cynthiab

Members-

Posts

53 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Blogs

Gallery

Store

Everything posted by cynthiab

-

It's a singer 111w series machine.

- 6 replies

-

- singer

- double needle

-

(and 1 more)

Tagged with:

-

I found your needles at WaWak. a 10 pak is around $5 US. https://www.wawak.com/sewing/needles/industrial-machine/schmetz-diamond-point-straight-stitch-industrial-machine-needles-134-35-r-2134-35-dpx35-135x16-dia-dpx16-dia-10pack/?gad_source=1&gclid=CjwKCAjw4f6zBhBVEiwATEHFVrIjIG4L1Po9i_1qOm55lI628Qzf_Oe8DrX7N6r7nllP4ad1tAFXIBoCPAcQAvD_BwE#sku=smnd135124

-

Help with thread wrapping around bobbin case.

cynthiab replied to cynthiab's topic in Leather Sewing Machines

Thank you I'm on it, and will get back to you. -

Help with thread wrapping around bobbin case.

cynthiab replied to cynthiab's topic in Leather Sewing Machines

Thank you kgg. I checked it and it is seated properly. I have experimented with different threads. A 136 on top and a 92 in the bobbin case. It was a tiny bit better However, I'm still getting the threads wrapped around under the top edge of the bobbin case periodically. The stopping and turning seemed to be the culprit. But not always. I have followed what wizcafts suggested on the needle position before turning. That helped a bit too. However it's still hit or miss if I can sew on a peice of webbing to leather without it jamming up in the bobbin area or shreadding the thread. Ugh! By the way, I did retime the needle and made sure the gap between hook and needle was correct. Didn't help... -

Help with thread wrapping around bobbin case.

cynthiab replied to cynthiab's topic in Leather Sewing Machines

Is it possible that my bobbin case opener is out of time? (the little finger that moves back and forth) Untitled video (3).mp4 Sorry I couldn't upload a longer video. 1. 4 MB is all she takes. -

Help with thread wrapping around bobbin case.

cynthiab replied to cynthiab's topic in Leather Sewing Machines

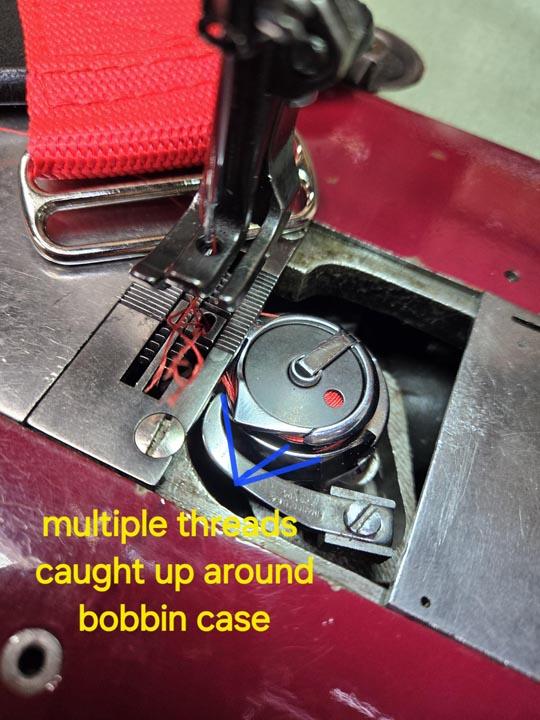

I oopsed and forgot to up load some photos of the issue Im having with this. Hopefully this will help. -

Help with thread wrapping around bobbin case.

cynthiab replied to cynthiab's topic in Leather Sewing Machines

kgg, thank you for your input. I appreciate your time. The reason I switched from a #22 to a 23 needle is that I was getting skipped stitches with the 22. If I sew a straight line I'm good with the #23. The problem comes when I make a stop and pivot for a turn; then after a few stitches more it's jammed. I have tryed to watch it with the cover open but the material covers the hole when I turn. Please bring out your magic wand and fix this... -

Help with thread wrapping around bobbin case.

cynthiab replied to cynthiab's topic in Leather Sewing Machines

Thank you Wizcrafts, I make my turns with the needle tip just entering the top of the leather. Between 1/8 th a 1/16 deep. If I bury it deeper I end up sooner or later twisting the needle or getting skipped stitches. What are your thoughts on this? -

Hi guys. I'm working on a project on 1/4 inch leather and sewing on webbing straps. My machine is a Singer 111w155. My thread is 92 Bonded Poly, my needle is a #23 leather point. My stitches are nice until I make a turn. Then the machine jams up with multiple threads wrapped around the bobbin case (but not always). I'd like to know if others had this problem and how it was resolved. Thanks for your time and consideration, this has been driving me crazy.

