Edsbear

Members-

Posts

32 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Blogs

Gallery

Everything posted by Edsbear

-

Thank you, yes I agree both Cechaflo and Sailrite are great channels but I am trying to French seam the top plate where it meets the boxing, so basically a top stitch on the top and a top stitch on the side boxing with the twin needle, maybe its not possible

-

I am trying to French seam the border(border and top plate) of a seat cushion which is square. The problem is that when I get to the corner the stitches end up misaligned and don't go around the corner parallel so look rubbish. I wondered if anyone had some tips on this, its easy doing a 90 degree turn on a flat piece but this driving me mad at the moment. I am using a twin needle with split bar 3/8" gauge.

-

Just to update that the bonded nylon thread solved the problem. thanks to the helpers here

-

Thanks for your help, I have ordered some bonded nylon cones

-

I must admit the left hand thread doesn't look or lay as nice as the right hand Some suppliers are saying use bonded nylon because its multi directional?

-

Thanks for the info, I had no idea about that, I will try to get some

-

Hi All, My Brother LT2-B835-3 is sewing ok but sometimes roughly every 10th or 20th stitch I get quite a big knot showing on the left hand underside, right side is fine. does anyone have any ideas what could possibly cause this please. Many thanks

-

Thanks for your input everyone, much appreciated

-

Hi, does anyone know what size drill and tap would be used for a Brother B837. I want to fit a binder attachment to the bobbin plate, some holes already in the bed seem to be the same thread as the presser foot screw but I can find the info. Many thanks

-

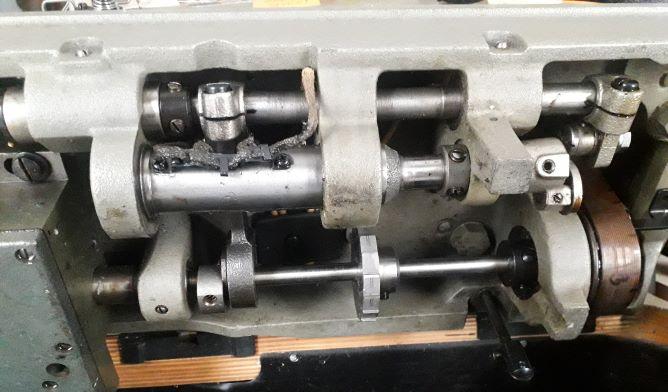

Nice one fibersport such a simple thing causing so much grief. My machine is a large bobbin top loader but the cover plate is flat, no bumps. I am waiting for a new timing belt because it looks like it might be the original and has a bit of slop in it, I'm hoping this will help. The machine is not stitching too bad now but still has to have a lot of upper tension and very little in the bobbin.

-

The base of my Brother B837 looks a bit different to the 211g156 but there must be something similar to adjust but cant see which bit Thanks everyone

-

Thanks Quade, I have adjusted the reverse lever stop to make a bigger stitch but this doesn't make any difference. Still not the same as forward. I still cant find the adjustment to equalise forward and reverse stitch length

-

Hi, My Brother LS2-B837 won't reverse into the same holes, the reverse stitch is smaller. I have adjusted the reverse lever stop to make a bigger stitch but this doesn't make any difference. Does anyone know if there is something else to adjust to balance the stitches Many thanks

-

Thanks Garyak, I started from the beginning several times and bobbin is in the correct way but the upper tension always ends up really high and hook has to be retarded to get a decent stitch Cheers

-

Thanks for the response, I though I was the only one... I cant retard the hook anymore because it will hit the needle eye area. I have tried various distances from the needle but still I have to use excessive upper tension. One thing I noticed today was the the timing belt seems slack and can easily be slipped off the gear and with the flywheel aligned with the marks on the machine the timing mark on the lower gear doesn't quite line up, seems about half a tooth out. I will order a new belt and hoping that will help. The belt looks original so maybe its about time it was changed. Machine is a Brother LS2-B837 Many thanks

-

Hi, Can anyone shed some light on why my Brother B837 needs the hook timing retarded to sew, the upper tension also needs to be very tight. The hook needs to be right at the bottom of the needle scarf if the hook is timed by the book the bottom thread loops. Could this be a main timing issue or belt slip? Thanks

-

My singer 201k will sew 3 layers of leather but if I want to sew 4 layers it seems to struggle with creating a nice stitch. My questions are: can I make this machine more heavy duty or do I need a walking foot machine can the maximum stitch size be increased by modifying Many thanks

-

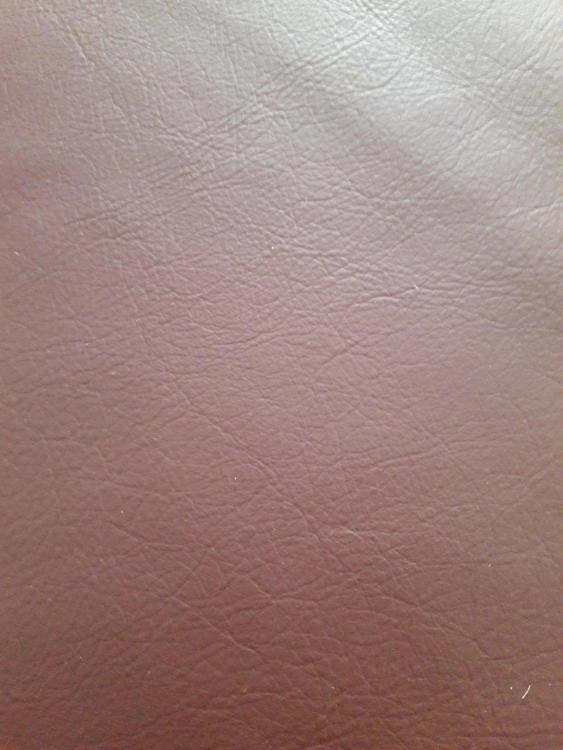

I have sewn a seat cover and the lighter leather colour under the top colour is showing between the stitches, Does anyone have an idea what's happening here please. Picture attached it explains it better. Many thanks

-

Thickness is approx .056" (1.42mm) and 32"x20" straight sided

-

Can you advise the best option for stretching please?

-

Maybe cow hide cant be stretched? its not thick enough for a belt HS, so thick belt leather stretching may be different to cow hide stretching. Maybe I posted in the wrong forum but I do appreciate all your inputs.. All the best

-

-

-

Hi, Thickness is approx .056" 1.42mm and 32"x20" I don't know how tanned or kind, I'm not that experienced, the leather was given to me

-

Hi, Is it possible to stretch pieces cut from a leather hide, only needs stretching about 1/2". Steam maybe or will it shrink back to original size? Thanks