-

Content Count

361 -

Joined

-

Last visited

Posts posted by Garyak

-

-

-

20 hours ago, Matt S said:20 hours ago, Matt S said:Is that with or without pre-punching the holes?

Whatever it takes to better than the rest, and whatever I do is.

-

10 hours ago, DrmCa said:Which needle system do you use, in that size?

I’ll have to look. I use two different types. The needles that came with it were ball point so I swapped needles. No doing anything to the machines I use 23 in the 16 and 17 system for my 29k. The others fit my Union Special 61300 and I’ll have to look. Crazy thing, neither will work in the other, but the both work in the patcher. Go finger.

-

On 1/11/2022 at 10:45 AM, JollyDodgerCanvas said:I bought one years ago and as a repair machine it's fine. For making new leather products I would look elsewhere. It is difficult to run a perfectly straight line of stitches, but that's not what the machine was designed for! I keep mine for mending things I don't want to disassemble and the 360 degree sewing is amazing if you are aware of the machines limitations, the bobbin is small so it's not a production machine by any standard. As for scratching the surface of your work, get another presser foot and fill the teeth with JB weld and then keep it rough sanded for traction, not hard to do. For applying patches to hats and jacket sleeves it can't be beat and is worth every penny for that alone.

No complaints, makes nothing but money, and people look better. Only used for 207. My TAKING 29k is maxed at 138, but it’s brown. Doesn’t matter what rig is chosen, it matters who’s driving. Whatever the operator is using it for is still gonna look like the last thing made by that operator. 15000$ machine, or a goodwill freebee. You still gotta add skill.

-

There’s one that gives me the blues now and again, but I get over it. My grandpa worked there in the 40’s and 50’s. If he hadn’t started loosing his mind I’d take him in so he could speak to the manager… Ha! Wanting to know why they won’t honor my free ………… coupon from 44…. I really have some . A lot, back to 33. Man I got lost on this one. Blues, I know my local Big T store has piles of full hides in all kinds of blues in what looks pebble grain. Looks like your pic.

-

Urine has used in the tanning of leather since the very very start. It was actually used for the heavy metals being pissed out in human urine. I still get sides that smell like piss, although piss is not used anymore, supposedly. Use as usual. Carry on.

-

19 hours ago, fredk said:What is your secret to keeping your work space so organised?

I need to sort out my place, yet again, to find something and some space to work

Keep each bobbin with the correct machine. Other than that don’t put exacto knives in your back pocket. Hope for the best. Live on the edge. I have no idea where anything is.

-

Thanks fellas, and I totally agree with everything said. I’d love to spend a year or so playing with one, maybe someday, but not this day!

-

I’ve been looking at the Durkopp Adler 969. From what I’ve found online it looks to be a very capable machine. I’m positive it’s built with the same quality that is Adler, my question is, or my fear is, all the ‘Lectric functions that I’ve spent a lifetime doing manually. Push button tension? Push button everything. Is it worth almost 10 grand in the long run? Anybody had one since they came around in 2013? Opinions? Thanks.

-

6 hours ago, Bert03241 said:Well I think its a nice sheath but theres so much clutter in the picture its hard to tell. Compliment your work with a nice clean back ground when you photograph it.

JMHO

There is a method to this madness. I don’t know what it is, but I know where it’s at. Maybe. Thanks man!

-

-

-

On 7/22/2020 at 4:09 PM, Miroslaw said:Good day. I need your help and advice on choosing a sewing machine for sewing leather. I have experience with sewing textiles, but as far as working with leather is concerned, I'm just a rookie. I want to start sewing car seats and upholstery. Unfortunately, I have no familiars, who would be engaged in sewing such products. I'm sure it should be a flatbed machine. But I have doubts about what kind of the feed mechanism to choose - top & bottom or compound feed. I have heard and read different opinions on this matter. What are the features of the choice?

My purchase budget - around $ 1200. Brands represented in my country - Juki, Typical, Durkopp-Adler, Golden Wheel, Hightex, Zoje. One seller also advised me model Typical GC 20606-1. Do you think this will be a good choice? I don't want to be wrong, because I won't have another try. Thank you in advance.

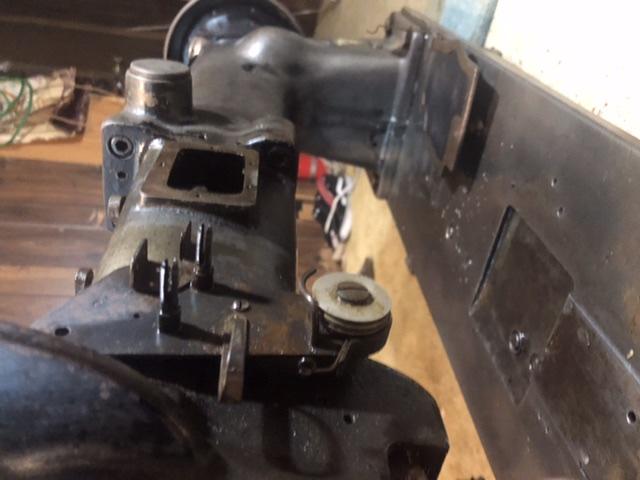

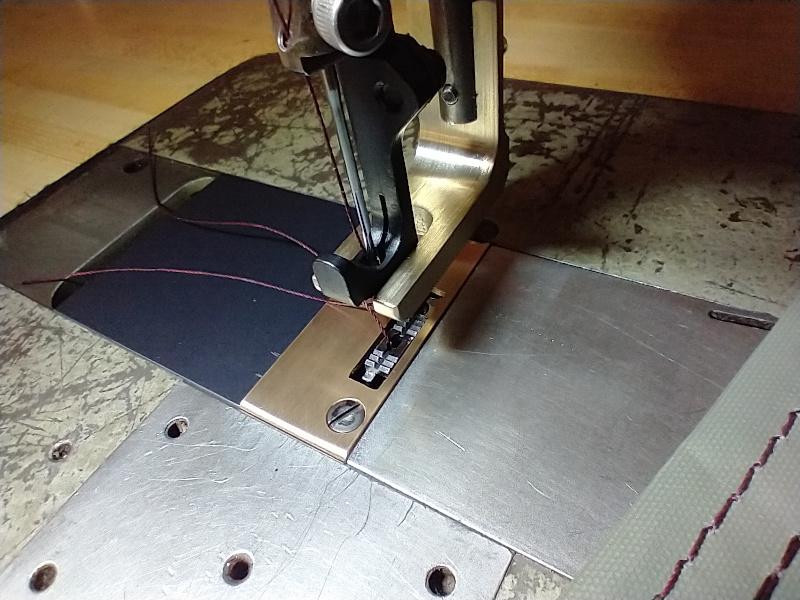

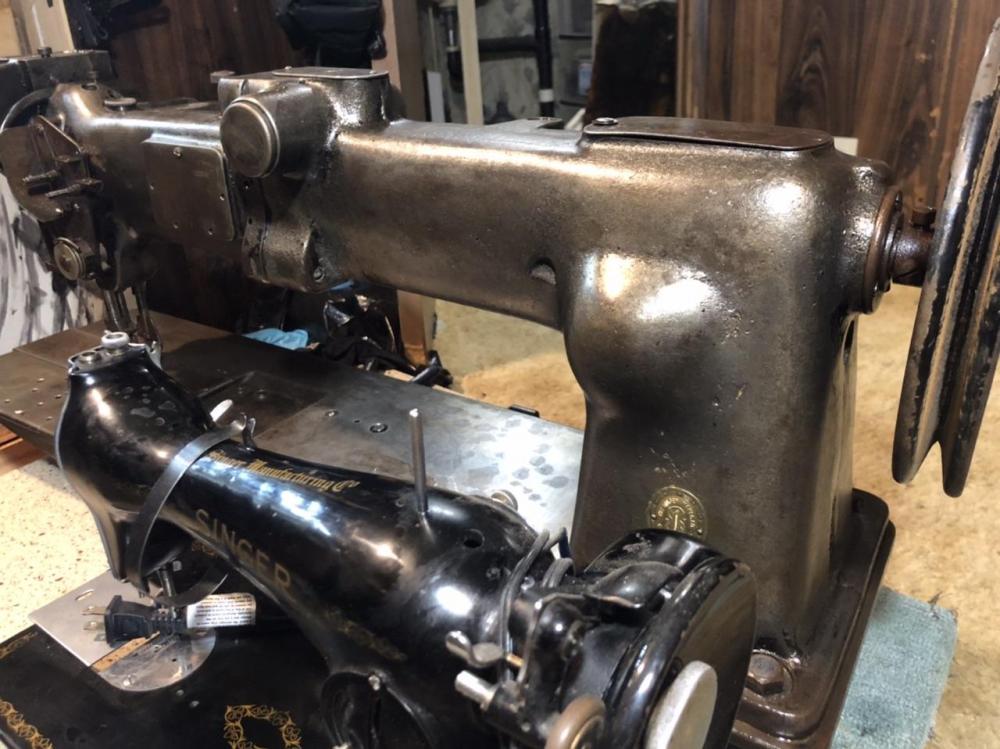

I picked up this 145w204 at a once in a lifetime deal. Supposed to be a great rig for upholstery. 7/8 lift compound walker. Sparkly clean inside and out. It had never been cleaned. I might sell, prefer trade

-

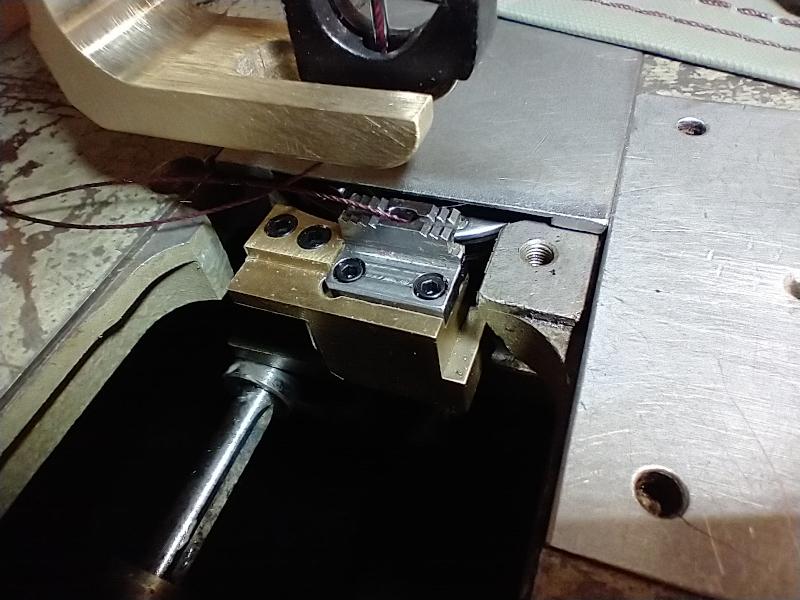

16 hours ago, SARK9 said:If you can get the right parts. You will need all the usual stuff: Inner and outer foot, feed dog, needle plate and possibly a needle bar as well. I can't tell if your check spring is still there for the thread controller assembly, but both sets of tension discs and springs are missing. If you use the 144W style of outer (presser) foot, you will have to rotate the presser bar 90 degrees. The Juki LG-158 I have has single and double needle versions....mine was the 158-1 (single) but I didn't care for the original setup for those same parts and made some with a more specific design for my work. The good news is it seems that some of the Singer parts are more plentiful, but there's not really a lot of variety.

-DC

That’s pretty slick Man. I dig it.

-

Man. Thanks a lot. You laid that out perfectly. I see exactly what your saying. I appreciate it. Now if I could find parts.

-

-

-

-

-

42 minutes ago, Matt S said:It's a top-feed-only, like most (all?) patchers -- only the foot drags the material along, since the foot is steerable in any direction. The foot that comes as standard is rather aggressive (since the machine is designed for sewing cloth rather than leather). Many people wrap it in rubber tape to reduce the marks that would be left on leather.

Regards stitch spacing, if the item is pre-punched the procedure would be to adjust the stitch regulator to as close as possible to the punched length. The machine would never exactly match the holes so there would have to either be a bit of jiggery-pokery making sure the needle lines up with the hole each time, or maybe the foot grippage is so light and needle is stiff enough to guide the piece a little once the tip enters the top of the hole. Either way, this approach is still prone to stitch length/spacing errors and must be about as slow as needle-and-awl saddle stitch.Yeah, it’s slow, slower than needle and awl. Horribly slow. I don’t know why I’d even try to share such an awfully slow process on such a piece of crap machine. Sorry i wasted your precious time.

It’s called a stitch marking wheel. They’ve been available now for a day or two. You have about an 1/8 of an inch on most sewing machines. 1/8th= 2-32nds=4-64ths . How much time would it take, and how hard do you think it would be to get your needle to match up if you were (pre punching) holes? You got a whole 1/8 to work with? I don’t care how you stitch, if it works for you, do it. There are literally 100’s of these machines purchased everyday, with 100’s of people that don’t know how to use them. It’s my job to teach the ones wanting to learn. Most of them folks, it’s all they can afford. They work with what they have, and not worry what the next man thinks. The ones that really get it move on to bigger and better machines if it fits their need, but I can guarantee you the Clsp stays in rotation. Unless you got a Claes/Pfaff you ain’t patching with 207. Clsp laughs at 207. My cobra gets scared at the mention of 207. Any problems with using the CLSP successfully are not with the machine. Any questions I can reached in person thru Singer sewing center Corpus Christi Texas. Ask for the industrial service mechanic, on Saturday’s at Tandys instructing a class, or on Facebook. Questions only. I don’t care if I’m not doing it right according to Paul. -

Who’s making top notch work with them? There’s a few hundred of us over at Patcher Solutions (Proven DIY) FB group. Shoe makers, sheath makers, patchers, etc… if it’s patchers, or patcher related, it’s there. Need help, tips, it’s there. You’re invited. P.S. A pair of custom Air Jordan’s made on the CLSP will set you back a grand.

-

-

On 11/24/2021 at 11:43 AM, chrisash said:My question is how well it sews, we all know they are built to a low price level,

But how different is a patcher say singer 53 or older, row of stitches than a Chinese patcher that's set up properly.

If you were given two sets of stitches could you really identify what one was made by the Chinese version

They are completely different. I have both a cobra and China patcher. My patcher sews with the best out there. It excels in the fact that it can sew 207 on both ends, unlike the rest of the patchers (except Claes/pfaff) that top out at 138. A sewing machine is nothing but a tool. It’s only going to do what the operator makes it do. It’s only going to do what it was designed to do, and the China patcher does exactly what it was designed to do. Lots of folks are producing top notch leather work with it, ive never had a complaint. 4-3/4 stars when used as intended, without physical changes to the rig. Singer 29-1 thru the latest clone (cobra,techsew,Consew,etc) are all singer 29s. The China patchers next of kin is the Bradbury.two completely different set ups.

-

2 hours ago, PocoOso said:Very nice indeed. The white stitching sure compliments the white spot. Real clean look. Excellent!

Thanks man.

Singer 145w204

in Leather Sewing Machines

Posted · Report reply

My 145w204 had been sitting since the 70’s when I purchased it a couple weeks ago. It had no rust, but was covered in decades of warehouse storage, spiders, and varnished oil. Machine wasn’t seized, but very close to it. Mainly old oil that had turned to glue. Got it tore down and polished everything clean and smooth. Stitched like a champ. Belt came in and I swapped out the old dry rotted one. Still worked, but not for long. So I put the new belt on exactly like the manual calls for, and I’ve done it 50 more times to be sure. Long story short, everything looks perfect, hooks to needle, runs smooth and quiet, my problem, the feed dogs will not keep time with the needle. At zero feed yes, they line up, start adding stitch length and forget about. Almost seems like something is 180 degrees off. I did not disassemble anything on the eccentrics, just clean and oil. I did check for loose bolts but all was good. So that’s the the gig, my feed dogs and needles won’t time, but everything else looks good. Any advice, hints, or means to a solution would be greatly appreciated. Thanks.