-

I'm sorry to hear this, he will be missed. My heart goes out to his family.

-

Let us,know how this all works out for you. You have an audience.

-

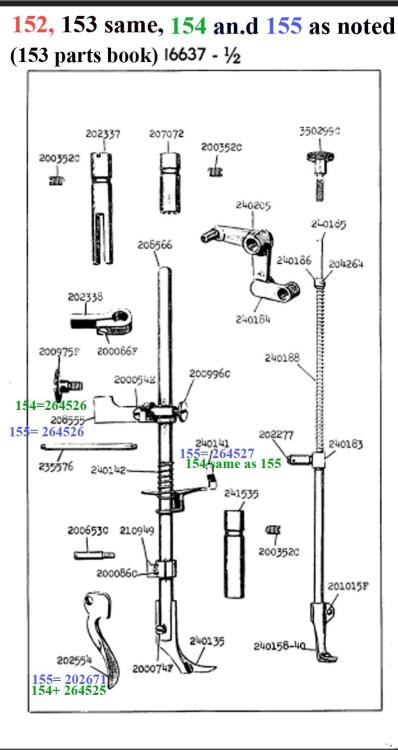

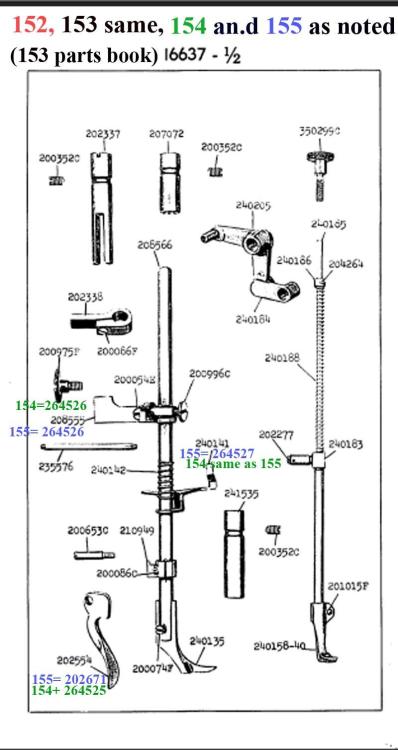

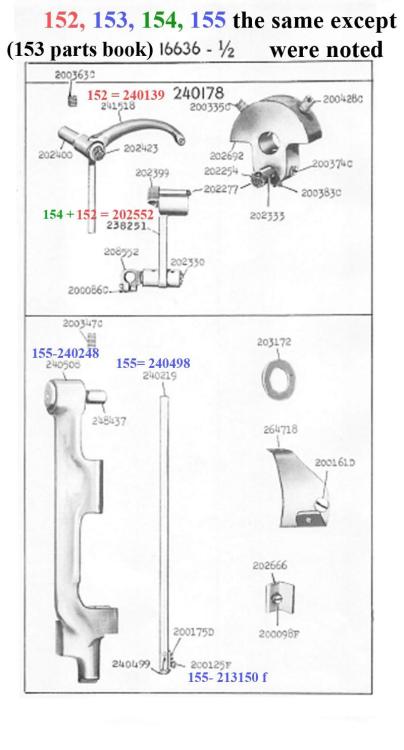

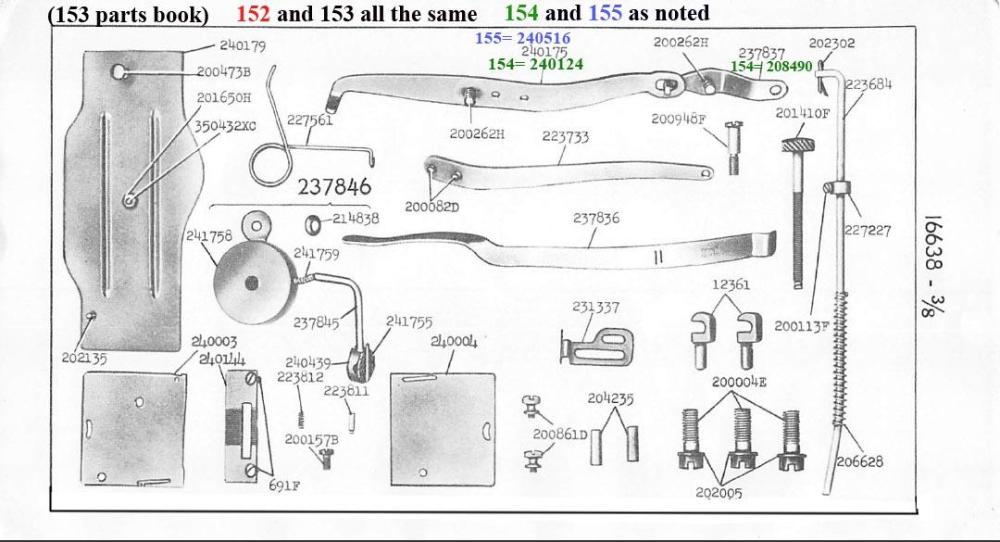

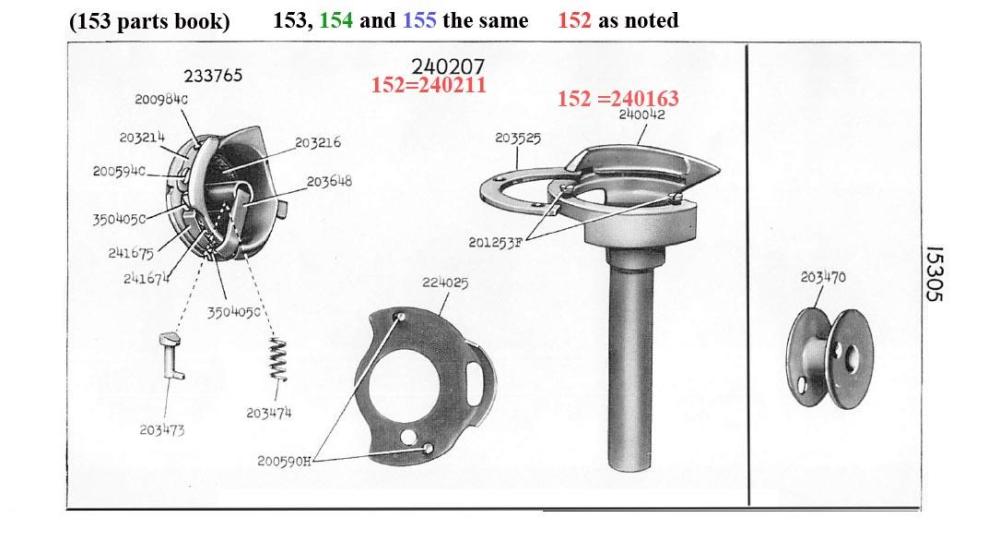

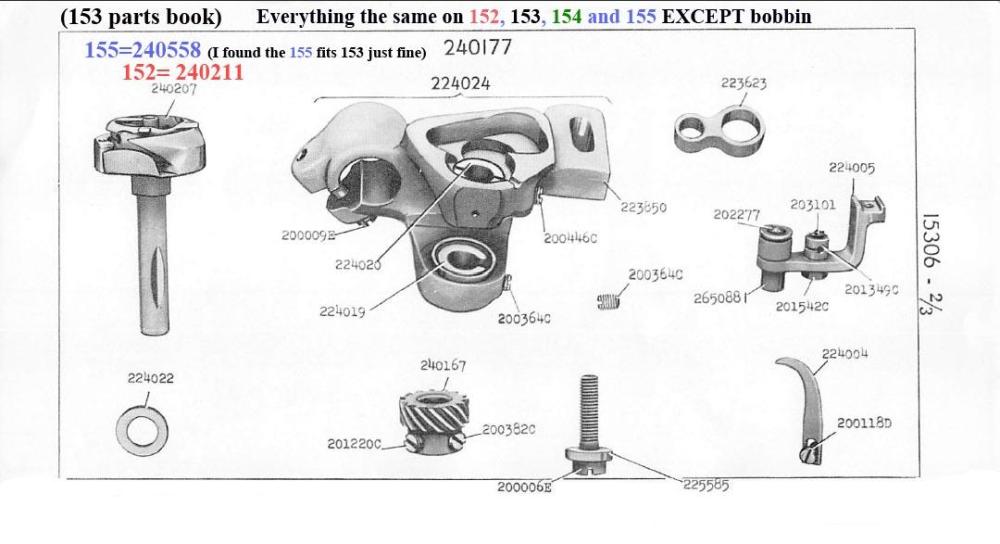

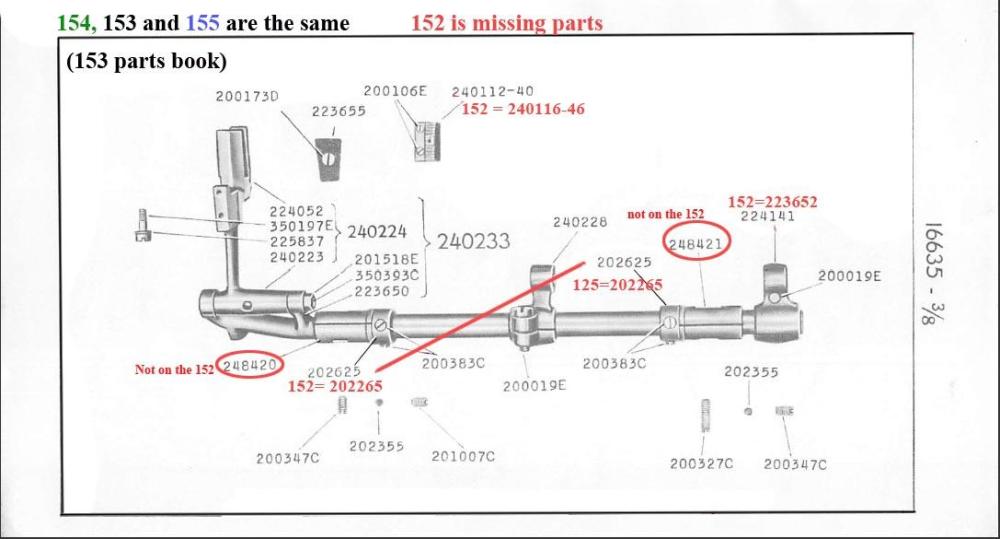

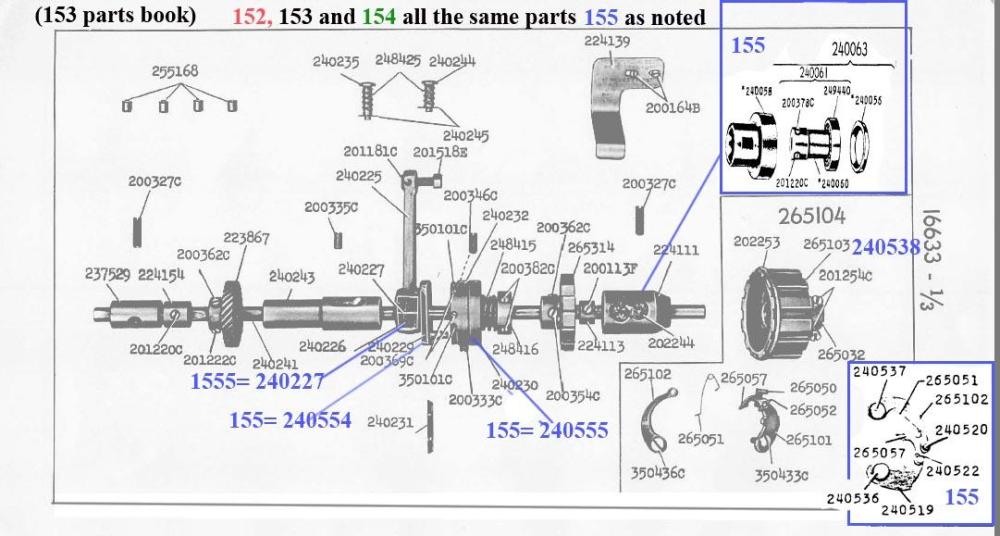

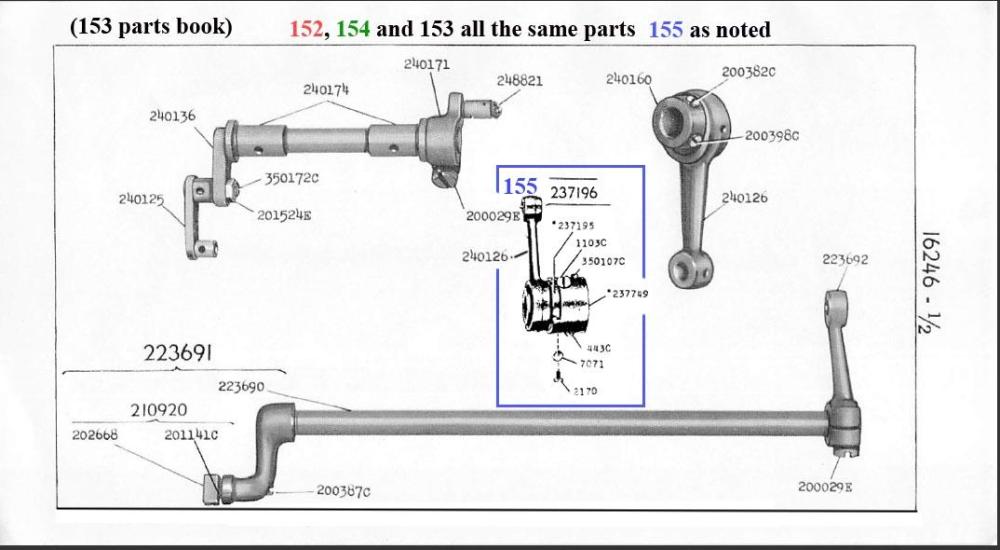

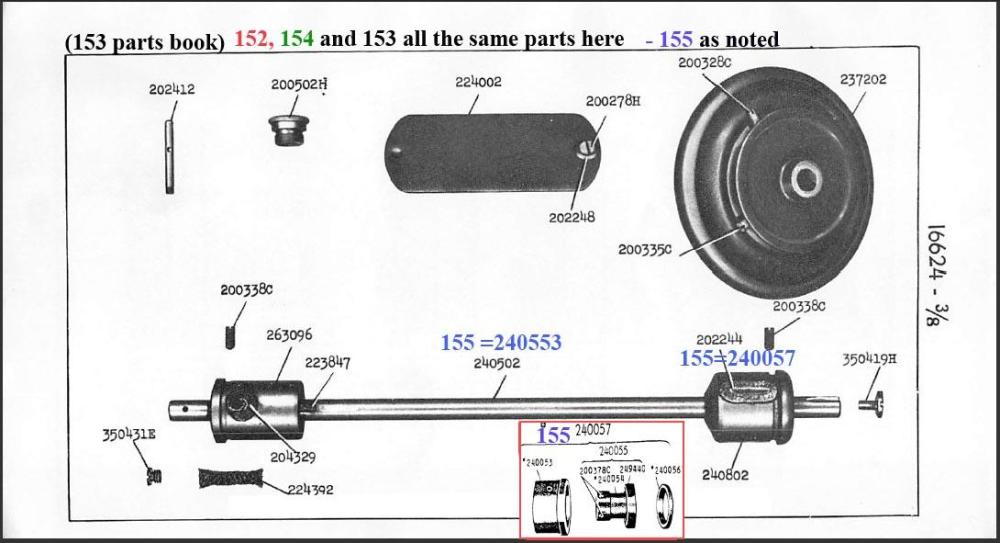

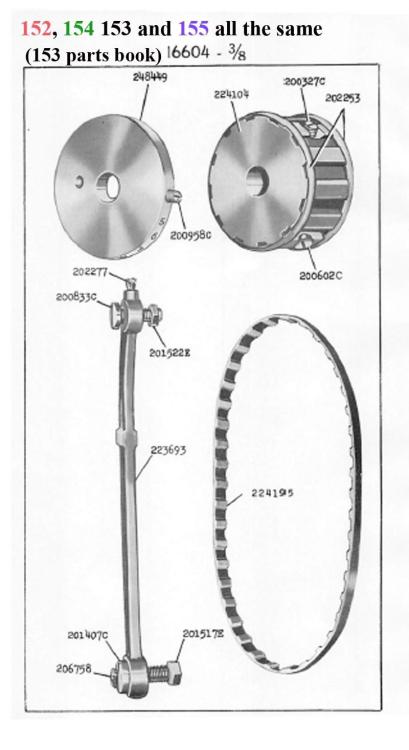

Charted Differences Between Singer 111w, 152, 153, 154, 155

cynthiab replied to cynthiab's topic in Leather Sewing Machines

CowboyBob, super, I will call you at your business. -

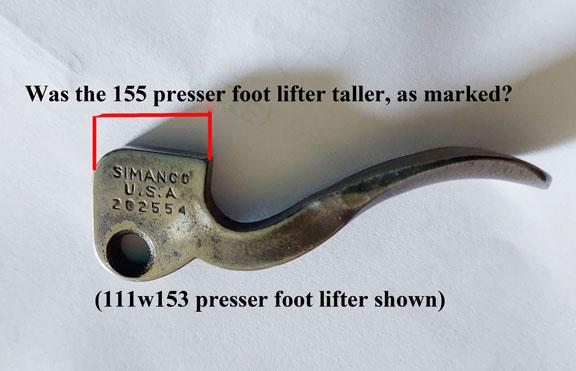

Charted Differences Between Singer 111w, 152, 153, 154, 155

cynthiab replied to cynthiab's topic in Leather Sewing Machines

