cynthiab

Members-

Posts

53 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Blogs

Gallery

Store

Everything posted by cynthiab

-

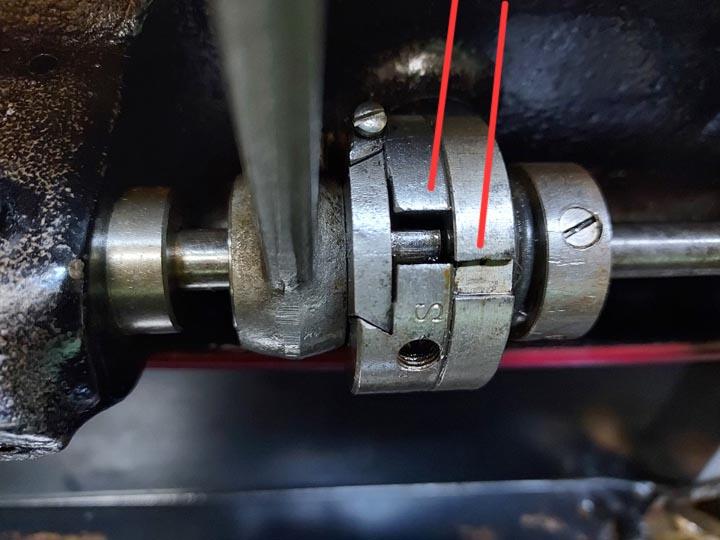

Hi guys, First I’d like to thank Uwe Grosse for his fabulous videos. I would never have got this Singer 111W153 machine running properly without them. Also, I’d like to thank Wizcrafts, kgg and Cowboy Bob for all their great instructions on getting this machine up and running. She now has a fresh paint job and looks great. (I will send photos soon) With that said I can’t leave well enough alone. I have had periodic problems with my stitch length. In that, when I press the button and turn the wheel sometimes it is impossible to turn very much. It sort of grinds to a stop locks up. I watched Owe Grosse’s video titled “Singer 111w155 stitch length issues. Feed Eccentric Adjustment” That seemed to help a bit, but I can’t get the number 5 directly in the center of the window anymore (looks like maybe 5.5) And worse, on the other end I can only get to 30 and sometimes 32, then again some times to only 28 before it locks up. It is variable. Anyone else have this problem? I did notice on Uwe’s video that his disks underneath have a divit that lines up differently from mine. I have attached photos of his and my machines with red lines pointing out the differences. Could it be that I need to loosen mine and turn it until it lines up like his? (I “think” his was set on #5, mine was too) Is there a groove in the shaft that a screw sits in that will dictate how it is set? Also, I’m strongly considering replacing my hook driving shaft because I feel it has a slight bend in it. (a tight spot when I turn the hand wheel) Is this a nightmare job or can it be done by me without too much hassle? Thanks guys! Cindy

-

What fun!! I really enjoyed this little film. Thanks for sharing!

-

Singer 111W155 Big loops underneath at slower speeds HELP

cynthiab replied to cynthiab's topic in Leather Sewing Machines

shoepatcher Thank you I'm seeing that it is the case -

Singer 111W155 Big loops underneath at slower speeds HELP

cynthiab replied to cynthiab's topic in Leather Sewing Machines

Thank you Wizcraft, That's pretty interesting. The worst trouble Ive had was with my 138 white thread. It almost gritty feeling when unwinding from the base, and on all my cones, regardless of thread type, it is much harder to pull thread when its at the bottom of the cone. Is that a standard thing? I buy all my threads from The Thread Exchange. Do you have another place to suggest? -

