Leather2

-

Posts

92 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Blogs

Gallery

Posts posted by Leather2

-

-

-

9 hours ago, EmilyRose said:

Hey— thanks for clicking! I’m a new member, in my thirties and joined to learn more so I could buy a used custom saddle confidently. Nice to meet you here! When eye -balling a saddle what are some things you have learned to pay special attention to? I love reading on this forum and have tried to deduct what separates good, better, best. Below is a custom saddle from a maker who is no longer in business ( according to seller) and builder has zero online presence.

I love details and I absolutely would love any insight from leatherworkers and saddle builders on what to pay attention to, other then straightforward basics when looking at a saddle for sale. This saddle is a 2 days drive, and if I could find a website, Facebook page, business card, or another saddle made by the same maker, to compare , I wouldn’t feel so clueless.

Don Gonzales has some great videos addressing your questions.

-

On 11/30/2023 at 9:36 AM, Paul514 said:

Hi everyone,

im now an offical member

This guitar strap is my favorite out of all the guitar straps I've ever had. I got it long after the store closed in Alabama.

Levy's no longer makes it.

If anyone is interested in duplicating this strap please let me know.

I will be staring an online used guitar store in 2024 and would love to sell this strap and also I wouldn't mind having a few more for myself.

I would be looking for 5 - 10 straps at first I think.

Thanks for reading,

Paul

I have braided much leather, but if you want to sell some tooled guitar straps, let me know, and I can show you some of my work.

-

-

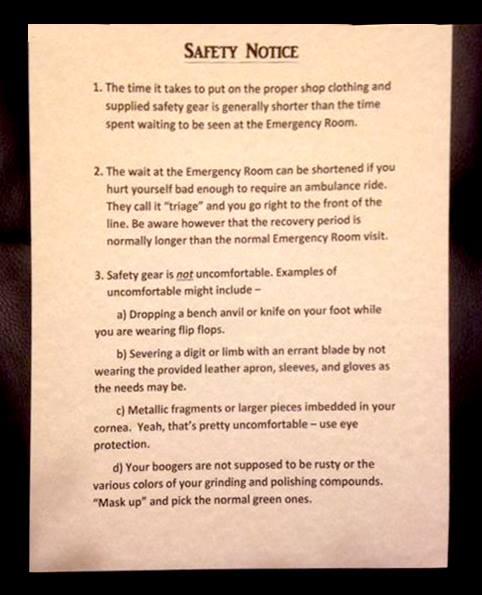

7 minutes ago, bruce johnson said:

As Chuck said my needs are different than most people. I am refurbishing old tools and sharpening new ones. My realistic safety procedure is this.

My grinders are all turned around on the bases so the top rotates away from me. I have big arrow stickers on each end of the motor to remind me of the direction of rotation. I work on the top of the wheels. I can see my edges and I feel like I have better control of the angles. I have tubs behind each wheel to catch extra compound that flies off when applying. If something catches, it goes away from me.

There are exhaust fans behind the grinders that will pull the dust out. I had a consult with a dust control industrial advisor to determine what capacity fans I needed. Overkilled it - full air exchange every 2 minutes. I have an overhead air filtration unit too (Rikon). I've got an air quality meter and noticeable differences when they are on. There are summer days if we have a forest fire blowing our way my shop air is better than outside.

Safety gear - mask with N99 cartridges. I have a face shield now from Benchmark Abrasives - awesome deal and allows masks with cartridges. Leather apron. I wear leather welding sleeves over my arms.

The looser the wheels the more they can catch a back edge and throw a tool. Gonna be honest, it happens but way less than it used to. I don't like the airway buffs and stopped using them. Yes they run cooler, yes they are durable and perform well. Yes those folds/pleats catch back edges and throw tools like crazy. I also have gotten away from much pressure on the wheels. I almost want a butterfly kiss touch and works better than pressing into the wheel. That was a hard habit to break -grinding or buffing. I watch my angles and edges and am careful when I get to tips and corners. Again, working off the top of the wheel gives me a better picture. When I am working on handles and bolsters the edges of the blades get taped with two layers of aluminum tape. I threw more tools doing handles than edges.

Thanks.

BTW where do you get your buffing wheels? And what thickness and diameter do you prefer for green compound. Thanks

-

31 minutes ago, chuck123wapati said:

Hand sharpening or polishing a razor sharp piece of metal at 1800 rpm with a buffing wheel is the most dangerous thing anyone can think to do and is usually done by very experienced knife makers or folks who re sell like Bruce. The only thing Bruce's safety poster(very cool btw) leaves out is if you don't need to run the machine and can use a safer method then don't. It simply isn't needed for day to day sharpening if that is your plan. Compound on a strop is what you need for that. On compounds you can find specs and uses for the different colors on the company sites usually. The compounds i buy came with a chart showing what material each is designed for.

