LanceR

-

Content Count

35 -

Joined

-

Last visited

Posts posted by LanceR

-

-

Thanks @Josacraw and @RKBrown, if I wind up with one of these that will make at least three of us in North Carolina with these. I suspect we would do well to keep in touch regarding parts and accessories and model specific tips and tricks.

I'm a half hour north of downtown Winston-Salem.

What's PSMC?

Lance

-

@Josacraw, I'm looking at getting one of these and deciphering the thread sizes from the manual is like reading computer code to me. Do you know what the largest size thread is that these will handle gracefully? I use a good bit of 18 ounce canvas and would like to use something heavier than my Consew 226R and 227 will handle as I like the look of a larger contrasting tread.

And have you been able to get good bobbins and other bits and pieces for it?

Thanks

Lance

-

Dave, I'm on Old Mill Rd in Pinnacle. We'll have to get together sometime.

Lance

-

Maybe my patterns are bigger than some others but I use X-Board floor protector. It comes in rolls at building centers, flooring stores etc.

https://www.homedepot.com/p/TRIMACO-35-in-x-100-ft-X-Board-Surface-Protector-12370/300095507

Lance

-

Sorry that I can't help with the adjustment but if you haven't already put in a new needle, I suggest that you do so in order to be sure that the issue isn't a bent needle.

Lance

-

Thanks. Anyone else?

-

Has anyone used the OLFA cutters and if so, what are your thoughts compared to the Fiskars or Kai cutters? And how much does fabric weight matter for cutting wheel size"

Thanks

Lance

-

???

-

20 hours ago, thefuzzynavel said:I hope you're still here. My client has an atlus clutch and I need a new disk for it.

Call Bob at the number at the bottom of his post..... Before I really found this site I cut a new cork disk from a larger disc for my Necchi with an Atlas clutch to replace the crumbling leather disc it used to have. It would have been a lot easier to have the correct disc in hand.

Lance

-

I'm far from an expert but I suspect that your machine is mechanically identical to the -25 etc except possibly for the length of some parts. The parts and operating manuals and the spec sheet are all linked on Consew's website:

https://www.consew.com/View/Consew-Model-206RBL-25

Lance

-

I have a former military knife and accessory roll from a field kitchen set. I'll dig it out today and post some pictures (I hope). It has pockets for everything from peelers to a sharpening steel and has leather blade covers that go into the knife pockets.

Lance

-

Hello from Pinnacle, NC. I'm a half hour north of Winston-Salem.

Lance

-

2 minutes ago, Wizcrafts said:There is a time limit of just an hour or two for editing a post. However, moderators can edit any time.

There are programs that manipulate photos and can save them at greatly reduced file sizes, with minimal loss of detail. I sometimes use FastStone Photo Resizer for quick reduction. I have other expensive programs that can do magic when needed, but Photo Resizer does it good enough for our purposes..

Thanks. I'll look into it.

Lance

-

Thank, Wiz

When I posted the post I got a message stating that there was a size limit of 1.46 MB. I'm a bit of a dinosaur with computers and would appreciate any advice as to what to do. I don't remember having photo loading issues in the past although I am using a new phone. If I'm reading things correctly the pictures are around 3 MB.

EDIT: I'm still not getting notices of replies to the thread and don't see a way to check or change that. And is there a time limit to edits? I don't see a way to edit the post from last night.

Best regards to all,

Lance -

Well, I finally got back to the Consew 226R-2 and it turned out to have more issues than I had suspected. It had been set up with a Tennessee Attachments piping binder and pretty much every adjustment that could be monkeyed with had been. I got the new needle plate, dog, foot sets etc so today I got it put together and fully adjusted .

The stitch length had been adjusted so it couldn't go lower than 9 stitches per inch in forward but would run at 4 SPI in reverse (the machine is supposedly 5 SPI max in either direction) so a search here set me straight on fixing that and getting them to match, I put in the new needle plate and dog in and adjusted the dog height, had to re-index the stitch indicator ring to match the actual stitch length, adjust the presser foot height etc.

I cut a hunk of 840D nylon packcloth and used it to do the stitch length and tension final adjustments. I kept folding it and 16 layers later....

As I had hoped it would, the machine acts like it's not even there. Now that the machine is cleaned up it looks pretty good. It came from a state auction out of the North Carolina prison system and it has far less wear and tear than I would have expected.

And late last month I got a Consew 227 cylinder bed machine that was correctly set up and running well. It'll be an interesting ride learning to sew on it while standing.