Singer 111W155 Big loops underneath at slower speeds HELP

cynthiab replied to cynthiab's topic in Leather Sewing Machines

Thank you all for your very astute suggestions... From needle selection to tension suggestions, all are very valid and I looked into all of them. However, last night I removed the cover plate to watch the bobbin threads in action. What I saw was the thread was getting hung up on the little tab on the bobbin case that goes under the feedog plate. Which got me to thinking about this ole machine. When I bought this machine a few years ago I was told it was a 115.... I'm pretty sure is not. I'm not 100 percent sure what machine this is. The stitch length selector starts at 5 . So, maybe it is a 153 or 154? So do I have no business trying to run a T208 through this machine? This leads me to my next question for you wonderful people is... How do I find out what machine I have? The serial numbers have been removed. I have heard that you can tell by the height of the foot lift. But, if I'm measuring foot lift... Is that measuring done when the presser foot is lifted to move the fabric (lower lift position) or when it is at the high lift position (to disengage the tension disk)? Or is it the height the walking foot lifts while working? LAST question, I promise. I use 16oz and 8oz size cones of 92 and 138 thread and I have noticed that the thread spools out with VERY uneven tension from my cones. I have a net on the cones and when the thread is coming from the bottom of the cone it is VERY hard to pull off. I have experimented with sliding the net all the way down until there is only 1/2 inch of net just at the very bottom. That didn't help. Ive tried to raise or lower my cones to see if that would help, nope. So is there some magical position I should have my cones set at to get a smoother and even pull off? Or are there special cone nets that are better than others? -

Hi guys, I don't know if I'm posting in the right place, but here goes. I have a singer 111w155 I'm using T208 thread with a #23 leather needle on 1/8 thick chrome tanned leather and thick poly webbing (about 1/8th thick) sewing them together. If I stitch at a faster speed I get little if any looping underneath. I would prefer no looping of course... Here is the real problem, if I slow down or stop or just stitch slower I get big loops underneath. Also if I turn a sharp corner, you guessed it, I get a loop. To fix this I have replaced the tension group. That helped a little bit, my old tension was pretty beat... but I still have the looping just not AS bad. I have fiddled with the tension spring, that didn't cure it. I tried different sized needles, nope, didn't work. I have re-threaded the machine, nope, didn't work. In the photo you can see where I slowed down, loops, and where I sewed faster, no loops. I know someone posted about this a while back but I cant find that post. So... Any ideas on how to get this machine to stop making big loop underneath? Thank you for your time.

-

Hi guys, I don't know if I'm posting in the right place, but here goes. I have a singer 111w155 I'm using T208 thread with a #23 leather needle on 1/8 thick chrome tanned leather and thick poly webbing (about 1/8th thick) sewing them together. If I stitch at a faster speed I get little if any looping underneath. I would prefer no looping of course... Here is the real problem, if I slow down or stop or just stitch slower I get big loops underneath. Also if I turn a sharp corner, you guessed it, I get a loop. To fix this I have replaced the tension group. That helped a little bit, my old tension was pretty beat... but I still have the looping just not AS bad. I have fiddled with the tension spring, that didn't cure it. I tried different sized needles, nope, didn't work. I have re-threaded the machine, nope, didn't work. In the photo you can see where I slowed down, loops, and where I sewed faster, no loops. I know someone posted about this a while back but I cant find that post. So... Any ideas on how to get this machine to stop making big loop underneath? Thank you for your time.

- 1 reply

-

- loops

- singer 111w

-

(and 2 more)

Tagged with:

-

If your LZ1 is a Chinese clone of the sailrite LZ1, the working parts/castings are very weak. I have hade to replace a ton of parts in mine ( with sailrite parts) so that when I tighten a screw it dosent strip out ( I'm not that strong) or when I sew through tough stuff the mechanics don't snap. Just my experience...

