-

Content Count

46 -

Joined

-

Last visited

About BianVariani

-

Rank

Member

Contact Methods

-

Website URL

https://bianvariani.com

-

Skype

bian.variani.inc

Profile Information

-

Gender

Male

-

Location

Vancouver, Canada

-

Interests

Leather Belts, Leather Belt Design, Leather Belt Machinery

LW Info

-

Leatherwork Specialty

Leather Belt Designer, Leather Belt Machine Engineer

-

Interested in learning about

Leather Belt Design tips and tricks

-

How did you find leatherworker.net?

Google

Recent Profile Visitors

The recent visitors block is disabled and is not being shown to other users.

-

This just cuts the belt strap tip, billet end, and the holes, not the whole strap itself.

- 10 replies

-

Please note, the design is a concept design and the cutting die would need to be added.

- 10 replies

-

Does anyone have any videos on the belt strap build/process you use?

- 10 replies

-

Share what you use? My cutter is not a commercial cutter, nor for sale, just a design for myself!

- 10 replies

-

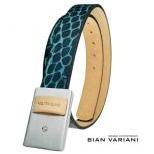

Here is a NEW design concept I have been working on to cut leather belt straps? The guides and the tooling are self centered. No Setup on tool changes, just drag and drop. What do you think? Any improvements, comments or suggestions? Please share the leather belt strap punch and cutters that you use?

- 10 replies

-

I use to use this manual Press for many years until I mastered my NEW design.

-

more old designs

-

This is an update to practicing on building manual press punches.

-

This is another design that was used as a learning experience.

-

Over the past 10 years, I created all kinds of prototypes. This design went nowhere aside from using it as educational.

-

Please note that the self-centering guide is versatile and can be easily interchanged with other guides. For example, it can be replaced with guides designed for hot stamping, edge stitching, edge-painting, or precisely positioning holes in various offset locations. As I travel across the country and visit retail locations that carry my products, a common request from people I meet is whether I can make them a belt right now. In the past, I had to decline due to the lack of tools on hand. However, I have now bridged that gap, allowing me to say "Yes, absolutely!" This innovation has made my process more flexible and versatile, enabling me to meet customer requests wherever I am.

-

The belt hole distances I use are tailored to the belts I create. However, it's a valid suggestion to update the design to make the spring-loaded alignment bearing adjustable. The cutting plate, which incorporates this spring-loaded bearing, is interchangeable, allowing for different dies or cutting plates to be used as needed. The cutting plate itself functions as a die integrated into my manual hand press. Depending on the project, I use various custom-made dies and cutting plates designed specifically for the belts I produce. One of my concerns with die-based punches that rely on a clicker press is the limitation imposed by the fixed design of the die. If the die components are welded together, you're restricted to that specific design. I needed a tool that allowed flexibility, where I could easily swap out cutting and punching tools in my manual hand press, which led to the development of my design. My goal was to create a small, lightweight, and portable press/punch that is user-friendly and versatile enough to make belts on demand, whether I'm in a hotel room, at a trade show, or visiting a client. Clicker presses are often too heavy, bulky, and restrictive from a design standpoint. I wanted the freedom to create and adapt designs as needed, which my model allows. While I own a range of clicker presses, from manual to hydraulic, and even high-end machines capable of punching belts at high speeds, none offer the on-demand design flexibility that my portable press does.

-

Thank you for the above. If you google any one of my products and I have many, you will find out that I do not sell them or market them anywhere. My intentions are to network with like minded people in the leather industry. What is your opinion on my leather punch? Do you find it an asset or a valuable tool for belt makers?

-

I am showcasing / showing off what I make. Maybe someone else may need help or advice that I can help with. Every post made does not have to be for sale?!?

-

Precision BASE for the belt press/punch/cutter