I know I didn't give a positive response to using these machines and don't know your skill level with power tools but i too have to warn of the risks.

However good luck on your endeavor and be really really carful.

Thanks Chuck, it’s always good to remember how dangerous the tool you are using can be.

-

1 minute ago, bladegrinder said:

The only reason I stacked them was my wheels are 10" and at the time all I could find were 1/4", that was pre-internet days ha ha.

black is pretty much the opposite of green. if your looking to use this just for sharpening white and green should be all you need.

Ok, thanks

-

On 11/3/2023 at 5:17 PM, Goldshot Ron said:

I acquired vintage handtools that belonged to a saddle maker who moved out of our area. Here are seven C.S. Osborne spring punches that I am offering for sale. I am asking $45 for each punch, and that includes shipping within the United States.

#1 is in good condition. The tool says size 2, but the tube size is a number 7. This punch is CS Osborne, Newark NJ.

#2 is in good condition, size 3.

#3 is tube size 4

#4 is in good condition, size 6

#5 is in good condition, size 8

#6 is in fair condition, size 9

#7 is in poor condition, tube size 6, but tool says 2.

I have buffed the cutting edges, and they all cut. The anvils are okay for light use, but you may want to change them out for heavy use. Replacement tubes can be purchased from Weaver, and the threaded tube ends are all the same.

Send you a Direct Message

-

-

3 minutes ago, dikman said:

I'd just like to reinforce what Bladegrinder said - buffing wheels can be extremely dangerous if you get a "catch"! The loose floppy ones in particular, I approach them with a degree of caution, having had a few things grabbed by them and flung hard against the wall behind. I have a couple of different grits but I tend to use green mostly, seems to work fine for my needs.

Thank you,

-

3 hours ago, bruce johnson said:

I'm definitely the wrong guy to ask. I have 5 variable speed grinders and then three VS bench lathes (essentially small bench buffers). Some of wheel/grit combinations are 1/2 inch on an arbor for my drill press. Everything for the grease based compounds on the grinders are two stacked 1/2' wheels. I use 1" denim wheels for five grits of greaseless compounds. For waxy grease based compounds I use sisal, spiral sewn treated and spiral sewn non treated, and loose wheels. Once I get past the greaseless compounds I use four grease based compounds currently. All my compounds come from Maverick Abrasives now. They have been more consistent and economical for me.

Black compound on sisal is most aggressive and removes grit marks pretty well. Makes a nice transition step up from the 600 grit greaseless. Next step is green - treated wheels first and then spiral sewn regular wheels to give a nice reflective polish and most people probably quit there. I go to purple compound on a spiral and then a loose wheel and it really brightens up after the green. I use pink on a loose wheel as a final buff or softer materials - the pink is really more of a polish than much abrasive - can use it on wood, plastic, or brass to really make it pop.

For my leather stropping wheels - black and green then purple on a loose wheel

Thanks Bruce

-

49 minutes ago, TomE said:

Mine is one wheel with the cotton layers sewn together to make a firm edge. My buffing wheel is 3/4" x 6". Fits the curved blade of a hoof knife. I don't have experience with black compound. Green is plenty fine for my blades. I buy supplies from Farrier Product Distribution or Sharpeningsupplies.com.

Thank you

-

9 hours ago, bladegrinder said:

I believe I have the same buffer but 3600 rpm. I use it in knife making and have had it about 30 years. what I use are 1/4" wheels stacked to 1" you can find them at Trugrit abrasives or other knifemaking suppliers. whether you use one or stack them there is considerable time involved getting it balanced on the shaft to run true, you just have to keep adjusting it on the shaft until it runs smooth and there's no vibration. if your going with two compounds I'd go with white and green, green being the finest...and messiest. get a wheel for each compound.

congrats on the buffer, I believe the Baldor with 3/4" shafts are the best out there. and be careful a buffer can be the most dangerous machine in the shop.

Edit...the wheels I use are spiral sewn.

Thank you, Is there a reason you stack the wheels instead of getting a bigger wheel?

Just now, TomE said:I agree with @bladegrinder's choices. I have a 3/4hp Baldor motor with 5/8" shafts and a sewn cotton buffing wheel. I use green compound for everything. The other side is a deburring wheel. Has lasted 12 yrs in a machine shed although I'm hearing a bit of bearing noise. I use it for hoof knives and leather tools.

How corse is black compound vs green compound??

thanks

-

Hi all. I was recently able to pick up a baldor slow speed buffer for sharpening my leather tools, and I am wondering what brands and styles of buffing wheels are best. The arbor is 3/4in an I am thinking of doing six inch wheels.

How many ply/how thick should the wheels be? Should they be stiff canvas? Yellow? White?Also, as far as compounds go, I am planning to do two different compounds. What ones should I do? Green and Black? Green and Gray? Also what are some quality brands I can get?

thank you.JC

-

-

They sold

-

Garret Wade point knives in great condition, I ended up not using them as much as I thought I would.

