-

Content Count

360 -

Joined

-

Last visited

Posts posted by Garyak

-

-

10 hours ago, Annikita said:Apologies if this has been covered in previous threads but....I couldn't find them.

I was all prepared to set up my much-anticipated and very cheap Chinese Shoe Patcher this evening, but I've run into trouble very early - considering the lack of info available on this particular issue, I'm guessing it's either not common or I'm missing something obvious. (Normally I'm pretty handy, but tinkering with sewing machines is a bit new to me.)

I'm trying to mount the hand wheel - I realize where the inner/outer bearers are supposed to go (as well as the small niche) but....I think the inner bearer is in the wrong place? I'll attach a photo. There are some screws to the left of it that I thought perhaps might shift some pieces, but so far none of my tools can budge them.

Help would be VERY appreciated. My new hip bag isn't going to sew itself!

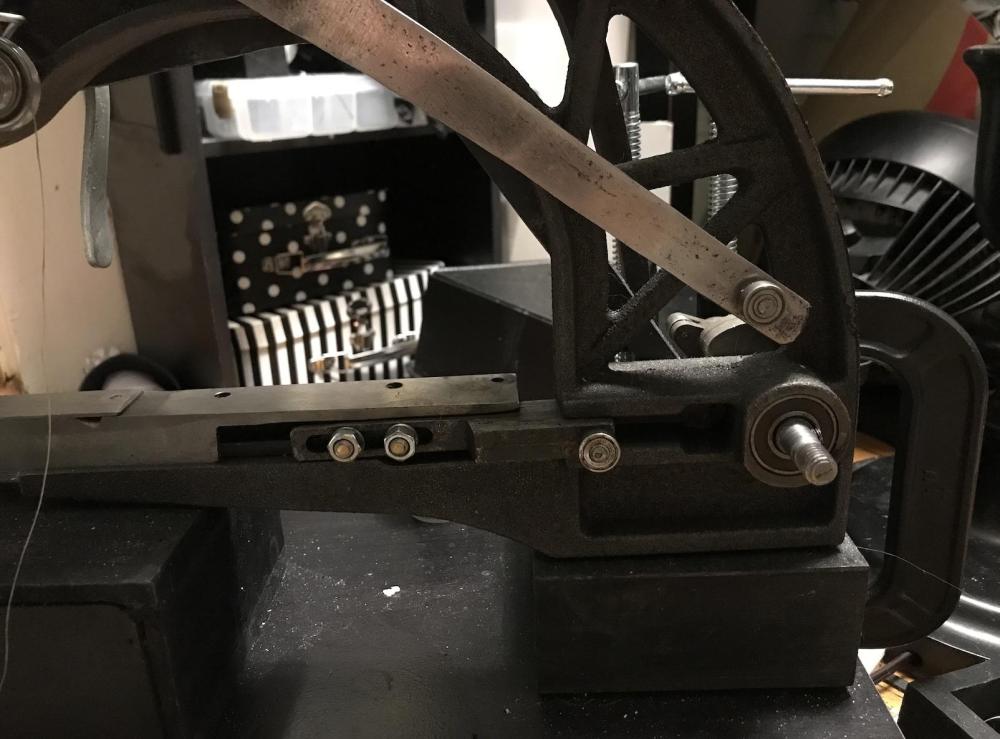

Nothing is wrong with the machine. Turn the shaft till the rocker arm Bering lines up with its slot, and the slot on the shaft lines up. You gotta work with it. You cannot hurt that thing so don’t worry about breaking something.

-

1 hour ago, toxo said:This thread should be gold for those that come after.

