the pulley too but if anyone else has an outlet, please post. Thanks again,

-

Now I am missing the hinge parts that poke into the base of the machine. Are these the right ones ? Are they available ? or should I make 2. Thanks.

-

EXCELLENT ! Thank you !

-

Hi folks. I just found, and bought a SInger 111W155. I'm curious of the mfg. date but see nothing online other than it was made in CN. Serial # W1415235 18" x 48" table with step pulleys and clutch / brake at the upper ones. Pretty nice shape. I'm guessing 40's ? Thanks

-

Thanks Gents ! I am watching for parts, or a basket case to get parts for my 7-33. Been watching / searching for a couple months now. I wanted to look around a bit before diving into implementing my own design / parts for the lift and feeding. Only 7's I see are complete machines for over 2G's. I don't need one that badly. Will be a neat project. I have everything I need on hand, I just need to find the time to put it all together. Thanks again,

-

Hi folks. I see this Adler 20-2 listed: https://cnj.craigslist.org/bfs/d/neshanic-station-commercial-sewing/7043565022.html Is this a copy of the Singer 7 class ? Interchangeable parts ? Looks very similar but I don't see much info posted around the web about it. Just curious, thanks.

-

I have recently acquired nice Singer 211G166 that came with several sets of feet. Various size cording and a standard flat set. The # on the flat outer foot is 517538 Made in W. Germany which is the same as in the parts manual. But, when I look online at the various stores, all of the feet listed for this models part #'s start with 240***. This foot in particular seems to be listed as 240148, . The main thing I see is that the 517538 that I have is somewhat shorter from the bottom face to the mounting hole than the cording sets buy about 3/32". The cord sets hold the fabric well but the flat foot doesn't come all the way to the throat plate. Two layers of fairly heavy fabric will slide freely when all the way down. I see where to adjust the foot height but am wanting to be sure I am using the proper parts. Maybe the presser height was adjusted up at some time to accommodate thicker materials, never needing to go clear to the plate for the thinner stuff ? ? ? Thanks

-

I finally found where I saw it: https://batonrouge.craigslist.org/atq/d/saint-amant-singer-heavy-duty-sewing/7010051830.html I sent an inquiry asking for the badge info but never got a response. 16-188 looks like a very good guess though. If it is, would that be a true walking foot or the sort of vibrating presser like the original 7 class ? Thanks guys.

-

While searching for parts, I happened upon this. Is this a hack job, or what. This is all the info I have. Does anyone recognize the model ? Curious, looks like a "custom" modification. Just wondering Thanks

-

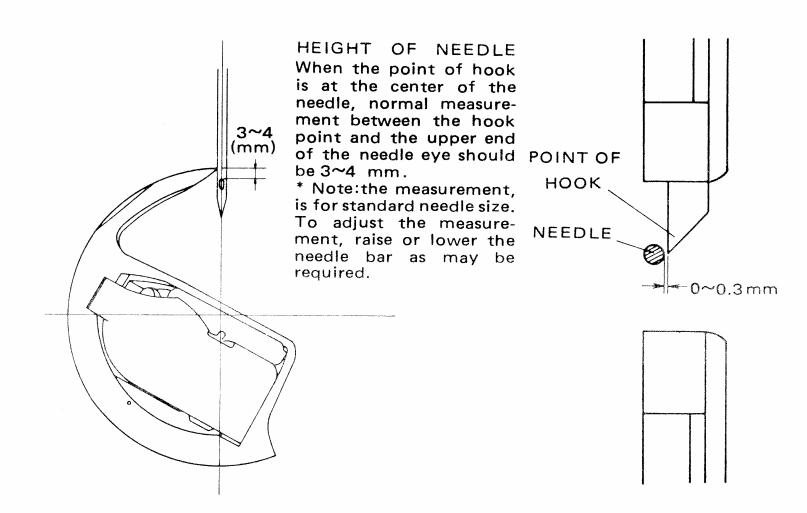

That is good to know .... I guess I'm sure there is some wear there, but it does seem to sew OK, just that the hook can rub the needle if set to spec. This old 7 appears to have many miles on it. May find out more later, thanks Bert. Being a precision machinist, I get a little (lot) picky at times. I can make almost anything exactly as it needs to be .... I just need to find out or determine exactly HOW it needs to be. Thanks again Bert, Good day.

-

Please excuse the bump, I misspoke . I DO know how the measure the wear precisely. The MAX allowable difference, or clearance, between the OD of the shuttle and the ID of the race is what I'd like the info on. And the thickness of the shuttle compared to the depth of the pocket that it runs in. I can move shuttle towards and from the needle by nearly .5 mm. I don't want to go too deep into the repairs if these major components are worn beyond usefulness. Thanks much for any info.

