-

Content Count

361 -

Joined

-

Last visited

Posts posted by Garyak

-

-

14 hours ago, chuck123wapati said:just saw this on ebay it might be a better choice however i dont have a clue if it is .https://www.ebay.com/itm/175519867019?hash=item28ddcca08b:g:JmUAAOSwws9jjbjM&amdata=enc%3AAQAHAAAA4KF6KWiybMXD%2BYAu5FHmSL%2BLXn6krZ3Cq4JyddSJrexZZPvCVBYzgjyZywhG2V60Ua9FFPVSDAw%2BZdNbTP2411ovHWLouCUohlwBw7glVyrOXHJsqCAqB3JpBN0Bnb2hFE20asrT2VhCX%2BsMJLoLKqR5eCU3sIoXjlYK9yFCHNzP7g%2FXZigbH%2B1ysqxFJqrInIFcvi%2BVhuXmjMllaxDuc1rcasdvoFDtSZdG0mqpZUbpj8hFyUXoAmBJYdOdboaIcWB1KPW4EfVu2vyIXDs29DHmGfNazOa1qsg9qTYdnjef|tkp%3ABFBMhPnjqpxh

There’s a few of the eBay patchers that are made at the Ta-King plant and actually use the same parts as Cobra, and any other brand name manufactured by Ta-king. Which few I don’t know. They do a good job of making them all the same. I do know that after market support, and parts are non existing for most of them. I’d suggest going cheap on the China patcher. If anything you’ll learn something messing with it. There’s really no reason why it can’t be a valuable addition to your hustle. There’s folks making top o the line product on nothing but a China patcher. Then save up and buy the outrageously priced patcher of your choice. Definitely worth the investment.

-

Switch needles systems to 135x17 23 needle and time it up tight to the hook and the CLSP is a cheap machine that can sew heavier weight material with heavier thread (207) than the Cobra 29-18 patcher. I own both. Using the recommended universal HX-1 needles will get you no where fast. Mine paid for itself first time I used it, and has completed many jobs the Cobra couldn’t even attempt. Tip; do not pay extra for someone to “go thru it first”. Only thing that’s gone thru is your cash.

-

-

4 hours ago, Constabulary said:So here it is - my latest barn find, a Dürkopp class 17 patcher. I just picked it up this Sunday morning from the grandson of the former owner which died in 1989 but he went out of business way earlier. So this machine probably has not been touched for 50 years or more. This is my first Dürkopp class 17 ever, I had a class 18 before but yet no class 17.

I have to figure what subclass it is. I assume it is a short arm with medium hook but have to free the hook first and check my records. All parts seem to be present except 1 spring but that should not be a big issue. It is mounted on a GÖRICKE branded treadle base but the machine definitely is Dürkopp made. Interestingly there seems to be a small pedestal mounted between treadle base and machine. Unfortunately no further accessories and no drawer.

It seems to be a very early model cause the later class 17 had different needle plates and different tension units.

So I have a nice project for the the upcoming cold days (if we will have cold days at all). Next will be a generous oiling to free some the moving parts and especially the hook (needle plate is "frozen"). I´m really looking forward to get this thing running again.

Some pictures:

I’ve never seen one period. Super cool find, and definitely can’t wait to see your magic worked….

-

On 11/2/2022 at 7:00 AM, Frodo said:Curious, What is the price tag on that backpack I am guessing. Minimum $800/$1000. Up to $1500.

You nailed it at 1500, I’m working on making another one, gonna change it up on the pattern and it’s gonna be solid elephant. No cow. Gonna be cool.

-

2 hours ago, sbrownn said:I have one just like it that I never use but I'm surprised at what they are worth.

3400$ shiny and brown for a new one.

-

-

-

I used the 5$ skiving knife sold at your local go to place for 34 years, never giving a thought of purchasing a mechanical or powered skiver, till my hands gave out and I had surgery. I didn’t do much research into options available and went into debt with the purchase of a TECHSEW SK-4. I know you said you’re not at a point to buy a bell skiver and neither was I, but it was well worth it. Would buy again. I never knew skiving could be so easy, and just plain satisfying to watch with a bell skiver. I’m interested to see what other folks use besides a bell skiver and what the results are…..

-

Here’s what I got, my work is 95% exotics, and the rest veg, chrome, oil tan, I use olive oil exclusively on everything. I seal with a satin sheen because I don’t care for shiny. Roll with what you know. This is what I know. 35 years with no complaints….. patch it up!

-

Imma tell you right now, I notice things like that, and I would definitely complement you on it, and commence to talking your ear off. Like me and my sewing machine shirts I make. I do it for that reason. Ordinary folks will have no idea, but when someone notices and knows what it is, usually gonna be a good conversation…

-

3 hours ago, Doc Reaper said:I’m in North Carolina, I want those exotic leathers.

Snapper, Gator, and Roo, where does one go????Check out Mr. John Fong. You can find him in the LC&SJ. He writes articles on exotics and their uses, and in the classifieds you can find his contact info. He absolutely does not do the computer thing… so it’s old school. Good man.

-

Those are pretty cool man.

-

16 minutes ago, battlemunky said:Another sick piece @Garyak. Your lacing makes me not hate laced edges.

You know what bro, the cat who taught me everything I know, I mean everything cause I’ve never changed anything he taught me, told me, I’m gonna show you how to do this, you’ll do it my way while I’m teaching you, then when we’re done, you do whatever you want…. Dude taught me a few core things of leather skills, and told me to kick rocks. That was 35 years ago. Ain’t changed nothing. Been told you’re doing it wrong, etc… no complaints here… thanks bro.

