-

Content Count

44 -

Joined

-

Last visited

Posts posted by Patrick1

-

-

Should be my last post to this topic. Did a revision the the holster plate and beefed it up some over the bridge and extended the surface area where the leather lays. I must say these are pretty stout plates. I'm only doing stainless plates and dropped the price to $135.99 per set. Anyone who purchased the old revision will be getting a free upgrade. Thanks for your business at https://heprecision.com/

-

The slot is .221 wide and can be purchase at https://heprecision.com/ price is stainless $70.00 for stainless and $55.00 black oxide finish plus shipping

-

I upgraded my friends CB-3500 with a needle positioner like my Cobra 4. When I added it to my Cobra 4 I purchased the whole kit, motor, box and needle positioner. I had a hunch I would have compatibility problems with the electronics box that my machine came with and sure enough I kept getting errors so all I did was replace the box and it worked great. I also added the Extreme narrow feed dog and stainless flat plate with a Cobra style presser foot. He wanted to see the needle better than you can with the Cowboy supplied foot.

-

I've added the stainless plate if anyone is interested at $145.99 for the set. More cost for the material plus machine time and cutting tools. https://heprecision.com/

-

-

I revised my price for the holster plate with feed dog down to $125.99 per set plus shipping. I'll only have 13 sets to ship on Monday if you want one. The picture on my website shows metal finish but the ones I ship will be black oxide finish. I posted a video on YouTube https://youtu.be/msSnYaxQVp8 and this set smokes the competition. I ran it fast as my machine will stich with no hang ups. It does the full stich length of the machine and sews just as you would with a normal plate and feed dog.

-

Yes, $165.00 a set plus shipping. You can have any color you want as long as it's black, as in hot black oxide finish I use for bluing my firearms. To keep cost's down I will not be offering the plate in Stainless. The feed dog is made from 4143 prehardened alloy steel and the plate is made from A36 structural steel. I should have my website heprecision.com updated by Thursday to purchase the set but they won't ship until Monday the 19th as I had to order material for the feed dog.

-

On 11/23/2022 at 5:37 PM, Uwe said:That presser foot set and flat-top throat plate look beautifully made. Did you make them yourself?

