-

Posts

92 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Blogs

Gallery

Store

Everything posted by RidgebackCustoms

-

Sometimes buying tools from alternative sources can save you money. Like buying gasket punches from auto suppliers can save big money over buying hole punches. I find that bookbinding has a lot of overlap in the tools between leatherworkers and bookbinders. You can find skiving knives and bone folders at reduced prices compared to your typical sources for leather tools. www.talasonline.com https://www.talasonline.com/Bone-Folders?quantity=1&number=352&length=42

-

What are some tools that changed your leatherwork?

RidgebackCustoms replied to Kenzi's topic in Leather Tools

A hard lesson. I remember when I was learning to skive (book binding). I decided the knife I had was the problem. So I saved up and bought a nice skiving knife from Chartermade. Beautiful tool. Showed up pristine and ready to work. Took it to the bench and basically had the same problems. Realized I probably just needed to practice. Nothing wrong with having great tools. I've learned a really great tool can let you focus on the skills because your problems will just be you. -

What are some tools that changed your leatherwork?

RidgebackCustoms replied to Kenzi's topic in Leather Tools

DMT Diamond stones (not the hatched pattern ones, the full width kind, metal bed). I tried water stones, sandpaper, etc. Both work, but the diamond stones let me focus on just the sharpening as I was learning. The 3/4" and 1" skiving knives from Lisa Sorrell. Those things came to my door screaming sharp, no break in or touch up required, so I could focus on learning the inlay work, not the sharpening. -

Learning to do Portraits of People

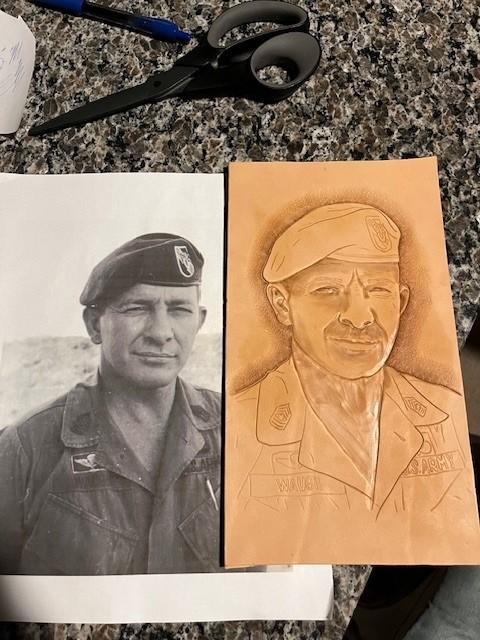

RidgebackCustoms replied to RidgebackCustoms's topic in Figure Carving

New portrait. I'm fascinated by the biographies that The Fat Electrician keeps putting together. Latest portrait is COL Bob Howard. Bob is the most decorated Green Beret of all time. That sentence is staggering when you take into account the breadth of men and valorous actions accounted for in the subset "every green beret ever". Hard to say where the discrepancies are between the portrait and the picture in this case. Off the cuff I think the skin texture is too smooth. On the next one I'm going to try the sandpaper trick (320 grit) to give some texture to the skin. Open to critique as always.- 11 replies

-

- portrait carving

- figure carving

-

(and 1 more)

Tagged with:

-

Learning to do Portraits of People

RidgebackCustoms replied to RidgebackCustoms's topic in Figure Carving

Good tip. I prefer hard copy of references, but anymore they're harder and harder to find. Sucks being an analog man living in a digital world.- 11 replies

-

- portrait carving

- figure carving

-

(and 1 more)

Tagged with:

-

Learning to do Portraits of People

RidgebackCustoms replied to RidgebackCustoms's topic in Figure Carving

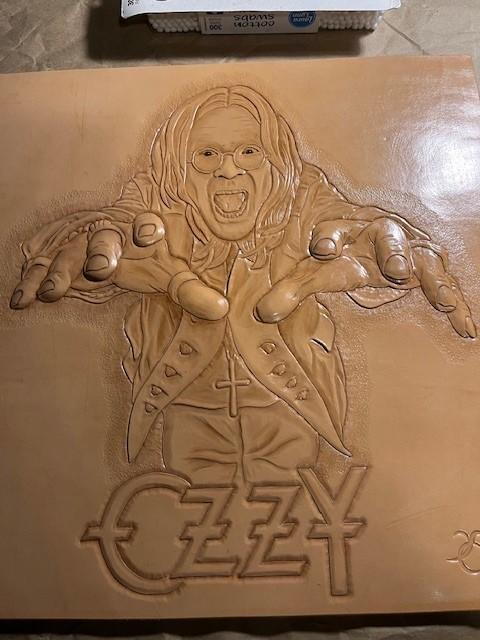

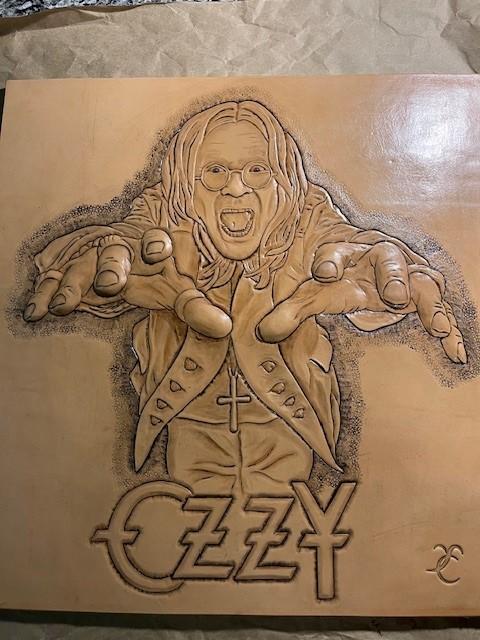

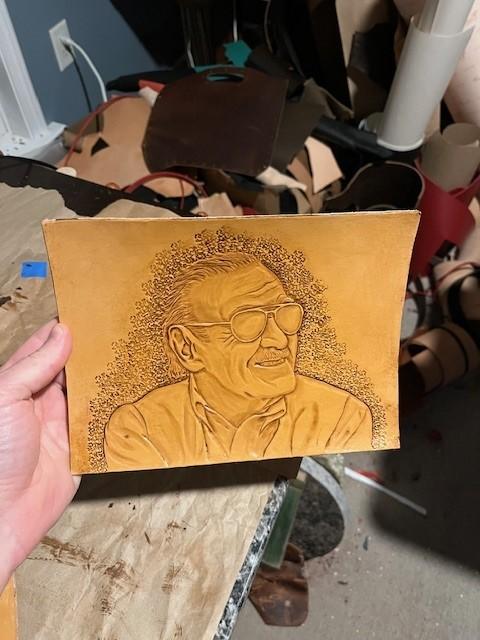

Was able to finish up 2 portraits this week. Next one is none other than Ozzy Osbourne. Granted, labeling the portrait is a little bit of cheating lol. This is my first time doing deep embossing (around the hands) to achieve more depth to the piece. I like the effect, but find I can't get the crisp detail out of the carving if I try to add tooling to the embossed section. The filler material (Renia 3D embossing filler) has a lot of give to it. I wonder if a hard setting epoxy or similar may be a better solution? Also maybe I should tool, emboss, then retool to establish the crispness that I lose by pushing out the embossed section? Not sure. I also used the black eco flo antique which I find I prefer the dark brown of the other portraits. The black is too much of a contrast for my taste. The brown seems to marry the leather undertones better, but just my opinion.- 11 replies

-

- portrait carving

- figure carving

-

(and 1 more)

Tagged with:

