aslfkjaslfkjasflkj

Members-

Posts

24 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Blogs

Gallery

Everything posted by aslfkjaslfkjasflkj

-

Pfaff 335 Max Thread size?

aslfkjaslfkjasflkj replied to aslfkjaslfkjasflkj's topic in Leather Sewing Machines

Not sure what class as its a clone, but the max foot lift is 14mm. So I'm assuming similar to a H4? What kind of fabric are you sewing for this hockey gear? I sew 1000D nylon and I'm getting a heavier duty cylinder arm for normal sewing. Then was looking into a 335 clone for binding as my thoughts was I don't need a thicker thread just for sewing binding on. Also I have the option of going down in thread size for some lighter weight stuff. However I think I'm leaning towards getting 2 heavier cylinder arms, one for normal and one dedicated binder. -

Pfaff 335 Max Thread size?

aslfkjaslfkjasflkj replied to aslfkjaslfkjasflkj's topic in Leather Sewing Machines

Thanks Glenn, thought that would be the case. Its my understanding that a 335 class machine is pretty lightweight. I was going to get one as a dedicated binder machine. So probably not using above a tex 70 thread. How do they fair up when sewing over ~4mm - 6mm / 10oz - 16oz in terms of leather thickness? -

As I understand the 335 can take up to a t90 thread. Is it possible to get it to sew v138 / t135 thread? Looking to sew heavy weight nylon and one thing I've noticed between machines is the Pfaff has a relatively small hole in the feed dog compared to heavier weight cylinder arm machines.

-

Binding Bracket vs Moving Arm

aslfkjaslfkjasflkj replied to aslfkjaslfkjasflkj's topic in Leather Sewing Machines

Thank you both for your replies. According the the KH Sew product page it should fit the Juki LS 1341. Also I am 99% certain the Global WF 1575 is a clone of the Juki LS 1341, I will however double check with the dealer. I wanted a Juki LS 1341 originally however my local dealer informed me that it is no longer produced and they new model is "LS2 342S / SC922BN / CP180C" which ~ £5300 dependent on the Euro, hence why I'm going with the global. KH Sew does sell a matching feed dog and needle plate for both the brackets I listed in the OP so that shouldn't be a problem. Also the Global WF 1575 comes in a binder model. My plan was to order the WF 1575 default machine but with the binder version's parts, e.g feed dog, needle plate etc. However I will have to check if the KH parts will work and vice versa. To double check, on any bracket if I want it to be syncronised it has to have the "piston" which fits in the feed dog? Have used College before and had no issues. Have seen there binders but from memory they weren't any right angle ones, don't quote me though. Did do a quick look for KH parts but couldn't see any binder-esqe parts though. Last off, regarding the actual binder I found a place called RG Attachments which appears to make binders to your specs, similar to Atlanta & Tennessee I'd imagine. I'd never seen any custom attachment maker in the UK until stumbling across them. Maybe other UK people know of some more? Kind Regards P.S I'm struggling to make an account on KH Sew , says I need to press the capthca but I cant see one on the page? Anyone able to enlighten me? -

