Oldiesfan

-

Content Count

60 -

Joined

-

Last visited

Posts posted by Oldiesfan

-

-

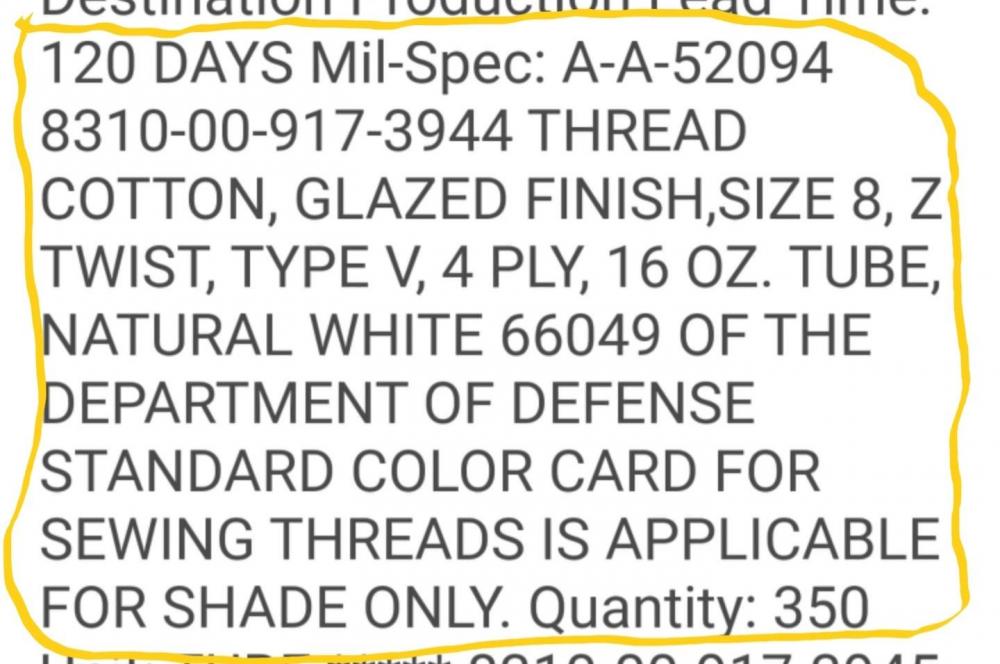

9 hours ago, Wizcrafts said:Regarding the "shoe thread," ask the seller to check the label to see which way it is twisted. Most single needle sewing machines with hooks spinning clockwise require left, or reverse, or Z twist thread. But, some shoe sole stitchers require right twist thread. If you use right twist in a standard sewing machine it may unravel as you sew.

Note, some twin needle machines may require right twist for the outside needle if that hook spins counterclockwise..

Look at what's mentioned in the printscreen . Z Twist .