Thank you Cowboybob, By hand lifter you mean the leaver in the 4th photo right? Just trying to keep it straight in my mind. I bought a hand lifter supposedly part # 202671 for the 111w155 and got one that is exactly like the one pictured; which is for the 111w153 or 111w152 Part # 202554 So I guess I will have to send it back. Do you by chance have any of these for sale? (part# 202671) Also the lifting bracket #208555 in photo 3 ...wasn't there a difference there too or am I mistaken. (part number for 111w155 is 264526) -

Charted Differences Between Singer 111w, 152, 153, 154, 155

cynthiab replied to cynthiab's topic in Leather Sewing Machines

Ok, so I don't know if I should start this on as a new topic, but... Somewhere in the past I remember a posting about the differences between the 111w155 lifting bracket, presserfoot lifter as well as the needle bare spring bracket. I think I remember photos of the differences. Id love to find that post again. Does anyone have that posting saved? I have attached a few photos of what I'm asking about Plus I have added a few photos showing the differences between the 111w155 needle bar bracket and the 152, 153 and 154 bracket and differences between the 111w155 and 152, 153, 154 Stitch length eccentric -

Looking fo a quality 111w155 hook driving shaft

cynthiab replied to cynthiab's topic in Leather Sewing Machines

Thank you Wizcafts! -

Hi all, Looking for a quality 111w155 hook drive shaft . Part # 240241 I had purchased one on eBay but I'm not satisfied with the quality of the metal (it was supposedly made in Japan) It is a soft metal that when I lightly run a file over the end it removes metal. (not so on the original) Does anyone know where I can purchase a NOS or a better quality drive shaft? Thanks!

-

Singer 111W Tight/Stuck Stitch Length Wheel

cynthiab replied to cynthiab's topic in Leather Sewing Machines

Cowboy Bob, Thank you for the suggestions. When I have loosened it did help a little. I will loosen it some more. I let you know if I have success. Fingers crossed, that it would be that easy. -

Singer 111W Tight/Stuck Stitch Length Wheel

cynthiab replied to cynthiab's topic in Leather Sewing Machines