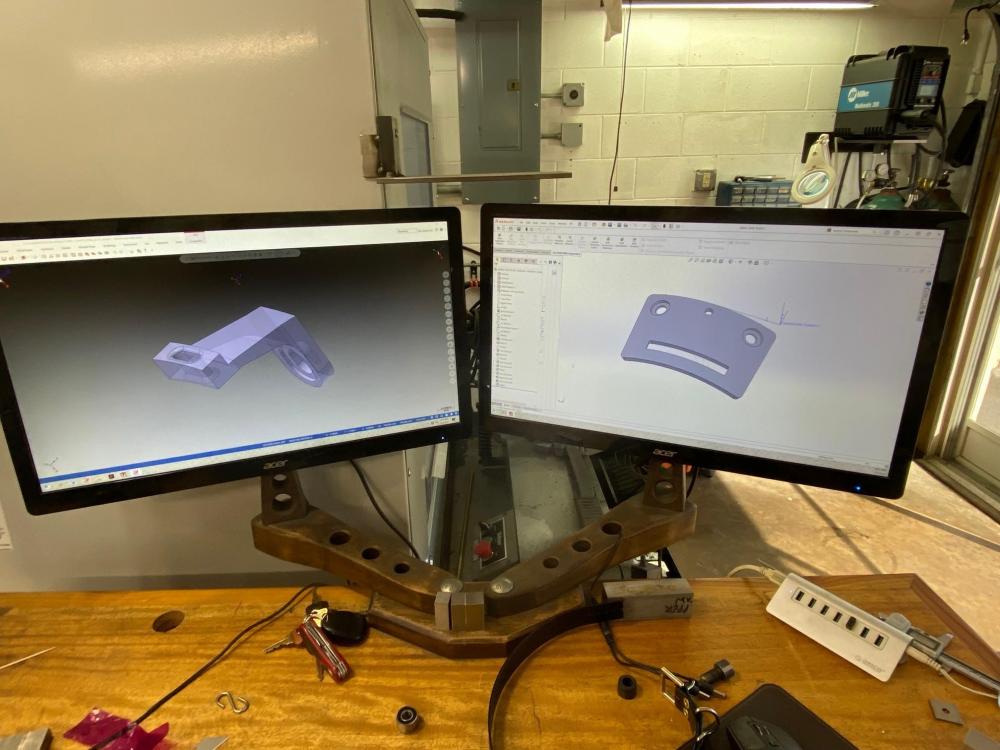

Yes and thank you. I have a fully equipped cnc mill shop with all the bells and whistles and have watched your videos on YouTube, you do a great job explaining stuff.

-

On 11/23/2022 at 5:28 PM, Hildebrand said:I am very interested in something like this. Do you have any plans to produce and sell these?

Thank you,

Todd

There is a little problem with the Chinese machines or it's just my machine. The needle bar is not inline with the feed bar so I had to go with a larger hole in the pressure foot. I tried a set out on my friends CB3400 with the bigger hole and it worked flawlessly. I also had to adjust the presser bar laterally. Long story short a lot of folks aren't comfortable messing with the mechanics of the machine so I'd probably open a can of worms for myself if I sold them. I'd like too but that's my only concern. I'll contact you If I decide to.

-

On 11/23/2022 at 3:10 PM, TomE said:Interesting design. No need to back out of corners as for the typical inline feet (?). Is the piece in the foreground made of 2 layers sewn together? Did you sew the bottom layer after stitching the layers together? I am interested in using inline feet to stitch tight against a raised leather feature. I can do it with the inline feet from Bob Kovar, which are quite nice, but I often sew raised leather pieces by hand in order to get closer to the raised edge and keep the border narrow.

Yes the piece in the foreground is 2 layers. I sewed the bottom after the 2 layers were sewn together.

-

-

I did some R&D on making the conventional inline pressure foot and wasn't happy about not starting on the edge or potential moon craters on the leather. With this set-up I can get to .135 thou to the edge with a 277 thread and 200/25 needle and it works just as I was sewing with a regular set, and no adjustments needed.

-

-

3M Synthetic Wax Protectant for cars works great on my cast iron table saw top.

-

Made in the U.S.A. narrow dog with a flat plat and works great. Made the small slot plates but don't think I'll be needing them. I think the flat plate is better for what I'm doing, definitely more control. Also made a holster plate and down the road will make the stirrup plate when I build my saddles. Awesome idea!

-

Great idea, so I decided to make my own parts on my Haas cnc mill. Will up load the finished product later in the day. Was going to make the stirrup and holster plate and along came this post. Not into selling them just rather make my own stuff. Received my Cobra 4 last week and as you can see the stitch size plate had to be shimmed before they shipped it to me. Not too happy about that from the Leather machine co. Chinese world class manufacturing. Have to make a new plate without the shim.

-

-

How do I buy the Stholman books

Narrow feed dog FLAT Plate for Cowboy CB4500 and Cobra 4

in Leather Sewing Machines

Posted · Report reply

The Xtreme narrow eliminates 1/6 in slot width and the slot in the feed dog is also smaller but can take a 200/25 needle and 277 thread. Doesn't sound like much but it is when sewing thin leather. I use the Xtreme narrow for everything up to a 277 thread and have no issues with it sewing the thick stuff. The feed dogs have the same radius as the round plates. A lot people prefer the flat plates as I do. The round plate gives you more clearance than a flat plate and conforms to the idea of a cylinder machine. I have had a few customers that wanted the round plate with the Xtreme narrow plate so I made them. I started making flat plates for the standard narrow feed dog because no on makes them and people were asking for them. I'm phasing out the black oxide finish because people prefer the stainless and actually more expensive for me to produce when I figure the time it takes to add the finish. If you look at the internals of your machine the majority of the parts are black oxide finish, it prevents corrosion. The slot size with the Xtreme narrow is .160 of an inch and .221 on my narrow plates.