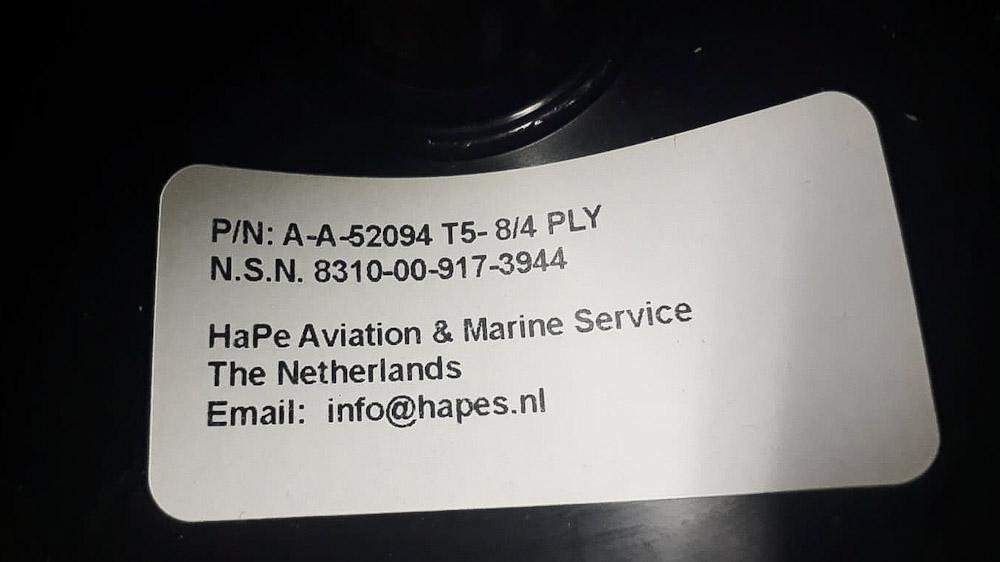

One page back you see a picture of the label .

-

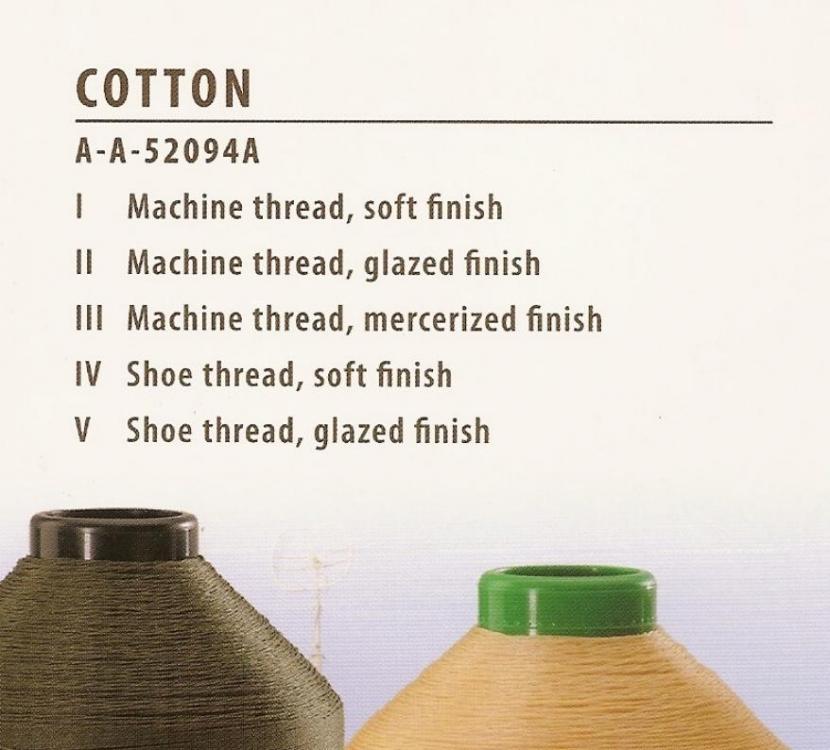

This is what i found on the internet . It also seems to be that a type IV and V are shoe threads . Type 1, 2 and III Machine threads. Look at the picture for info about a A.A. 52094A version .

Does that mean that a type V can't be used in my Singer 132K versions or 45k89 ?

-

56 minutes ago, jimi said:I ordered 3 rolls instead of all 12 . Let's say it's Cotton thread in this type i asked questions about . For what kind of sewing work can you use that thread ?

See label and Nsn

10 € a roll = cheap or expensive?

-

For as far i know it's a Cotton Z- Twist size 8 thread.

I

-

-

6 hours ago, jimi said:Who knows why they would want to do that but i have heard people took these parts off because of the noise the foot part made?? the model before the 89 was the one that made a louder noise i think, it was the 33 which was superseeded by the 89 around about the 1920´s, yes it does sound stupid Lol... The 45k93 was the last.....lets say....upgraded model before they changed to the 45A and 45B models, the badge on your machine is from the 1960´s i think so it should be in very good condition normally unless it has had a very hard working life. The table has given in and bent because the ones for the cylinder arm machines had a extra arm to support the machine underneath, so remember this if you make a new table top! The 53,56,89 had a lot of accessories available for them back in the day which unfortunately never seem to come with the machines people find these days?? you can see them in the parts manual, the only ones that are usually found with the machines are the material guides and sometimes the swing arm like the one on yours.