kgg, thank you for those videos. I think I will go for replacing the shaft. It seems pretty straight forward. I hope I don't make a mess of it. The stitch selector video was helpful too. Tomorrow I'll go have another look at it and see what I can do. I'll get back you you on the results. -

Singer 111W Tight/Stuck Stitch Length Wheel

cynthiab replied to cynthiab's topic in Leather Sewing Machines

AlZilla Thank you for your reply, I tested it as you suggested On the 5 setting, I get 5 stitches per inch ( really 4 3/4 ) By stitches I mean not needle holes, but stitches, so 6 needle holes. Is that how you are counting too? Since I did that now I can not get it to move past 10 stitches before it locks up and can't turn the hand wheel. Seems it is getting worse. Any ideas what is going on? -

Singer 111W Tight/Stuck Stitch Length Wheel

cynthiab replied to cynthiab's topic in Leather Sewing Machines

Here is her new paint job. I used rustoleum 2x Cranberry and Max 2k clear epoxy. That clear epoxy is fantastic but very nasty stuff to be exposed to. So if you use it gear up professionally. -

Singer 111W Tight/Stuck Stitch Length Wheel

cynthiab replied to cynthiab's topic in Leather Sewing Machines

kgg, Yes I have removed the belt to test it. I also placed a scew driver up next to the shaft (near the bobbin saddle) as I turned it and I'm pretty sure there was a tiny wobble. The feed dog cam has worn uneven spot on the follower ( don't know the name, it's shaped like a U). Is replacing the shaft a ugly job or a cake walk? Are there any little things I need to look out for when I replace the shaft? -

Singer 111W Tight/Stuck Stitch Length Wheel

cynthiab replied to cynthiab's topic in Leather Sewing Machines

Hi Cowboy Bob. Thank you for your suggestion. I had taken the scews out like Uwe suggested in his video. Cleaned the shim, oiled entire unit all up. ( this was after 48 hour so wd40 and heat to get the screws loose) It was much better but still I can't get to all the numbers of stitches. I locks up some times at 28, 30 or 32 and I can't quite get to 5 only 5.5.