-

-

2 hours ago, Wild Bill46 said:I'm posting a bit late here, BUT that's some great looking work !

And you can pass that on to your buddy, from me . Nice, nice, nice.

Thanks man!

-

-

Now I want some bear grease…..

-

-

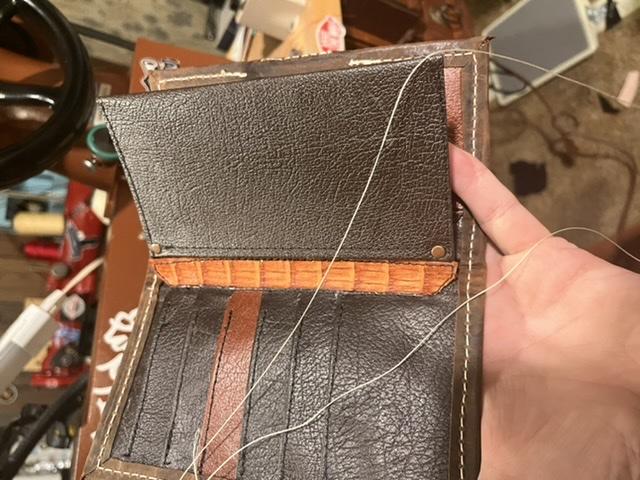

On 9/26/2022 at 6:12 AM, PastorBob said:Nice work. Love the croc!

6 hours ago, doubleh said:That is nice. I won't let my wife see it. She is a purse and shoe junky and would want one.

Thanks PastorBob, and doubleh, thank you too, tell your wife I can make’em in elephant, rattler, hippo, etc!

-

1 hour ago, AndyL1 said:Wow, these are fantastic! Love the turtle inlay and overall design and execution.

Thanks man, I appreciate it.

-

-

Used pro resist before antique and satin sheen to seal it up, and thanks y’all.

On 9/24/2022 at 8:47 AM, chuck123wapati said: 1 hour ago, Zonker1972 said:

1 hour ago, Zonker1972 said:looks really good!! A+. what are you using for a top coat for the veg tan leather? resolene? Tan Kote?

On 9/24/2022 at 8:43 AM, Frodo said:Bad ass as usual Gary,

7 hours ago, Frodo said:Doc, that’s Gary he does some freaking amazing work using Exotic inlay work and he uses a Chinese patcher to do it.

Gary has some design talent and it showsThanks guys!

-

1 hour ago, Doc Reaper said:Ok, where did this one come from????

Which one bro?

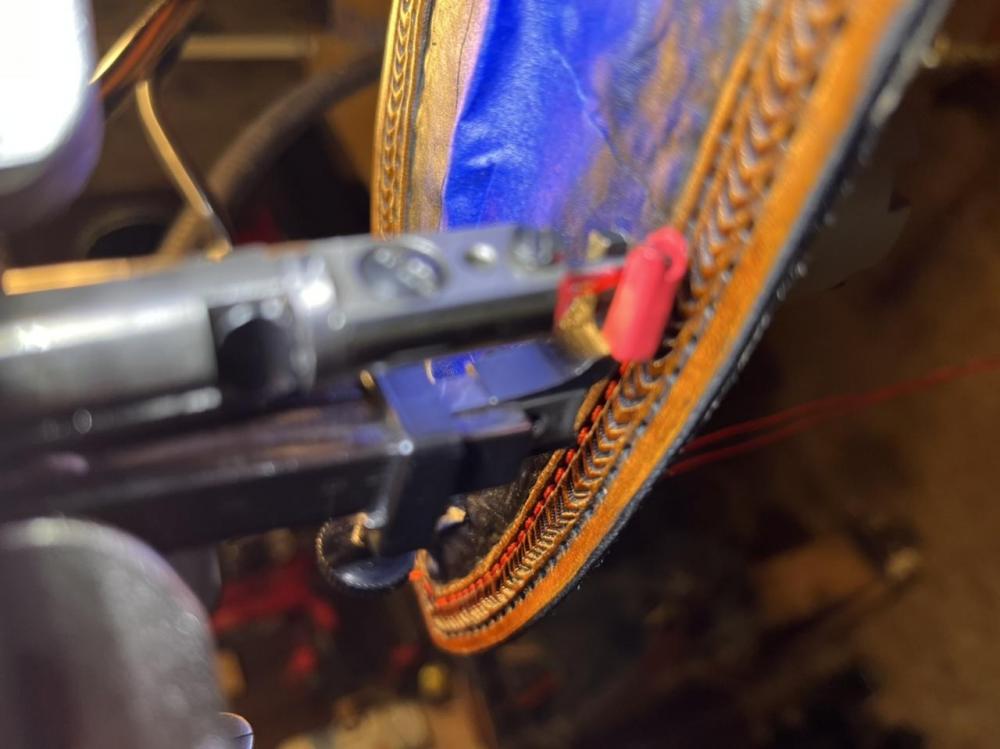

Patcher stitch line

in Leather Sewing Machines

Posted · Report reply

Right size needle, enough presser foot presser to ensure the item being sewn stays in constant contact with the needle bed, make sure the needle scarf is facing the hook, perfectly left to right. West to east if your in Louisiana and make sure the bobbin is would nicely and feeding the right direction. Should get you fixed up.