Machine is in a nice condition .

This because they are built like a Abraham's and had probably no hard working live . I bought a massive oak tabletop ( 1000x600x40mm ) . I also put an extra arm underneath for support. But i think that it's not necessary haha .

I paid +- 50 € for this machine . Not included the gasoline that was needed for the pick-up .

-

8 hours ago, jimi said:Hi Oldiesfan, yes the machine is missing some parts. The 45K89 was called a kick foot machine, here is a video of one restored, if you want to see the parts you need it is best to download the parts manual and look them up. By the looks of it you are missing quite a lot of parts which are very hard to find but not impossible. By the looks of the badge your machine could be from the 1960´s but it has unfortunately been left out in the rain a long time!! With the parts missing it is equivalent to a 45k93 with a roller foot, the 93 had reverse but no roller foot and the 25 had the roller foot but no reverse???Lol....

Thanks for the reply!

I searched for the 45k93 model looks and indeed my 45k89 looks the same .

The Farmer told me that he bought this machine as a roller-foot version . So I believe that before he bought it somebody removed the parts that were necessery for a walkingfoot type to turn it in a Roller-foot version .

Question ! Why turn it i a roller-foot. What are the benefits?

It never stood in the rain haha .

The seller ( farmer ) put it outside the Barn so we cut pick it up when nobody at home .

Eventtuell he was at home and helped with dragging the 45k89 to the Car . A heavy Pfaff Cast iron machine base made almost impossible to do this alone or with my Wife as helper.

The machine is in working order and after more cleaning and some polishing it will Sewing even better .

-

Does someone know if there's something missing on my machine

There so many different 45K(89) versions that it's possible nothing is missing

There so many different 45K(89) versions that it's possible nothing is missing  But for now is a question!

But for now is a question!

-

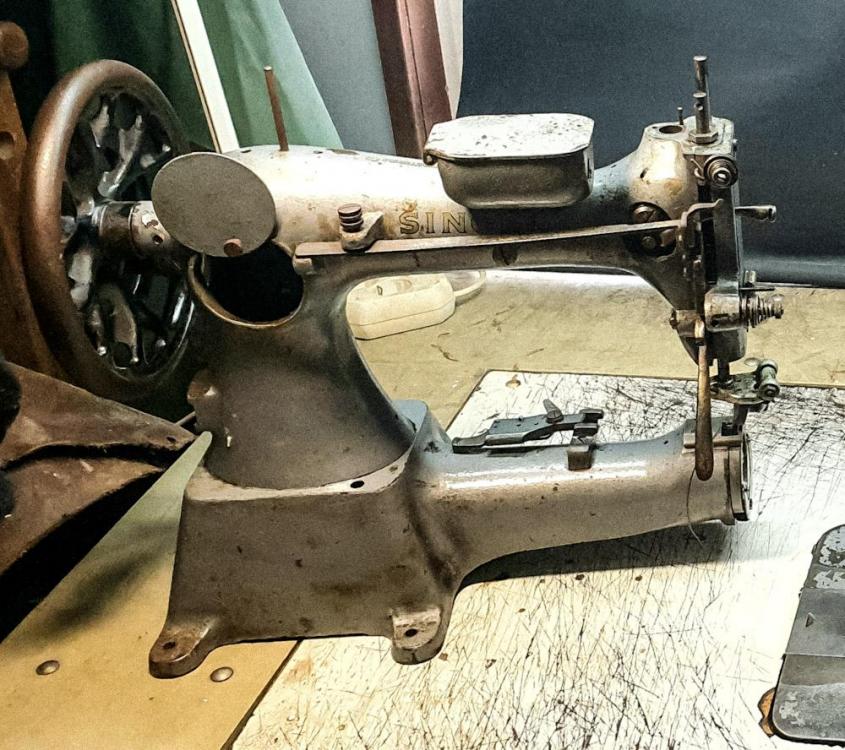

This Singer 45K89 stood for 18 years in a barn . The Farmer ( has Horses and Cows) used it for repairs .

