Search the Community

Showing results for tags 'hook'.

-

Does anyone know this company (https://www.miketony.com.tw/en/product-c34798/Hook-And-Shuttle-Hook.html)? Reputation?

-

Hi Recently I have received from dad CLAES 200-2 in good condition, but it is missing bobbin, hook and hook drive, as a tinker I've decided to recreate them from scratch in CAD software, then CNC or 3d metal print it. There are some pictures of it on google, but it's hard to determine dimensions. Could any good soul on this forum, who has this machine, make some pictures of it and measure it for me? After testing it I will post here all files free to all

-

Howdy! I recently purchased an experienced Juki LU 563. As I have been acquainting myself with the machine, it has been working very well. Yesterday, as I was sewing some canvas and leather, the needle broke. This seemed to throw off the timing, as the bobbin hook isn't picking up the needle thread. There aren't any repair guys within about an hour and a half from here, so I'd like to learn how to adjust this myself. Can anyone offer some pointers? Thank you very much! -Peter

- 18 replies

-

- juki

- juki 563. timing

-

(and 1 more)

Tagged with:

-

Hi all. Was just doing some troubleshooting on my Juki 1541 which I still have backlash issues with (see previous post) when I noticed this. https://imgur.com/a/xXCrUWJ On each rotation of the hook it doesn't stop in the same position. Is this normal? Kind Regards,

-

Open to sensible offers for these rare SD28 parts..in pounds sterling £ Will post worldwide at cost..buyer is responsible for any import duties/taxes. Shuttle/hook with 2 bobbins...hook looks good and it picks up thread in my machine, has some surface rust and pitting on the bottom. 2 more spare bobbins. Super rare harness stitching plate with edge guide and screw..in great condition. Needle strike plate or whatever it is called...size 5/6 14 used needles...some have slight surface rust and or wax build up but could be cleaned, sharpened a re-used? Mostly size 6 with a few 5s I think? In my other post I have a fully working Junker & Ruh SD28 with needles for sale.

- 9 replies

-

- junker and ruh

- junker

-

(and 9 more)

Tagged with:

-

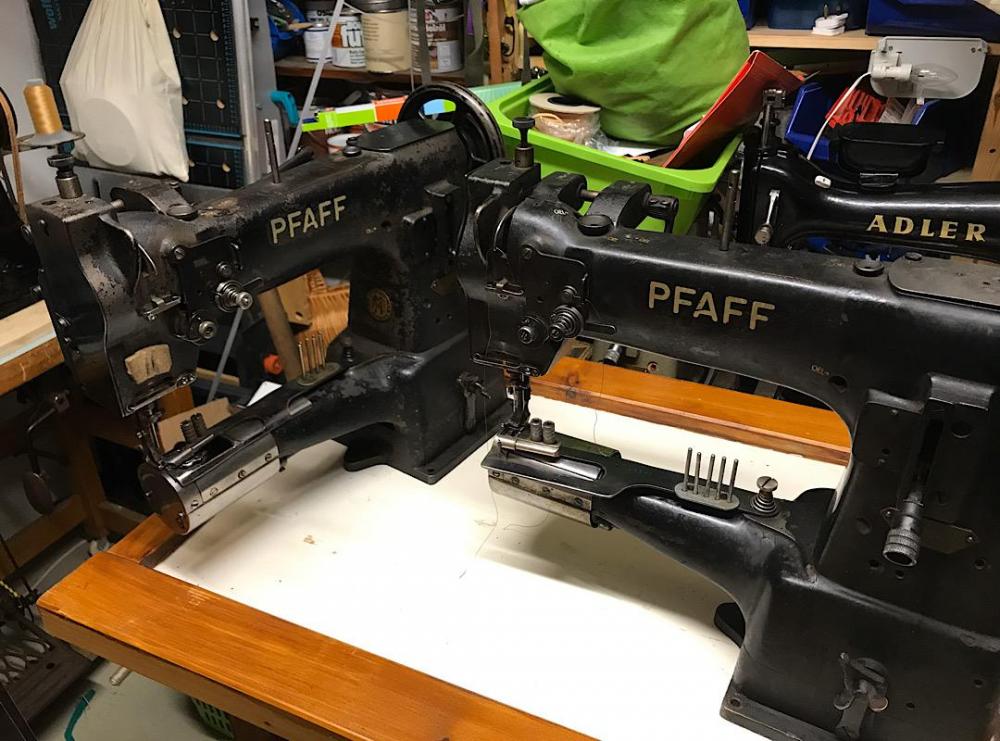

so first the funny part: on friday was a day to tell the grand children about .. i was at the printers for a magazine we print - and on the way was an old shoemaker who sold some tools and leather — well .... nothing nice there, but in the corner i saw this beautiful pfaff 345 with walking feet and synchronised (!) binder ... „could you use that?“ he asked .... what a question .. after my remark that a tension spring is missing, he came up with even more binding stuff and led me into the backoffice ... „here... do you need that one also?“ — a twin !!! a second pfaff 345 h2 or h3 —/ some thread and a 2 h talk followed ... what a beautiful day!! incredible happy bodo here the sad part; on one machine the hook is broken ... is there any place where i can buy one other than for 200 euros?? and — how to ger that part of of the machine? thx in advance ... cheers bodo

-

After a couple of pretty severe needle strikes my usually very reliable sewing machine (Seiko LCW-8BL) has developed persistent problems. Mostly thread jams and needle thread breakages. I've done the usual re-threading, bobbin changing and needle replacement to no avail. However I've noticed that the tip of the hook looks like it's been chipped and I suspect that it's piercing and cutting the needle thread. These are the best photos I was able to get. It looks like the hook is a little shortened, and the inside edge is very sharp. The outer edge of the hook is smooth and polished. A replacement good quality hook is not cheap but it's a cost I'm just going to have to swallow if that's what's needed. What are my chances of grinding and polishing the damaged hook into function? Should I just pony up for a Hirose?

- 9 replies

-

- sewing machine

- hook

-

(and 3 more)

Tagged with:

-

Ok, sewing machine gurus, I have a Ferdco 900B that I acquired when I bought a guy out, that sews just ok, but doesn't hold bobbin tension very well. I've maxxed out the bobbin tension, I've taken the spring off and cleaned out the gunk accumulated under it, replaced the spring with a different one (that came in a box of parts that came with the machine). Neither of the springs show very much wear, nor does the surface of the bobbin case under the spring. However, the little notch at the far end of the slot under the spring, that the thread is supposed to snap into shows some wear, and I believe the thread is slipping out of it as the thread spools off the bobbin from side to side. Even when the thread is properly in the little notch, however, I can't adjust it to have enough tension. There is no beehive spring inside the bobbin case, and I'm not sure there ever was one. The manual shows to change the bobbin with the opening in the case down, so the bobbin drops right out, which makes me think there was never a spring to start with. The manual also states that the bobbin tension should be set to "slight resistance" when in my opinion, you'll never, ever get a tight enough stitch with "slight resistance" on the bobbin thread. My question is, can I replace JUST the bobbin case, or is it an integral part of the whole hook assembly? And if I DO need to buy the whole hook assembly, will the 441 hooks work? I know that the Ferdco was made from the Consew 754R, but haven't found much online for parts for that machine. The bobbin case itself looks identical to the one in my Cowboy 4500, on which incidentally, I can screw the tension down to where it pulls a pretty tight stitch. The bobbin case for the CB4500 does have the beehive spring, but I don't believe that alone can create the amount of tension that I can get from it, primarily because when I bought it new, the bobbin tension was set way too loose for my liking. Any advice?

- 16 replies

-

- bobbin case

- hook

-

(and 1 more)

Tagged with:

-

I have a large collection of hardware I'm selling. The amount in the photo might be less than what I actually have- I noticed more pieces after I took the photos. I am NOT selling individual pieces. Each photo has the grouping of what I'm selling. Please don't ask for a selection of each group, I won't do it. I also have a ton of real snakeskin hides I'll be posting soon for sale! Email me- fastest way for a response- Rachael@heavyleathernyc.com

-

I have a large collection of hardware I'm selling. The amount in the photo might be less than what I actually have- I noticed more pieces after I took the photos. I am NOT selling individual pieces. Each photo has the grouping of what I'm selling. Please don't ask to purchase a selection of each group! Email me for a quicker response- Rachael@heavyleathernyc.com I'm also selling tons of snakeskin hides soon!!!