Best regards to all,

Lance -

-

Yes, Belle, Constabulary hit it on the head. Although the 226R-1 has the same window as the Singer it's not used and while the adjustment on the 226R-1 is as shown in your last post but the idea is the same. I have the same machine and got it with the stitch length wheel mis-adjusted. I used needle punches into light card stock to be able to determine how many stitches per inch the machine was sewing, used the button to lock the shaft and then loosened the set screw you have indicated and aligned the correct setting on the adjusting wheel. Then a few lengths of stitches to confirm the setting was accurate showed that things were correctly set confirmed the setting.

You'll need to hold the card stock (or fairly stiff paper) down as the needle withdraws so the needle drag doesn't move it but it's a lot easier to accurately measure holes in paper than some fabrics so hand turning the wheel may be best.

Best regards to all.

Lance

-

Hi Don

Sorry for the delay but for some reason I'm not getting notifications of new posts even though I just checked for the 5-6th time to ensure I should be getting them. It's very hit and miss. I think I've gotten, at most, two or three notifications so far to any thread.

It has been instructive messing around setting the Consew up. I sit there with the parts manual and both the Consew and Singer instructions as neither is fully descriptive so that when a manual says to loosen the left side smoke shifter I can look to see what it looks like and where to find it. Kind of like learning to maintain M1 tank and Bradley Fighting Vehicle turrets in about 1981 or 1982 when they started to deliver them to us before we had our turret mechanics re-trained from M60s (but without the same consequences of screwing something up).

I got the new motor mounted, got the correct length belt, adjusted the bobbin winder and then found out that the inner presser foot I was sent had far too small of a hole in it to go over the "vibrating" presser bar. And the machine also has a raised throat plate and needs a flush one. I'm trying to figure out which of the oil wicks need replaced and whether I can even get to them short of a total disassembly. No worries though. I'm not losing any money due to the delays and I have more projects that have their own projects than any one guy should have.

Speaking of smokers I've built some custom smokers, have four smokers now and have five propane tanks sitting in the edge of our woods awaiting their turn to become trailer mounted wood burning smokers. The hold up for them now is that I ordered and paid for a new Hypertherm plasma cutter around 24 April and it looks like it's still going to be on back-order for several more weeks.

Ahh well, the size 69, 92 and 138 thread has arrived along with an assortment of needles and some other assorted bits and pieces so at least that stuff is in hand.

Best regards to all,

Lance

-

Wally, I've been working through a similar machine, a Consew 226R-2 and the knee lifter was clunky on it, too. The machine came from a correctional institution although it wasn't beat up and didn't have the kind of use that I'd have anticipated. The lifter was harder to operate than I would have expected and wasn't at all as smooth as one would wish. I'm not even sure it was reaching full height.

When I looked at it closer, the lifter was off center by a good bit and was pushing diagonally on the lift rod throughout it's range of motion. A look under the table revealed so many oversized and stripped out screw holes around the lifter that it was no wonder they couldn't properly position it. As a last resort before drilling them out and gluing in plugs of dowel I used 1/4" lag screws to put the lifter where it needed to go.

And the lift rod on the machine had a roller tip attached with a set screw that was clocked perpendicular to the travel of the oval pad on the lifter. After that got turned 90 degrees and in line with the lifting pads travel and the arm for the pad was properly adjusted the whole thing is much smoother and now it requires maybe 1/2 to 2/3 as much force as before to raise the foot.

The lifter has an adjustable length rod to eliminate any over-travel of the knee lift and the rod is too short so the knee lift lever can be pushed too far and put a lot of force on the machine's lift mechanism even when that's at full travel already. I will be replacing that rod with a longer rod to prevent abusing the machine by the knee pad arm traveling too far.

I'm very much learning as I go and for me a little time laying on my back under the machine was very rewarding in reducing the effort needed and reducing the chances of damaging the machine.

Best regards to all,

Lance

-

Thanks, Don

I had checked umpteen thread suppliers and done Google searches but although I have an account at Big Duck I hadn't thought to check there. The price seems high but the choices for 92 weight OD thread are few and for 138 bonded poly OD thread they seem pretty much non-existant so I ordered some bonded nylon. I just picked up a belt for the new motor, have needles and thread inbound and have some 10oz and 15oz duck in the dryer after pre-washing it to reduce shrinkage later so I hope to be tinkering with the Consew this weekend.

I have basting tape for both canvas and smoother fabrics and it has come in handy before, especially for felled seams and such.

I notice Frost River claims their packs are 18oz waxed canvas while Duluth uses 15oz plain canvas (duck?). I wonder if the 18oz from Frost River was 15oz before treatment or if it was 18oz which would likely make its 18-20oz now?