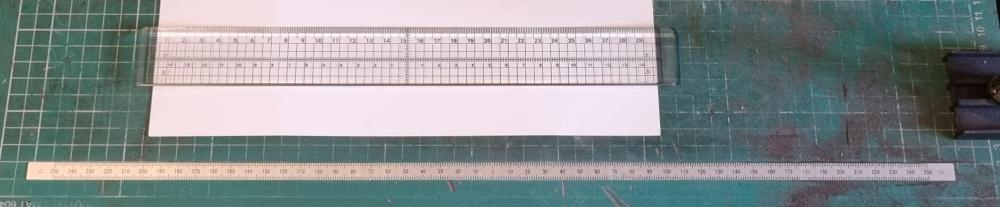

A couple small ones to start. How often do we need to find the center to place a tag or line up stitching? I might be slow on the uptake because I've only just stumbled across these centering rulers. One is stuck to the bench and the other is a plastic ruler that is see through with a metal edge for cutting.

This next one I've ordered but not here till tomorrow. I needed one of these the other day and didn't have one so like a lot of things I improvised.

Flexible Ruler 16 Inch 40cm Curve Ruler for Engineering Drawing, Design Graphics | eBay

More to follow.

I don’t understand how folks even attempt something without the center finding rulers. I still use the same ones I ordered from Dick Blick art supplies in 94. Definitely one of the first mandatory items needed in the tool box. Work off the center for everything, you can’t go wrong.

-

What’s up brother? Nice work!

-

5 hours ago, panchoskywalker said:These are pictures from the web. Both leather looks wrinkled giving that vintage look.

Those are what you’d call distressed leather. It can be anything, bovine, swine, etc. it’s done in the process off tanning.

-

On 4/15/2024 at 6:17 AM, Jryder said:Hello Nate...Im having problems with mine not grabbing the bobbin thread. Was sewing fine on 1 piece,,went to another now wont grab bobbin thread,,,about giving up. Have you been able to find that Air Force manual hes talking about ? I cant find it.

looking for all the help i can get....I have chandler/Alder67

https://drive.google.com/file/d/1BInD1kgMM1GeHjNmvX9pL5AuArThjFLI/view?

Uploaded file: 14218b_ch9_10.pdf

-

On 7/9/2020 at 10:33 PM, Nate88 said:Hi Community

I bought a Juki lu 563 in pretty rough shape. I've been working on it thanks to Uwe's incredible youtube videos. I am having a lot of trouble figuring out how to set the needle bar height correctly. I feel like I got the timing right for the hook, and it seems like it meets the needle at the right point. The issue I have is that when I am trying to sew material, the top stitch does not grab the bobbin thread. However, when I have everything taken apart and I'm testing out the hook, timing, needle bar height etc, it does work out and thread from the needle does successfully catch on the hook. I do have the hook as close as possible to the needle (without actual contact being made).

So, here's a little video of what it looks like. Can anyone give me any pointers on how to tune this a little better so that I can begin sewing?? This is my first industrial machine and first time working on sewing machines, so any help is really appreciated.

https://photos.app.goo.gl/6DiHxPw9gqdw7QAy8

-Nate

Google search the U.S. Air Force safety keepermans training manual. Skip the oxygen canisters section on to the sewing machine section. Here you will learn in the simplest of terms how to diagnose, and repair anything that could pop up on any sewing machine in the world. Even has a troubleshooting section… find your issue, right next to it is your solution. Any problems that can happen are caused by very specific things. Like skipped stitches or not grabbing the bobbin thread, there’s only a couple things that cause that, needle set incorrectly, wrong needle, presser foot isn’t keeping the material in contact with the bed, add presser foot pressure. I see people saying timing every time a stitch is skipped. With that PDF you will never ask another question online again. Covers 4 of the most common machines, 2 of each kind, oscillating shuttle (31-15), and rotary hook (singer 145 juki 158). Only two that matter to us anyway. You won’t be disappointed.

-

8 hours ago, Dannyofalltrades said:I just picked up an IMMACULATE Singer 29k-71 and the feed foot won't pull the work through. If I pull it, it goes to the appropriate length and stops, but there is no power going to make the foot pull the work through. Any help is appreciated.

Above the foot, there should be a stitch length screw/clamp. It slides up and down the feed bar. All the way down to full feed, up for zero.

-

On 3/13/2024 at 6:57 PM, TomHu said:When I turn the hand wheel with the presser foot up the needle goes up and down with no issue.

When I lower the presser foot or put something in the way for it to sew (presser foot up or down, it stops working.

I then have to use the side wheel that holds the motor belt to complete each stitch.

9313- Vibrating Presser Lifting Lever

9205 Litfting Lever Shaft Lever

9206 and 9207

In the head of the machine.

When the presser foot is down the 9313 is unable to move the 9205 to complete a stitch.

If I force it with the 9107 then it will do it, but not with the hand wheel alone. It seems like the force to complete the stitch in the head of the machine has been eliminated and I do not know why or how to fix it.If you need a better idea of my numbering system please see the manual with diagram link (https://www.springfieldleather.com/cobra-manuals/29-18 Manual.pdf)

Any advice, tips, or tricks are appreciated.

Have you tried tightening the belt, and maybe checking to see if oil dripped on it? If you’ve oiled the machine it’s gotten on the belt. Mine does anyway.

-

I believe that’s the same machine I just set up for Tandys a couple weeks back. Didn’t pay attention to servo. Imma see what it’s working with when I’m in the store again.

-

On 5/15/2007 at 10:52 AM, wayner123 said:I am looking to do something really interesting. I would be very interested in what weird/rare hides you all have seen or heard of. I think it would be great, as I am kind of stuck on ideas for what could else be leather?

Besides the standard exotics (ostrich, shark, snake, lizard, etc.) I have researched and found the following hides:

Beaver Tail

Elephant

Seal

Kangaroo

Frog

If any of you have seen or heard of any more please let me know. I do not approve of poaching in any way. I do however wonder if they make leather from deceased Zoo lions or tigers? This is just speculation. Again NO poaching!! Anyways, let me know guys and gals. Hopefully my upcoming project will be truly unique.

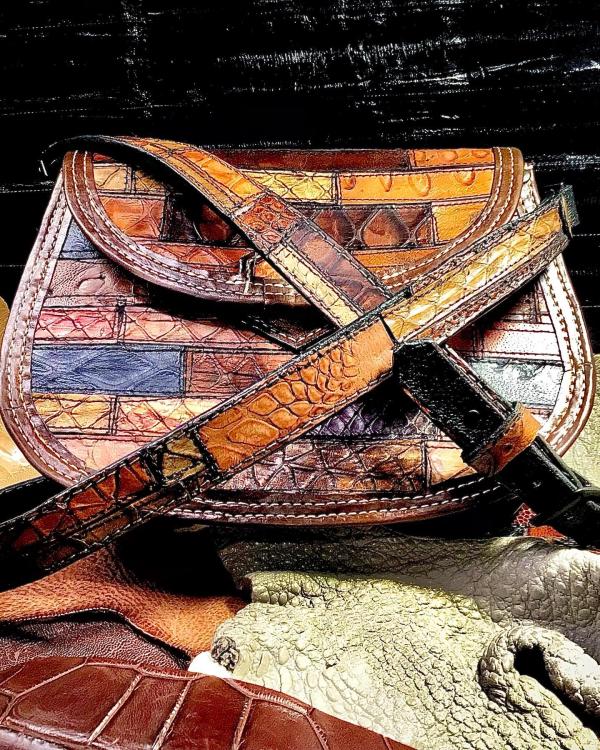

Snapping turtle, sturgeon, canebreak rattler, Texas hornback lizard, pangolin (anteater) turkey, hippo, snapping turtle, giraffe, Nile monitor, tegu lizard, and probably more I’m forgetting. I know it’s an old post, just in case anybody sees this, I have them all, in stock

-

Reliable 6000sm sew quite. Put one on my 145w204. Best thing since air conditioning.

-

Your needle isn’t set correctly, or even the wrong needle is installed.

-

Hold tight on that 500$ and go on a search, and find the used machine of your liking. You can find just about any machine out there for 500$. I have 12 machines running daily, I haven’t paid 500$ for any of them. Gotta look everywhere, daily, search like it’s your job. Estate sales are your friend. If a seller tells you it’s vintage, rare, any crap like that, they know absolutely nothing about the machine they’re selling. Gotta be able to talk..

-

12 minutes ago, SUP said:I actually really like this the most. It is unusual and one of a kind. No offense @toxo but the others are nice but repeatable and sometime seen. This one? Nope.

Thank you. I’ve dragged scraps around for the last 35 years… finally put’em to work.

-

-

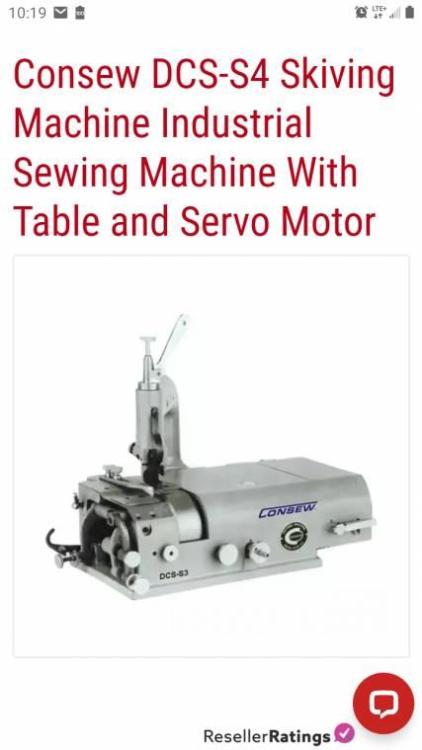

11 hours ago, DieselTech said:Guys & gals I'm wondering if I should buy a skiving machine. I make lots of belts, & wallets, & want to get into making bags at some point.

I'm looking at this consew dcs-S4 skiving machine. What is some of my benefits to having this machine?

Where is a machine like this most helpful & what can be done with it? What can I all do with it?

Will this machine be ok? Or are there other/better options out there?

Thanks any & all help will be appreciated.

I skived by hand, with the 5$ skiver I bought in 94 till 2 years ago. I bought the techsew. Definitely waited 30 years too long.

-

47 minutes ago, Constabulary said:What do you mean - looks like the bobbin / hook area is open cause I can see the hook driver on picture 2.

Pictures are fairly small.... what does the brass tag say? is it 65? If it is a Pfaff 65 then it is a darning machine but not a sewing machine.

If the machine is like this (German language website) there is no way to convert it to a 28 cause major parts are missing.

It’s just the first 3/4 inches of the cylinder arm I’m looking to remove. It has a seam, so I’m assuming it can be removed. I can’t see any other way to time the needle to the hook. Everything else has been pretty simple., thanks for responding bud, I appreciate it.

-

I pick up this old Pfaff and would really like to time it. I can’t access the front of the cylinder bed that covers the bobbin area. Any advice on how to access this part of the bed would be greatly appreciated, and how do you find the model of the machine? Looks like a 28, but badge says different… thanks in advance!!!

-

I have the original owners manual for the Thompson mini walker. I’ll try and get that and post it up tomorrow.

-

-

-

-

I’m assuming you got this sorted. I’m late, I could’ve helped but it you got with reliable you’re good. I got no dog in the chase, but I got a reliable 6000sm servo on my 145w, and I can’t imagine a better work horse. Very good choice. Just my opinion.

-

Some of y’all may have already heard about this, but for those who haven’t here ya go. Cowboy is finally shaking things up in the patcher department. No info on the cost, and not available till 2025. That’s per Cowboy rep in China. She did tell me they’re shooting for. 1/2 the price of Claes. Only makes sense, who’s gonna pay full price for a clone claes, just get a claes. YouTube video shows it running very smooth and quiet . Very quiet. I’m liking it.

Skiver clone

in Leather Machinery

Posted · Edited by Garyak · Report reply

Several folks on my group have them, and use them in their daily business. I have the Techsew version. Not much difference in the machines except in price. You’ll be fine. The key to success with skivers Is knowing angles and how to achieve them on the skiver. Just turning some screws.