Nothing moved when i tried to turn the large wheel . I paid a small amount of € for this machine .

Now a few days later the machine is running en stitching.

Not perfect because some parts need to be cleaned and polished .

When i look at pictures on the internet than i get confused! It looks that there are some parts missing! Or not ? Look at the pictures what i mean .

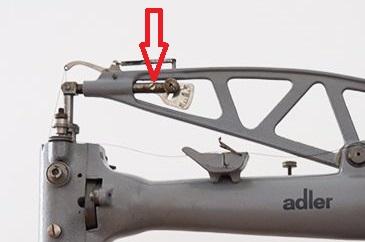

My machine has a roller-foot and no extra tension on top . Only that what you see in the first two pics . Picture 3 shows what i see on a lot of 45k machines .

Picture 4 shows the machine outside the farmers barn ready for pick-up.

The Kobold motor runs smooth, but also needs a cleaning and adjustments.

-

On 5/6/2021 at 6:52 PM, jimi said:Is it sharp on the edge of the cut out?? Could it be for cutting the thread??

No not sharp at all . Probably another reason why it's designed that way .

-

The quality of Singer Needles is ?

The 132ksv18 came with a bunch of Schmetz needles.

The Old man didn't want anything else .

Is Singer still today producing Industrial needles ?

-

44 minutes ago, Constabulary said:Don´t worry too much about needle - it will cause headaches.

There are several thousand different needle systems for different machines and similar needles sometimes have different "names".

There are several thousand different needle systems for different machines and similar needles sometimes have different "names".

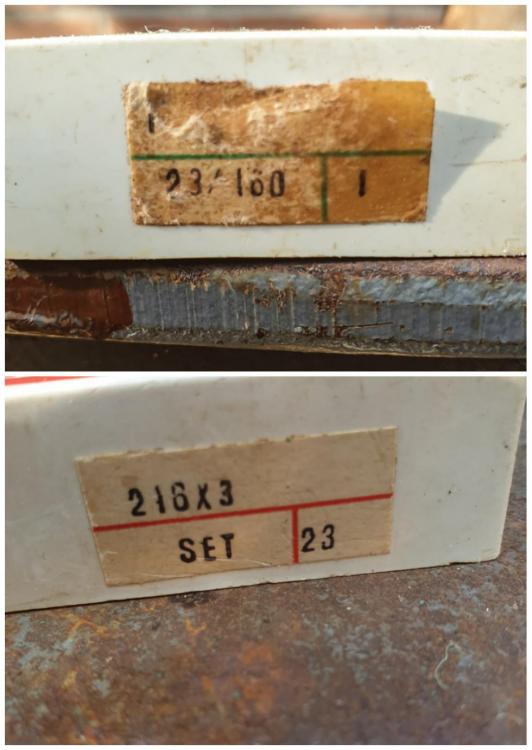

You can use System 214, 216 & 328 needles in your machine 214 & 328 are the same, 216 are a bit different around the tip (at least my 216 are a bit different compared with 214 / 328). On 214 & 216 the prefix (1, 2, 3, 5, 7....) is most likely and old description for a certain needle tip.

Really - don´t worry too much. 216 is not very common today that's why 214 / 328 is used instead. It would not surprise me when you order 216 you may get 214 in a 216 marked package instead. I have heard when you order 332 you may get 135x17 instead (same needle length but 332 has no scarf on the needle).

Regarding KY - not sure but maybe Singer had different facilities for manufacturing needles and one maybe was in Kentucky = KY. But that's a very wild guess.

Thanks for explaining and the no worries.

But ! ... i didn't worry haha . This because it is sewing oké.

So because of a certain needle tip they choose probably a 216 - 3 type instead a 1 or 2 as ISMACS is mentioning for a 132k ( 6 ) version .

-

14 minutes ago, kgg said:Looking at how the needle box has " X " printed the letter stamped in the needle looks like the same old style typeface set so it may very well be "X Y " or "X V" not "K Y" .

kgg

Some parts of the X on the box are worn off . I looked at maybe 30 needles and they all were showing a K Y . Not an X .