-

Nice machine, I'm jealous, lol. You might start your search for information in this group. They are a very active group, at least they were when I was digging around a few years ago. https://necchisewingmachineclub.groups.io/g/main

-

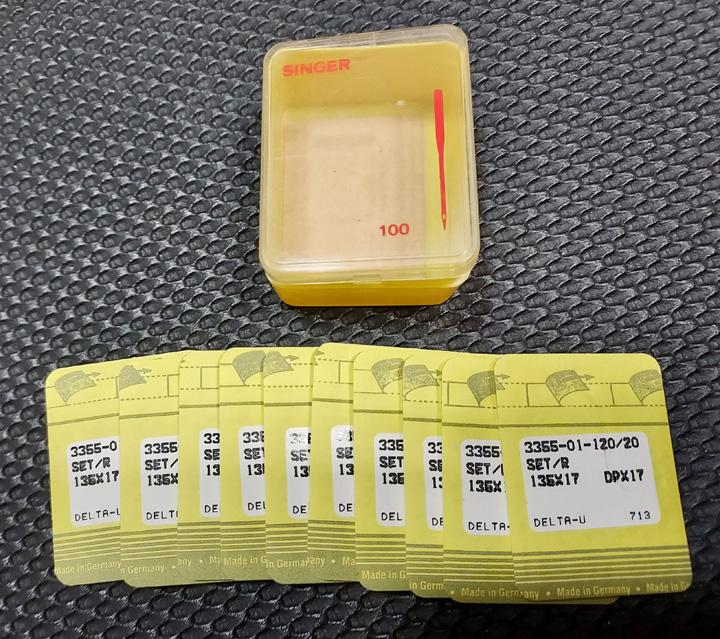

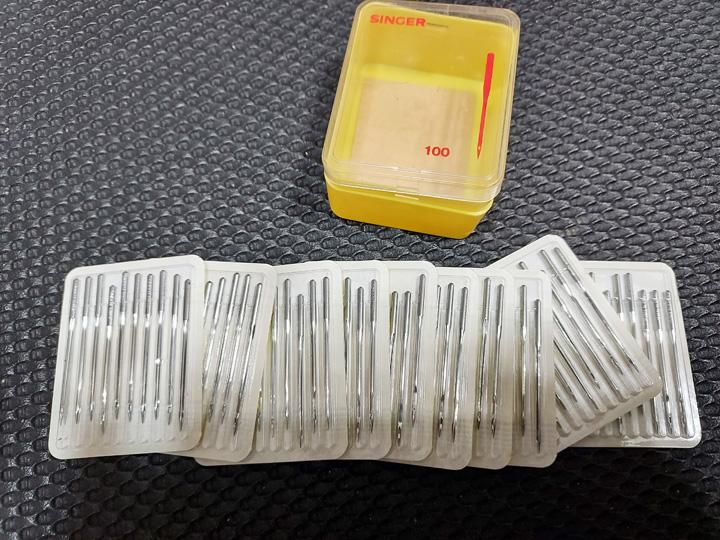

Hi guys, I have 5 boxes of 100 - NOS vintage Singer round point (standard) size 20 needles made in Germany. This is more than I could ever use, so... Im asking $20 for 1 box of 100 needles plus shipping. Let me know if you are interested.

-

Look at this add on Ebay. Good price even with the shipping -- SCHMETZ:328D/TRI triangular point 135x16/DPx16D,Nm:200/25 Sewing machine Needles or look at this one 135x16TRI Industrial Sewing Machine Needles-Sz16,18,19,20,21,22,24,25-Box of 100 here is another SCHMETZ:328D/TRI triangular point 135x16/DPx16D,Nm:200/25 Sewing machine Needles Just copy and past the above titles into ebay and search

-

Looks great! Plus its nice that you made a straight edge guide to switch out when needed. Good job! Can you give a close up shot with the guide down so we can see the feed dogs?