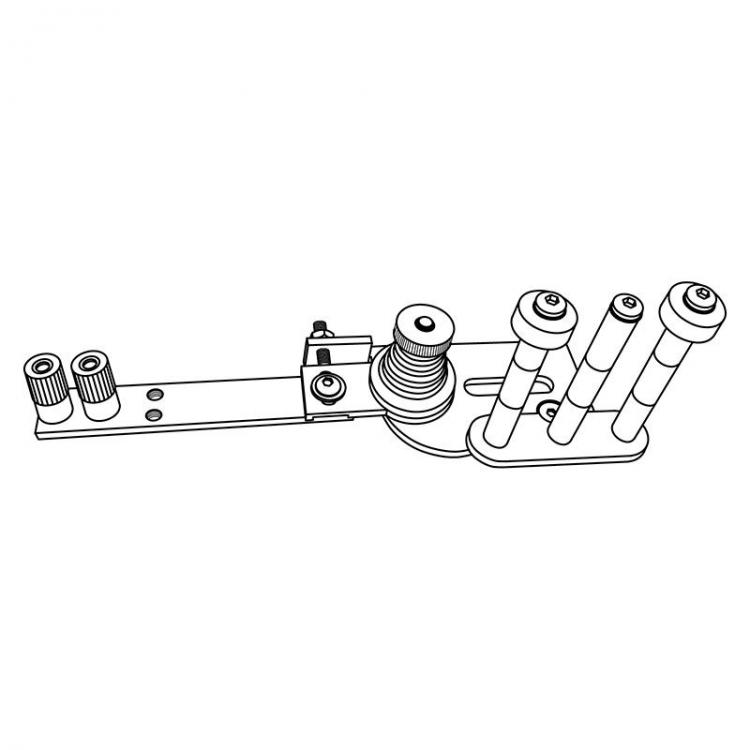

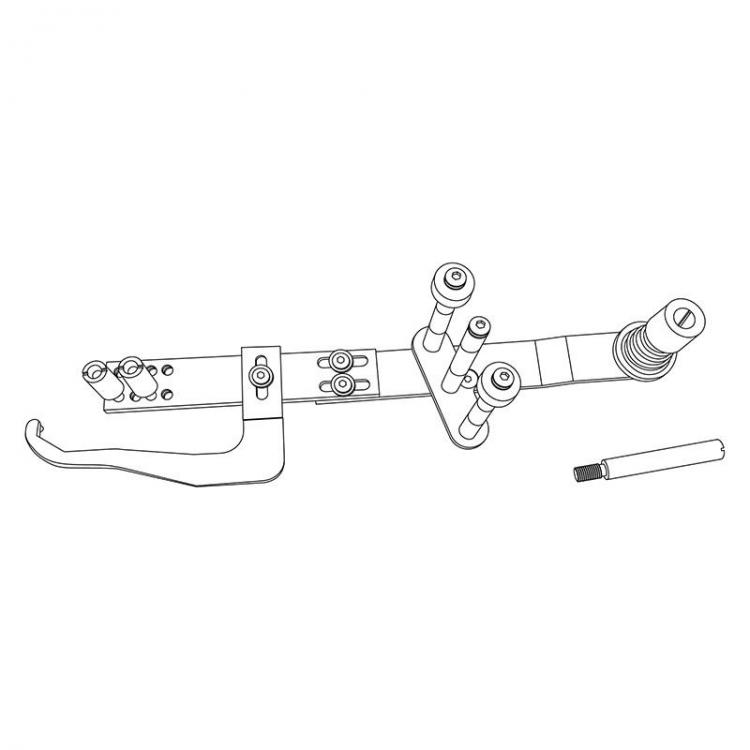

Hi All. Looking into getting a Juki 1341 clone (Global WF 1575) for binding. Was looking on KHSew and they have a "Swing Away Binding Bracket" 1st image & "Moving Arm" 2nd image. Do I have to have the "Moving Arm" in order for it to work as a syncronised binder? Or will the "Binding Bracket" also be syncronised? Thanks

-

I'll give those a go. I did notice that if I decrease the pressure on both feet the stiffness becomes less. Still there but not as much. Edit: I think this is due to the pressure of the feet Obviously due to the pressure being all the way down when it gets to the stage in the rotation the feed dog is pushing up against the presser feet which are pushing doing. So now I need to tinker with pressure. When trying to correct the every elusive problem where the bobbin thread shows through at the top when I stop and then start sewing again, I increased the pressure all the way as I'd read this could help. Never touched it again since then. Still having that issue too. At this point I don't know if I put this bobbin thread problem down to the fact that I'm sewing with ripstop lining and the tension has to be very high to pull through it.

-

Hi all. Back again with the Juki 1541 with its issues. When I rotate the hand wheel it is fine and smooth up until the needle gets to its lowest point. It then becomes very stiff and I have to use a significant amount more force to continue the rotation. I have felt the belt and although it does feel tighter at this point in the rotation it still moves if poked. Here's a video showing the point where it becomes very stiff. https://i.imgur.com/SVInN6b.mp4 Is this normal? My previous thread about the hook not stopping in the same place I believe is caused by this. If I set my needle positioner to stop at the point shown in the video, sometimes it will continue the rotation and kinda bounce back. I thought this was due to backlash in the gears however I now wonder if its due to the stiffness. It seems to need more force to get past the "stiff" point and then this is too much and it carries on the rotation when it should have stopped. Any ideas?