-

I have bought a lot of tools from these people, they are great! Here’s some of what they have left, all at great prices!

-

I ended up getting the machine for 1500. The gentleman included a stitch guide, a new motor he had as a backup, a new belt, lots of bobbins and bobbin assemblies and thread.

machine works beautifully!thanks for all your help!!

-

Thank you wiz and kgg

i am going to have a showing of their entire shop today!

i will keep you guys updated as to whether I get the machine or not. Thanks for all your feedback, it is sooo helpful to be able to have you share your knowledge and thoughts!

thank you again

-

What do you think would be a good price for the machine, just based off pictures?

i know you mentioned a lot of variables, but was wondering if it you could mention a price JUST based on pictures. Thanks

-

2 minutes ago, kgg said:

This is a class 441 machine with a small cylinder arm having around 9 inch work surface using the 794 needles. The actual work surface maybe less it depends on whether it is measured from the end of the cylinder arm or the needle to the body of the machine. Having such a short work area may pose a problem with some items. A machine with a 16.5 inch cylinder arm would be more versatile. I think this model was replaced by their 3200 model costing around $2600 new. With other machines like the Cobra and Cowboy there are narrow needle plates, presser feet and feed dogs available to allow those class 441 machines to sew thinner items, closer to the edge, use lighter thread thread then the regular / standard ones will allow. I don't know if they will fit the Artisan machines.

It is hard to determine whether this is a good deal without photo's it will depend on things like working condition, visible wear on places like the thread guides and your local area and maintenance. Buying a used machine is just like buying a used car. Two machines of the same age, one used in a commercial setting that was bet to death versus one used by a hobbyist will command different prices. I wouldn't go 65 percent the cost of a new machine, maybe 50 percent if it was in really nice shape.

Just my thoughts,

kgg

Here is the link. https://www.westernstarleather.com/ARTISAN-TORO-3000-SEWING-MACHINE-art3000_p_2011.html

the owners retired last December. -

I have an opportunity to look at a artisan toro 3000 for $1700.

the machine is being sold by a leather worker who is retiring. They are including extra bobbins needles etc..

is this a good deal, what should I offer?

-

25 minutes ago, kgg said:

This is a older Consew model as the new version is RB-55. To get the most out of the machine for your sewing needs you would really need to add a servo motor. A servo motor will give you the slow speed control needed with a very short learning curve where as a clutch motor is much, much more difficult. This upgrade will probably run about $200 and is worth every penny. That will drive your price up to about $950 and new Consew RB-5 will be about $1500. I would look for a newer version or just bite the bullet and spent the extra for a new one. Without seeing the machines condition etc if the price of the machine was including the cost of replacing the motor in the $500 range, maybe.

For doing wallets the RB machines should be quite capable but purses may pose a challenge depending on style, thickness of leather, thickness of seams, type of leather and size of thread. For doing circular type items you would be better off getting a cylinder arm machine (new or used) with a flat top attachment. That way you would be able to sew the flat items like wallets with the flat top attachment installed and cylinder items with it removed. I would suggest looking at Juki 341/ 1341 or clone.

You should take a few minutes and read the article by Wiz

Do you have a photo of the machine?

kgg

Thanks

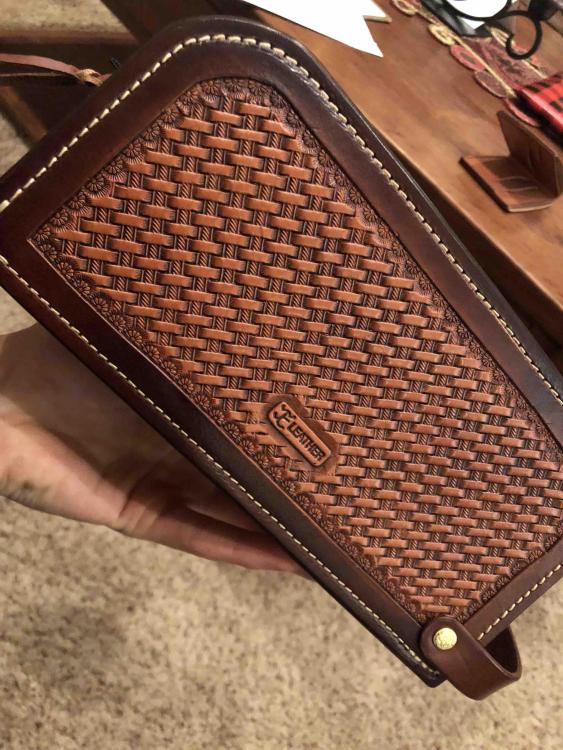

Sheridan Basketweave Shave Kit

in Show Off!!

Posted

I’m not sure I understand. Are you meaning that running a basket weave horizontally is better than angled?

the base is veg tan as well, the gusset is chap leather.