Looking at the Frost River, Cooke Custom Sewing and the Duluth packs as points of reference offers enough of a menu of ideas to keep me busy for a while just making some practice sub-assemblies and tinkering with nuances of layouts. I need a pack the rides lower than usual in order to be able to carry a canoe so shoulder straps need to be higher on the pack body than usual. Which argues for a deeper or wider pack than a taller pack so it sits low in the canoe to keep the center of gravity low.

And, for my purposes, plain duck would probably be better than waxed as the pack is going to be sitting in whatever water is in the canoe and the contents will be in waterproof bags as needed so a pack that will dry out faster is needed and I suspect that a waxed canvas pack, like coated packcloth will hold water inside it longer. And the ideas keep coming. At some point the good idea train will have to leave the station so I can make a few packs....

When are you coming to the OBX and are you going to do anything useful while you're here like crabbing or fishing?

Best regards to all,

Lance

-

On 6/7/2021 at 9:01 AM, jimi said:It Looks like it is for sewing on piping??

Yes, it's for welting/piping. For now it will come off and go in the tool chest that has my extra sewing things in it.

Best regards,

Lance

-

14 hours ago, DonInReno said:If you only buy one thread for the Consew, 92 weight is very versatile and is used in all sorts of upholstery and canvas work. Personally I like the looks of more pronounced thread and generally use 138 as my go-to for canvas projects, but 92 is strong enough for most things and usually hides well. This type of bag is often sewn with nothing other than ball point fabric needles since the leather is rather soft and not terribly thick, but mainly because leather needles aren't the best when attaching leather to canvas. I'm sure there's a specialized needle for this application, but if you are just getting your feet wet there's no need for anything special until you see a finished pack.

I'm not sure why you would use the Necchi on any parts of this kind of bag if you already have a 226r.

It sounds like a fun project - you're sure to learn a lot on it! Best of luck!

edit: I forgot to mention that there's a lot of difference between the various canvases available - duck is stiffer so it would be preferred in a bag like this, but the stiffness varies from supplier to supplier, as does the surface finish. This kind of bag often benefits from a stiffer back to help it hold it's shape, beit double layer, stiffener between layers, etc. If it's intended as a fashion bag with softer canvas I wouldn't know the firsts thing about that.

Thanks, Don

To date, I've been buying my canvas and duck from Canvas Etc in Auburn, Georgia. I've used their 10oz duck and #10/15oz duck on a few things. They have #10/15oz duck in colors on sale at $9 a yard (59" wide) and #8/18oz duck in colors at only $8.75. The #8 is available in olive drab and the #10 isn't and, at least for the first couple of projects, I wanted OD so that's what I'll order.

Yesterday I pretty much decided to run with 92 or 138 bonded polyester in the 226R. And with the #8/18oz duck I'd rather use the heavier 138 thread anyway. If I can find OD thread..... I found bonded nylon but so far at least, I'm striking out on polyester.

The new servo motor and feet bought from Cowboy Bob for the Consew are supposedly out for delivery in a UPS truck so I'll be hoping to be sewing on it by the weekend. And I haven't taken off and checked the tension disks so I'll do that this AM.

Now to order some rivets, burrs, setters, roller buckles etc......

Best regards,

Lance

-

23 minutes ago, nylonRigging said:when in doubt ? , for the finish look and outcome of new pattern and materials . I usually just mock up some sample pieces/panels to punch holes and thread threw, and scrutinize top and bottom with my choices .

You only using 1 machine ? . Test 1st to see what you can actually get away with on the thickness of the stacked combo of leather and fabric.

Thread ? , looks like they just using 69E for thread on the canvas/oil cloth on the main fabric body . For leather pieces it your choice for thread size, but little bigger than 69 will look better.

Needle ? . looks like you will mixing it up between using a fabric and blade point . Or . you can use just fabric needle for all .

Your Pic's. example, for the shoulder straps and the top weight bearing load spot . show the Fabric/canvas in the middle, between leather on top, and a leather backer reinforcement inside . So I would assume they are using a leather blade point when sewing the leather .

And if look at your Pic. there is a couple spots like inside bag top corners/closing flap, where there is a couple leather reinforcement backing square . canvas finish outside, leather inside bottom-side .Your going to use fabric needle on that because you will cut the Canvas thread weave on the outside finish .

.Thanks.

I have a1950s Necchi BU Mira in an industrial table that has handled size 69 thread and 4 layers of 10 oz canvas pretty well and which sews 2 layers of 1" tubular nylon just fine. I haven't yet had a reason to try anything heavier with it.