-

Hi all, I'd be grateful for some help getting my Pfaff 1445 going. I previous posted about feet, which I got from Hong Kong. They're mediocre but acceptable quality given the rarity of the machine. The machine wouldn't have been a bargain if it were free considering the time and expense that's gone into it. But hey, we've got another machine so I'll consider this thing a hobby. I've got the hook correctly timed, but I'm finding that it's very difficult to correctly balance relative top and bottom thread tension, or top dog pressure may be incorrect, or the bobbin case opener isn't correctly timed or distanced. Or all of these. Compound feed is accurately synchronized, needle bar centered in all dimensions, all stroke lengths are correct, bottom feed dog height properly set to ~.020" (.5mm) per the service manual. I've got a new needle plate, feed dog, and feet, which feed perfectly straight. I do need to take the needle plate over to the buffer and ease some of the edges the thread goes around. No problems with inconsistent tension between the cone of thread and tension rings. Top thread is correctly routed per the operating manual (unusual design and route). Bobbin thread is correctly placed and pulled. Pictures attached. Symptoms are: • Occasional skipped stitches and slightly inconsistent bottom stitch; the bottom and top quality don't match consistently • Backtack thread tension is very loose • Starting the stitch occasionally results in a squirrel's nest mess of thread on the bottom • When I get the top and bottom tension balanced such that the thread is more or less locking in the middle of my material, I occasionally find when turning the handwheel that the top thread is very tight as it crosses over the top of the bobbin and the motor may even slip on the belt I strongly suspect some kind of binding or tension issue is causing thread to get pulled off the bobbin or through the top inconsistently. I'm running a 3/4" HP servo motor with what I believe are the correct thread/needle combination for layers of 3 - 6 oz chrome tanned and retanned vegetable tanned leathers (the same size combination has always worked quite nicely on another machine).

-

Dear All, I am new to the forum and have a question that I imagine may already have been looked at by some of you. I was given a Frobana outsole stitcher in dubious shape but am keen to get it stitching. I am struggling a little to adjust the timing of the hook and am wary of getting too physical with the workings until I know which screws etc I need to deal with. Does anyone have any suggestions on this? I'm not sure of the model but it has a wooden base and no cowling over the machine....... looks like the one in this youtube post: Regards, Alex

.thumb.jpg.bd465a1ac087aff70a0be9b5916ae014.jpg)

.thumb.jpg.e42a5c3d7b4f60055a4c0f284425d761.jpg)

.thumb.jpg.81ec802b4691f4d72ceb2008d3574afa.jpg)

.thumb.jpg.b4a97f8ed100a8b60348b81659c0c5dc.jpg)

.thumb.jpg.7ae3796ef0aaadd3a3265f5c070a101d.jpg)

.thumb.jpg.7290c9b7679d11cc9f0b84102412a947.jpg)

.thumb.jpg.810f5bf1ce9c731fa0a64bad4b0fdc3b.jpg)

.thumb.jpg.759be88b49f421c6626bfef6cbc120db.jpg)

.thumb.jpg.d82928e4d2983aff29723e0f2f142985.jpg)

.thumb.jpg.eb098932b0d82c34692eb0c5d398bb06.jpg)

.thumb.jpg.1232903bbab395a0bb37b28a48d882ab.jpg)

.thumb.jpg.980baff6a6bc4aec1e4a0618391b647f.jpg)

.thumb.jpg.7a0834b06763e4ec7004b22633a78bf6.jpg)

.thumb.jpg.a90ecc4b1afc34a4a04da2c79ffd00a0.jpg)

.thumb.jpg.96c4e8197a560f7e8c10ae03f775b25d.jpg)

.thumb.jpg.d0b2dcd8abbaae9fb8f98341cde0c3ca.jpg)

.thumb.jpg.b3a34ce9ede9df15b38d7b2b472da25f.jpg)

.thumb.jpg.d8872f6ccc650b7dde88eb108257f07e.jpg)