-

Thanks folks ! This one was up for $550 ...... and is gone now. I'm learning more and more of what to watch for now, thanks again to you all.

-

That would be fantastic, but not likely to happen. Although I am watching for one. My tentative plan is a bit simpler but has a fixed stitch length and (for now) will not reverse. Thanks

-

Hi Gregg. I'm guessing you cut the normal knob end off of this piece, then weld an extension to the rear of the head allowing the fork to oscillate beyond center in the reverse direction and the 2 adjustable stop screws set the stitch length in both directions. What did you do with the presser bar to allow it to swing forward while in reverse ? I wish I had the parts, this would be quite simple and easy for me to do. But, keep in mind, I do not have ANY of the parts for the feeding. This machine builder either stripped everything out or possibly bought the 7-33 already stripped from Singer. (maybe at a reduced price) The bosses underneath where the pivot bolts go still have paint in the threads like they were never used. I don't even have the cam on the top shaft ... or the fork, or the 2 shafts underneath. And no lift bar for the dog. Thanks !

-

Hi Don, I've been checking frequently within my reasonable radius for remnants but am beginning to think this is futile. The few prices I've seen for some of the parts is beyond practical for what I would end up with. I'd be better of to buy a new machine ... or a good used one. I do still have a plan for my own feed system. Materials are free, design and build time are just for fun so that wont hurt too much. And then the machine will at least work for me. One issue I have not totally worked out yet is reversing. I can reverse the dog movement but with the vibrating presser following the dog, then returning by spring pressure to the leather bumper cushion, I'd need the foot to travel forward also. Maybe a spring on each side of the bar (front and back) .... both springs holding the bar in the center position when lifted. Then the bar and foot could swing either way. The other thought was a fixed bar (moving up and down only) with a wheel instead of the foot. Sound feasible ? This might be a project for the coming winter. Thanks again,

-

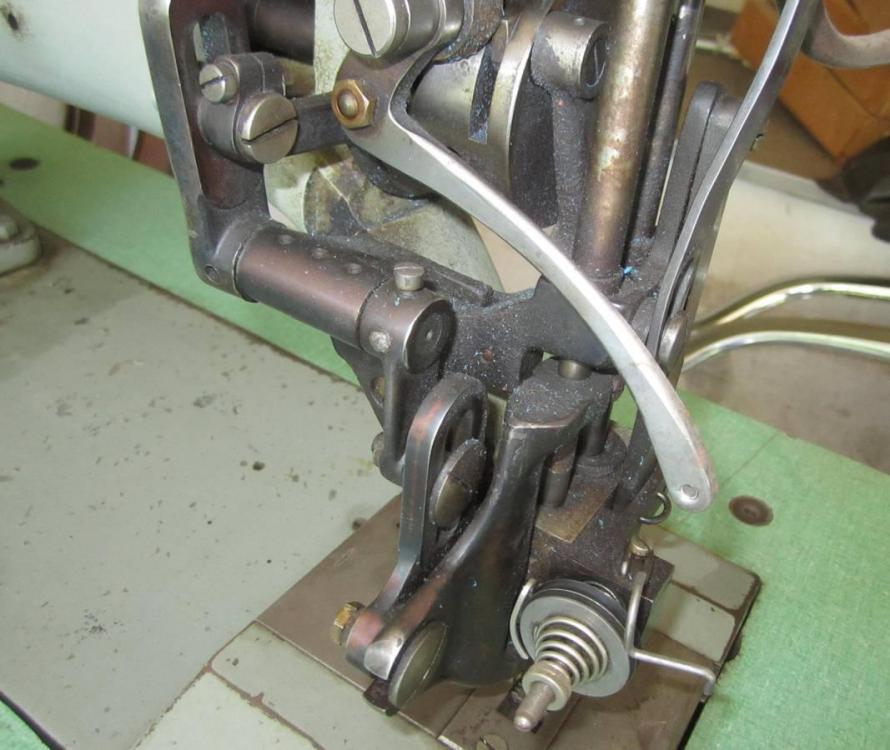

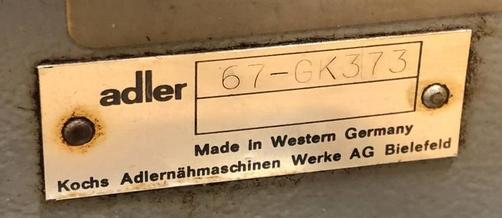

This Adler is for sale locally. No mention of a model number. I'd like to research this for possible purchase. Does anyone recognize the model ? Any pros/cons regarding this one ? Thanks