-

Should my hook spin like this?

aslfkjaslfkjasflkj replied to aslfkjaslfkjasflkj's topic in Leather Sewing Machines

What you see in the video is me pressing the foot pedal once at a time in order to complete a rotation with the needle positioner stopping in the down position. I watched the video you linked previously and all the hex screws next to the gear in the oil res were all tightened. I'm a novice when it comes to servicing a machine but it appeared to me that the gear in the oil res looked fine? Also this is a preowned 1541 no s. I know the hook basket has been replaced because when buying bobbin cases for it I bought the ones stated in the manual B1837-241-H00 only to find they didn't fit and then I ordered a generic BC-DMB1 case which fit. -

Should my hook spin like this?

aslfkjaslfkjasflkj replied to aslfkjaslfkjasflkj's topic in Leather Sewing Machines

I understand that the hook basket has some give in it however I am referring to where the hook stops after each rotation. If you watch the bottom middle of the hook basket, the 6 position on a clock, the hook doesn't stop at the same place each time. Sometimes it stop at the 6 position, sometimes, 7 sometimes at 9. This is what I am questioning as to if it is normal or not. I have a needle positioner so it is my assumption that the needle and thus the hook would stop at the same position each time. What you see on the video is me pressing the foot pedal once for it to complete a single rotation at a time. -

Should my hook spin like this?

aslfkjaslfkjasflkj replied to aslfkjaslfkjasflkj's topic in Leather Sewing Machines

Ah I understand now, thank you. Is this behaviour from the hook normal? -

Should my hook spin like this?

aslfkjaslfkjasflkj replied to aslfkjaslfkjasflkj's topic in Leather Sewing Machines

This is a timing issue? I thought it could be to do with the needle positioning due to the hook stopping st different positions when the needle is in the down position. Kinda at my wits end with this machine and its backlash problem. I tried everything mention in the previous thread to no avail. I hadn't notice the hook stopping at different positions in the past so I'm hoping fixing this will solve it. -

Hi all. Was just doing some troubleshooting on my Juki 1541 which I still have backlash issues with (see previous post) when I noticed this. https://imgur.com/a/xXCrUWJ On each rotation of the hook it doesn't stop in the same position. Is this normal? Kind Regards,

-

You're correct it doesn't however this isn't any way adjust it so that the spool pin sections aligns with the hole. There is the hole to the left circled in the image below. This appears to be more central over the spool. My only concern with this is the fact that its just a metal edge which may cause some issues with the thread? It does feel smooth but obviously it isn't plastic lined as the circular hole.

-

Hi, may bad for the slow response. If you're referring to to the image in my very first post, this was just an issue from the internet. I did it have it inserted bobbin side. I bought a new bobbin case with the slots in for the backlash spring just haven't got round to testing it in my machine yet. What is the "disc type backlash spring" is it the one in the previously mentioned image? Because I couldn't find the part number in the part book and after some digging I found a backlash spring which had the same part number minus the last digit. B1837241H0C is what I have.

-

This is going to be a long post so brace yourself. Bobbin Winding This is the thread path for the bobbin winder. This is my bobbin case which I made sure to clean out before any testing. There wasn't any lint anyway. When the bobbin is winding it appears to "wobble" not sure if that's normal. Here is the video of this: https://imgur.com/0sp0eqQ Thread Path Testing Info I insert the bobbin so that it spins the opposite way to which the hook spins. The following images of testing you will see a white line next to some stitches. This white line indicates when I stopped sewing. So you can see where the bobbin thread gets pulled up to the top. Grey on grey isn't the easiest to see but hopefully I have shown it well. Size 19 Needle Testing I started off by using a new size 19 needle with a bobbin tension of ~40gf. I tested the tension in a towa bobbin gauge and the bobbin tension was consistent. To save space here is the rest of the images for size 19 testing: https://imgur.com/a/iWuB4NK Size 18 Needle Testing I then switched to a new size 18 needle and I believe I increased the bobbin tension too. I continued testing and now it got to a point where I wasn't experiencing backlash all the time however it would still occur. At this point my top tension was very tight to the point where it couldn't be adjusted much more. The bobbin tension was also very tight around 75gf. So this wasn't a valid solution. Rest of size 18 needle testing: https://imgur.com/a/HWBzMsU I also tested on 1000D Cordura 4 Layers with a size 19 needle. As many have said the 19 needle is too large for this. However when I use the same needle on the 1000D with ripstop lining its as if the ripstop creates a lot of friction and I have to increase my top tension significantly to account for this. Is this something anyone else has experienced? Backlash Spring Testing I now decreased my bobbin tension to ~40gf and inserted a brand new backlash spring. However I have a problem. I have seen bobbin cases like this: This case has a slot for the backlash spring to sit in however mine do not so I insert the spring as follows: I am unsure as to if I should put it above or under this little piece: I put it in the tension gauge and as usual the bobbin didn't have consistent bobbin tension. As a matter of fact, this time the tension WITH the backlash spring, the bobbin tension decreased to ~34gf from 40gf which I have never experienced before. It has always increased the tension in the past. I continued testing using this current setup and sometimes it worked but not all of the time as you can see in the final images in "Size 19 Needle" imgur link. Here is a video as to what it looks like when sewing: https://i.imgur.com/OwNAM91.mp4 Final Thoughts I am unsure as to what else I can do with my current setup. All I can think of is to buy a bobbin case with the slots for the backlash spring as pictured above and some genuine bobbins. Thank you for taking the time to read this wall of text.