-

2 hours ago, jimi said:Not a clue

this is from Ismacs needle chart....this is the only thing i can see with XY not K referring to needles???

this is from Ismacs needle chart....this is the only thing i can see with XY not K referring to needles???

Note: A. Bryson published this list of machines with the following note: “Davis S.M. Co. machines with tension (sic) on top of arm take needle X (1X is given as 1x2); those with the tension on the side, or on the face plate, take needle Y (15x1)”

Thanks!

It ain't easy to find exact info .

A 132k6 = 216x1 or 216x2 needles . The one i use works ( fine ) with 216x3

. Why a 3 instead a 1 or 2 type ? could you ask .

. Why a 3 instead a 1 or 2 type ? could you ask .

In this box are still more than 100 needles. When new out of the shop probably 200+ . So I think they did get the right needle for the right job !?

-

12 hours ago, Wizcrafts said:That is the round, or barrel shaped adjuster I was referring to. I forgot that it has a scale with a pointer on the end for thin, medium or thick work. I was last sewing on my Singer 29K71 patcher that only has a round screw on the end of the slack adjuster. It resembles a long, round barrel. Hence, I think of it as a barrel adjuster. :-)

In any case, the more this adjuster is brought into play, the more loose or slack top thread is fed to the needle after the take-up reaches the top and moves down. With no slack, the top thread may fight against the action of the presser foot, causing slightly shortened stitches. However, the stitches will lie very tight against the leather.

A moderate amount of slack in the top thread will let the foot move a little more freely. You will get longer stitches that the minimum setting because the thread won't fight so hard against the motion of the foot.

In the maximum position there is so much loose thread that it will flop around as you sew. You will get your longest stitches in thick work. But, the thread could get caught by the tip of the needle or it could wrap around a leg of the presser foot and jam things up. However, if you are careful, this setting will give a reasonable stitch appearance while allowing the foot to pull the work a little more than might otherwise be the case. As anybody who uses a patcher machine has learned, the maximum stitch length is greatly reduced as you exceed 1/4 inch, or 6mm thickness.

Another thing one can do to get the longest possible stitch length in any thickness is to reduce the top and bottom thread tensions so they aren't fighting against the foot motion. This is especially helpful if the feed motion cam is badly worn.

Thanks for this reply. I will play with te tension . It's just by occasion that i need to sew thick leather

4 or 5 mm or + . This time the stitches were very tight as you can see . So tension was high and strong threads.

-

Nobody who has an answer

-

-

35 minutes ago, Wizcrafts said:I have a 30-7 and it gets 5 to the inch as well. If you ever find that it struggles to get a particular stitch length, increase the amount of slack thread using the barrel adjuster on top. More slack thread on top makes it easier to pull the work back with the foot. Of course, the bobbin tension should be minimized so it isn't fighting the feed.

Maybe it sounds silly

But what do you mean with " Barrel Adjuster " ?

My Dutch is better dan my English witch I barely use in live haha .

-

I long time ago I obtained a Adler 30-1 . A friend of mine who had problems with sewing had enough of it . So we traded

The same day of arriving i played with the tension and needle height ( it was not all the way in ) . Threaded it and it was sewing beautiful stitches .

Until today I never used the machine again .

Why did I use it today ?

Because of a question I had in the beginning the machine stood in the room .

Is the stitch length still okay ?

