Loudcherokee

Members-

Posts

97 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Blogs

Gallery

Store

Everything posted by Loudcherokee

-

First Belt

Loudcherokee replied to Loudcherokee's topic in Purses, Wallets, Belts and Miscellaneous Pocket Items

Are you referring to sanding the edges or the surface of the leather? LC I just use the fiebings pro dye on my edges, and not edge kote. Does that still apply with the paper towel? The inside is treated with neats foot. Would running alcohol take the dye off? LC -

A belt has been on my list of projects I want to do, and I finally wrapped it up today. I do not have a machine capable of sewing thick thread on thick leather, so this whole thing is saddle stitched by hand. About 9 hours worth of stitching. This is only my 4th of 5th leathercraft item so I'm still a little slow at stitching. The belt is 2 layers of 7/8 ounce veg tan strips that were pre cut at 1.5" thick. 4mm stitch spacing and ritza tiger 1mm thread was used. Finished in black with a natural inside, finished with neatsfoot oil. There is some slight waviness in my stitch line. Im still getting the hang of using the stitch groover. Ive been getting better with the wing dividers, but I wanted a groove on the belt so the stitches would set in at the surface. This is intended to be a gun belt for every day carry. Edges beveled with a #4 and burnished with tokonole, then the whole thing finished with resolene. I think next time I do one of these, and want to leave the inside natural, I will cover the inside with masking tape. I handled this belt ALOT during all the stitching, and there was some dye rub off from my fingers to the natural interior. I used a wool dauber to top off the edges, and don't have a clean line on the inside. Im open to suggestions on how to do edges better and cleaner. Open to critiques for any and all errors noticed. Im still learning and would appreciate the feedback. LC

-

Amazon shoe patcher machine frustrations

Loudcherokee replied to Loudcherokee's topic in Leather Sewing Machines

I don't believe the seller does, but there is a tack shop that has a few replacement parts. The stitcher was a gift so I'm not 100% sure who the seller was. LC -

Amazon shoe patcher machine frustrations

Loudcherokee replied to Loudcherokee's topic in Leather Sewing Machines

Well I'll still give it the good ole college try when the bigger needles get here. It made that one row of stitching with the 207 beautifully. If it doesn't work, I will move on to the 138. Is 138 up top and 92 in the bobbin strong enough for a double layer 7-8 ounce belt meant for carrying a gun edc? If not I guess I'm stuck saddle stitching a 42" belt. Can ya'll recommend an affordable machine capable of stitching 207 in 16 ounces of leather that is under the $500 mark? I cant justify $2k on a machine that is right now just a hobby. LC -

Amazon shoe patcher machine frustrations

Loudcherokee replied to Loudcherokee's topic in Leather Sewing Machines

I'll check into that. Im sure ive got something laying around that will work. Ive read of people using plasti-dip on the foot as well. I just ordered some size 24 needles in the recommended 135x16 size. Looking forward to hopefully getting this thing running correctly. I have removed several burrs from the machine already, but haven't given any special attention to the thread path. The bobbin hook is quite sharp. Enough to produce an "ouch" if I grab it incorrectly. So if I get this thing up and running, realizing the bobbin may not hold enough thread to stitch a whole belt, what would be the best way to refill the bobbin mid-stitch? Back stitch a few stitches then keep going? Or will that cause a jumbled mess of thread? Or what about using a smaller size thread in the bobbin, say a 138 and the 207 up top? LC -

Amazon shoe patcher machine frustrations

Loudcherokee replied to Loudcherokee's topic in Leather Sewing Machines

Thank you for that info. I will look into those needles for sure. In regards to the foot, what should I do if its leaving marks but isn't moving the leather? I think I may have smoothed the teeth out too much, but its still leaving marks. LC -

Amazon shoe patcher machine frustrations

Loudcherokee replied to Loudcherokee's topic in Leather Sewing Machines

Is this the modification I see mentioned where you have to file the needle bar? Or is that type of needle just a drop in? LC -

Amazon shoe patcher machine frustrations

Loudcherokee replied to Loudcherokee's topic in Leather Sewing Machines

I went back to the super thin thread that came with the machine. It is operating correctly now. When the new thread and needles get here, I will attempt it again. This stuff is SUPER thin. I also see that I need to smooth out my presser foot some more. I filed down the teeth, then hit it on the belt sander and it feels smooth, but its still marking up this pull up leather. I do need to learn to stitch apparently. When removing the item, I snip the threads, and when pulling the threads taught on the piece to snip close they just pull out. I know I need go back stitch, and I've tried and still get a little pull out, but not as much as if I don't back stitch at all. Let me see if I'm doing this right. I make 3 full stitches, and while the foot is up, I rotate the drum 18p degrees, and go back over those three stitches, then again when the foot is up, I rotate the drum and stitch back over those 3 original stitches a 3rd time. I end my stitch line like this as well. Do I have that right? LC -