-

I'm interested in this too. If anyone has any thoughts or suggestions, I'm all ears! I have also noticed the screw hole is pretty big. Edit: I just found this - I think it will help some... I htin

-

Sailrite LZ1 Reverse Stitch too short

cynthiab replied to cynthiab's topic in Leather Sewing Machines

MtBiker, Thank you for your advice. This little clone is just like the Sailrite LSZ1. But as expected it is made with poor quality pot metal, even the working parts. I have replaced a ton of the parts with Sailrite parts and she sews nicely, except for the reverse being small. I might just have to live with that. I have owed a proper Sailrite brand LSZ1 and there is SUCH a difference in the quality of the machine. I would advise all to --- avoid these clones. They are frustrating money pits. The only reason I have this is I bought it for $20 at a yard sale...(thinking, wow what a deal!) I have pumped hundreds of hours fixing the darn thing (over and over) and MANY hundreds of dollars in replacing parts. She at this point is a keeper. -

Sailrite LZ1 Reverse Stitch too short

cynthiab replied to cynthiab's topic in Leather Sewing Machines

kgg, Thank you for the links for the Sailrite Fabricator, unfortunately, unless I'm missing something, my machine the LZ1, and the Fabricators mechanics are different. Bummer. I wish I could use that resource. I will fiddle around with the other link you sent https://www.youtube.com/watch?v=Z93bfzwAHP4 and get back to you. In the mean time ... Does anyone else have this problem? How did you fix it? -

kgg Great, keep us informed!

-

Hi guys, I hope you can help. I have a Sailrite LZ1 clone that I picked up in a yard sale for $20 US. Couldn't resist. Its green and looks like the old Thompson machines. It however has all the bells and whistles of the LZ1. The problem I'm having is that the REVERSE stitch (at its greatest length) is about half the length of the forward stitch. Has anyone come across this? Is there a way to remedy this?

-

KKG, Thank you for the well made little stitch length guide. It fits my little yard sale find LZ1 clone perfectly. Love it, and it was a breeze to put on my machine. Keep up the good work and keep coming up with these cool ideas.

-

Hey kgg, Just a heads up - I went to your web site www.warlockdesigns.com and this is what showed up "Welcome to Nopper Tollers!" Its a Dog breed site. You might want to check on that. Let us all know when this is straightened out... I'm rather interested in your stitch length regulator. Cheers

-

Just wanted to share a find of a supplier of good oiler felts for your machines. I bought the "sample kit" --- Industrial Felt Samples - 1/8" 1/4" 1/2" Thick from the Felt Store. (Each block is 3x3in.) and costs only $9.00! https://thefeltstore.com/collections/samples-all/products/f-5-industrial-felt-samples I bought the medium hardness and thought it was just right, but they do have a "firm" if you need that. I used a hole cutter to get the exact size I needed for each of my oil wells. Looks good and works even better :>) Plus I have plenty left over for the future. Hope this is helpful to some of you.

-

Oiling the sewing hook on pfaff 545

cynthiab replied to suncat33770's topic in Leather Sewing Machines

Could you include a photo of your page 5? I'm thinking that if it is like my Singer 111, there is a Tiny tiny little oil felt inside the edge of the bobbin case. You might have "cleaned" it out thinking it was dust/dirt like I did. -

singer 111w155 Help with Singer 111w155

cynthiab replied to cynthiab's topic in Leather Sewing Machines

Well I just perused the files and found the Toledo Industrial Sewing Machine Parts link and it is fantastic. Ive ordered the Vibrating Presser Bar Extender and Spring for only $8 each. Nice score! The only things I cant seem to find are the two missing screws. Any thoughts? Anyone have measurements available?- 11 replies

-

- machine belt

- repair

-

(and 2 more)

Tagged with:

-

singer 111w155 Help with Singer 111w155

cynthiab replied to cynthiab's topic in Leather Sewing Machines

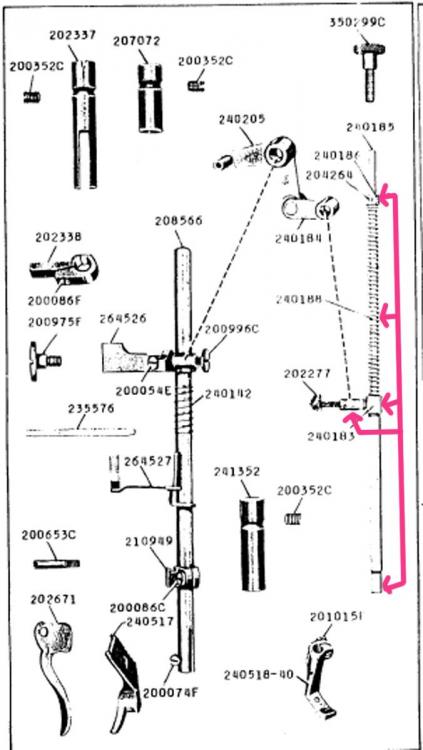

Wizcraft, Ahhh , maybe I'm not getting it right. I figured that when I raise the foot by using the lever on the back and measured the distance between the feeddog plate and the bottom of the foot, that was it..... That 5/16ths measurement was the thing that informed me that my machine was not a 111w155, or so I think. Is the lift supposed to be measured another way? LOL I'm being hopeful here. Id love or this thing to be a 155. Well another glitch has hit me along the way. This is a bummer. While cleaning the nose I noticed that I'm missing the bar and spring that goes under the thumb screw to raise or lower the pressure on the middle walking foot. How critical is this, and how hard is it to replace? Or even, is it possible to find one? Anyone parting out a machine have one of these? The part numbers for the missing piece are.... 240185 Extension with 240264 Set Screw and 240186 Collar, and lastly the spring that goes over it # 240188 I have posted a photo of the nose of my machine with the missing part area highlighted and a page from the 155 schematic (page 17) Is it possible to make one? If so could someone send me the specs on the bar and spring? (I'd be way happier to buy on from a part-out machine :>) I also noticed the there are 2 missing set screws under the machine, and have posted a photo of where they are located. Anyone have any of these laying around ? Or does anyone have specks on the size, thread count and pitch of the thread. ?- 11 replies

-

- machine belt

- repair

-

(and 2 more)

Tagged with:

-

singer 111w155 Help with Singer 111w155

cynthiab replied to cynthiab's topic in Leather Sewing Machines

Thank you Chrisah, Ive seen this before but it's good, but still doesn't answer the question of how to tell them apart. Visually on the outside I THINK they are exactly the same. But is there something under or inside that will tell me is it is a 152 or 153? How does one tell if it is heavy duty or for lighter work. Is the main shaft thicker? Are the cogs/gears bigger?- 11 replies

-

- machine belt

- repair

-

(and 2 more)

Tagged with:

-

singer 111w155 Help with Singer 111w155

cynthiab replied to cynthiab's topic in Leather Sewing Machines

Wyowally and 327fed thank you for your replys I will look into the manuals you mentioned. And yes, last week I joined the group "Vintage Industrial Sewing Machines" that you mentioned. I will take a look at those files, thank you for reminding me. Also I'm relived to know that there are machines that are very similar. That will make research on repairs much easier. But now I have to say, after fiddling around with the machine a bit more I'm convinced that it is NOT a 155 but maybe a 152 or 153. The reason is the the presser foot when lifted is only 5/16th high....Of course it was sold to me as a 155 :>( .... and the badge is missing of course...and the serial number has been removed. (There is a handwritten number on the top that says “111w155”, which I'm sure is totally meaningless, lol) So obviously when it was sold to me and the guy before me as a 155 it was a ruse. Bummer, BUT if it is a 153 I will not be TOO bummed, but if it is a 152; I will not be happy at all; since I hope to be sewing 10 to 12oz (or thicker if possible) vegetable tanned leather. Hmmm, So that brings me to how to tell the difference. The 152 and the 153 both have a maximum stitch length of 5 and a foot height of 5/16ths and as far as I can tell they both look alike. SO, how do I tell the difference between a 152 and a 153? Is there any other defining attribute between the two machines? Anybody out there have any insight about this dilemma?- 11 replies

-

- machine belt

- repair

-

(and 2 more)

Tagged with: