-

Content Count

44 -

Joined

-

Last visited

Posts posted by Patrick1

-

-

I'm not making black oxide parts anymore. Everything is now stainless. Any parts I did black oxide was with hot salts cooked in a bath. You can get more info here https://feeds.brownells.com/userdocs/learn/Inst-113 Bluing Booklet.pdf

-

-

No I'm only making parts for the Juki 441 or 441 clones and the Durkopp -Adler 205. Guess I should clarify, I'm not making any more feed dog and plates for the CB 3200, but my Narrow presser foot set and left presser foot fits the CB 3200.

-

I do make a #25 for the CB3200 but the demand is low for the 3200 so it's best to contact me directly to see what I have in stock.

-

A lot of screw thread sizes on these machines date back to the thread sizes that Singer used in their machines so your pretty much out of luck. Your best bet would have been to purchase a shuttle hook assembly of eBay for 28 bucks and use it for parts.

-

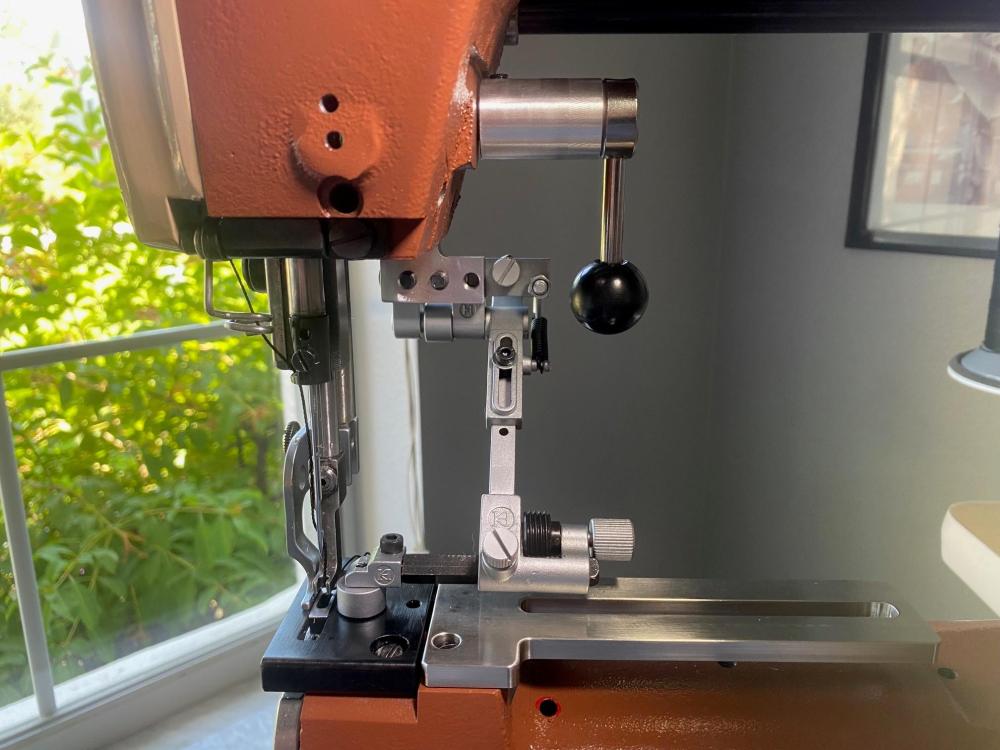

arrow presser foot now available for the Adler 205-370. Get to within 1/8 of an inch to the edge on ledges and hard to sew areas. Also have the streamlined Double presser foot and left presser foot for the Adler 205-370. Available at https://heprecision.com/

-

-

Folks with the COWBOY CB 3200 now can upgrade thier machines to a Narrow feed dog and plate made specifically for the CB 3200. 3 sizes available. #25 for #25 needles and below, #23 for #23 needles and below, and #20 for #20 needles and below. Check them out at https://heprecision.com/

-

@jrk65 should invest in a XTREME #25 NARROW FEED DOG WITH FLAT STAINLESS PLATE at heprecision.com for your Ferdco. Had a customer purchase one for his Ferdco last week with the same set-up as yours and similar issues. Don't have to stick my neck out here, feed dog, feed dog, feed dog! As @RockyAussie was saying about the oil, it's extremely important. Had another customer who purchased a brand spanking new CB 4500 with feeding issues. Had him pull the side plate, put some oil the presser and center foot bars and everything in between and now it runs as it should.

-

@Kgg, I'm still not enlightened. What parts become weak? Are you talking about the tension spring? If so replace it. Running the bobbin in the clockwise direction will eventually damage the bobbin spring. Sounds like some kind of folklore with no mechanics to it.

-

Enlighten me @kgg on why you would change the rotation of the bobbin except for adding another problem as in screwing up the spring.

-

Narrow presser foot set. About as close as you will get when sewing an edge. Answer to the limitations of an inline foot. https://heprecision.com/

-

Best upgrade for your 441 clone. No more leather falling into the slot when trying to do an edge. Serrated feed dogs for the Xtreme # 25 flat plate. Great for Biothane. Check them out at https://heprecision.com/

-

Wiz said; Another difference that bothers me about the 441 type machines is that the manual pressor foot lift lever is on the inside of the head, where it can be blocked by the work light or edge guide. Simple part solves that problem. https://heprecision.com/shop/ols/products/extension

-

Used to live there in Bozeman, then I went to Portland for a spell where I met my wife and she wanted the beach so we ended up in Florida for the last 11 years. Montana is God's country and the riding you can do up there is incredible not to mention the mountains is the best place to train a horse. Just got to find a few acres in the Bitterroot valley and put up shop.

-

The above post I posted to Facebooks Cobra tips and tricks in regards to thier admins Waste of time post on aftermarket parts. As far as I know the Chinese and me are the only ones doing aftermarket parts for the 441 clones. Uwe closed his store. It in no way does that reflect reflect on Leatherworker.net admin or sight.

-

I posted this to the admin on Cobra tips and tricks

The greatest enemy of knowledge is not ignorance, it is the illusion of knowledge.

This is my rebuttal to aftermarket parts. Having spent 48 years as a Toolmaker/Machinist/CNC Programmer designing, building, and manufacturing parts from aerospace to power generation I think I am a little qualified to rebut some of the negative comments the folks in admin have about aftermarket parts.

In those years I learned it’s best to have another set of eyes to look at production processes, tooling, and fixturing required to make the product. in other words, is what we are doing the most efficient and safest way at accomplishing that task.

I purchased a Cobra 4 about 3 years ago for the purpose of building 2 saddles for when my wife and I relocate to Montana. There are other things we wanted to do with the machine so that’s when I found shortcomings to the machine. I wasn’t going to purchase the deluxe package because I figured I could make the slotted plates that they sold with the package.

Doing research, I came across a post RockyAussie did on the narrow feed dog and plate on leatherworker.net. RockyAussie was kind enough to give the dimensions he used so I made my own. (I have my own CNC milling shop). I also made the slotted plates they sell. RockyAussie’s idea was ground breaking to say the least and people are fortunate to be able to purchase it from Rocky or Cowboy.

My wife wanted a flat plate because she is used sewing on a flat surface so I made a flat plate for RockyAussie’s feed dog that I made and found out that I preferred the flat plate to the round plate too. Other people wanted the flat plate too, so I made a bunch of them up.

I wanted to get closer to the edge than I could with Rocky’s design so I made one that is 1/16 slimmer than Rocky’s. In the end I wanted to push the limits of my so-called TANK that admin calls it and came up with 2 smaller feed dog and flat plates.

So this brings us back to the slotted plates that Cobra and Cowboy sell as a stopgap. My designs keep the original intent of the machine because they have a feed dog. Customers that I have talked to have had problems using the slotted plates and especially the holster plate.

Doing a cost, benefit analysis, the Cobra 4 with the proper so-called aftermarket parts I don’t require a second machine for the leather products I am sewing. I am 100% certain that the wonderful people that have purchased the said product’s feel the same way.

I can only guess why admin wants to slam my products, (maybe they won’t sell you that second machine) but they are doing a great disservice to the folks that have purchased the Cobra 3 and 4. I’m not here to push my products but defend them against willful ignorance.

-

A closed mind is like a clenched fist, it can't receive anything.

-

Just talked to a saddle maker in Texas and with the latest and final version, the length of stich isn't as long when sewing an arched segment. Guess not, the pivot point is a lot less. Something I didn't think about when I designed them. Another plus to an awesome product. Guess I'll have to send Tom the latest pressure foot.

-

Had a lot of folks interested in my version of an inline foot but it's not so I went back and increased the clearance of .010 of an inch per side on the presser foot and made it for a tighter radius. I'm 99% sure it should fit the 441 clones. Posted a video of it in action at https://www.youtube.com/watch?v=Tk2g3PJN4A8 . The presser foot and center foot are 17-4 stainless heat treated to RC 36. Works with up to #25 needle and a 277 thread. Can purchase at https://heprecision.com/

-

Had a person from Wales contact me about making a narrow feed dog and plate for the Juki LS-340 clones. Just throwing a question out there if people would be interested that. From what I can tell the current feed dog gap is about .300 of an inch. I could drop it to .160. Any feedback would be appreciated.

-

-

To expand the capability of my Cobra 4 I designed 2 needle specific feed dogs and plates. The Xtreme #23 will only accept a #23 needle and below and the #20 will only accept a #20 and below. The benefit is enormous, I don't need a smaller machine, my Cobra 4 now does 2/3 oz chrome tan leather and it buries the knot. Blows my mind on how great it did with the soft deerskin leather with the #20 plate and #19 needle. I posted a couple vids https://www.youtube.com/watch?v=4QhQGEylubE and https://www.youtube.com/watch?v=vNUa7lG08NA . If interested in upgrading your Cobra or Cowboy machines they will be available 16 Jan 2023 at https://heprecision.com/

-

No, the black oxide coated plates are made of low carbon steel and rust easily if not treated. I still have some black oxide plates in stock and will remove them from my website when they are all sold. The feed dogs are have a black oxide finish and are made of 4142 pre heat treated chrome moly steel.

Ordered A Cobra Class 4

in Leather Sewing Machines

Posted · Report reply

The purpose of the holster plate with feed dog is to maintain the the design of the machine. It sews just like the regular feed dog and plate. You can go fast or you can go slow, and even back up with no issues. It's the same with the narrow plates and feed dogs. The