As I understand it, the Consew 226R will handle up to 138 thread. The smaller leather backing pads can likely be sewn with 69 thread as the only thing on the exterior is stitching and the structure is due to the rivet through the strap and backing pad. and there's a good chance the only need for 92 or 138 thread will be for cosmetics on the large leather pads where the shoulder straps attach to the upper body and perhaps on a thicker built up shoulder strap

Duluth uses 15 oz canvas on their packs. As they use the ounce designation that normally indicates plain weave canvas and not the # designation that would normally indicate duck I'm unsure if they use plain weave canvas or if they use duck and they are just avoiding confusing customers. I guess a call to them would answer the question. I need to order a few items from them anyway. I have #10/15 oz duck on hand and plan to see how the Necchi does with increasing layers of that with a jeans needle and bonded thread.

Duluth advertises that unfinished fabric edges on the interior of their packs is normal but I'd much prefer finished edges So if I use the Mire on those I may up the seam allowance so I can finish the edges with bias tape after sewing the seams. The BU Mira has a reputation of punching well above its weight on heavy fabric so we'll see how it does. After testing I may only want to make one or two packs with it but in any case I will also be keeping my eyes open for something a bit more powerful, too.

I will be ordering some of the Springfield Leather remnant and scrap leather and maybe a couple of the $25 or $35 sides to tinker with. Between the leather and the duck I have now I can see how the machines do and make some test/practice sub assemblies.

But another concern and part of what drove this thread is hoping to avoid buying too many #1 spools of thread that I won't be needing for these projects. At over $20 a spool that could strand a fair bit of $$ so the better an educated guess on thread I can make the less chance I'll buy something unnecessary.

Best regards,

Lance

-

Good call. It comes back as a "Pre-made cord welt folder guide. http://www.tennattachment.com/741 Pre-Made Cord Welt Folder.html

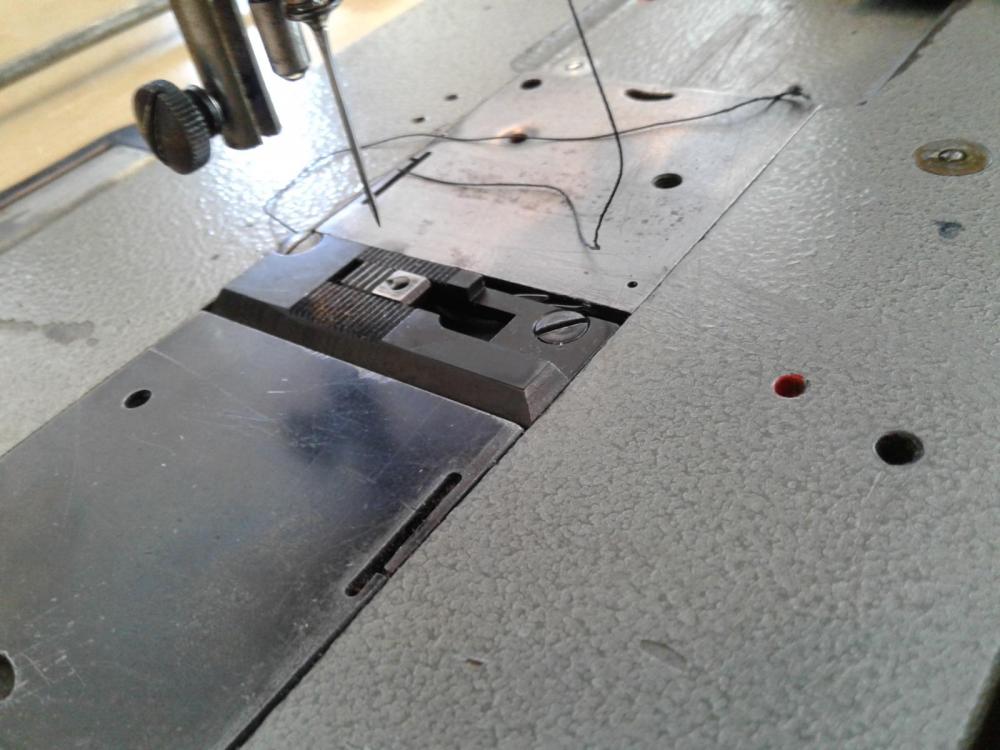

Here's a picture of the feed dog area. The machine came without any feet. I bought it from the North Carolina state surplus site and it came from the NC Department of Corrections.

Thanks for the reply and best regards,

Lance

Durkopp Adler 291 what to look at

in Leather Sewing Machines

Posted · Report reply

Thanks. I thought I was going to get over there Friday or yesterday but it'll have to wait for the week of the 28th.

Lance