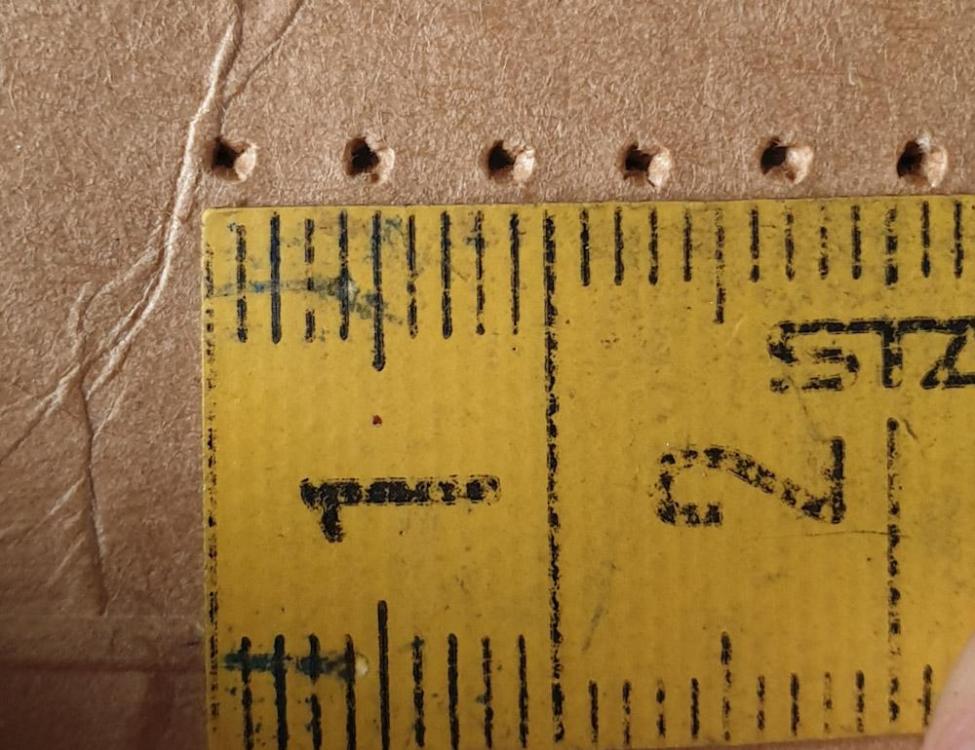

I threaded the machine after a test on thick paper . After that I'll used 5 mm leather and no changing of tension . No matching thread and needle also . See pictures of results.

Last picture shows needle holes in 5mm leather.

Stitch lenght on max ( 5mm and little bit over )

How old this long-arm 30-1 Adler is i don't now . Serial 79936 .

-

On 3/29/2021 at 6:06 PM, JayEhl said:Howdy from Texas!

Thank you very much

-

Thanks for all the reply

Bushings instead of Bearings!

I don't no if I dit wrong

But I used Kroon oil, SMO 1830 Sewing machine oil to lubricate the Bushings.

But I used Kroon oil, SMO 1830 Sewing machine oil to lubricate the Bushings.

-

-

@Constabulary can you tell me something about the difference between te two Shuttle hooks in the pictures ?

There are 2 tings which you can see while looking at te two .

See pictures and arrow pointers .

Thanks for your helping hand so far

-

27 minutes ago, DonInReno said:If it runs smooth there’s no reason to change bearings. However you should lubricate them. Use an oil intended for electrical motors - probably something like 20 drops of oil in each bearing each year. There will be a third oil cup at the very front of the motor and the pulley shaft will have two additional bearings.

It’s not clear if the bearings that support the shaft the pulley is attached to are lubricated by the oil cup in that area or if that oil cup only lubricates the back and forth action of the clutch mechanism. On newer motors the two bearings that support the pulley shaft are sealed, but you might have to see if there’s a way to get some oil into yours.

I noticed the two ( not a third) oil caps and did lubricate them in the beginning . One thing that bothers me is that there's a lot of dust in the clutch area .

I think that the seller never or hardly cleaned the sewing machine and Electric Transmitter .

New bearings !? What i will do is, use the machine for a while and will see if something change in sound or motor behaving .

I hope that somebody can give me a production date of this transmitter. And if it's was maybe a original one that was delivered in this set ?

With some reason for this 132ksv18 I mentioned in also another topic .

Needles And Threads

in Leather Sewing Machines

Posted · Report reply

When this thread is ( maybe ) waxed , why should i wax it again . On my 45k89 is a huge waxe pot . So I this machine can handle waxed thread ... i think !

"Glaze or mercerised, but not Bonded" . What do you mean with bonded ?

The machines i use for sewing are 132k6 ,132ksv18 and a 45k89 ( with waxe pot on top )