-

Yes, I have needle positioning so when I stop the needle stays in the fabric at the same point each time. Presser foot also is applying pressure and I have increased the pressure substantially but no change. What do you mean by this? How does one "dumb down" the machine? Also if I size up to v92 how exactly would this solve the backlash issue? Being in the UK there isn't that much choice when it comes to bonded threads.

-

My issue isn't starting a seam. I started a seam by holding the tails tight and sewing back and forth securing the stitch. My issue is when I stop mid stitch. When I stop the bobbin continues to spin thus loosening the bobbin thread. When I begin to sew again the bobbin thread gets pulled up to the top side of the material. After a few stitches the bobbin thread goes back under tension and I don't have another issue until i stop. Then the problem repeats. Can I ask why you dislike bonded poly? What are the differences compared to bonded nylon?

-

I will checkout the links you posted. I am 99% sure this is a backlash issue. I didn't mention this previously, my bad. When I am sewing constantly I have little to no issues. My problem is when I stop sewing. The stitch will be fine until I stop, when I begin sewing again the first stitch or first few stitches will pull the bobbin thread to the top. As far as I'm aware this is thread backlash. Maybe I am wrong. I hope this clears things up a bit. I will post in this thread on Monday more details with my current setup including thread guide path. Kind Regards

-

Yes I meant bobbin. I am using aftermarket bobbins so I might look into some genuine ones if I can't get this resolved. I've also read that aluminum bobbins are supposed to be better for backlash. Any input of this? I will update this thread on monday with my thread path. I am using A&E Sunstop 3000m v69 grey thread. I am sewing a sling bag. I'm using 1000d PU Nylon and ripstop lining. I am now sewing all the pieces together, which as mentioned previously I have a minimum seam of 7 layers up to 14 in some parts. I've had issues with consistent stitches but I put this down to a number of things. This machine is second hand and didn't come with all the thread guides etc. I recently purchased all the missing parts. But I still have issues with the backlash. I've always placed the bobbin into the case as shown in the manual. I will try it the other way as wiz suggested.

-

Thank you for the help thus far. I am using a thread guide pin/top post and threading it counterclockwise opposite of the direction coming off the spool. The needle size is something I'm a bit unsure of. I was originally using size 18 serv7 needles. Which seemed fine for a few layers of 1000d and lining however I'm now sewing bag pieces together where I have a minimum of 7 layers and up to 14 in some parts of the same stitch. I then sized up to a size 19 needle. Would this be too large? My thought was that the thread seemed to be having a hard time going through thicker seams so I sized up.

-

I think I have tried this in the past however I will try again. Just to be clear, when you refer to the rotation of the hook. If I load the bobbin from the side and look at the hook from this angle, in my case the left side of the machine. The hook spins counter clockwise. So I should insert the bobbin so that it spins counter clockwise as when inserted this will spin opposite the machine. Hopefully I got that right. Also should I bother with the backlash spring? As the inconsistency in tension leaves a poor stitch which in my opinion is worse than the backlash as most of my sewing consists of straight lines and not having to stop. Thanks

-

I am using V69 Bonded Polyester thread in my Juki 1541 and I'm having backlash issues. I'm using steel bobbing and I have tried tightening the bobbin tension to no avail. I have tried using a backlash spring (pictured) however this causes inconsistencies in the stitch and I still sometimes get backlash. I have tested with the spring in a tension guage and the tension goes up and down. Without the spring it is consistent. I have also tried multiple springs. I sew at 100spm and at this point I'm at my wits end. Is there anything I'm missing? Kind Regards