-

Learning to do Portraits of People

RidgebackCustoms replied to RidgebackCustoms's topic in Figure Carving

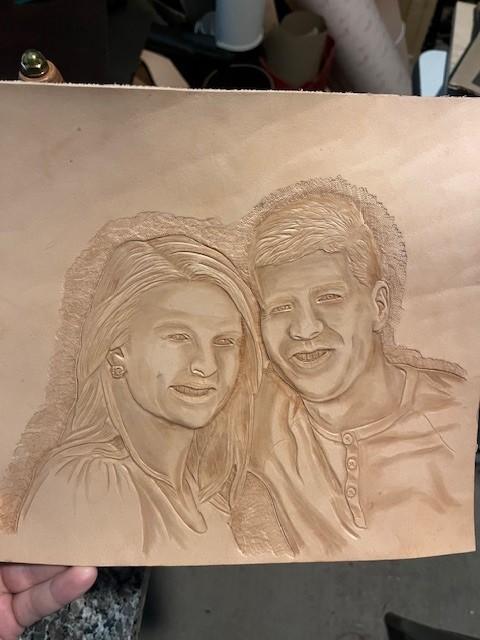

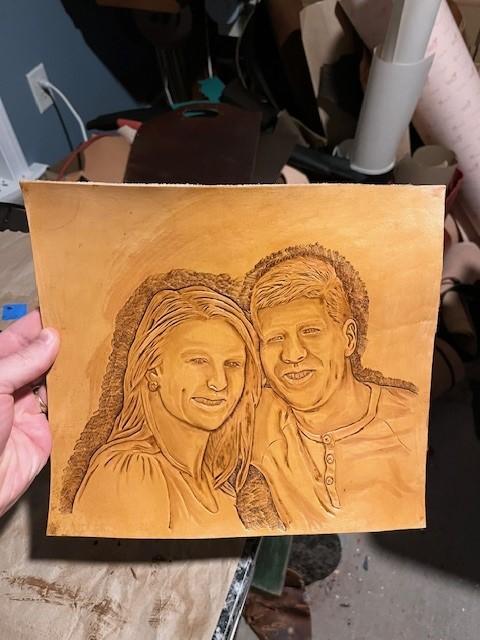

Finished another one. Used a sub-standard piece of leather because it's what I had. There are a couple of fat wrinkles running horizontal through the center of the portrait. I don't think I nailed the likeness, but this is why we practice.- 11 replies

-

- portrait carving

- figure carving

-

(and 1 more)

Tagged with:

-

Tips/advice for 1st craft market tent?

RidgebackCustoms replied to ThisIsMyFirstRodeo's topic in Marketing and Advertising

Have bags / pack out bags for after a sale. Plain brown bags sized for whatever you're selling. My very first sale I just handed it to them and they had to carry it around the rest of the show. Was something I didn't even think of and one of my "duh" moments cemented in my brain. -

Show Me Your Stamp Organizer

RidgebackCustoms replied to RidgebackCustoms's topic in Leatherwork Conversation

It's never enough lol. -

Show Me Your Stamp Organizer

RidgebackCustoms replied to RidgebackCustoms's topic in Leatherwork Conversation

@BlackDragon Your maul storage catches my eye. -

Show Me Your Stamp Organizer

RidgebackCustoms replied to RidgebackCustoms's topic in Leatherwork Conversation

@PastorBob Good looking 1911 you got there. Holster project I'm assuming. What do you think of the brass stamps? I see them there in the picture. I just started dipping my toe in the water and picked up a set of brass backgrounders. Also, what's your work surface and does it span the whole length of the bench? Is it a white UHMW? -

Show Me Your Stamp Organizer

RidgebackCustoms replied to RidgebackCustoms's topic in Leatherwork Conversation

@bruce johnson That's a lot of tool density in a little area. Love it! I'm trying to plan ahead as my tool collection increases. My last solution (in the background) I outgrew really quickly and it never was quite right (poor tool density, super heavy, etc.). The rolls in a box I like! It would be nice to not have to pack up a tool roll when I go mobile. I've had my eye on some new Wayne Jueschke tools, but haven't pulled the trigger. Still in the process of getting more of the basics from Barry King. I have a Bob Beard basket weave stamp I'm on the wait list for. Haven't heard of a lot of the other makers. I'll have to educate myself. -

Across the posts I've seen a ton of different organizer solutions. Most of them are home grown. I'm always looking for the next better mouse trap, so show me your tool organizer. Here's my current solution, but show me yours. Uses a 3 foot section of 2 x 4 cut in 2. One of the boards is slimmed down to create an opening that does 2 things. Keeps the dirt, leather plugs, etc. out of the bottom of the hole and lets me see the color marks on the back end of my stamps. For stamps that look similar I mark the back ends with some colored electrical tape. I've never seen anyone else do this, but it just makes sense to me. Easy to spot the low angle beveler vs the standard angle beveler when I inevitably take both out and leave them on the stone as I tool. Biggest shortfall I have is that the capacity is limited. I punch columns 1" on center to allow finger space to either side, but the tool density could definitely be increased.

-

Learning to do Portraits of People

RidgebackCustoms replied to RidgebackCustoms's topic in Figure Carving

I like it!- 11 replies

-

- portrait carving

- figure carving

-

(and 1 more)

Tagged with:

-

Learning to do Portraits of People

RidgebackCustoms replied to RidgebackCustoms's topic in Figure Carving

It's definitely on my list to integrate into my work, but no pyrography experience on leather. Are you a trial and error guy or do you know any tutorials I should check out?- 11 replies

-

- portrait carving

- figure carving

-

(and 1 more)

Tagged with:

-

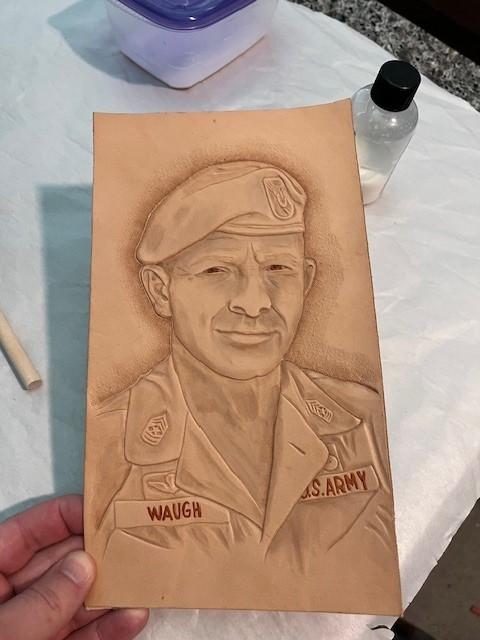

Rather than post a new thread for each project (posted 2 in the show-off thread), figured I'd just start a thread I and others could add to. I'm learning to do portraits. I started down the rabbit hole doing comic book art carvings. I struggled with the faces, so started researching how to do it better and that effort expanded into pursuing realistic portraits. I've really enjoyed the learning process. I'm hoping this thread can turn into lessons learned, progress photos, and a place for others that may be pursuing the same goal to ask questions. My number one tool I've found besides practice is the videos from Elk Track Studios by Annie Libertini. I've downloaded and used those, but was also fortunate to be able to take one of her live classes in 2024 at Sheridan. The first photos here are a self-portrait of me and my wife and a portrait of CSM Billy Waugh. Annie recommends not doing portraits with teeth, as they look weird. After doing the self-portrait, I can confirm. Would definitely recommend not doing toothy smiles. CSM Billy Waugh is an amazing figure in military history. If you don't know who it is and you want to kill > 1 hour of time check out the video. (The video contains a lot of military humor / crass humor, so be forewarned).

- 11 replies

-

- portrait carving

- figure carving

-

(and 1 more)

Tagged with:

-

Edge beveling 101

RidgebackCustoms replied to ThisIsMyFirstRodeo's topic in Leatherwork Conversation

For concave blades/rounded bevelers I use a straight piece of MDF and use the beveler itself to round the corner of the MDF. I then have a stropping block that holds compound pretty well and is perfectly matched to my beveler. Granted, using a beveler to cut MDF is not good for the tool, but it's a one time thing so the dulling it causes is minimal. Not sure I would use this trick for expensive bevelers, but for the cheap ones (which is all I have) it works great. Thank you! -

Edge beveling 101

RidgebackCustoms replied to ThisIsMyFirstRodeo's topic in Leatherwork Conversation

"They be more what you call guidelines than say actual rules" Since the fibers on the flesh side are a little looser and harder to cut cleanly, I tend to cut it first. The presence of the full width of the leather supporting the cut makes it easier. I can push down slightly as well as forward and the fibers don't tend to smush down as I run the line since they're fully supported. -

-

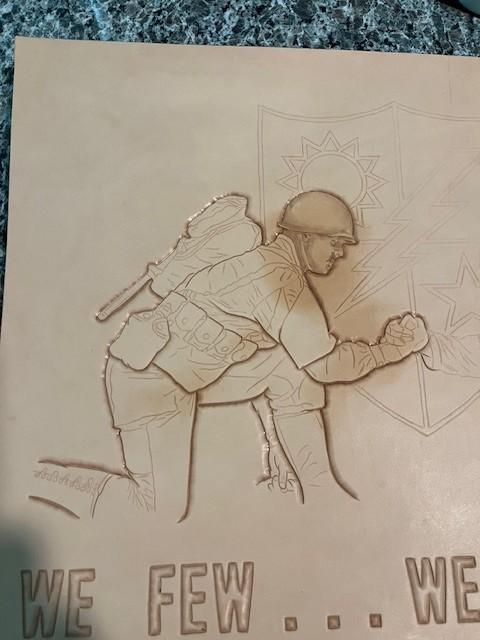

Added color. First time using the Eco Flo Hi-Lite stain. I like it MUCH better than the gel antique or the fiebing's antique pastes. Easier to get the pigments off the areas you don't want them with the Hi Lite. This is their Briar Brown.

-

Need Help Getting Started In South Carolina

RidgebackCustoms replied to Edge1's topic in Getting Started

I'm from Easley. Didn't know there were others in the area. Anyone interested in a meet up? -

Video from the event:

-

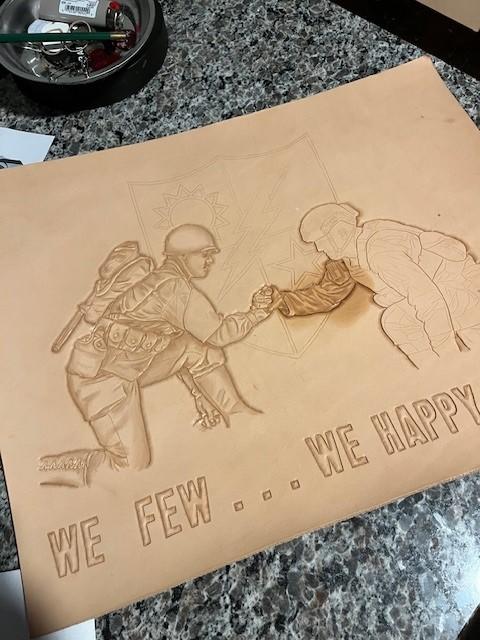

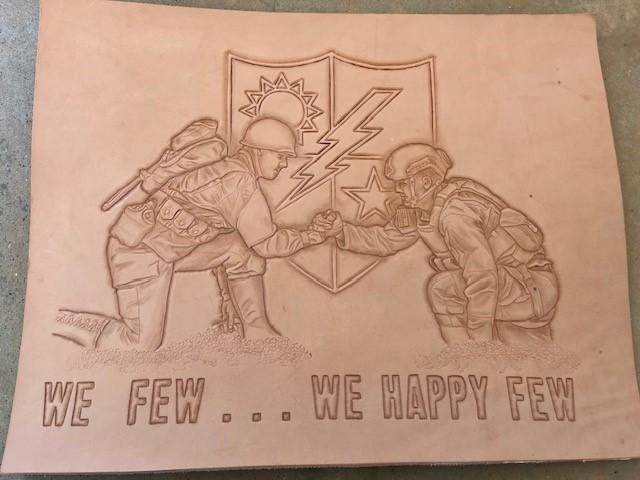

In 2019, members of the 2nd Ranger Battalion, 75th Ranger Regiment, reenacted climbing the cliffs of Pointe Du Hoc for the 75th anniversary of D-Day. Some of the Rangers were dressed in period accurate uniforms while others were dressed in modern combat gear. The picture, used as reference, was taken that day. Members of the original 2nd Ranger Battalion were responsible for climbing the cliffs and silencing the guns firing onto the beaches that day, June 6, 1944. I got to spend a long holiday weekend in the shop and this felt like an appropriate piece for the holiday.

-

Fair. I was scared to try on the first portrait, but think I'm going to give it another go to see if I can get the eyes behind the glasses. I think I may try to dye the background to increase the contrast.

-

https://www.weaverleathersupply.com/products/chahinleather-holster-leather?variant=44039388397708 Weaver's Chahin leather is pre-dyed and still will case and stamp. I've used it for guitar straps using simple stamp patterns and it works well.