Amazon shoe patcher machine frustrations

Loudcherokee replied to Loudcherokee's topic in Leather Sewing Machines

I've got some more thread and needles on the way, some 138 I think? And some size 21 and 22 needles. The needle is situated with the channel facing the left. Can you explain the drop test for the bobbin? Am I holding the thread and letting the bobbin drop? What do you mean by changing the size of the needle? LC -

Amazon shoe patcher machine frustrations

Loudcherokee replied to Loudcherokee's topic in Leather Sewing Machines

Well I followed kggs suggestion, and I got it stitching but now it won't lock the stitch and it breaks about the 5th stitch and both threads pull out of the leather with ease. LC -

Amazon shoe patcher machine frustrations

Loudcherokee replied to Loudcherokee's topic in Leather Sewing Machines

I found a way to resize in my phone. Lets see if this works. Hey it worked! The original image was 2.4mb. It resized to a little over 500kb. Thanks for the suggestion! LC -

Amazon shoe patcher machine frustrations

Loudcherokee replied to Loudcherokee's topic in Leather Sewing Machines

I did see that and haven't gotten back to the machine to try it again. As for the images, when I tried posting those, I kept getting a warning of 1.46mb max file size. The pics were taken from my phone so I'm not sure how to reduce the size. Thats why I used the hosting site. I'd rather not use it but I had to. Maybe the 1.46mb limit is because I'm new? LC -

Amazon shoe patcher machine frustrations

Loudcherokee replied to Loudcherokee's topic in Leather Sewing Machines

That thread is 207 with a #18 needle that came with the machine. Ive ordered some 21 and 22 size needles but they aren't here yet. I've noticed that the thread is going up under the bobbin shuttle, the part with the gear on the bottom, occasionally. Its also wrapping around the bobbin shuttle itself. It appears that the claw is at times piercing the thread rather than grabbing it like it is supposed to. LC -

Amazon shoe patcher machine frustrations

Loudcherokee replied to Loudcherokee's topic in Leather Sewing Machines

Here is what I'm now dealing with. I set the timing on the cams, arm, and bobbin shuttle, and also slightly enlarged the hole in the plate. I don't know what happened. It was stitching fine. If you look at the first picture you'll see how well it was stitching in the second picture. The link is a short video, followed by a picture of the aftermath. https://imgur.com/a/uwHAuBG LC -

Thanks for the references! Yes I do need to get some books. I mostly rely on you-tube how to's and some of the articles on here. I will check out some of these places for sure! I did see some stuff on Springfield site that I liked. I cant claim credit for that pouch though. Thats a screen capture of a pouch from dieselpunk. LC

-

So my shoe patcher came in. After a thorough degreasing and building a makeshift stand for it, I threaded it up and started messing around. The first stitches were ok with the super thin thread that came with the machine, until I tried some thicker leather. 2 layers of 7-8 ounce it does not like. I messed around with the tension up top and finally got it to feed through that 7-8 ounce double stack, and then decided to switch thread types. I put in some 207 and threaded it up, and it will stitch, but not well. The bottom of the piece looks a mess and it keeps lifting my leather off the arm when the needle moves up. I kept tinkering and eventually got it to thread nicely and make a beautiful stitch, and then went to pull the bobbin out and the whole works came out. Ever since I cannot get the needle to pick up the bobbin thread. It keeps making birds nests underneath the plate and getting wrapped under the bobbin and ive broken 3 needles. When I finally got it it to grab the bobbin thread, I threw in a piece of leather to see if it was stitching correctly and this happened. Any ideas? Also, where can I find size 20 or 22 needles for this thing? Biggest i can locate are size 18. LC

-

Thanks again for the info! The snaps i have currently are parallel spring i think. The ebay seller got back to me and said they are unsure of the thread size on the dies. They appear to be similar to the other Chinese dies that I'm finding so maybe they will work with other round spring snaps. I will check out those machines you posted. Thank you! LC ETA - that machine from very baby looks just like one on Amazon that uses 1/4" shank dies. The craft tool looks nice, but ouch dies are $120 a set!

-

I sent them a message asking what the thread size is on the dies, and if they will work with Pull the Dot snaps. Thanks for finding that! LC

-

Wow! Thats alot of info! Thank you for taking the time to explain all that. The press i ordered has M8 threads for the dies, so when looking for the button type snap dies ( like what would be used on a holster) I'll make sure to look for that thread size. I had originally thought the line 24 just had a longer post than the line 20 due to Tandy website listing the 24 for 8/9 ounce leather and the 20 for 4/5 ounce. Good to know its an actual diameter measurement. If I get rolling with this and can justify one of the nice Master Tools machines later on, I'll look into that but for now I'm ok using the cheaper stuff from Ebay and Amazon. LC

-

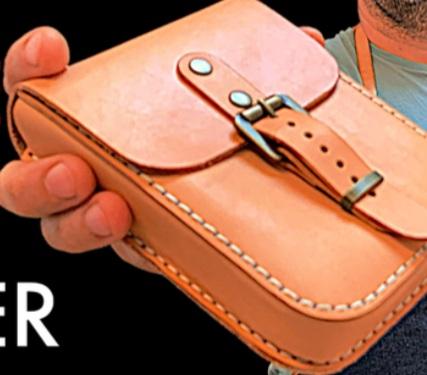

Hey guys! Man I'm getting excited about making all this stuff, but I'm running into some roadblocks. Mainly, nomenclature. Theres things I want, but I don't know what they are called, therefore I cant search! Is there some sort of "dictionary" for all the hardware names and stuff? Three examples, in my introductory thread I mentioned looking for a certain kind of closure and couldn't figure out the name and couldn't find any no matter what search terms I used. Turns out if was called a tuck-tite clasp! Someone was very helpful with that, along with a link. Second example, all the buttons and snaps. Apparently there are some designated as Segma, 831, 655, etc and others are Line 20 and Line 24. Im getting lost in the mix. Third example, in the pic attached, what is the small flat ring that is holding down the loose strap called? I know the buckle is a "roller buckle" but the only thing I'm finding for the ring part is "rectangular ring" and this doesn't seem to be the same thing. Lastly, where is a good supplier of these types of hardware? While I'm learning, im ok using the bulk stuff found on Amazon and ebay, for example 50 assorted size bronzed buckles for 10 bucks, but I know the finish will flake off on those eventually. Where is a good supplier of quality hardware like these? LC

-

Do these look right? Is the line 20/24 snap considered an 831 in the Segma designation? https://www.ebay.com/itm/4pcs-Set-10-12-15mm-Snap-Button-Dies-Mold-Fastener-Tool-For-Hand-Press-Machine/293818327385?_trkparms=aid%3D1110006%26algo%3DHOMESPLICE.SIM%26ao%3D1%26asc%3D20190917065201%26meid%3D8446804e768f4ae4948f7e9a5b4fea75%26pid%3D100935%26rk%3D1%26rkt%3D12%26mehot%3Dco%26sd%3D152480114727%26itm%3D293818327385%26pmt%3D1%26noa%3D0%26pg%3D2332490%26algv%3DSimplAMLv5PairwiseWebWithDarwoV3BBEV2b%26brand%3DUnbranded&_trksid=p2332490.c100935.m2460 ETA those are probably wrong. I think the 20/24 style is actually 201 not 831. This is all so confusing. Almost as bad as thread sizes! LC

-

Thanks! That one on ebay is listed out of stock but I found a similar kit and placed an order! Appreciate the assistance! I will still need to either find some dies or get a good hand tool for the line 20/24 style button snaps though. I plan to use those on a few things. LC

-

Thanks! I'll check those out. I looked at the line 20 and line 24 snaps. Those are different than what I'm using, which was a 655. They will require a different tool all together. LC

-

The ones I ordered didn't have that designation. It was a multi-pack in 3 different sizes, but the post size is all the same. Lc

-

Hello, I'm on the hunt for an affordable hand press to set buttons and snaps into my projects. I tried last night to set some with the little rods and anvil that came with my button kit and it was a nightmare. I ruined about 10 posts, caps, and sockets before I got one to take hold. I found this one on Amazon, but it doesn't come with any dies. I can only find dies for 15mm buttons. I want to be able to use 10mm and 12.5mm buttons as well. https://www.amazon.com/dp/B07VB2SXQS/?coliid=I2A921RJXL9IEF&colid=238SAUAALRARW&psc=1&ref_=lv_ov_lig_dp_it Is there anything similar out there that doesn't cost $200? LC

.jpg.d60258221c476480a6e073a8805645bb.jpg)